Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Siriporn Taokaew | -- | 3262 | 2023-07-12 07:34:15 | | | |

| 2 | Rita Xu | Meta information modification | 3262 | 2023-07-12 07:48:48 | | | | |

| 3 | Rita Xu | Meta information modification | 3262 | 2023-07-12 07:50:37 | | | | |

| 4 | Siriporn Taokaew | Meta information modification | 3262 | 2023-07-18 07:32:05 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Taokaew, S. Ionic Liquids Used in Dissolution of Cellulose. Encyclopedia. Available online: https://encyclopedia.pub/entry/46669 (accessed on 07 February 2026).

Taokaew S. Ionic Liquids Used in Dissolution of Cellulose. Encyclopedia. Available at: https://encyclopedia.pub/entry/46669. Accessed February 07, 2026.

Taokaew, Siriporn. "Ionic Liquids Used in Dissolution of Cellulose" Encyclopedia, https://encyclopedia.pub/entry/46669 (accessed February 07, 2026).

Taokaew, S. (2023, July 12). Ionic Liquids Used in Dissolution of Cellulose. In Encyclopedia. https://encyclopedia.pub/entry/46669

Taokaew, Siriporn. "Ionic Liquids Used in Dissolution of Cellulose." Encyclopedia. Web. 12 July, 2023.

Copy Citation

Cellulose is the most abundant natural polymer, which has attracted great attention due to the demand for eco-friendly and sustainable materials. The sustainability of cellulose products also depends on the selection of the dissolution solvent.

cellulose

ionic liquid

hydrogel

regeneration

1. Introduction

The development of products with durability, repairability, and reusability is a sustainable way to mitigate environmental impacts and move toward a circular economy. The impact on the environment has manifested from the continuous use of petroleum-based resources that must be substituted with alternative renewable and eco-friendly resources [1][2]. Biomass-based raw materials are a promising replacement of non-renewable, petroleum-based materials for advancing the efforts toward achieving a sustainable society. In order to achieve the desired levels of sustainable growth and to mitigate environmental pollution, biomass has been applied to reduce wastes and develop value-added products [3]. Expanding the use of such biomass-based materials does not only address the societal need for low-cost materials, but also reduces carbon footprints [4][5]. As a consequence of the abundance of renewable biomass materials in nature, its rational use is of great significance for the sustainable development of the chemical industry [6].

Cellulose is a biomass source with the potential to replace fossil fuels through its use in the production of value-added chemicals such as 5-hydroxymethylfurfural and levulinic acid [7]. It is a natural polymer available from diverse sources such as plants and from the extracellular production of several microbial genera, particularly Gluconacetobacter xylinus [8][9]. Cellulose can be obtained from wastes such as paper [10], textile [11][12][13], oil palm frond [14], and crop straw [15][16]. Due to its availability, biodegradability, non-toxicity, hydrophilic nature, inexpensive cost, and multifunctionality, cellulose is attractive and shows promise for utilization in sustainable material engineering. The processibility of cellulose allows it to be formed into various types of materials, for example, into hydrogels [17] and/or applied in its dry form as aerogels [18]. Cellulose hydrogels (jelly-like solids) are obtained by the regeneration or crosslinking of cellulose in solutions into a 3D shape, which are different from the non-cross-linked gel-like suspension of nano- or micro-fibrillated cellulose [19][20][21]. Due to the presence of hydroxyl groups in cellulose, the cross-linking in the hydrogel is formed through hydrogen bonding, which is reconstructed during the cellulose regeneration and solvent removal process [22]. Numerous hydroxyl groups in cellulose and other hydrophilic groups, e.g., carboxyl and amino groups, present in the cellulose derivatives, enable the entrapment of large volumes of water [23][24]. Depending on their applications in biotechnology, cosmetology, and ecology, a variety of sizes, from macro to nanogels, such as membranes, films, fibers, microspheres, or nanoparticles, can be fabricated by various interactions [25][26]. Those interactions are hydrogen bonding, electrostatic interactions, van der Waals forces, and physical entanglements of the cellulose molecules and/or their blends [25][26]. One of the main limitations of processing native cellulose is that it is difficult to dissolve in conventional organic or inorganic solvents due to the abundance of hydrogen bonds. The cellulose derivatives, e.g., carboxymethylcellulose, are much easier to dissolve, but multiple production steps are required to produce such derivatives [27]. The native cellulose is a semi-crystalline polymer comprising a high order of crystalline regions and a lower order of amorphous regions [28]. The rich hydrogen bonds between and within cellulose polymer chains are beneficial for the mechanical properties of cellulose crystals which greatly enhances mechanical strength of highly crystalline cellulose materials [29]. However, the resultant strong and complex 3D inter- and intramolecular hydrogen bonding network contributes to the chain rigidity and insolubility of cellulose, which must be disrupted for dissolution [30][31]. The bonding disruption can be achieved by the derivatization of hydroxyl groups of cellulose or comparative formation of a stronger hydrogen bond with other strong hydrogen-bonding solvents [30][31]. The solvents that have been used in the sol–gel process of cellulose are: N-dimethylacetamide (DMAc)/LiCl [32]; tetrabutylammonium fluoride/dimethyl sulfoxide (TBAF/DMSO) [33]; alkali/urea (NaOH/urea/H2O, LiOH/thiourea/H2O, etc.) [34][35]; N-methyl morpholine oxide (NMMO) [36][37]; NMMO/DMSO [38]; ZnCl2 aqueous solutions [39][40][41][42]; ZnCl2 molten salt hydrates [43]; molten hydrates of LiClO4 NaSCN/KSCN/LiSCN and LiCl/ZnCl2 [44]; molten salt hydrates of ZnBr2 and FeCl3 [45]; LiBr trihydrate molten salt [46]; and ethylenediamine solutions of NaSCN, KSCN, or NaI [44][47]. However, harsh dissolution conditions, such as high temperature, strong corrosiveness from the alkali metal hydroxide, and long processing time, have been reported [48]. Direct non-derivatizing dissolution of cellulose by the NMMO-based Lyocell process is commercialized. Although it is less-time consuming, the thermal stability and side reaction of NMMO, which decreases the performance of hydrogel fibers, remains a concern [49]. The ZnCl2 aqueous solutions and inorganic molten salt hydrates have been of interest as cellulose dissolution solvents in recent years due to their ease of preparation and low cost [41][42][50]. However, the solubility of cellulose in such inorganic salts is low and requires a high temperature or long dissolution time, causing energy consumption and hydrolysis [50][51].

Ionic liquids (ILs) are considered to be desirable eco-friendly solvents and have been used to replace the organic solvents for cellulose dissolution under milder conditions. A regular crystalline structure is difficult to form because of the asymmetry of ILs and the reduced electrostatic forces between the cations and anions [52]. Therefore, they can be liquid at low or room temperature. The ILs can form comparatively stronger hydrogen bonding with the native molecular hydrogen bond network within cellulose structures, causing hydrogen bonding disruption and dissolution. Due to their main advantages besides their high cellulose dissolution ability, ILs have low vapor pressure and are efficiently recycled in order to avoid their propagation in ecosystems. Cellulosic solutions in ILs can also be converted into ionogels or hydrogels by simple operations such as regeneration in cellulose antisolvents [53].

2. Ionic Liquids Used in Dissolution of Cellulose

2.1. Pure Ionic Liquid Systems

Anions and cations of ILs strongly affect cellulose solubility. The ILs containing cations with an unsaturated heterocyclic ring have the ability to dissolve cellulose because of their π electron delocalization of the ring. Such cations are active to interact with cellulose by providing more space for anions to form hydrogen bonds with cellulose. In contrast, the larger volume of ILs containing cations with the saturated heterocyclic ring slows down cations and anions transfer, which is less favorable for cellulose dissolution [54]. The options for cellulose dissolution have been ILs with aromatic imidazolium or pyridinium cations [55][56]. The imidazolium salts, such as 1-allyl-3-methyl imidazolium chloride (AmimCl), 1-buthyl-3-methyl imidazolium chloride (BmimCl), and 1-ethyl-3-methylimidazolium acetate (EmimAc), have received attention [57][58]. A series of substituted imidazolium cations, paired with lactate or glycolate anions, was developed by Meenatchi et al. [59]. For 5% w/w of cellulose solution, 1-ethyl imidazolium lactate showed the highest dissolution power within 20 min at 80 °C because of its higher number of acidic protons (C-2, C-4, C-5) which, in turn, favor the formation of more hydrogen bonds with oxygen atoms of cellulose. The replacement of the acidic C-2 proton by a methyl group (2-methylimidazolium) reduced the dissolution power, which suggested the substitution decreased the hydrogen bond interactions [59].

The anions also play a vital role in the breakage of the native cellulose hydrogen bond network because of the strong electronegativity, allowing anions to form strong hydrogen bonds with the hydroxide groups of cellulose. After being combined with various cations possessing alkyl functional groups, Cl−, acetate (Ac−), dimethyl phosphate (DMP−), and diethyl phosphate (DEP−) anions (acidic protons) strongly exhibit the ability to dissolve cellulose [60]. In contrast, weak hydrogen-bonding anions, e.g., BF4−, PF6−, and Tf2N−, are not suitable for cellulose dissolution [61][62]. The Cl−-based ILs are widely adopted as a small-sized hydrophilic hydrogen bond acceptor, for instance BmimCl is frequently used due to its thermoplasticity and thermal processability [63][64][65][66]. The EmimAc provides better solubility for cellulose due to its lower viscosity (~140 mPas at 25 °C and 10 mPa s at 80 °C) and to the fact that it forms easily processable and stable cellulose solutions; it is also less toxic (LD50 > 2000 mg/kg) and less corrosive than BmimCl [67][68][69][70]. Therefore, it has been a choice for creating regenerated cellulose hydrogels, especially in the form of fibers, because it requires less energy during the shaping process [71]. The AmimCl is also able to dissolve cellulose at a higher concentration than BmimCl [55][72], owing to its high Cl− concentration, electrochemical stability, and compatibility of hydrogen bond acceptors providing more interaction sites for hydroxyl groups of cellulose [73][74]. AmimCl is an effective IL for cellulose dissolution and hydrogel fabrication. The regenerated cellulose produced from AmimCl has the highest crystallinity, tensile strength, and transparency compared with those from BmimCl and EmimAc [72]. Even though AmimCl shows greater cellulose dissolution capability than EmimDEP [75], the content of depolymerized cellulose increases more with time and temperature in AmimCl than in EmimDEP [75]. Xu et al. [76] studied Amim(MeO)PHO2 IL for cellulose dissolution and decomposition. To increase the ionicity of this IL, Na2PHO3 inorganic salt, having an anion structure similar to that of Amim(MeO)PHO2, was added to form a composite solvent system (Na2PHO3/Amim(MeO)PHO2) and facilitate cellulose dissolution. The Na2PHO3 addition reduced H+ concentration of the solvent system, which inhibited the decomposition of cellulose. The lower viscosity of Na2PHO3/Amim(MeO)PHO2 solvent caused 22% w/w cellulose to dissolve at 80 °C over 48 h. With the increase in Na2PHO3 content, the degree of polymerization and thermal stability of the regenerated cellulose increased, but the crystallinity decreased relative to that of the original microcrystalline cellulose (MCC), because the long molecular chains exhibited difficulty in forming new hydrogen bonds during regeneration [76].

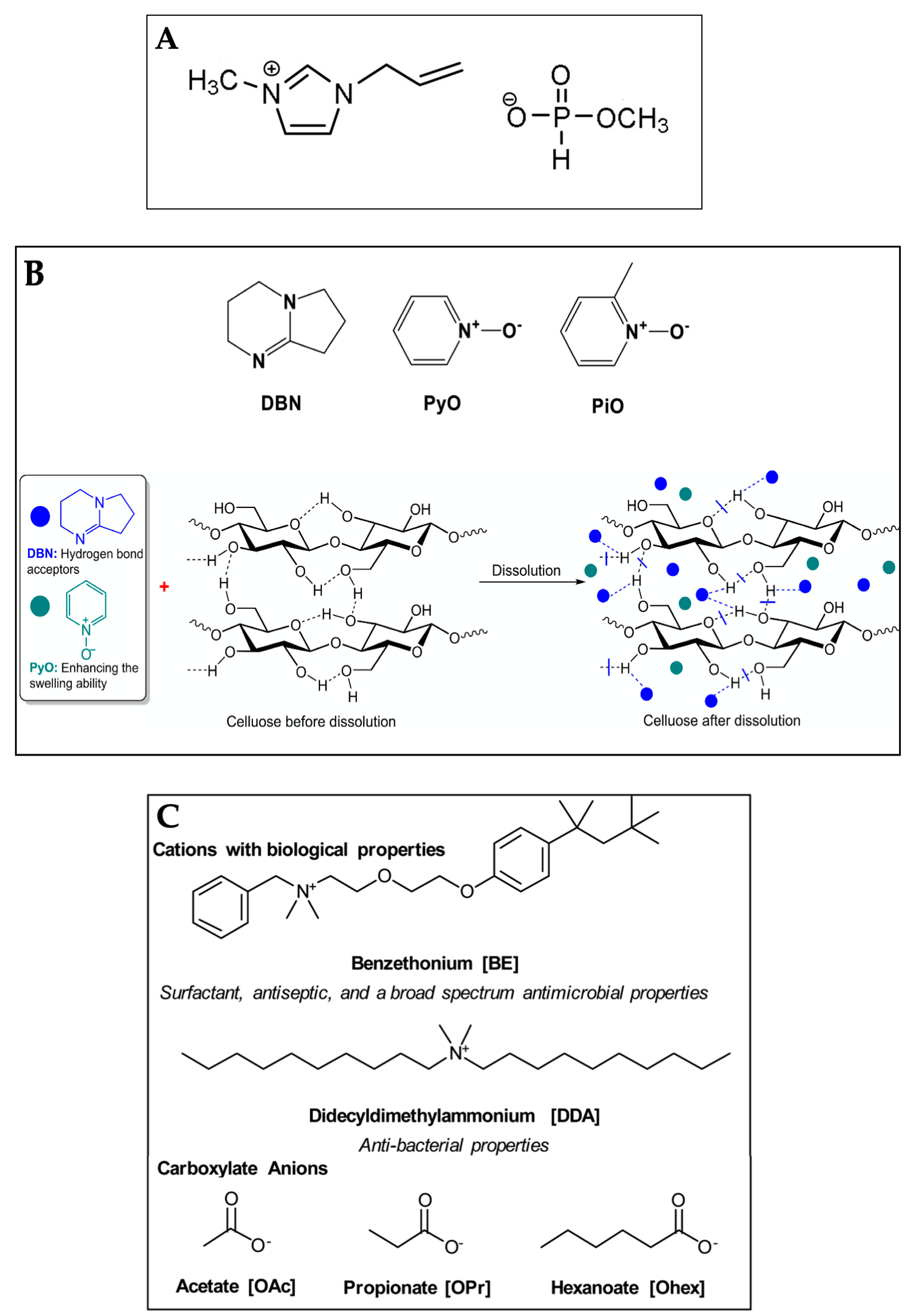

One of the advantages of imidazolium-based ILs is their capability to dissolve cellulose even at room temperature. However, some drawbacks are the high viscosity and difficulty in cellulose dispersion due to the strong association between the anions and cations [77]. When ILs are used in the presence of lignin in the pulp or impurities, side reactions such as acetylation may occur at high temperatures above 100 °C [78]. Therefore, the researchers have studied new ILs for efficient cellulose dissolution. Li et al. [79] developed a series of superbase-derived ILs such as: 1,8-diazabicyclo [5.4.0] undec-7-ene (DBU) including 1,8-diazabicyclo [5.4.0] undec-7-enium (DBUH) carboxylate, e.g., OAc−; and 1,5-diazabicyclo [4.3.0] non-5-ene (DBN) including 1,5-diazabicyclo [4.3.0] non-5-enium (DBNH) carboxylate with lower viscosity and high cellulose solubility. The DBUH ethoxyacetate has the higher cellulose dissolution capacity (14.8% w/w wood pulp at 80 °C) [80], but lower corrosion to steels than EmimAc and AmimCl [81]. On the other hand, some organic N-oxide-based solutions can dissolve cellulose efficiently, but the drawbacks are the instability of the N-oxides and the high dissolution temperature leading to the partial degradation of cellulose. Lui et al. [82] prepared DBN coupled with two N-oxides, i.e., pyridine N-oxide (PyO) and 2-picoline-N-oxide (PiO). The solvents dissolved cellulose efficiently at temperatures lower than 80 °C. The solvent DBN/PyO, at molar ratio of DBN and PyO of four, showed the cellulose solubility of 10.9 and 14.1% w/w at 50 and 70 °C, respectively. Galamba et al. [83] studied benzethonium- and didecyldimethylammonium- based ILs combined with short alkyl carboxylate anions to dissolve MCC at a concentration of 4% w/w. The polymeric cellulose hydrogel structures varied depending on the type of ILs and the ratios between cellulose and IL. However, after regeneration, some ILs remained in the hydrogel structures, which was advantageous in terms of the antibacterial/antimicrobial response of the hydrogels. Some new IL systems for cellulose dissolution, as reported in recent studies, are shown in Figure 1.

Figure 1. Chemical structures of 1-allyl-3-methylimidazolium methyl phosphonate (Amim (MeO)PHO2) (A), 1,5-diazabicyclo [4.3.0] non-5-ene (DBN), pyridine N-oxide (PyO) and 2-picoline N-oxide (PiO) with graphic dissolution mechanism of cellulose (B) and benzethonium (BE)- and didecyldimethylammonium (DDA)-based ILs combined with short alkyl carboxylate anions (C).

2.2. Ionic Liquid–Cosolvent Systems

One of the problems with using ILs to process cellulose is the high viscosity of the cellulose/IL solutions. The use of IL/cosolvent mixtures is an option that can modify the properties of the IL solvent by improving the rheological properties of the cellulose mixture, to reduce the viscosity of the solvent system and to accelerate the mass transfer process. The solvation of cation and anion by the cosolvents enhances the production of more free anions from anion–cation pairs, which readily interact with cellulose [84][85]. The frequently used cosolvents are polar aprotic organic solvents like DMSO, dimethylformamide (DMF), dimethylacetamide (DMAc), and dimethylimidazolinone (DMI). Zhou et al. [86] studied the cellulose solution state and formation mechanism by using these four cosolvents with EmimAc, BmimAc, AmimCl, and BmimCl. Acetate-based ILs and a high cosolvent content facilitated the formation of a molecularly dispersed state. In contrast, a state of coexistence of single molecular chains and undissolved cellulose microdomains gradually converted into a molecularly dispersed state when using chloride based ILs or a low content of cosolvents. The cosolvents DMF and DMAc promoted the molecular dispersion of cellulose better than DMSO and DMI. In IL/cosolvent systems with a high hydrogen-bonding basicity (>0.92) and a large amount of small ion cluster structures, cellulose favors the formation of a molecularly dispersed state. Cellulose dissolution capacity can be increased at lower processing temperature. Importantly, this IL/cosolvent system reduce the quantity of IL used in cellulose dissolution [87]. Other recent studies also indicate the advantages of the mixed IL/cosolvent system for cellulose dissolution that time, temperature, and viscosity of cellulose mixture in IL solutions are reduced by the inclusion of a cosolvent [88][89]. Hawkins et al. [88] studied the dissolution time of flax fibers in EmimAc as a function of temperature and DMSO concentration. The dissolution rate was maximized when using an equal amount of EmimAc to DMSO, whereby the dissolution was about three times faster than that in the pure IL. The independence of an activation energy (Ea), required for the dissolution of flax fibers in EmimAc, on DMSO concentration suggests that flax fibers dissolution is not primarily a viscosity-driven process. The result is related to the work of Chen et al. [90]; the dissolution is not only governed by viscosity, but also by solvent power.

Due to its low cost, low toxicity, and low viscosity, DMSO is a suitable candidate for a cosolvent. A series of IL/DMSO systems have been studied as shown in Table 1. The efficiency of IL/DMSO mixtures in cellulose dissolution and derivatization depends on the structures of ILs [91] and temperature [92]. With increasing temperature, the specific interaction between cellulose and the solvent increases [92]. Ferreira et al. [91] studied the effect of the presence of an ether linkage in the sidechain of imidazolium acetate (ImAc) using RMenImAc, R = 1-butyl or 2-methoxyethyl, n = 1 or 2 and the mixtures with DMSO. The mixture of BmimAc–DMSO was more efficient for the dissolution of MCC and acylation of cellulose because the mixture was less viscous, more basic, and formed stronger hydrogen bonds with cellobiose. Using the corresponding ILs with C2–CH3 instead of C2–H (1-butyl-2,3-dimethylimidazolium acetate and 1-(2-methoxyethyl)-2,3-dimethylimidazolium acetate) increased the concentration of dissolved cellulose [91]. Increasing the amount of DMSO does not only improve cellulose solubilization, but also leads to the formation of a more pronounced macroporous structure of the hydrogel [93].

Table 1. Recent studies on IL/DMSO solvent systems used for cellulose dissolution.

| IL | Concentration of DMSO in IL and Temperature to Dissolve Cellulose | Concentration of Cellulose | Ref. |

|---|---|---|---|

| C3OMeImAc C4MeImAc (BmimAc) C3OMe2ImAc C4Me2ImAc |

60% mole, 60 °C 60% mole, 60 °C 60% mole, 60 °C 60% mole, 60 °C |

12% w/w MCC a 16% w/w MCC a 19% w/w MCC a 22% w/w MCC a |

[91] |

| BmimAc | 20% w/w, 70 °C | 8% w/w MCC, Avicel, and α-cellulose b | [93] |

| 40% w/w, R.T. c | 20% w/w Avicel b | [94] | |

| 40% w/w, R.T. c | ~10% w/w MCC b | [95] | |

| 75% w/w, 80 °C | 14% w/w cellulose powder b | [96] | |

| BmimCl | 50% w/w, 15–75 °C | 3% w/w cellulose powder b | [92] |

| 30% w/w, 120 °C | - | [97] | |

| EmimAc | 50% w/w, 60 °C | 2.5% w/w cotton b | [98] |

| 25% w/w, 50 °C | 10% w/w MCC b | [99] | |

| 75% w/w, 80 °C | 14% w/w cellulose powder b | [96] | |

| EmimCl | 75% w/w, 80 °C | 14% w/w cellulose powder b | [96] |

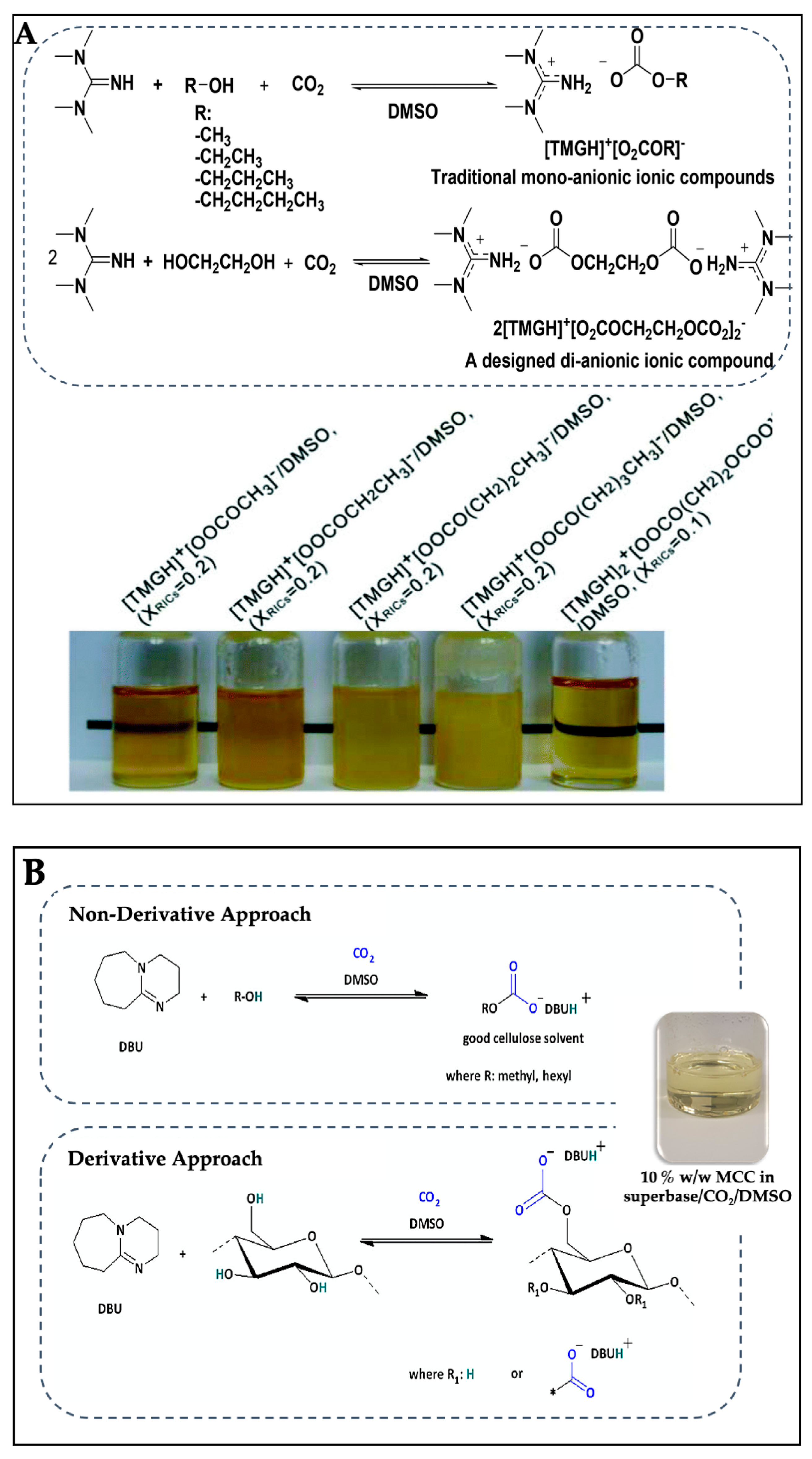

In designing a new IL solvent system for cellulose dissolution, reversible/switchable reactions with CO2, a well-recognized greenhouse gas, have been extended [100][101][102]. Xie et al. [100] reported that the CO2-based reversible IL/DMSO solvent could dissolve MCC up to 10% w/w under mild conditions at 60 °C and a CO2 pressure of 2.0 MPa for 2 h, when 1,1,3,3-tetramethyl guanidine (TMG) was used as a base, in conjunction with methanol, ethanol, propanol, butanol, and ethylene glycol (Figure 2A). Yang et al. [103] also reported that DBU/DMSO could promote the dissolution of cellulose pulp at the relative low temperature of 50 °C in the presence of CO2. This is because the addition of CO2 causes the reversibility or switch-ability of this solvent system by changing the polarity from nonpolar to polar and reversing to its initial nonpolar state upon the release of CO2 [104][105]. Cellulose dissolves in this solvent system by nonderivative and derivative approaches (Figure 2B). In the nonderivative approach, simple alcohols such as methanol, hexanol, or ethylene glycol, in the presence of strong organic bases such as DBU, react with CO2 leading to the formation a DMSO–carbonate species solvent that can solubilize cellulose [100]. In the derivative approach, the superbase activates cellulose first and, thereafter, reacts with CO2 to form a DMSO-soluble cellulose carbonate intermediate [106].

Figure 2. Reaction of 1,1,3,3-tetramethyl guanidine (TMG) with methanol, ethanol, propanol, butanol, and ethylene glycol in the presence of CO2 and dimethyl sulfoxide (DMSO) to form reversible ILs (TMGHO2COR) (A). Pictures illustrate 5% w/w of microcrystalline cellulose (MCC) solution in the reversible ionic compound (RIC) solvents at the different molar fractions in DMSO after CO2 capture (XRIC). Nonderivative and derivative approaches of the CO2 switchable 1,8-diazabicyclo [5.4.0] undec-7-ene (DBU) super base solvent system (B). Picture illustrates 10% w/w of MCC solution in superbase (DBU)/CO2/DMSO solvent.

Since the reversible reaction between cellulose, organic base, and CO2 is exothermic, the resulting high temperature is not suitable for cellulose dissolution. Therefore, the temperature used in most studies is in the range of 30–60 °C. At 30 °C, increasing the pressure of CO2 above 20 bar (2 MPa) increases in the carbonate formation and cellulose solubilization kinetics in 10 min, whereas at 40 bar (4 MPa), the carbonate formation is reached within 5 min. On the other hand, for CO2 pressures below 2 MPa, the solubilization of 3% w/w MCC is slower but occurs within 15 min [107]. At 30 °C and CO2 pressures of 0.2 MPa, the solubility of MCC in DMSO/DBU at weight ratio of DBU of 0.1 can reach 9% w/w. However, increasing the weight ratio of DBU to 0.5 slightly inhibits the MCC solubility. This indicates that the DBU amount influences MCC dissolution behavior [108]. At the higher temperature range of 40–60 °C, the dissolution of cellulose derived from a cassava pulp waste in DBU and ethylene glycol, which produces a switchable polarity solvent containing the cation of DBU (DBUH+) and the anion of ethylenedicarbonate (O2COCH2CH2OCO22−) in the mixture with CO2, can be achieved in less than 30 min under CO2 pressure of more than 5.0 MPa [109]. Under 1 atm (0.1 MPa) in an open system, the obtained cellulose is stable and suitable for the preparation of cellulose hydrogel fiber by wet spinning [110]. Besides TMG and DBU, clear cellulose solutions were obtained in 1,5,7-Triazabicyclo [4.4.0] dec-5-ene (TBD) under 1 MPa CO2 at 50 °C for 3 h [111], and 2-tert-butyl-1,1,3,3-tetramethylguanidine (BTMG) under 1 atm (0.1 MPa) CO2 at room temperature for 5 min [112], but cellulose was not dissolved in triethyl amine (TEA) [111]. Instead of DMSO, other organic solvents with low Henry’s constants, such as propylene carbonate and sulfolane, are used as CO2 absorbents to increase CO2 absorption capacity in the solvent, so that the cellulose dissolution is enhanced. With the addition of propylene carbonate, the paper cellulose dissolution can be increased from 1.0 to 5.0% w/w, while those for microcrystalline cellulose and corncob cellulose are increased from 5.0 to 10.0 and 7.0% w/w, respectively, at 60 °C and a CO2 pressure of 0.5 MPa. The chemical and crystalline structures of the regenerated cellulose is not affected by the addition of these CO2 absorbents [113].

References

- Xia, Z.; Li, J.; Zhang, J.; Zhang, X.; Zheng, X.; Zhang, J. Processing and valorization of cellulose, lignin and lignocellulose using ionic liquids. J. Bioresour. Bioprod. 2020, 5, 79–95.

- Yeboah, W.O.; Kwofie, E.M.; Wang, D. Circular bioeconomy potential of rice husk as a bioplastic resource: Techno-environmental assessment. Bioresour. Technol. Rep. 2022, 20, 101248.

- Ahrens, T.; Drescher-Hartung, S.; Anne, O. Sustainability of future bioenergy production. Waste Manag. 2017, 67, 1–2.

- Gan, W.; Wang, Y.; Xiao, S.; Gao, R.; Shang, Y.; Xie, Y.; Liu, J.; Li, J. Magnetically Driven 3D Cellulose Film for Improved Energy Efficiency in Solar Evaporation. ACS Appl. Mater. Interfaces 2021, 13, 7756–7765.

- Nie, S.; Hao, N.; Zhang, K.; Xing, C.; Wang, S. Cellulose nanofibrils-based thermally conductive composites for flexible electronics: A mini review. Cellulose 2020, 27, 4173–4187.

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748.

- Li, X.; Xu, R.; Yang, J.; Nie, S.; Liu, D.; Liu, Y.; Si, C. Production of 5-hydroxymethylfurfural and levulinic acid from lignocellulosic biomass and catalytic upgradation. Ind. Crops Prod. 2019, 130, 184–197.

- Taokaew, S.; Nakson, N.; Zhang, X.; Kongklieng, P.; Kobayashi, T. Biotransformation of okara extracted protein to nanocellulose and chitin by Gluconacetobacter xylinus and Bacillus pumilus. Bioresour. Technol. Rep. 2022, 17, 100904.

- Taokaew, S.; Nakson, N.; Thienchaimongkol, J.; Kobayashi, T. Enhanced production of fibrous bacterial cellulose in Gluconacetobacter xylinus culture medium containing modified protein of okara waste. J. Biosci. Bioeng. 2023, 135, 71–78.

- Long, L.-Y.; Weng, Y.-X.; Wang, Y.-Z. Cellulose Aerogels: Synthesis, Applications, and Prospects. Polymers 2018, 10, 623.

- Wang, L.; Huang, S.; Wang, Y. Recycling of Waste Cotton Textile Containing Elastane Fibers through Dissolution and Regeneration. Membranes 2022, 12, 355.

- Zhong, X.; Li, R.; Wang, Z.; Wang, Y.; Wang, W.; Yu, D. Highly flexible, transparent film prepared by upcycle of wasted jute fabrics with functional properties. Process Saf. Environ. Prot. 2021, 146, 718–725.

- Ma, Y.; Zeng, B.; Wang, X.; Byrne, N. Circular Textiles: Closed Loop Fiber to Fiber Wet Spun Process for Recycling Cotton from Denim. ACS Sustain. Chem. Eng. 2019, 7, 11937–11943.

- Selvakumaran, N.; Lazim, A. Superabsorbent hydrogel from extracted oil palm frond waste cellulose using microwave irradiation for cadmium ion removal from aqueous solution. Chem. Chem. Technol. 2019, 13, 518–525.

- Miao, X.; Lin, J.; Bian, F. Utilization of discarded crop straw to produce cellulose nanofibrils and their assemblies. J. Bioresour. Bioprod. 2020, 5, 26–36.

- Su, R.; Wang, F.; Ding, J.; Li, Q.; Zhou, W.; Liu, Y.; Gao, B.; Yue, Q. Magnetic hydrogel derived from wheat straw cellulose/feather protein in ionic liquids as copper nanoparticles carrier for catalytic reduction. Carbohydr. Polym. 2019, 220, 202–210.

- Pang, J.; Wu, M.; Zhang, Q.; Tan, X.; Xu, F.; Zhang, X.; Sun, R. Comparison of physical properties of regenerated cellulose films fabricated with different cellulose feedstocks in ionic liquid. Carbohydr. Polym. 2015, 121, 71–78.

- Wang, H.; Qian, H.; Luo, Z.; Zhang, K.; Shen, X.; Zhang, Y.; Zhang, M.; Liebner, F. ZCIS/ZnS QDs fluorescent aerogels with tunable emission prepared from porous 3D nanofibrillar bacterial cellulose. Carbohydr. Polym. 2019, 224, 115173.

- Afsahi, G.; Dimic-Misic, K.; Gane, P.; Budtova, T.; Maloney, T.; Vuorinen, T. The investigation of rheological and strength properties of NFC hydrogels and aerogels from hardwood pulp by short catalytic bleaching (Hcat). Cellulose 2018, 25, 1637–1655.

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25.

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494.

- Dutta, S.D.; Patel, D.K.; Lim, K.-T. Functional cellulose-based hydrogels as extracellular matrices for tissue engineering. J. Biol. Eng. 2019, 13, 55.

- Wu, C.; McClements, D.J.; Li, L.; He, M.; Li, Y.; Teng, F. Fabrication of composite hydrogels by assembly of okara cellulose nanofibers and gum Arabic in ionic liquids: Structure and properties. J. Mol. Liq. 2022, 349, 118132.

- Zainal, S.H.; Mohd, N.H.; Suhaili, N.; Anuar, F.H.; Lazim, A.M.; Othaman, R. Preparation of cellulose-based hydrogel: A review. J. Mater. Res. Technol. 2021, 10, 935–952.

- Tian, W.; Gao, X.; Zhang, J.; Yu, J.; Zhang, J. Cellulose nanosphere: Preparation and applications of the novel nanocellulose. Carbohydr. Polym. 2022, 277, 118863.

- Song, M.-H.; Pham, T.P.T.; Yun, Y.-S. Ionic liquid-assisted cellulose coating of chitosan hydrogel beads and their application as drug carriers. Sci. Rep. 2020, 10, 13905.

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Technol. 2021, 112, 532–546.

- Kim, S.H.; Lee, C.M.; Kafle, K. Characterization of crystalline cellulose in biomass: Basic principles, applications, and limitations of XRD, NMR, IR, Raman, and SFG. Korean J. Chem. Eng. 2013, 30, 2127–2141.

- Wohlert, M.; Benselfelt, T.; Wågberg, L.; Furó, I.; Berglund, L.A.; Wohlert, J. Cellulose and the role of hydrogen bonds: Not in charge of everything. Cellulose 2022, 29, 1–23.

- Cao, Y.; Zhang, R.; Cheng, T.; Guo, J.; Xian, M.; Liu, H. Imidazolium-based ionic liquids for cellulose pretreatment: Recent progresses and future perspectives. Appl. Microbiol. Biotechnol. 2017, 101, 521–532.

- Xu, H.; Zhang, D.; Wu, F.; Cao, R. Deep oxidative desulfurization of fuels based on CoCl2 ionic liquid oxone solutions at room temperature. Fuel 2017, 208, 508–513.

- Han, Q.; Gao, X.; Zhang, H.; Chen, K.; Peng, L.; Jia, Q. Preparation and comparative assessment of regenerated cellulose films from corn (Zea mays) stalk pulp fines in DMAc/LiCl solution. Carbohydr. Polym. 2019, 218, 315–323.

- Choe, D.; Kim, Y.M.; Nam, J.E.; Nam, K.; Shin, C.S.; Roh, Y.H. Synthesis of high-strength microcrystalline cellulose hydrogel by viscosity adjustment. Carbohydr. Polym. 2018, 180, 231–237.

- From, M.; Larsson, P.T.; Andreasson, B.; Medronho, B.; Svanedal, I.; Edlund, H.; Norgren, M. Tuning the properties of regenerated cellulose: Effects of polarity and water solubility of the coagulation medium. Carbohydr. Polym. 2020, 236, 116068.

- Qiu, C.; Zhu, K.; Zhou, X.; Luo, L.; Zeng, J.; Huang, R.; Lu, A.; Liu, X.; Chen, F.; Zhang, L.; et al. Influences of Coagulation Conditions on the Structure and Properties of Regenerated Cellulose Filaments via Wet-Spinning in LiOH/Urea Solvent. ACS Sustain. Chem. Eng. 2018, 6, 4056–4067.

- Peng, J.; Li, Y.; Liu, X.; Ke, G.; Song, D.; Wu, S.; Xu, W.; Zhu, K. Cellulose film with air barrier and moisture-conducting character fabricated by NMMO. J. Mater. Sci. 2021, 56, 18313–18326.

- Zhang, J.; Tominaga, K.; Yamagishi, N.; Gotoh, Y. Comparison of Regenerated Cellulose Fibers Spun from Ionic Liquid Solutions with Lyocell Fiber. J. Fiber Sci. Technol. 2020, 76, 257–266.

- Gorbacheva, S.N.; Yadykova, A.Y.; Ilyin, S.O. A novel method for producing cellulose nanoparticles and their possible application as thickeners for biodegradable low-temperature greases. Cellulose 2021, 28, 10203–10219.

- Zhao, J.; Deng, M.; Li, S.; Guan, Z.; Xia, Y.; Yang, J.; Lin, X. Room temperature preparation of cellulose nanocrystals with high yield via a new ZnCl2 solvent system. Carbohydr. Polym. 2022, 278, 118946.

- Tong, Z.; Meng, J.; Liu, S.; Liu, Y.; Zeng, S.; Wang, L.; Xia, Q.; Yu, H. Room temperature dissolving cellulose with a metal salt hydrate-based deep eutectic solvent. Carbohydr. Polym. 2021, 272, 118473.

- Shu, L.; Zhang, X.-F.; Wang, Z.; Yao, J. Structure reorganization of cellulose hydrogel by green solvent exchange for potential plastic replacement. Carbohydr. Polym. 2022, 275, 118695.

- Zhang, X.-F.; Ma, X.; Hou, T.; Guo, K.; Yin, J.; Wang, Z.; Shu, L.; He, M.; Yao, J. Inorganic Salts Induce Thermally Reversible and Anti-Freezing Cellulose Hydrogels. Angew. Chem. Int. Ed. 2019, 58, 7366–7370.

- Shen, C.; Hu, C.; Zhang, W.; Lin, X.; Qi, W.; Zhang, Z.; Gu, J. Acidified ZnCl2 molten salt hydrate systems as hydrolytic media for cellulose I and II nanocrystal production: From rods to spheres. Cellulose 2022, 29, 7629–7647.

- Fischer, S.; Leipner, H.; Thümmler, K.; Brendler, E.; Peters, J. Inorganic Molten Salts as Solvents for Cellulose. Cellulose 2003, 10, 227–236.

- Sun, L.; Han, J.; Wu, J.; Huang, W.; Li, Y.; Mao, Y.; Wang, L.; Wang, Y. Cellulose pretreatment with inorganic salt hydrate: Dissolution, regeneration, structure and morphology. Ind. Crops Prod. 2022, 180, 114722.

- Huang, Z.; Liu, C.; Feng, X.; Wu, M.; Tang, Y.; Li, B. Effect of regeneration solvent on the characteristics of regenerated cellulose from lithium bromide trihydrate molten salt. Cellulose 2020, 27, 9243–9256.

- Hattori, K.; Arai, A. Preparation and Hydrolysis of Water-Stable Amorphous Cellulose. ACS Sustain. Chem. Eng. 2016, 4, 1180–1186.

- Zhou, Y.; Zhang, X.; Zhang, J.; Cheng, Y.; Wu, J.; Yu, J.; Zhang, J. Molecular weight characterization of cellulose using ionic liquids. Polym. Test. 2021, 93, 106985.

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206.

- Sen, S.; Martin, J.D.; Argyropoulos, D.S. Review of Cellulose Non-Derivatizing Solvent Interactions with Emphasis on Activity in Inorganic Molten Salt Hydrates. ACS Sustain. Chem. Eng. 2013, 1, 858–870.

- Przypis, M.; Wawoczny, A.; Gillner, D. Biomass and Cellulose Dissolution—The Important Issue in Renewable Materials Treatment. Appl. Sci. 2023, 13, 1055.

- Wang, Y.; He, H.; Wang, C.; Lu, Y.; Dong, K.; Huo, F.; Zhang, S. Insights into Ionic Liquids: From Z-Bonds to Quasi-Liquids. JACS Au 2022, 2, 543–561.

- Hopson, C.; Rigual, V.; Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rodríguez, F. A new approach for the use of cellulose-rich solids from biorefinery in the formulation of gel-like materials. Ind. Crops Prod. 2022, 186, 115230.

- Li, Y.; Liu, X.; Zhang, Y.; Jiang, K.; Wang, J.; Zhang, S. Why Only Ionic Liquids with Unsaturated Heterocyclic Cations Can Dissolve Cellulose: A Simulation Study. ACS Sustain. Chem. Eng. 2017, 5, 3417–3428.

- Zhang, J.; Xu, L.; Yu, J.; Wu, J.; Zhang, X.; He, J.; Zhang, J. Understanding cellulose dissolution: Effect of the cation and anion structure of ionic liquids on the solubility of cellulose. Sci. China Chem. 2016, 59, 1421–1429.

- Paiva, T.; Echeverria, C.; Godinho, M.H.; Almeida, P.L.; Corvo, M.C. On the influence of imidazolium ionic liquids on cellulose derived polymers. Eur. Polym. J. 2019, 114, 353–360.

- Jadhav, S.; Ganvir, V.; Singh, M.K.; Shanmuganathan, K. Synthesis of N-oxyethylene substituted imidazolium-based zwitterions as a recyclable solvent for cellulose dissolution. Cellulose 2023, 30, 87–109.

- Morita, T.; Okada, H.; Yamada, T.; Hidaka, R.; Ueki, T.; Niitsuma, K.; Kitazawa, Y.; Watanabe, M.; Nishikawa, K.; Higashi, K. A study combining magic-angle spinning NMR and small-angle X-ray scattering on the interaction in the mixture of poly(benzyl methacrylate) and ionic liquid 1-ethyl-3-methylimidazolium bis(trifluoromethanesulfonyl)amide. Phys. Chem. Chem. Phys. 2022, 24, 26575–26582.

- Meenatchi, B.; Renuga, V.; Manikandan, A. Cellulose dissolution and regeneration using various imidazolium based protic ionic liquids. J. Mol. Liq. 2017, 238, 582–588.

- Liu, Y.-R.; Thomsen, K.; Nie, Y.; Zhang, S.-J.; Meyer, A.S. Predictive screening of ionic liquids for dissolving cellulose and experimental verification. Green Chem. 2016, 18, 6246–6254.

- Lefroy, K.S.; Murray, B.S.; Ries, M.E. Effect of Oil on Cellulose Dissolution in the Ionic Liquid 1-Butyl-3-methyl Imidazolium Acetate. ACS Omega 2022, 7, 37532–37545.

- Wahlström, R.M.; Suurnäkki, A. Enzymatic hydrolysis of lignocellulosic polysaccharides in the presence of ionic liquids. Green Chem. 2015, 17, 694–714.

- Haq, M.A.; Habu, Y.; Yamamoto, K.; Takada, A.; Kadokawa, J.-I. Ionic liquid induces flexibility and thermoplasticity in cellulose film. Carbohydr. Polym. 2019, 223, 115058.

- Idenoue, S.; Oga, Y.; Hashimoto, D.; Yamamoto, K.; Kadokawa, J.I. Preparation of Reswellable Amorphous Porous Celluloses through Hydrogelation from Ionic Liquid Solutions. Materials 2019, 12, 3249.

- Wang, Y.; Xie, T.; Zhang, J.; Dang, B.; Li, Y. Green fabrication of an ionic liquid-activated lignocellulose flame-retardant composite. Ind. Crops Prod. 2022, 178, 114602.

- Hu, Y.; Guo, Q.; Liu, P.; Zhu, R.; Lu, F.; Ramaswamy, S.; Wu, Y.; Xu, F.; Zhang, X. Fabrication of Novel Cellulose-Based Antibacterial Film Loaded with Poacic Acid against Staphylococcus Aureus. J. Polym. Environ. 2021, 29, 745–754.

- Spörl, J.M.; Batti, F.; Vocht, M.-P.; Raab, R.; Müller, A.; Hermanutz, F.; Buchmeiser, M.R. Ionic Liquid Approach Toward Manufacture and Full Recycling of All-Cellulose Composites. Macromol. Mater. Eng. 2018, 303, 1700335.

- Chen, F.; Sawada, D.; Hummel, M.; Sixta, H.; Budtova, T. Unidirectional All-Cellulose Composites from Flax via Controlled Impregnation with Ionic Liquid. Polymers 2020, 12, 1010.

- Duchemin, B.J.C.; Mathew, A.P.; Oksman, K. All-cellulose composites by partial dissolution in the ionic liquid 1-butyl-3-methylimidazolium chloride. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2031–2037.

- Khakalo, A.; Tanaka, A.; Korpela, A.; Hauru, L.K.J.; Orelma, H. All-Wood Composite Material by Partial Fiber Surface Dissolution with an Ionic Liquid. ACS Sustain. Chem. Eng. 2019, 7, 3195–3202.

- Vinogradova, Y.S.; Chen, J.Y. Micron- and nano-cellulose fiber regenerated from ionic liquids. J. Text. Inst. 2016, 107, 472–476.

- Zheng, X.; Huang, F.; Chen, L.; Huang, L.; Cao, S.; Ma, X. Preparation of transparent film via cellulose regeneration: Correlations between ionic liquid and film properties. Carbohydr. Polym. 2019, 203, 214–218.

- Xue, Y.; Li, W.; Yang, G.; Lin, Z.; Qi, L.; Zhu, P.; Yu, J.; Chen, J. Strength Enhancement of Regenerated Cellulose Fibers by Adjustment of Hydrogen Bond Distribution in Ionic Liquid. Polymers 2022, 14, 2030.

- Jiang, J.; Xiao, Y.; Huang, W.; Gong, P.; Peng, S.; He, J.; Fan, M.; Wang, K. An insight into the influence of hydrogen bond acceptors on cellulose/1-allyl-3-methyl imidazolium chloride solution. Carbohydr. Polym. 2017, 178, 295–301.

- Zhou, L.; Pan, F.; Liu, Y.; Kang, Z.; Zeng, S.; Nie, Y. Study on the regularity of cellulose degradation in ionic liquids. J. Mol. Liq. 2020, 308, 113153.

- Xu, K.; Xiao, Y.; Cao, Y.; Peng, S.; Fan, M.; Wang, K. Dissolution of cellulose in 1-allyl-3-methylimidazolium methyl phosphonate ionic liquid and its composite system with Na2PHO3. Carbohydr. Polym. 2019, 209, 382–388.

- Fumino, K.; Peppel, T.; Geppert-Rybczyńska, M.; Zaitsau, D.H.; Lehmann, J.K.; Verevkin, S.P.; Köckerling, M.; Ludwig, R. The influence of hydrogen bonding on the physical properties of ionic liquids. Phys. Chem. Chem. Phys. 2011, 13, 14064–14075.

- Zweckmair, T.; Hettegger, H.; Abushammala, H.; Bacher, M.; Potthast, A.; Laborie, M.-P.; Rosenau, T. On the mechanism of the unwanted acetylation of polysaccharides by 1,3-dialkylimidazolium acetate ionic liquids: Part 1—Analysis, acetylating agent, influence of water, and mechanistic considerations. Cellulose 2015, 22, 3583–3596.

- Li, X.; Li, H.; Ling, Z.; Xu, D.; You, T.; Wu, Y.-Y.; Xu, F. Room-Temperature Superbase-Derived Ionic Liquids with Facile Synthesis and Low Viscosity: Powerful Solvents for Cellulose Dissolution by Destroying the Cellulose Aggregate Structure. Macromolecules 2020, 53, 3284–3295.

- Wang, X.; Zheng, W.; Guo, Z.; Nawaz, H.; You, T.; Li, X.; Xu, F. Rheological characteristics of novel cellulose/superbase-derived ionic liquid solutions and the coagulation process towards regenerated cellulose films. Green Chem. 2023, 25, 1597–1610.

- Li, X.; Wang, X.; Nawaz, H.; Zhang, J.; Chen, X.; Cheng, P.; You, T.; Ramaswamy, S.; Xu, F. The choice of ionic liquid ions to mitigate corrosion impacts: The influence of superbase cations and electron-donating carboxylate anions. Green Chem. 2022, 24, 2114–2128.

- Liu, Q.; Yu, H.; Mu, T.; Xue, Z.; Xu, F. Robust superbase-based emerging solvents for highly efficient dissolution of cellulose. Carbohydr. Polym. 2021, 272, 118454.

- Galamba, J.; Alves, V.D.; Jordão, N.; Neves, L.A. Development of cellulose-based polymeric structures using dual functional ionic liquids. RSC Adv. 2021, 11, 39278–39286.

- Zhao, Y.; Liu, X.; Wang, J.; Zhang, S. Insight into the Cosolvent Effect of Cellulose Dissolution in Imidazolium-Based Ionic Liquid Systems. J. Phys. Chem. B 2013, 117, 9042–9049.

- Xu, A.; Zhang, Y.; Zhao, Y.; Wang, J. Cellulose dissolution at ambient temperature: Role of preferential solvation of cations of ionic liquids by a cosolvent. Carbohydr. Polym. 2013, 92, 540–544.

- Zhou, Y.; Zhang, X.; Yin, D.; Zhang, J.; Mi, Q.; Lu, H.; Liang, D.; Zhang, J. The solution state and dissolution process of cellulose in ionic-liquid-based solvents with different hydrogen-bonding basicity and microstructures. Green Chem. 2022, 24, 3824–3833.

- Sánchez, P.B.; Tsubaki, S.; Pádua, A.A.H.; Wada, Y. Kinetic analysis of microwave-enhanced cellulose dissolution in ionic solvents. Phys. Chem. Chem. Phys. 2020, 22, 1003–1010.

- Hawkins, J.E.; Liang, Y.; Ries, M.E.; Hine, P.J. Time temperature superposition of the dissolution of cellulose fibres by the ionic liquid 1-ethyl-3-methylimidazolium acetate with cosolvent dimethyl sulfoxide. Carbohydr. Polym. Technol. Appl. 2021, 2, 100021.

- Shamsuri, A.A.; Abdan, K.; Jamil, S.N.A.M. Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review. e-Polymers 2021, 21, 869–880.

- Chen, F.; Sawada, D.; Hummel, M.; Sixta, H.; Budtova, T. Swelling and dissolution kinetics of natural and man-made cellulose fibers in solvent power tuned ionic liquid. Cellulose 2020, 27, 7399–7415.

- Ferreira, D.C.; Oliveira, M.L.; Bioni, T.A.; Nawaz, H.; King, A.W.T.; Kilpeläinen, I.; Hummel, M.; Sixta, H.; El Seoud, O.A. Binary mixtures of ionic liquids-DMSO as solvents for the dissolution and derivatization of cellulose: Effects of alkyl and alkoxy side chains. Carbohydr. Polym. 2019, 212, 206–214.

- Wittmar, A.S.M.; Koch, D.; Prymak, O.; Ulbricht, M. Factors Affecting the Nonsolvent-Induced Phase Separation of Cellulose from Ionic Liquid-Based Solutions. ACS Omega 2020, 5, 27314–27322.

- Satani, H.; Kuwata, M.; Shimizu, A. Simple and environmentally friendly preparation of cellulose hydrogels using an ionic liquid. Carbohydr. Res. 2020, 494, 108054.

- Kikuchi, K.; Kaneko, K.; Seonju, J.; Fukaya, R.; Yamada, M.; Ishii, H.; Inoue, T.; Shimizu, A. Influence of gelation temperature on physicochemical properties of cellulose hydrogels prepared from ionic liquid/DMSO solution. J. Mol. Liq. 2023, 376, 121465.

- Ilyin, S.O.; Kostyuk, A.V.; Anokhina, T.S.; Melekhina, V.Y.; Bakhtin, D.S.; Antonov, S.V.; Volkov, A.V. The Effect of Non-Solvent Nature on the Rheological Properties of Cellulose Solution in Diluted Ionic Liquid and Performance of Nanofiltration Membranes. Int. J. Mol. Sci. 2023, 24, 8057.

- Layek, S.; Banerjee, P.; Sarkar, N. An insight into the dissolution of cellulose in 1-butyl-3-methylimidazolium chloride-DMSO binary Mixture: Exploring the dynamics of rhodamine 6G and fluorescein. J. Mol. Liq. 2021, 339, 116817.

- Liu, Y.; Jing, S.; Carvalho, D.; Fu, J.; Martins, M.; Cavaco-Paulo, A. Cellulose Dissolved in Ionic Liquids for Modification of the Shape of Keratin Fibers. ACS Sustain. Chem. Eng. 2021, 9, 4102–4110.

- Müller, K.; Zollfrank, C. Ionic liquid aided solution-precipitation method to prepare polymer blends from cellulose with polyesters or polyamide. Eur. Polym. J. 2020, 133, 109743.

- Lei, L.; Lindbråthen, A.; Sandru, M.; Gutierrez, M.T.; Zhang, X.; Hillestad, M.; He, X. Spinning Cellulose Hollow Fibers Using 1-Ethyl-3-methylimidazolium Acetate–Dimethylsulfoxide Co-Solvent. Polymers 2018, 10, 972.

- Xie, H.; Yu, X.; Yang, Y.; Zhao, Z.K. Capturing CO2 for cellulose dissolution. Green Chem. 2014, 16, 2422–2427.

- Jin, L.; Gan, J.; Hu, G.; Cai, L.; Li, Z.; Zhang, L.; Zheng, Q.; Xie, H. Preparation of Cellulose Films from Sustainable CO2/DBU/DMSO System. Polymers 2019, 11, 994.

- Zhang, L.; Shi, W.; Sheng, H.; Feng, S.; Yao, M.; Chen, P.; Zheng, Q.; Xie, H. Unique CO2-switched cellulose solution properties in the CO2/DBU/DMSO solvent system and the preparation of regenerated materials. Green Chem. 2021, 23, 5856–5865.

- Yang, Y.; Song, L.; Peng, C.; Liu, E.; Xie, H. Activating cellulose via its reversible reaction with CO2 in the presence of 1,8-diazabicycloundec-7-ene for the efficient synthesis of cellulose acetate. Green Chem. 2015, 17, 2758–2763.

- Onwukamike, K.N.; Lapuyade, L.; Maillé, L.; Grelier, S.; Grau, E.; Cramail, H.; Meier, M.A.R. Sustainable Approach for Cellulose Aerogel Preparation from the DBU–CO2 Switchable Solvent. ACS Sustain. Chem. Eng. 2019, 7, 3329–3338.

- Zhang, L.; Shi, W.; Wang, J.; Jin, L.; Hu, G.; Zheng, Q.; Xie, H.; Chen, P. Unique gelation and rheological properties of the cellulose/CO2-based reversible ionic liquid/DMSO solutions. Carbohydr. Polym. 2019, 222, 115024.

- Zhang, Q.; Oztekin, N.S.; Barrault, J.; De Oliveira Vigier, K.; Jérôme, F. Activation of Microcrystalline Cellulose in a CO2-Based Switchable System. ChemSusChem 2013, 6, 593–596.

- Onwukamike, K.N.; Tassaing, T.; Grelier, S.; Grau, E.; Cramail, H.; Meier, M.A.R. Detailed Understanding of the DBU/CO2 Switchable Solvent System for Cellulose Solubilization and Derivatization. ACS Sustain. Chem. Eng. 2018, 6, 1496–1503.

- Wang, J.; Xue, Z.; Yan, C.; Li, Z.; Mu, T. Fine regulation of cellulose dissolution and regeneration by low pressure CO2 in DMSO/organic base: Dissolution behavior and mechanism. Phys. Chem. Chem. Phys. 2016, 18, 32772–32779.

- Nanta, P.; Skolpap, W.; Kasemwong, K.; Shimoyama, Y. Dissolution and modification of cellulose using high-pressure carbon dioxide switchable solution. J. Supercrit. Fluids 2017, 130, 84–90.

- Li, J.; Lu, S.; Liu, F.; Qiao, Q.; Na, H.; Zhu, J. Structure and Properties of Regenerated Cellulose Fibers Based on Dissolution of Cellulose in a CO2 Switchable Solvent. ACS Sustain. Chem. Eng. 2021, 9, 4744–4754.

- Xu, Q.; Song, L.; Zhang, L.; Hu, G.; Du, J.; Liu, E.; Zheng, Q.; Liu, Y.; Li, N.; Xie, H. Organocatalytic Cellulose Dissolution and In Situ Grafting of ϵ-Caprolactone via ROP in a Reversible DBU/DMSO/CO2 System. ChemistrySelect 2017, 2, 7128–7134.

- Wang, C.-G.; Li, N.; Wu, G.; Lin, T.T.; Lee, A.M.X.; Yang, S.-W.; Li, Z.; Luo, D.H.-K. Carbon Dioxide Mediated Cellulose Dissolution and Derivatization to Cellulose Carbonates in a Low-pressure System. Carbohydr. Polym. Technol. Appl. 2022, 3, 100186.

- Zhang, J.; Mi, S.; Liu, F.; Qiao, Q.; Na, H.; Zhu, J. Enhanced dissolution of cellulose in CO2 switchable system by solvent with low Henry’s constants as CO2 absorbent. Cellulose 2022, 29, 6745–6758.

More

Information

Subjects:

Biochemical Research Methods

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.6K

Revisions:

4 times

(View History)

Update Date:

18 Jul 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No