| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Vladimir Zyubin | -- | 4258 | 2023-07-26 12:37:49 | | | |

| 2 | Rita Xu | -75 word(s) | 4183 | 2023-07-27 03:31:58 | | |

Video Upload Options

Process Oriented Programming (POP) is a programming paradigm based on the concept of "processes" that determine the response (outputs) of a reactive system based on events (states of internal and external variables, timeouts). A process-oriented program is a set of interacting processes that can change their behavior (reaction to events), start and stop other processes, and be executed in parallel. The languages created within the framework of POP (e.g. Reflex, IndustrialC, poST) fit very well for specification various control algorithms, which can consist of hundreds and thousands of processes. In addition to the fact that process-oriented programs structurally and conceptually correspond to the technological description of the plant under control, they also have the following remarkable property. In process-oriented algorithms, the use of data is usually local, limited to one or more processes.

1. Introduction and Motivation

-

First of all, in the field of automation, parallelism is an integral part of the control algorithm. This circumstance is reflected in so-called process-oriented languages; for example, in the recently developed poST language, which is a process-oriented dialect of the IEC 61131-3 Structured Text [13]. In the poST language, a program is built as a set of weakly dependent processes—FSM-like structures. Therefore, the process-oriented specification of the control algorithm contains information about its possible parallelization.

-

Secondly, in contrast to parallel programming goals, the need for parallelization is primarily caused not by the desire to reduce the computation time but by the desire to reduce the cost of the system as a whole and the cost of its maintenance by using smaller, less expensive, and more flexible microprocessors, reducing the length of wires, reducing the complexity of wiring, and improving maintainability, providing the opportunity to implement various control strategies [3][14].

-

Thirdly, for control problems, an extremely important circumstance is the possibility of formally verifying the algorithms being created. For the process-oriented paradigm, researchers developed the mathematical model of hyperprocesses. Informally, a hyperprocess involves expanding the processes in the system into one process by periodically turning on the logical processes in the program according to the round robin strategy to execute the code in their current states. A number of formal methods for the process-oriented programming languages have been developed [15][16] based on the semantics of a hyperprocess. Correspondingly, when developing a methodology for the topologically independent programming of control systems based on a process-oriented approach, it is desirable to reuse the existing verification methods.

2. Distributed Control Systems for Vehicles

3. Design of Distributed Control Systems Based on IEC 61131-3/61499

4. Solving Conflicts in Distributed Systems

5. Design of Distributed Control Systems Based on Process-Oriented paradigm

5.1. Plain method

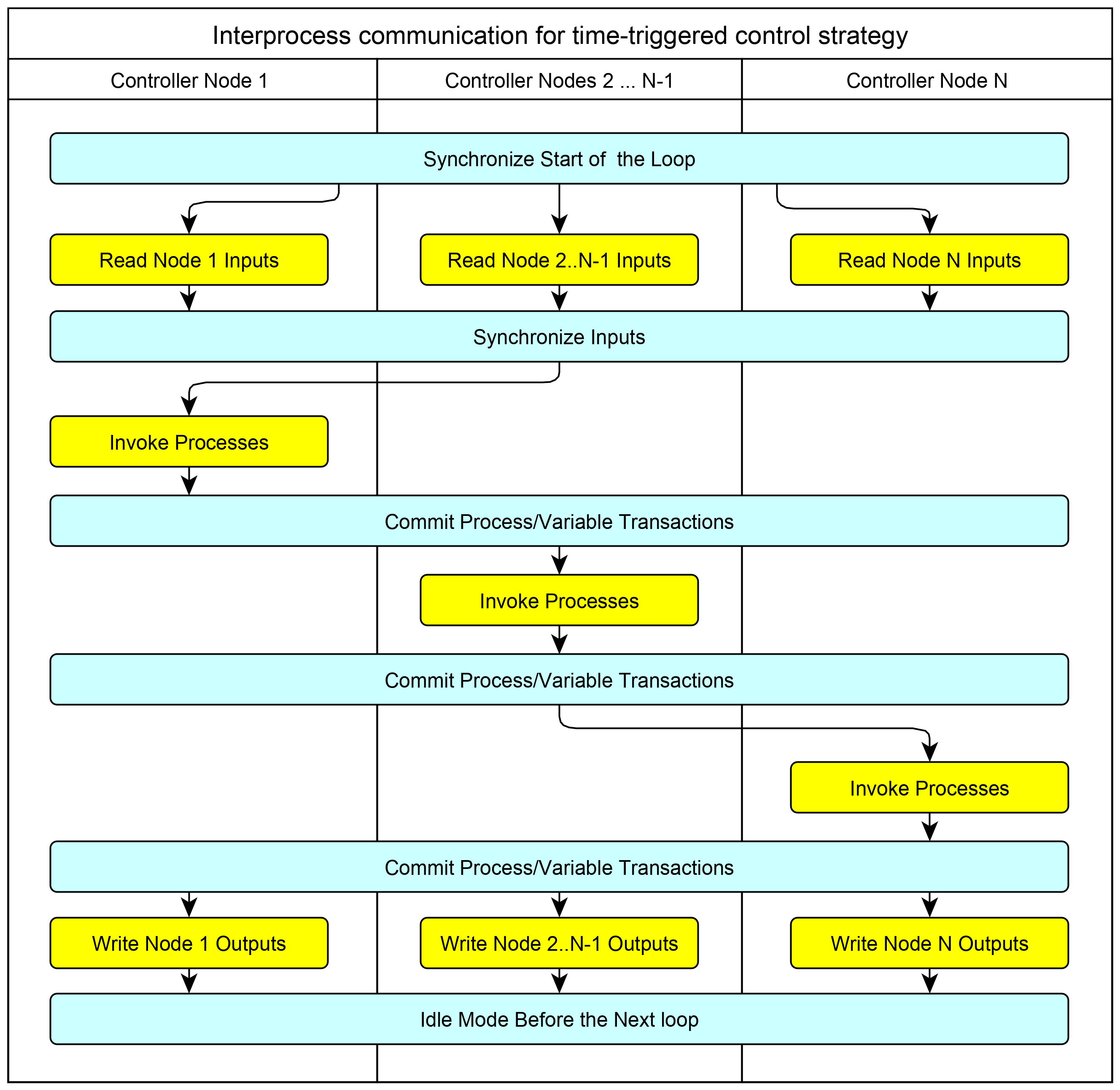

Figure 1. Preserving the hyperprocess semantics while deploying a process-oriented specification on a distributed architecture.

This approach enables researchers to generate a distributed application for any topology, comprising nodes up to the number of processes in the original process-oriented specification. When specifying the control algorithm, researchers do not care about the number of nodes, their type, and the network topology. This makes this approach topology-free programming.

Advantages of the approach:

- deterministic behavior of a distributed system;

- a high degree of granularity up to placing only one process on a node of the distributed system;

- preserving the semantics of the monolithic implementation.

Besides the advantages, the designed model also leads to a more intricate software architecture as only one PLC can have access to a single output module. It also requires additional communication between multiple PLCs to share information such as input/output module data and program data. As a result, there is an increase in both hardware costs and engineering effort required [31].

5.2. Ad Hoc method

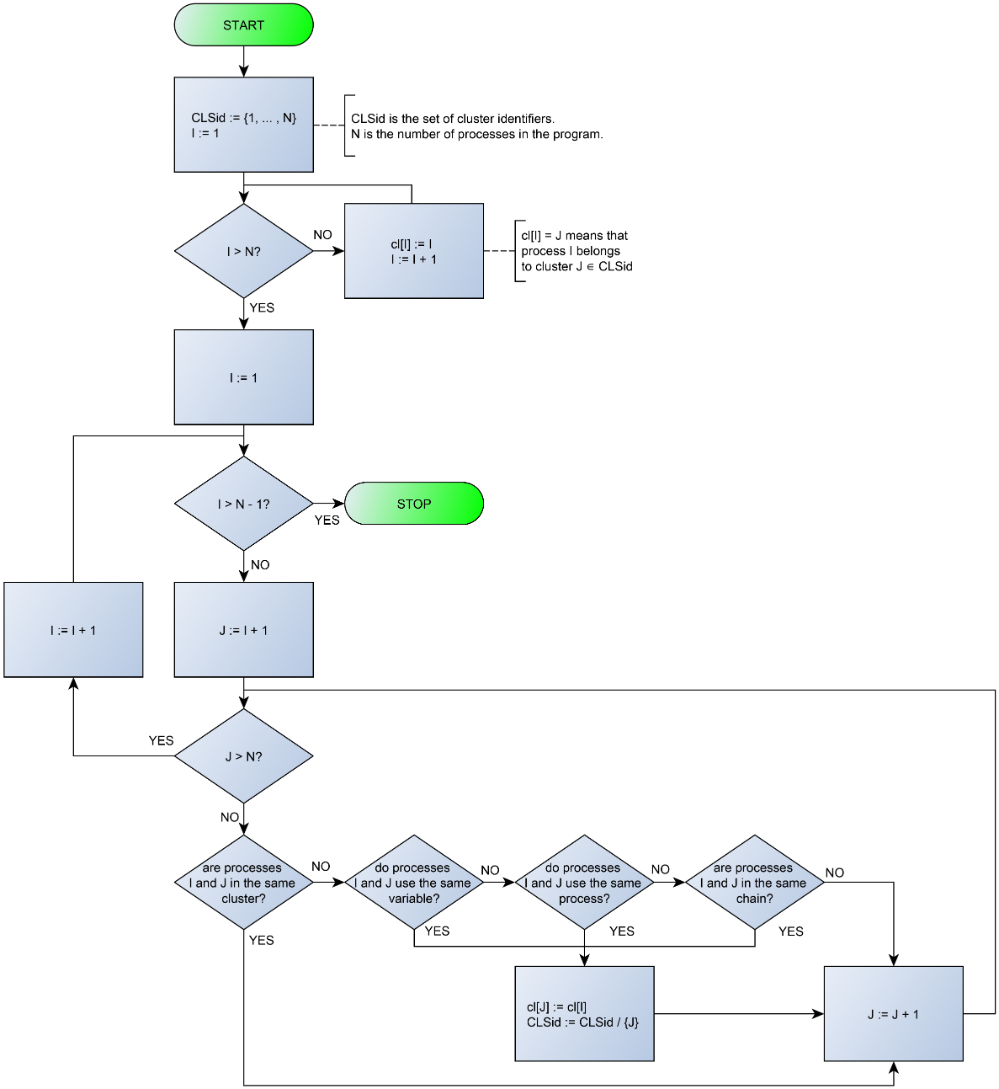

There are various alternative approaches aimed at minimizing the overhead associated with inter-process data synchronization. To minimize the computational complexity of inter-node synchronization, which should ideally be excluded, the set of program processes can be divided into independent groups (clusters) with the finest possible granularity. The requirements for partitioning a control algorithm according to a process-oriented specification into clusters are as follows:

- processes using the same variable should both be in the same cluster;

- two processes using the same process should both be in the same cluster;

- processes forming a loop relative to the use relation should be in the same cluster.

Figure 2 demonstrates the algorithm flowchart that extracts clasters from a process-oriented specification.

Figure 2. Partitioning algorithm flowchart.

6. Summary

A topologically independent specification of distributed control algorithms with the process-oriented programming paradigm can be deployed with the plain approach based on a network of microcontroller nodes. In this schema, only operations for reading input and writing output signals are physically parallelized, and the algorithm itself is executed sequentially, similarly to a centralized implementation, with synchronization of information messages and the order of execution over the bus. The approach constructively ensures the absence of data races and the preservation of the semantics of the original process-oriented program, which means the applicability of existing methods for verifying centralized process-oriented programs to distributed process-oriented programs. This opens the door to the formal verification of distributed programs using already developed approaches.

In particular, model checking method for process-oriented programs proposed in [50][51] can be applied with minor corrections that concern constructing several independent action lines of parallel processes with regard to given clusters. Also it is possible to use process-oriented deductive verification methods proposed in [15][52] by applying them to each cluster separately with the original program annotations.

In [53] an algorithm for splitting a process-oriented specification into clusters, which eliminates the need for data synchronization, is proposed. The study of the algorithm on case study shows that clusters can be arranged in any arbitrary combination on the computing nodes of a distributed system. In any combination, the physical signals are processed locally and the implementation does not require data synchronization.

References

- Capehart, B.L.; Capehart, L.C. Web Based Energy Information and Control Systems: Case Studies and Applications; CRC Press: Boca Raton, FL, USA , 2021.

- Chakraborty, S.; Ramesh, S. Programming and Performance Modelling of Automotive ECU Networks. In Proceedings of the 21st International Conference on VLSI Design (VLSID 2008), Hyderabad, India, 4–8 January 2008 ; pp. 8–9.

- Dongik Lee; Jeff Allan; Stuart Bennett. Distributed Real-Time Control Systems using CAN; Springer Science and Business Media LLC: Dordrecht, GX, Netherlands, 2003; pp. 357-385.

- Sakle, S.V.; Kadam, M.R.; Dhande, M.J. Review paper of Vehicle control system using CAN protocol. Int. J. Orange Technol. 2021, 3, 40–45.

- Drozdov, D.; Atmojo, U.D.; Pang, C.; Patil, S.; Ali, M.I.; Tenhunen, A.; Oksanen, T.; Cheremetiev, K.; Vyatkin, V. Utilizing software design patterns in product-driven manufacturing system. In Proceedings of the International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing, Paris, France, 1–2 October 2020.

- Kleanthis Thramboulidis; IEC 61499 vs. 61131: A Comparison Based on Misperceptions. J. Softw. Eng. Appl. 2013, 06, 405-415.

- Thomas Strasser; Alois Zoitl; James H. Christensen; Christoph Sünder; Design and Execution Issues in IEC 61499 Distributed Automation and Control Systems. null 2010, 41, 41-51.

- Thramboulidis, K. Different perspectives [Face to Face; “IEC 61499 function block model: Facts and fallacies”]. IEEE Ind. Electron. Mag. 2009, 3, 7–26.

- Kim, J.C.; We, K.S.; Lee, C.G.; Lin, K.J.; Lee, Y.S. HW resource componentizing for smooth migration from single-function ECU to multi-function ECU. In Proceedings of the 27th Annual ACM Symposium on Applied Computing, Trento, Italy, 25–29 March 2012; pp. 1821–1828.

- Fox, G.C.; Williams, R.D.; Messina, P.C. Parallel Computing Works!; Elsevier: Amsterdam, The Netherlands, 2014.

- Vajk, T.; Dávid, Z.; Asztalos, M.; Mezei, G.; Levendovszky, T. Runtime model validation with parallel object constraint language. In Proceedings of the 8th International Workshop on Model-Driven Engineering, Verification and Validation, Wellington, New Zealand, 17 October 2011; pp. 1–8.

- Edward A. Lee; The Past, Present and Future of Cyber-Physical Systems: A Focus on Models. Sensors 2015, 15, 4837-4869.

- Vladimir E. Zyubin; Andrei S. Rozov; Igor S. Anureev; Natalia O. Garanina; Valeriy Vyatkin; poST: A Process-Oriented Extension of the IEC 61131-3 Structured Text Language. IEEE Access 2022, 10, 35238-35250.

- Shaila P. Kharde Rachana V. Vairal; A Review on Vehicle Control System by Using CAN Protocol. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2015, 4, 8678-8682.

- Igor Anureev; Natalia Garanina; Tatiana Liakh; Andrei Rozov; Vladimir Zyubin; Sergei Gorlatch. Two-Step Deductive Verification of Control Software Using Reflex; Springer Science and Business Media LLC: Dordrecht, GX, Netherlands, 2019; pp. 50-63.

- Vladimir Zyubin; Igor Anureev; Natalia Garanina; Sergey Staroletov; Andrei Rozov; Tatiana Liakh. Event-Driven Temporal Logic Pattern for Control Software Requirements Specification; Springer Science and Business Media LLC: Dordrecht, GX, Netherlands, 2021; pp. 92-107.

- Controller Area Network CAN, an Invehicle Serial Communication Protocol. J1583_199003. Available online: https://www.sae.org/standards/content/j1583_199003/ (accessed on 6 July 2023)

- Sergey Staroletov. A Software Framework for Jetson Nano to Detect Anomalies in CAN Data; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, United States, 2023; pp. 490-498.

- Obermaisser, R. Event-Triggered and Time-Triggered Control Paradigms; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004; Volume 22.

- Albert, A. Comparison of event-triggered and time-triggered concepts with regard to distributed control systems. Embed. World 2004, 2004, 235–252.

- G Leen; D Heffernan; TTCAN: a new time-triggered controller area network. Microprocess. Microsystems 2002, 26, 77-94.

- Woonhyuk Baek; Seyong Jang; Hoin Song; Soontae Kim; Bongsob Song; Dongkyoung Chwa; A CAN-based Distributed Control System for Autonomous All-Terrain Vehicle (ATV). null 2008, 41, 9505-9510.

- K. Tindell; A. Burns; A.J. Wellings; Calculating controller area network (can) message response times. Control. Eng. Pr. 1995, 3, 1163-1169.

- Chen, R.; Liu, B.; Pan, M.; Zhou, H. Design of Distributed Control System for the Pick-up Robot Based on CAN Bus. In Proceedings of the 2019 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4–7 August 2019; pp. 102–107.

- Liangfei, X.; Jianfeng, H.; Xiangjun, L.; Jianqiu, L.; Minggao, O. Distributed control system based on CAN bus for fuel cell/battery hybrid vehicle. In Proceedings of the 2009 IEEE International Symposium on Industrial Electronics, Seoul, Korea, 5–8 July 2009; pp. 183–188.

- Shiau, J.K.; Hung, W.S.; Chang, C.M. Development of a Distributed Multi-MCU Based Flight Control System for Unmanned Aerial Vehicle. J. Appl. Sci. Eng. 2015, 18, 251–258.

- Christensen, J.H. Design patterns for systems engineering with IEC 61499. In Proceedings of the Verteilte Automatisierung-Modelle und Methoden für Entwurf, Verifikation, Engineering und Instrumentierung (VA2000), Magdeburg, Germany, 22–23March 2000; pp. 63–71. Available online: http://www.holobloc.com/papers (accessed on 6 July 2023).

- Valeriy Vyatkin; Hans-Michael Hanisch; Cheng Pang; Chia-Han Yang; Closed-Loop Modeling in Future Automation System Engineering and Validation. null 2008, 39, 17-28.

- Kleanthis Thramboulidis; A cyber–physical system-based approach for industrial automation systems. Comput. Ind. 2015, 72, 92-102.

- Schwab, C.; Tangermann, M.; Lueder, A. The modular TORERO IEC 61499 engineering platform-Eclipse in automation. In Proceedings of the 2005 IEEE Conference on Emerging Technologies and Factory Automation, Catania, Italy, 19–22 September 2005; Volume 2.

- Wenbin Dai; Valeriy Vyatkin; Redesign Distributed PLC Control Systems Using IEC 61499 Function Blocks. IEEE Trans. Autom. Sci. Eng. 2012, 9, 390-401.

- Luis Ribeiro; Mats Bjorkman; Transitioning From Standard Automation Solutions to Cyber-Physical Production Systems: An Assessment of Critical Conceptual and Technical Challenges. IEEE Syst. J. 2017, 12, 3816-3827.

- Patil, S.; Drozdov, D.; Vyatkin, V. Adapting software design patterns to develop reusable IEC 61499 function block applications. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 725–732.

- Patil, S.; Drozdov, D.; Zhabelova, G.; Vyatkin, V. Refactoring of IEC 61499 function block application—A case study. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), Saint Petersburg, Russia, 15–18 May 2018; pp. 726–733.

- Luis Alberto Cruz Salazar; Daria Ryashentseva; Arndt Lüder; Birgit Vogel-Heuser; Cyber-physical production systems architecture based on multi-agent’s design pattern—comparison of selected approaches mapping four agent patterns. Int. J. Adv. Manuf. Technol. 2019, 105, 4005-4034.

- Vladimir Zyubin; Andrei Rozov. Using Process-Oriented Structured Text for IEC 61499 Function Block Specification; Springer Science and Business Media LLC: Dordrecht, GX, Netherlands, 2021; pp. 217-227.

- Guellouz Ep Addad, S. Towards a New Methodology for Design, Modelling, and Verification of Reconfigurable Distributed Control Systems Based on a New Extension to the IEC 61499 Standard. Dissertation zur Erlangung des Grades des Doktors der Ingenieurwissenschaften der Naturwissenschaftlich–Technischen Fakultät der Universität des Saarlandes und Tunisia Polytechnic School, Carthage University, 2021. (accessed on 6 July 2023). . Zertifiziert mit dem DINI-Zertifikat 2019 für Open-Access-Publikationsdienste. Retrieved 2023-7-26

- Roopak Sinha; Partha S. Roop; Gareth Shaw; Zoran Salcic; Matthew M. Y. Kuo; Hierarchical and Concurrent ECCs for IEC 61499 Function Blocks. IEEE Trans. Ind. Informatics 2015, 12, 59-68.

- Benedikt Marschall; Markus Schleicher; Axel Sollich; Thomas Becker; Tobias Voigt; Design and Installation of an Agent-Controlled Cyber-Physical Production System Using the Example of a Beverage Bottling Plant. IEEE J. Emerg. Sel. Top. Ind. Electron. 2021, 3, 39-47.

- Hopsu, A.; Atmojo, U.D.; Vyatkin, V. On portability of IEC 61499 compliant structures and systems. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 1306–1311.

- Ernesto Monroy Cruz; Luis Rodolfo Garcia Carrillo; Luis Alberto Cruz Salazar; Structuring Cyber-Physical Systems for Distributed Control with IEC 61499 Standard. null 2023, 21, 251-259.

- Alexandre Parant; François Gellot; Damien Zander; Véronique Carré-Ménétrier; Alexandre Philippot; Model-based engineering for designing cyber-physical systems from product specifications. Comput. Ind. 2023, 145, 103808.

- Edsger W. Dijkstra; The structure of the “THE”-multiprogramming system. Commun. ACM 1968, 11, 341-346.

- Dhoked, S.; Golab, W.; Mittal, N. Recoverable Mutual Exclusion; Springer Nature: Berlin/Heidelberg, Germany, 2023.

- John C. Eidson; Edward A. Lee; Slobodan Matic; Sanjit A. Seshia; Jia Zou; Distributed Real-Time Software for Cyber–Physical Systems. null 2011, 100, 45-59.

- Lee, E.A. Plato and the Nerd: The Creative Partnership of Humans and Technology; MIT Press: Cambridge, MA, USA, 2017.

- Marten Lohstroh; Christian Menard; Soroush Bateni; Edward A. Lee; Toward a Lingua Franca for Deterministic Concurrent Systems. ACM Trans. Embed. Comput. Syst. 2021, 20, 1-27.

- Huailin Li; Qinsen Liu; Mengnan Liu; Bangyong Sun; Bin Du; Robust Deadlock Control for Reconfigurable Printing Manufacturing System Based on Process Algebra. IEEE Access 2023, 11, 42473-42484.

- Vladimir E. Zyubin. Hyper-automaton: a Model of Control Algorithms; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, United States, 2007; pp. 51-57.

- Tatiana V. Liakh; Natalia O. Garanina; Igor S. Anureev; Vladimir E. Zyubin. Verifying Reflex-software with SPIN: Hand Dryer Case Study; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, United States, 2020; pp. 210-214.

- Anna A. Ponomarenko; Natalia O. Garanina; Sergey M. Staroletov; Vladimir E. Zyubin. Towards the Translation of Reflex Programs to Promela: Model Checking Wheelchair Lift Software; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, United States, 2021; pp. 493-498.

- Ivan Chernenko; Igor Anureev; Natalia Garanina. Proving Reflex Program Verification Conditions in Coq Proof Assistant; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, United States, 2021; pp. 485-488.

- Vladimir E. Zyubin; Natalia O. Garanina; Igor S. Anureev; Sergey M. Staroletov; Towards Topology-Free Programming for Cyber-Physical Systems with Process-Oriented Paradigm. Sensors 2023, 23, 6216.