Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Wojciech Kolanowski | -- | 1738 | 2023-07-19 11:13:04 | | | |

| 2 | Conner Chen | Meta information modification | 1738 | 2023-07-21 03:27:37 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Nair, S.S.; Trafiałek, J.; Kolanowski, W. Production of Edible Films and Coatings. Encyclopedia. Available online: https://encyclopedia.pub/entry/46968 (accessed on 05 March 2026).

Nair SS, Trafiałek J, Kolanowski W. Production of Edible Films and Coatings. Encyclopedia. Available at: https://encyclopedia.pub/entry/46968. Accessed March 05, 2026.

Nair, Surya Sasikumar, Joanna Trafiałek, Wojciech Kolanowski. "Production of Edible Films and Coatings" Encyclopedia, https://encyclopedia.pub/entry/46968 (accessed March 05, 2026).

Nair, S.S., Trafiałek, J., & Kolanowski, W. (2023, July 19). Production of Edible Films and Coatings. In Encyclopedia. https://encyclopedia.pub/entry/46968

Nair, Surya Sasikumar, et al. "Production of Edible Films and Coatings." Encyclopedia. Web. 19 July, 2023.

Copy Citation

Generally, edible films and coatings are the primary forms of edible food packaging. The differences between edible films and coatings lie in their physical form and application process. Edible films are obtained as solid laminated sheets and then used as a food wrap that can be removed or consumed with food, whereas coatings are applied to foods in liquid form by coating, spraying, and immersion. After drying, an edible layer over the food is formed, and it can either be removed or consumed.

edible packaging

edible coatings

environmental pollution

1. Production of Edible Films and Coatings

Generally, edible films and coatings are the primary forms of edible food packaging. The differences between edible films and coatings lie in their physical form and application process. Edible films are obtained as solid laminated sheets and then used as a food wrap that can be removed or consumed with food, whereas coatings are applied to foods in liquid form by coating, spraying, and immersion. After drying, an edible layer over the food is formed, and it can either be removed or consumed [1]. There are basically two processes for making edible films: wet and dry processes [2]. The main components used for the production of edible films and coatings include a film-forming material, a solvent, and additives (e.g., plasticizers, emulsifiers, antimicrobials). The specifications of these components are important; film-forming materials should be polymer-like polysaccharides, proteins, lipids, or composites, and they must have filmogenic properties. Solvents and plasticizers are selected on the basis of their compatibility with the selected polymer. Solvents can dissolve polymers and also modify their mechanical and barrier properties, which include alcohol, water, citric acid, acetic acid, lactic acid, and hydrochloric acid. Plasticizers can reduce brittleness, increase flexibility, decrease porosity, and improve the mechanical properties of films. However, the selection of each component will depend on the food product being used, and it does not alter the organoleptic properties of food. The effectiveness of edible films and coatings depends on the chemical composition of the polymer and the final properties of the films [3].

2. Wet Process

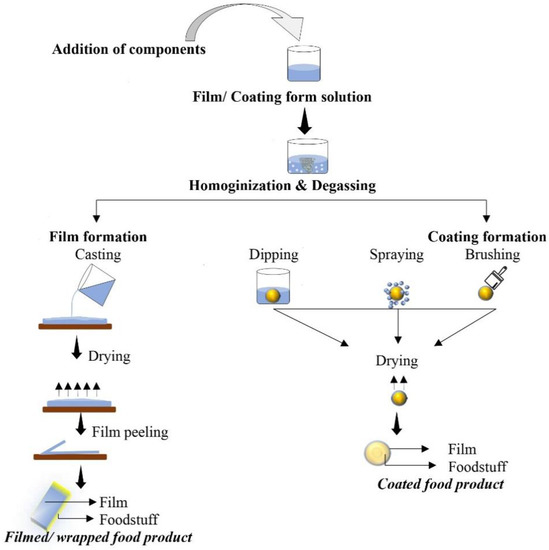

The wet process, mainly comprising the casting method (or solvent casting), is the most commonly used method for the production of films on a laboratory or pilot scale. In the wet process, the film-forming contents are homogenized with a solvent and dried to obtain a film. This process involves three steps. Dissolving or dispersing the biopolymers in solvents is typically the first step that needs to be carried out to generate films. Additives like antimicrobial agents, plasticizers, and flavoring or coloring agents [4] are added to the matrix material to boost these materials’ durability and flexibility [1]. Adjusting the pH and heating the solutions above their melting point to increase their solubility is a possible requirement. This film-forming solution is then cast onto a flat surface and dried at the proper temperature and relative humidity; the resulting film can then be used to wrap the food products [2]. In the casting step, the film-forming solution is poured into a predefined mold or Teflon-coated glass plate. The drying step allows for solvent evaporation, which makes a mold-attached polymer film. In this step, air driers like hot air ovens, tray dryers, microwaves, and vacuum dryers are used for the casting of films [5]. Figure 1 shows a schematic representation of the casting process for edible film production.

Figure 1. Schematic representation of the production of edible films (Casting method) and coatings.

A significant advantage of the casting method is that it can be easily employed without special equipment. Additionally, as many food-processing materials cannot withstand higher temperatures, lower temperatures during the processing steps can be beneficial. The casting process, on the other hand, has drawbacks such as a longer drying time, which makes it unsuitable for commercial manufacturing. In addition, moving film production from the laboratory to large-scale production presents a challenge due to the possibility of variations in quality and a risk of limiting the constant development of commercial operations caused by factors like heating, speed, and temperature [5].

3. Dry Process

In the dry process, added contents are converted into films by using the thermoplastic behavior at low moisture levels [6]. The dry process is more varied and consists of the extrusion method, compression molding, injection molding, etc. [1].

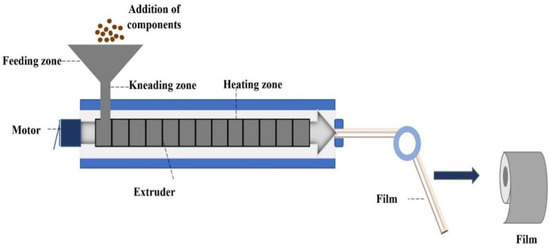

The extrusion process is a method of producing edible films on a commercial scale that consists of three zones: feeding, kneading, and heating. This method can change the structural properties and improve the physicochemical characteristics of extruded films [7]. In the feeding zone, film components are mixed, and air compression is applied to minimize the moisture content of these components. This process is also known as a “dry process” because it functions best with a small amount of water or solvents. As the ingredients move through the kneading zone, the strain, temperature, and density of the mixture rise. Then, these materials are heated above their glass transition temperature to facilitate a conversion into a melt form, which is extruded through a suitably shaped nozzle by the rotating force of an extrusion screw. The resulting materials are then subjected to cooling to form the film [8]. Mechanical and thermal energy are used in this process for the production of extruder-based films. Screw speed also has a role in specific mechanical energy. Different screw speeds alter film properties such as shear rate, homogeneity, and stress, as well as the control of residence time, which allows for the addition and removal of additives like stabilizers. As the screw speed increases, the torque value of the extrusion method to obtain films decreases. Other factors such as screw speed, barrel temperature, feed moisture content, die diameter and pressure, energy input, etc., are necessary to ensure that the extrusion process affects the final products. Figure 2 shows a schematic representation of the extrusion process of edible film production [5][6].

Figure 2. Schematic representation of the production of edible films via the extrusion method.

The extrusion method has better mechanical and optical properties than the casting process, and it also requires less energy and time to process the material. Extrusion processing is also a widely employed commercial technique in the food industry that offers high performance at a reasonable cost. However, the extrusion method has some drawbacks, which are limited to materials with low temperature tolerance and low moisture levels. For example, chitosan is not a thermoplastic material and cannot be extruded [6].

Compression molding is one of the oldest methods and is considered a sustainable process due to its low energy requirement and rapid formation. Here, the film-forming contents are heated under high pressure in the mold until they solidify. Processing time is also a critical parameter for determining the properties of films. This step is usually used in combination with the extrusion method to prepare the film-forming material before its main thermoforming process. Ceballos et al. [9] developed an edible film from starch and yerba mate extract using extrusion and compression molding. Their study revealed that films produced via the compression-mold technique with yerba mate extract can improve the shelf life of foods, providing a promising active food packaging material.

The injection molding method is mainly used to make plastic items, but it is also appropriate for the mass production of edible films. This method consists of three stages, namely, filling, packing, and cooling, and its parameters are injection pressure, molding temperature, and pre-injection pressure temperature [10]. This method can be used in conjunction with the extrusion method to obtain a film. Studies on the injection molding method are scarce [6].

4. Production of Edible Coatings

The film-forming solution can be directly applied to food surfaces as coatings in the form of liquid suspension, emulsion, or powder. Methods like dipping, spraying, brushing, fluidized bed processing, and the panning method are used to apply edible coatings to food products, followed by drying. Figure 1 is a schematic representation of the process used to produce edible coatings.

The dipping method is the oldest and most common method used to coat edible coatings on foods such as meat products, fruit, and vegetables [5]. This method is one of the ideal choices for coating irregular food surfaces [7]. The surface tension, density, and viscosity of the coating solution are significant in estimating the thickness of the film. The dipping method involves dipping a product directly into an aqueous coating solution, removing it, and subsequently subjecting it to air drying to produce a delicate membranous film that envelops the product’s surface. Another method for coating formation is the foam application method. Emulsions are typically used in this method. The foam breaks through a lot of tumbling so that the coating solution can be uniformly applied throughout the product’s surface [11].

The spraying method is preferred when only one surface needs to be coated and a thin layer of coating is necessary. Compared to pan or fluidized bed coating, it is a more precise form of coating application, wherein the solution is applied to the food surface using pressure (60–80 psi) [10]. However, in this method, after coating and drying one/the upper surface of the product, the product needs to be rotated or spun to cover the other lower surface. This method is mostly preferred for products with large surfaces. In this coating process, the spray nozzle plays a crucial role as it can influence factors like droplet size, surface tension, spray distance and angle, flow rate, overlap speed, viscosity, temperature, and pressure of the coating fluid [7][11].

Fluidized bed processing is a process that involves applying a very thin coating to dry particles of extremely low size and/or density. In this method, the small particles that are to be coated are added to a rotating fluidized bed. A centrifugal force pushes the coated particles towards the equipment’s wall. Also, the equipment is designed to allow for airflow; thus, the combined effects of airflow and centrifugal force effectively counter the total force acting on the food particles [7][11].

The pan-coating method is used to cover hard, almost-spherical particles in thin or thick layers [5]. This coating can prevent the loss of moisture and lipids and can provide additional flavors to the coated product. The pharmaceutical and confectionery industries both use the pan-coating method to cover the products with this coating material. In this method, the pan is a large, rotating bowl in which the item to be coated is placed. A ladle or spray is used to add the coating solution to a rotating pan. To apply the coating solution throughout the food’s surface, the product is rotated in the pan [11].

References

- Trajkovska Petkoska, A.; Daniloski, D.; D’Cunha, N.M.; Naumovski, N.; Broach, A.T. Edible Packaging: Sustainable Solutions and Novel Trends in Food Packaging. Food Res. Int. 2021, 140, 109981.

- Barbosa, C.H.; Andrade, M.A.; Vilarinho, F.; Fernando, A.L.; Silva, A.S. Active Edible Packaging. Encyclopedia 2021, 1, 360–370.

- García-Anaya, M.C.; Sepulveda, D.R.; Zamudio-Flores, P.B.; Acosta-Muñiz, C.H. Bacteriophages as Additives in Edible Films and Coatings. Trends Food Sci. Technol. 2023, 132, 150–161.

- Moura-Alves, M.; Esteves, A.; Ciríaco, M.; Silva, J.A.; Saraiva, C. Antimicrobial and Antioxidant Edible Films and Coatings in the Shelf-Life Improvement of Chicken Meat. Foods 2023, 12, 2308.

- Suhag, R.; Kumar, N.; Petkoska, A.T.; Upadhyay, A. Film Formation and Deposition Methods of Edible Coating on Food Products: A Review. Food Res. Int. 2020, 136, 109582.

- Ajesh Kumar, V.; Hasan, M.; Mangaraj, S.; Pravitha, M.; Verma, D.K.; Srivastav, P.P. Trends in Edible Packaging Films and Its Prospective Future in Food: A Review. Appl. Food Res. 2022, 2, 100118.

- Punia Bangar, S.; Chaudhary, V.; Thakur, N.; Kajla, P.; Kumar, M.; Trif, M. Natural Antimicrobials as Additives for Edible Food Packaging Applications: A Review. Foods 2021, 10, 2282.

- Wang, Q.; Chen, W.; Zhu, W.; McClements, D.; Xuebo, L.; Liu, F. A Review of Multilayer and Composite Films and Coatings for Active Biodegradable Packaging. npj Sci. Food 2022, 6, 18.

- Ceballos, R.L.; Ochoa-Yepes, O.; Goyanes, S.; Bernal, C.; Famá, L. Effect of Yerba Mate Extract on the Performance of Starch Films Obtained by Extrusion and Compression Molding as Active and Smart Packaging. Carbohydr. Polym. 2020, 244, 116495.

- Lisitsyn, A.; Semenova, A.; Nasonova, V.; Polishchuk, E.; Revutskaya, N.; Kozyrev, I.; Kotenkova, E. Approaches in Animal Proteins and Natural Polysaccharides Application for Food Packaging: Edible Film Production and Quality Estimation. Polymers 2021, 13, 1592.

- Tufan, E.G.; Borazan, A.A.; Koçkar, Ö.M. A Review on Edible Film and Coating Applications for Fresh and Dried Fruits and Vegetables. Bilecik Şeyh Edebali Üniv. Fen Bilim. Derg. 2021, 8, 1073–1085.

More

Information

Subjects:

Environmental Sciences

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

3.8K

Revisions:

2 times

(View History)

Update Date:

21 Jul 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No