Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Guo, Y.; Liu, L.; Yin, W.; Lu, H.; Lei, G.; Zhu, J. Developing High-Power-Density Electromagnetic Devices. Encyclopedia. Available online: https://encyclopedia.pub/entry/46435 (accessed on 08 February 2026).

Guo Y, Liu L, Yin W, Lu H, Lei G, Zhu J. Developing High-Power-Density Electromagnetic Devices. Encyclopedia. Available at: https://encyclopedia.pub/entry/46435. Accessed February 08, 2026.

Guo, Youguang, Lin Liu, Wenliang Yin, Haiyan Lu, Gang Lei, Jianguo Zhu. "Developing High-Power-Density Electromagnetic Devices" Encyclopedia, https://encyclopedia.pub/entry/46435 (accessed February 08, 2026).

Guo, Y., Liu, L., Yin, W., Lu, H., Lei, G., & Zhu, J. (2023, July 05). Developing High-Power-Density Electromagnetic Devices. In Encyclopedia. https://encyclopedia.pub/entry/46435

Guo, Youguang, et al. "Developing High-Power-Density Electromagnetic Devices." Encyclopedia. Web. 05 July, 2023.

Copy Citation

Advanced magnetic materials, particularly nanocrystalline and amorphous magnetic materials, exhibit distinct magnetic properties that allow for efficient magnetic flux concentration and minimize energy losses. As a result, they are ideal for implementation in high-power-density electromagnetic devices. Additionally, integrating these materials into electromagnetic devices can result in both substantial reductions in core loss and improvements in efficiency.

nanocrystalline

amorphous magnetic materials

electromagnetic device

high power density

1. Introduction

Over the past few decades, there has been a growing demand for smaller, lighter, and more cost-effective energy conversion devices, resulting in widespread applications of high-power-density transformers and electrical machines [1][2][3][4][5][6][7][8][9][10]. Increasing the operating frequency is a straightforward approach to achieving high power density, which reduces the required materials like copper conductors or magnetic cores, leading to smaller and lighter devices. However, operating at high frequencies can cause excessive power loss and heat generation, leading to device performance deterioration or even failure. Power loss in an electromagnetic device primarily comprises copper loss, core loss, and mechanical loss, with the copper loss being the dominant component at power frequency. As the operating frequency increases, the core loss quickly rises and may even surpass the copper loss. Consequently, researchers have undertaken extensive studies to reduce core loss in electromagnetic devices, and the utilization of advanced magnetic materials holds great promise as a solution [11][12][13][14][15].

Advanced magnetic materials, particularly nanocrystalline and amorphous magnetic materials, exhibit distinct magnetic properties that allow for efficient magnetic flux concentration and minimize energy losses. As a result, they are ideal for implementation in high-power-density electromagnetic devices [16][17][18][19][20][21]. Additionally, integrating these materials into electromagnetic devices can result in both substantial reductions in core loss and improvements in efficiency.

Nanocrystalline magnetic materials typically consist of nanoscale crystalline grains, although it is important to note that not all nanocrystalline materials include an amorphous matrix. While some nanocrystalline materials do possess an amorphous matrix surrounding the crystalline grains, there are also nanocrystalline materials that exist as pure crystalline structures without any amorphous component. These materials achieve their unique properties and enhanced performance through the refinement of the grain size and the presence of high-density grain boundaries. Amorphous materials are distinguished by their unique atomic arrangement, which lacks the medium- and long-range order typically found in crystalline structures. Instead, these materials exhibit a disordered arrangement of atoms, with short-range order present in localized clusters. However, this short-range order does not exhibit periodic repetition, leading to the absence of long-range order throughout the material. The absence of a crystalline structure contributes to the distinct properties and behaviors observed in amorphous materials, including their notable magnetic and electrical characteristics. Both nanocrystalline and amorphous magnetic materials exhibit high magnetic permeability and electrical resistivity, making them well-suited for efficiently concentrating magnetic flux and minimizing power losses in electromagnetic devices. Consequently, they find extensive applications in various fields, including transformers, inductors, and electrical machines [22][23][24][25][26][27]. Nanocrystalline materials offer advantages such as improved saturation magnetization compared to their bulk counterparts and higher operating temperatures, making them suitable for high-power applications. On the other hand, amorphous materials commonly possess excellent soft magnetic properties and low coercivity, making them highly desirable for applications requiring low core losses and high-frequency operation. The selection between nanocrystalline and amorphous magnetic materials depends on the specific application requirements, including desired magnetic properties, operating conditions, and cost considerations. A careful evaluation of the trade-offs and performance characteristics of each material is necessary to determine the most suitable choice for a particular application.

2. Developing High-Frequency High-Power-Density Transformers with Nanocrystalline Magnetic Materials

2.1. Research Status and Routes

Nanocrystalline magnetic materials provide distinct advantages over amorphous magnetic materials in the design of high-performance transformers and inductors. One notable advantage is their higher saturation flux density, which allows for increased magnetic energy storage capacity. Additionally, nanocrystalline materials exhibit lower coercivity, enabling efficient magnetization and demagnetization processes. These combined attributes contribute to enhanced performance and overall efficiency in magnetic devices. Secondly, they exhibit a higher permeability at high frequencies, making them ideal for high-frequency applications such as power electronics, telecommunications, and renewable energy systems. Therefore, the use of nanocrystalline magnetic materials has become increasingly popular in the development of high-frequency high-power-density transformers and inductors.

As early as 1996, the potential of nanocrystalline magnetic materials for transformer construction was explored by Draxler and Styblikova [28]. They compared the performance of different core materials, including nanocrystalline, amorphous, and permalloy materials, and highlighted the benefits of using Vitroperm, a nanocrystalline magnetic material produced by Vacuumschmelze. In 1998, Ferch [29] reported on the use of nanocrystalline SiFe alloy Vitroperm cores in light transformers for switched-mode power supplies operating at a frequency of 10–20 kHz. This resulted in a more compact and lightweight system with significantly higher frequency capabilities.

In 2000, Costa et al. [30] designed a flyback converter transformer with a stress-annealed Finemet core, achieving low transformer loss and low temperature rise. Finemet is a nanocrystalline magnetic material produced by Hitachi Metals, Ltd. that is suitable for pulse applications due to its very low loss density and high operating temperature features. In 2005, Shen et al. [31] designed a high-power-density Finemet core transformer for resonant converter systems. Lin et al. [32] investigated the magnetic flux density distribution in the cross-sectional area of the Finemet ribbon in 2009. In 2010, Shafik et al. [33] designed a transformer for high current and low voltage DC/DC converters using Nanoperm, a nanocrystalline magnetic material produced by Magnetec GmbH, realizing very low core loss. In 2013, Seltzman et al. [34] designed, analyzed, and constructed a resonant transformer for high-power-switch mode power supply using a nanocrystalline iron core, validating the high volt-seconds and low loss at high switching frequencies achievable with nanocrystalline iron cores.

In 2014, Sefa et al. [35] conducted a comparative study on medium-frequency transformers with SiFe material of 0.1 mm thickness and nanocrystalline material of 0.018 mm thickness, demonstrating the superiority of the latter for operating frequencies above 3 kHz. In 2017, they designed a medium-frequency power transformer with a nanocrystalline core, which outperformed the one with SiFe sheets [36]. In 2015, Kauder and Hameyer [37] compared the iron losses of standard silicon steel and nanocrystalline materials for power transformers in a dual active bridge converter, showing that the nanocrystalline material Vitroperm has much higher electric resistivity and lower specific iron loss than SiFe materials such as JFE JNEX900, NO10, H80-23L, H85-27L, and M150-30S. Additionally, in 2015, Jiang et al. [38] evaluated and measured a high-frequency transformer with a nanocrystalline Vitroperm 500F core, which has a relative permeability of about 20,000. The transformer efficiency exceeds 99% when the frequency is below 100 kHz and the magnetic flux density is within 0.66 T. In 2016, Warnakulasuriya et al. [39] developed a nanocrystalline core transformer of 100 kW and 20 kHz for a DC/DC converter. They discussed the advantages and disadvantages of using nanocrystalline cores by comparing them with ferrite cores.

In 2017, Li et al. [40] used the finite element method to calculate the core loss of a high-frequency transformer with a nanocrystalline alloy core while taking into account the effects of magnetic hysteresis. In 2018, Grybos et al. [41] investigated the magnetic properties of nanocrystalline composite cores for use in high-frequency transformers and inductors. The nanocrystalline cores have stable magnetic permeability, low power loss density, and the potential to develop a wide range of magnetic parameters. In the same year, Ruiz-Robles et al. [42] designed and fabricated medium-frequency transformers with nanocrystalline cores for DC-DC dual active bridge-type converters. They tested a 1 kVA and 5 kHz lab prototype, which demonstrated an efficiency of over 99%. They also compared two lab-scale medium-frequency transformer prototypes, rated at 1 kVA, 120 V/240 V, and 1 kHz, with nanocrystalline and silicon steel cores. The experimental results revealed that the nanocrystalline core transformer has greater power density and efficiency [43]. In 2019, Liu et al. [44] optimized the design of a high-frequency transformer with a nanocrystalline alloy core and Litz-wire for minimizing copper loss. Based on finite element analysis, the efficiency of the optimized transformer can reach up to 99.6%.

In 2020, Chen et al. [45] presented a design and prototype of a medium-frequency transformer with a nanocrystalline core rated at 1 kV, 200 kVA, and 10 kHz, achieving a power density of MW/m3 and an efficiency of 99.45% at a forced air-cooling temperature of 62 °C. In 2021, Li et al. [46] investigated high-frequency transformers using flexible nanocrystalline flake ribbons, achieving a core loss reduction of over 50% compared to their ferrite core counterparts. In 2022, Luo et al. [47] reported the characterization of nanocrystalline flake ribbons for high-frequency magnetic cores. Compared to the ferrites N87 and N27, the nanocrystalline flake ribbon exhibits lower power loss, higher saturation flux density, and better temperature stability in the frequency range of 85–300 kHz, making it an excellent substitute for ferrite in high power density core components.

2.2. Brief Comments

The summarized achievements highlighted the significant advantages of nanocrystalline magnetic materials in the design of high-performance transformers and inductors. These materials have been proven to offer superior properties compared to traditional amorphous and silicon steel materials, making them ideal for high-power-density and high-frequency applications. The studies demonstrated that nanocrystalline magnetic materials, such as Vitroperm, Finemet, and Nanoperm, enable the development of more compact and lightweight systems with increased frequency capabilities. They exhibit higher saturation flux density, lower coercivity, and higher permeability at high frequencies, resulting in improved efficiency and power density. This makes them suitable for various applications, including power electronics, telecommunications, and renewable energy systems.

It is worth noting that the development and application of nanocrystalline magnetic materials are not without challenges. The cost of manufacturing nanocrystalline materials is relatively higher, and the fabrication processes are more complex compared to traditional materials. Additionally, the stability of magnetic properties under different temperatures and external magnetic field conditions requires further research and optimization.

In conclusion, the research and practical applications of nanocrystalline magnetic materials in transformers and inductors have shown promising results. Their unique combination of high performance, compact size, and improved efficiency has opened up new possibilities for the advancement of electromagnetic devices. Continued research and development in this field will contribute to further enhancing the performance and reliability of nanocrystalline materials, driving the progress of modern power systems and electronic technologies.

3. Developing High-Frequency High-Power-Density Transformers with Amorphous Magnetic Materials

3.1. Research Status and Routes

Amorphous magnetic materials are suitable for transformers with low or medium frequencies due to their higher magnetic permeability at lower frequency ranges. They are also more cost-effective than nanocrystalline magnetic materials, making them accessible for specific applications. Milkovic et al. [48] reported the use of an amorphous core transformer magnetic link in an electronic current transformer as early as 1977, which outperformed the Fe-Si core transformer. In 1984, Yamamoto et al. [49] conducted a design study of amorphous core transformers and found that the core loss of the amorphous core transformer was only about 25% of that of a 5000 kVA silicon steel core transformer. Then, Alexandrov et al. [50] presented the design considerations and economic impact of amorphous ferromagnetic materials for distribution transformers in 1987, showing significant economic savings depending on the transformer design. In 1999, Lee et al. [51] developed a three-phase power transformer with superconducting windings and amorphous cores to reduce both copper and core losses. In 2007, Wang et al. [52] achieved an efficiency of 98.5% for a 630 kVA three-phase transformer with high-temperature superconducting windings and amorphous alloy cores.

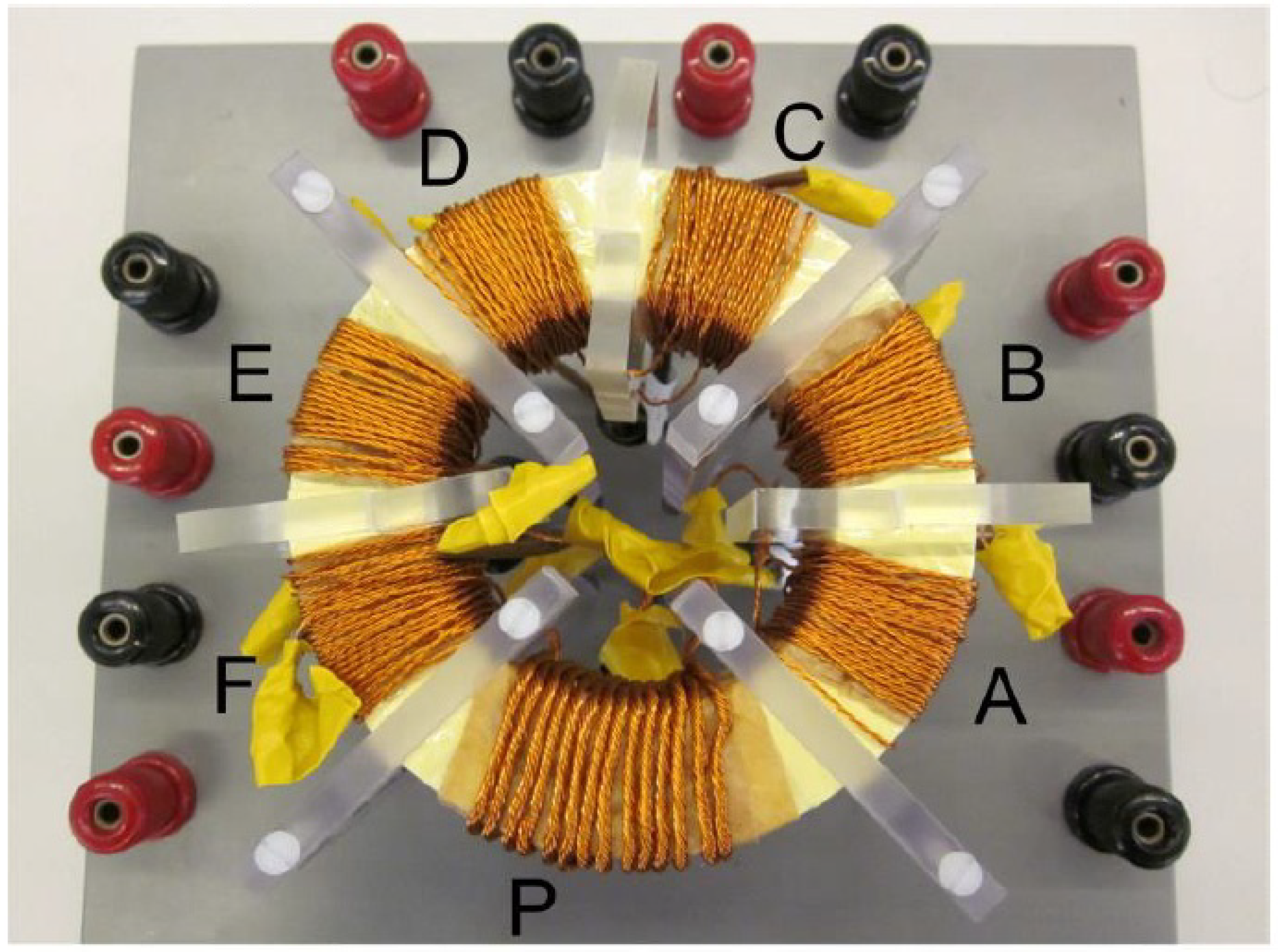

In 2014, Islam et al. [53][54][55][56] designed high-frequency magnetic links for power converters used in grid-connected renewable energy systems with Metglas alloys 2605S3A and 2605SA1 cores, as shown in Figure 1, where the alphabets A, B, C, D, E, and F are the 188 six secondary coils. The design aimed to produce isolated and balanced multiple DC sources for the converter utilizing the magnetic link, while the use of an amorphous core helped reduce the transformer volume and loss. They developed a 1.73 kVA lab-scale system with a modular 5-level cascaded converter to convert 210 V DC to three-phase 1 kV RMS 50 Hz AC.

Figure 1. Photos of high-frequency magnetic links with Metglas amorphous alloy cores.

In 2017, Jafari et al. [57] designed and implemented a multi-winding high-frequency transformer with an amorphous magnetic core to couple multiple converters in a smart microgrid. In 2018, Islam et al. [58][59] developed a common high-frequency magnetic bus with amorphous and nanocrystalline magnetic alloys, such as 2605SA1, 2605S3A, 2705M, 2714A, 2826B, Vitroperm, and Finemet, to replace the common DC bus in order to simplify the integration of multiple sources of existing technologies. In the same year, Xu et al. [60] presented the design of Fe-based amorphous core transformers for pulsed power supplies and switched-mode power supplies operating at medium frequencies. In 2019, Kiran et al. [61] compared the characteristics of high-frequency transformers with amorphous magnetic material Metglas 2605S3A and nanocrystalline material 1k107. Additionally, in 2019, Khan et al. [18] applied an amorphous alloy multi-winding magnetic link of high frequency and high-power-density for generating balanced DC supplies for a five-level neutral point clamped converter. In 2021, Kiran et al. [62] investigated the use of distributed winding topology in amorphous magnetic material-based high-frequency transformers to increase the power transfer capability. In 2022, Liu et al. [63] presented the design and optimization of distribution transformers with amorphous metal cores, highlighting their economic benefits and market competitiveness. Additionally, Zhang et al. [64] studied a shell-type high-power medium frequency transformer with an amorphous magnetic material core for high-power electronic applications.

3.2. Brief Comments

Amorphous magnetic materials demonstrate significant advantages and potential in the field of transformers. These materials exhibit higher magnetic permeability at low or medium frequencies, making them an ideal choice for transformers operating in these frequency ranges. Compared to nanocrystalline magnetic materials, amorphous materials offer cost-effectiveness, providing more economically feasible solutions for specific applications.

The research conducted over the past decades showcases the application and performance benefits of amorphous magnetic materials in transformer design. These studies demonstrate that utilizing amorphous magnetic materials can lead to lower core losses, reduced volume, and improved energy efficiency. These factors are crucial for enhancing the performance and efficiency of energy conversion systems, particularly in the realm of renewable energy. For instance, the use of amorphous magnetic materials in the design of high-frequency transformers enables the system to achieve isolated and balanced multiple DC sources while minimizing transformer volume and losses.

However, amorphous magnetic materials may also face challenges in terms of performance degradation at higher frequencies and relatively higher manufacturing costs. Therefore, when selecting transformer materials, it is essential to consider factors such as frequency, cost, and performance holistically. In conclusion, the research and application of amorphous magnetic materials demonstrate their potential and advantages in energy conversion and renewable energy systems.

4. Developing Electrical Machines with Nanocrystalline and Amorphous Magnetic Materials

4.1. Research Status and Routes

In addition to their use in transformers, research has also explored the potential applications of nanocrystalline and amorphous magnetic materials in electrical machines. While only a few studies have been conducted on the use of nanocrystalline materials [65][66], a considerable amount of research has been dedicated to the use of amorphous core electrical machines [67][68][69][70][71][72][73][74][75][76][77][78][79][80]. One of the earliest studies was conducted by Mischler et al. [67] in 1981, who constructed and tested an induction motor with an amorphous metal stator. They found that the core loss of the amorphous iron stator was 1 W at 60 Hz, whereas the corresponding core loss of a 0.35 mm M22 silicon iron core was 5 W. In 1982, Johnson et al. [68] presented applications of amorphous metals in electric motors and transformers, reducing core losses by over 70%. They also concluded that the performance is highly dependent on the processing methods of the cores, and significant efforts are required for material handling and accessible processing of the motors and transformers. In 1989, Fukao et al. [69] built and tested a super-high-speed reluctance motor with an amorphous metal Metglas alloy 2505S-2 as both the stator and rotor cores. At 48,000 rpm, the amorphous metal motor had only one-fifth the core loss of the corresponding silicon-iron motor. Furthermore, the cost appears competitive when the system already requires a variable-speed drive. In 1992, Jensen et al. [70] proposed an axial-flux permanent magnet brushless DC motor with a tape-wound amorphous iron Metglas 2605S-2 core, achieving very small core loss.

In 2005, Liew et al. [71] designed an axial-flux permanent magnet motor that used the cut amorphous magnetic material Metglas 2605SA1 as its core. This design offered higher power density and better winding utilization. In 2009, Wang et al. [72] developed an axial gap motor that utilized cut amorphous cores in the stator, which reduced iron loss and saved space. In 2011, Kolano et al. [73] developed a high-speed permanent magnet brushless DC motor with an amorphous magnetic material, Metglas 2605SA1, as the stator core. They found that the iron losses in the amorphous stators were considerably smaller than those in the conventional silicon steel stators. In 2014, Fan et al. [74] reported a motor with an amorphous alloy core that had a higher power density, was 32% smaller in volume, and had a 45% higher power density than the baseline motor. Also in 2014, Dems and Komeza [75] studied the performance characteristics of a high-speed induction motor with an amorphous alloy 2605SA1 core, achieving significantly reduced core losses compared to a conventional 0.5 mm electrical steel core. In 2016, Okamoto et al. [76] applied the amorphous magnetic material 2605HB1M as the core of an interior permanent magnet synchronous motor and achieved a 50% reduction in core loss compared to a non-oriented electrical steel 35H300 core.

In 2020, Li et al. [77] conducted a multi-physics analysis of a yokeless and segmented armature axial-field in-wheel motor utilizing amorphous alloy stator cores, demonstrating its potential as a simple, efficient, and reliable option for electric vehicles. In 2021, Simizu et al. [78] utilized a metal amorphous nanocomposite as the core of a flux-switching permanent magnet motor rated at 2.5 kW and 1400 Hz, indicating its suitability for motor applications with high magnetic switching frequencies. In 2021, Fan et al. [79] developed a high-speed induction motor utilizing amorphous alloy cores, aiming to address power loss and stress issues. In 2022, Chai et al. [80] analyzed the vibration characteristics of a high-speed switched reluctance motor that employed amorphous alloy cores to achieve high efficiency and high power density.

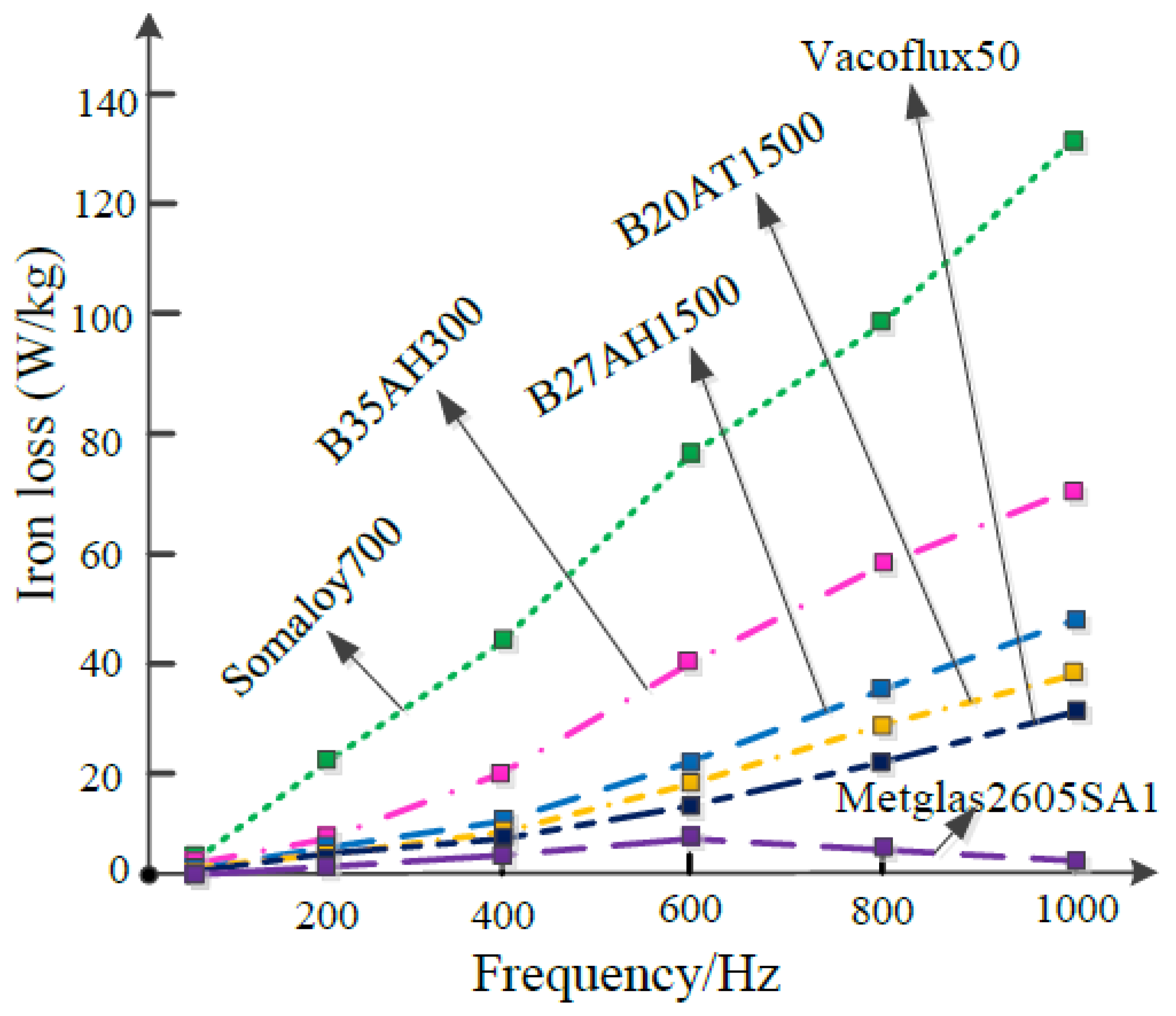

4.2. Magnetic Properties and Their Measurements

As shown in Figure 2, the iron loss of various motor stator core materials varies with the working frequency. Stators made of amorphous alloy exhibit significantly lower iron losses compared to silicon steel sheets. However, the manufacturing technology for batch production of amorphous alloy stampings is currently limited to simple non-slot structures. Soft Magnetic Composite (SMC) materials can be a suitable alternative for stator cores in high-speed permanent magnet machines. When the motor operates at frequencies higher than 2000 Hz, SMC materials outperform electrical steels in reducing core loss, thereby helping to minimize winding heating.

Figure 2. Iron loss of different core materials with respect to frequency [15].

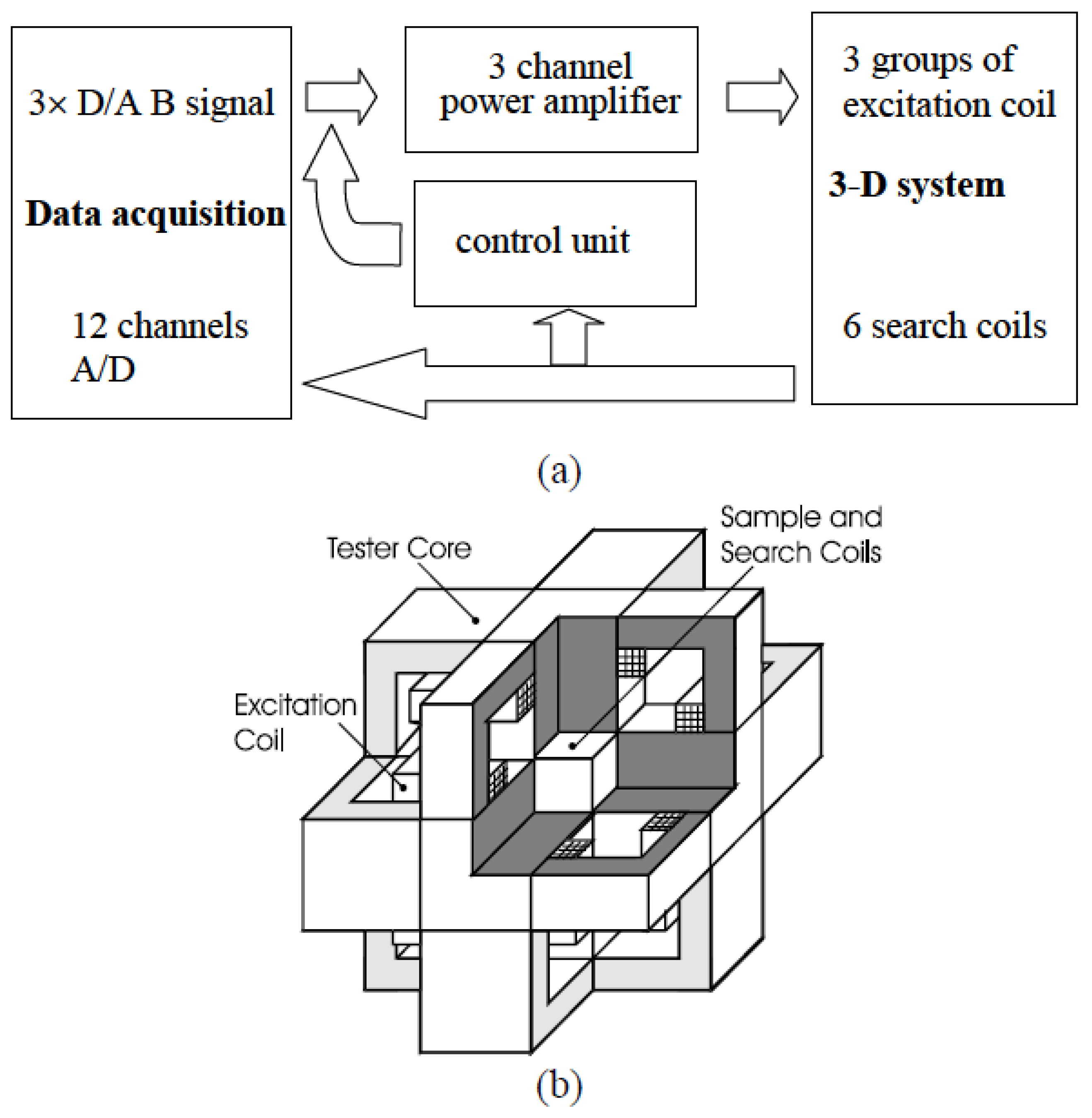

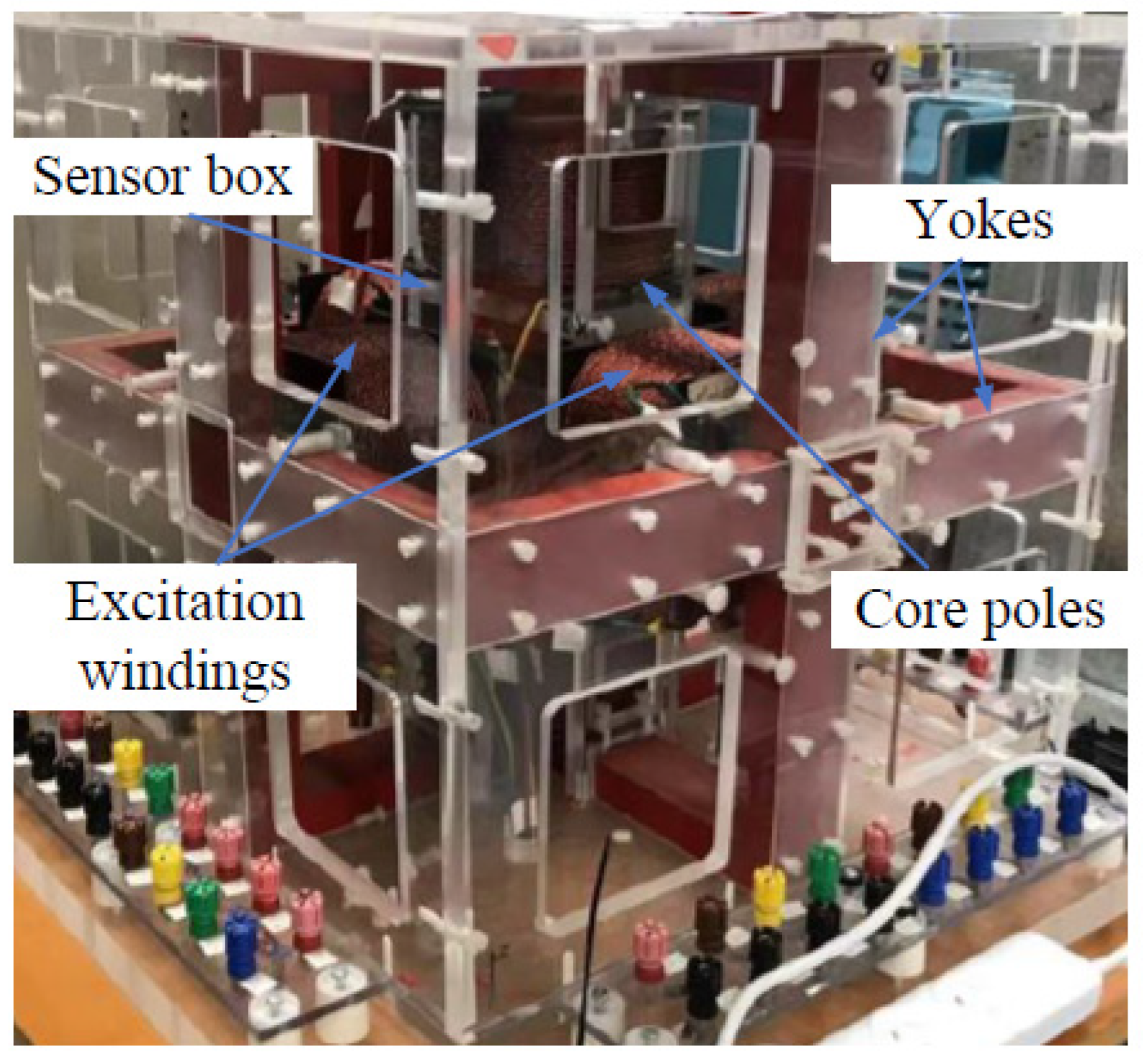

As for the measurement of 2-D magnetic properties, under the leadership of J. Zhu, the Magnetic Testing Group at the University of Technology Sydney (UTS) developed a square sample single sheet tester [81] for measuring various magnetic materials. This tester is equipped with a computerized digital signal processing system and is capable of measuring B-H relations and core losses under 1D alternating fluxes in specific directions as well as 2D circular or elliptical rotating fluxes with user-defined axis ratios. In addition, the magnetic field within the core of an electrical machine naturally exists in three dimensions, meaning that the B and H vectors form irregular loops in 3D space. This characteristic is particularly evident in 3D magnetic flux electrical machines such as claw poles and transverse flux machines [82]. Even with 1D alternating or 2D rotating magnetization, the magnetic material can exhibit 3D magnetic properties due to the motion of magnetic domain walls and magnetization rotation [83]. This phenomenon has been observed in SMC (Soft Magnetic Composite) materials, but it may also occur in amorphous materials and warrants further investigation. In 2001, the authors’ group also developed the world’s first 3D magnetic testing system, as depicted in Figure 3 and Figure 4. The measurement system comprises a 3D magnetic property tester, a computer data acquisition and control system, and a 3-channel power amplifier. The tester consists of six yokes, and three pairs of excitation windings are wound around these yokes. These excitation windings generate 3D magnetic flux in the material sample placed at the center of the tester.

Figure 3. 3D Vectorial Magnetic Property measurement system: (a) Block diagram and (b) structure 330 of 3D view [15].

Figure 4. A photo of the 3D vectorial magnetic property measurement system [15].

By controlling the magnitudes and phase angles of the excitation currents in the three axes, the tester can produce various flux patterns. These patterns include 1D alternating flux in any specified orientation, 2D circularly or elliptically rotating flux in a plane tilted at a specified angle from an axis, and 3D rotating flux patterns with the loci of the B vector tip forming a specified surface. The selection of the flux pattern depends on the specific measurement requirements. The computer data acquisition and control system, along with the 3-channel power amplifier, facilitate the control and monitoring of the excitation currents as well as the acquisition and analysis of the magnetic field data during the measurement process.

With the utilization of the 3D magnetic testing system, extensive experimental results have been acquired by subjecting various material samples to different magnetization patterns, including 1D alternating flux, 2D circularly rotating flux, and 3D spherical flux densities. More details concerning the experimental results can be found in the previous publications [15][84].

4.3. Brief Comments

The research status indicates a growing interest in the application of nanocrystalline and amorphous magnetic materials in electrical machines, expanding beyond their traditional use in transformers. While nanocrystalline materials have received relatively less attention, significant research efforts have been dedicated to exploring the potential of amorphous core electrical machines.

Early studies demonstrated the advantages of using amorphous metal stators, such as reduced core losses compared to traditional silicon iron cores. This finding has prompted further investigation into the performance of amorphous materials in electric motors and transformers. Researchers have explored various motor designs utilizing amorphous magnetic materials, such as axial-flux permanent magnet motors, high-speed brushless DC motors, and reluctance motors. These studies consistently report benefits such as reduced core losses, improved power density, and increased efficiency compared to their conventional counterparts. The use of cut amorphous magnetic materials, such as Metglas alloys, as motor cores has also shown promising results in terms of higher power density, improved winding utilization, and smaller motor size. These advancements have the potential to enhance the overall performance and compactness of electrical machines. Furthermore, the research highlights the potential cost competitiveness of amorphous-core electrical machines, particularly when variable-speed drives are already required in the system. Recent studies have explored the use of amorphous alloy stator cores in electric vehicles, indicating their potential for simple, efficient, and reliable motor designs. Additionally, the application of metal amorphous nanocomposites in flux-switching permanent magnet motors has also demonstrated their suitability for high magnetic switching frequency applications.

Overall, existing achievements have signified the increasing importance of nanocrystalline and amorphous magnetic materials in advancing electrical machine technology. These materials offer significant advantages in terms of improved efficiency, reduced core losses, higher power density, and potential cost competitiveness, making them a promising area for further exploration and development in the field of electrical machines.

References

- Lu, J.; Stegen, S.; Butler, D. High Frequency and High Power Density Transformers for DC/DC Converter used in Solar PV System. In Proceedings of the 2nd International Symposium on Power Electronics for Distributed Generation Systems, Hefei, China, 16–18 June 2010; pp. 481–484.

- Ambatipudi, R.; Kotte, H.B.; Bertilsson, K. High Performance Planar Power Transformer with High Power Density in MHz Frequency Region for Next Generation Switch Mode Power Supplies. In Proceedings of the 28th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 2139–2143.

- Islam, M.R.; Guo, Y.; Zhu, J.; Lu, H.; Jin, J.X. High-Frequency Magnetic-Link Medium-Voltage Converter for Superconducting Generator-Based High-Power Density Wind Generation Systems. IEEE Trans. Appl. Supercond. 2014, 24, 5202605.

- Bahmani, M.A.; Thiringer, T.; Rabiei, A.; Abdulahovic, T. Comparative Study of a Multi-MW High-Power Density DC Transformer With an Optimized High-Frequency Magnetics in All-DC Offshore Wind Farm. IEEE Trans. Power Deliv. 2016, 31, 857–866.

- Lu, R.; Yu, J.; Feng, D.; Bu, K.; Yang, Z.; Li, C.; Li, W. Modeling and Design of a Medium Frequency Transformer with High Isolation and High Power Density. In Proceedings of the 2021 IEEE Applied Power Electronics Conference and Exposition (APEC), Phoenix, AZ, USA, 14–17 June 2021; pp. 1694–1700.

- Chan, C.C.; Jiang, J.Z.; Chen, G.H.; Wang, X.Y. A Novel High Power Density Permanent Magnet Variable-Speed Motor. IEEE Trans. Energy Convers. 1993, 8, 297–303.

- Bangura, J.F. Design of High-Power Density and Relatively High-Efficiency Flux-Switching Motor. IEEE Trans. Energy Convers. 2006, 21, 416–425.

- EL-Refaie, A.M.; Alexander, J.P.; Galioto, S.; Reddy, P.B.; Huh, K.-K.; Bock, P.; Shen, X. Advanced High-Power-Density Interior Permanent Magnet Motor for Traction Applications. IEEE Trans. Ind. Appl. 2014, 50, 3235–3248.

- Chen, H.; Demerdash, N.A.O.; EL-Refaie, A.M.; Guo, Y.; Hua, W.; Lee, C.H.T. Investigation of a 3D-Magnetic Flux PMSM with High Torque Density for Electric Vehicles. IEEE Trans. Energy Convers. 2022, 37, 1442–1454.

- Wu, S.; Zhou, J.; Zhang, X.; Yu, J. Design and Research on High Power Density Motor of Integrated Motor Drive System for Electric Vehicles. Energies 2022, 15, 3542.

- Persson, M.; Jansson, P. Advances in Powder Metallurgy Soft Magnetic Composite Materials for Electrical Machines. In Proceedings of the IEE Colloquium on Impact of New Materials on Design, London, UK, 8 December 1995; pp. 1–6.

- Liew, G.S.; Ertugrul, N.; Soong, W.L.; Gayler, J. An Investigation of Advanced Magnetic Materials for Axial Field Brushless Permanent Magnet Motor Drives for Automotive Applications. In Proceedings of the 37th IEEE Power Electronics Specialists Conference, Jeju, Republic of Korea, 18–22 June 2006; pp. 1–7.

- Zhou, H.; Stoyanov, S.; Parsons, P.E.; McLaughlin, B.; Xiao, J.Q. Advanced Soft Magnetic Materials for High Frequency and High Power Applications. In Proceedings of the 26th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Fort Worth, TX, USA, 6–11 March 2011; pp. 163–167.

- Sarker, P.C.; Islam, M.R.; Guo, Y.; Zhu, J.; Lu, H.Y. State-of-the-Art Technologies for Development of High Frequency Transformers with Advanced Magnetic Materials. IEEE Trans. Appl. Supercond. 2019, 29, 7000111.

- Guo, Y.; Liu, L.; Ba, X.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. Designing High-Power-Density Electric Motors for Electric Vehicles with Advanced Magnetic Materials. World Electr. Veh. J. 2023, 14, 114.

- Islam, M.R.; Guo, Y.; Lin, Z.W.; Zhu, J. An Amorphous Alloy Core Medium Frequency Magnetic-Link for Medium Voltage PV Inverters. J. Appl. Phys. 2014, 115, 17E710.

- Kauder, T.; Hameyer, K. Performance Factor Comparison of Nanocrystalline, Amorphous, and Crystalline Soft Magnetic Materials for Medium-Frequency Applications. IEEE Trans. Magn. 2017, 53, 8401504.

- Khan, S.A.; Islam, M.R.; Guo, Y.; Zhu, J.G. An Amorphous Alloy Magnetic-Bus-Based SiC NPC Converter with Inherent Voltage Balancing for Grid-Connected Renewable Energy Systems. IEEE Trans. Appl. Supercond. 2019, 29, 5400108.

- Agheb, E.; Bahmani, M.A.; Hoidalen, H.K.; Thiringer, T. Core Loss Behavior in High Frequency High Power Transformers-II: Arbitrary Excitation. J. Renew. Sustain. Energy 2012, 4, 033113.

- Lu, H.; Guo, Y.; Zhu, J.; Zhong, J.; Jin, J. Soft Magnetic Materials for High Frequency High Power Density Transformers in Power Electronic Systems. Acad. Mag. 2007, 1, 11–16.

- Ahmad, Z.; Khan, S.; Waqar, S.; Maqsood, R.; Ali, Z.A. Magnetic and Structural Properties of Manganese Zinc Soft Ferrite for High-Frequency Applications. IEEE Trans. Magn. 2022, 58, 2801008.

- Grossinger, R.; Turtelli, R.S. Amorphous and Nanocrystalline Alloys. IEEE Trans. Magn. 1994, 30, 455–460.

- Hasegawa, R. Present Status of Amorphous Soft Magnetic Alloys. J. Magn. Magn. Mater. 2000, 215–216, 240–245.

- Willard, M.A.; Claassen, J.H.; Harris, V.G. Magnetic and Structural Properties of Amorphous and Nanocrystalline FeNi-based Alloys. In Proceedings of the 1st IEEE Conference Nanotechnology (IEEE-NANO), Maui, HI, USA, 28–30 October 2001; pp. 51–55.

- Varga, L.K. Soft Magnetic Nanocomposites for High-Frequency and High-Temperature Applications. J. Magn. Magn. Mater. 2007, 316, 442–447.

- Dumitrescu, B.; Ciureanu, S.A.; Cavrila, H. Magnetic Properties of Nanocrystalline Films and Amorphous Co-rich Alloys. In Proceedings of the International Symposium on Fundamentals of Electrical Engineering (ISFEE), Bucharest, Romania, 30 June–2 July 2016; pp. 1–4.

- Theisen, E.A. Recent Advances and Remaining Challenges in Manufacturing of Amorphous and Nanocrystalline Alloys. IEEE Trans. Magn. 2022, 58, 2001207.

- Draxler, K.; Styblikova, R. Use of Nanocrystalline Materials for Current Transformer Construction. J. Magn. Magn. Mater. 1996, 157–158, 447–448.

- Ferch, M. Light Transformers for Kilowatt SMPS Based on Nanocrystalline Soft Magnetic Cores. In Proceedings of the 7th International Conference on Power Electronics and Variable Speed Drives, London, UK, 21–23 September 1998; pp. 411–415.

- Costa, F.; Alves, F.; Desmoulins, J.B.; Herisson, D. Design of a Flyback Transformer Using a Stress Annealed Finemet Nanocrystalline Alloy. In Proceedings of the 31st Annual Power Electronics Specialists Conference, Galway, Ireland, 18–23 June 2000; pp. 308–313.

- Shen, W.; Wang, F.; Boroyevich, D.; Tipton, C.W. High Power Density Nanocrystalline Core Transformer Design for Resonant Converter Systems. In Proceedings of the 40th IEEE Industry Applications Society Annual Meeting, Hong Kong, China, 2–6 October 2005; pp. 2216–2222.

- Lin, Z.W.; Zhu, J.G.; Guo, Y.; Johansen, T.H.; Yoshizawa, Y. Flux Distribution at the Cross Section of Stacked Nanostructured Magnetic Ribbon. IEEE Trans. Magn. 2009, 45, 3912–3914.

- Shafik, Z.M.; Ahmed, K.H.; Finney, S.J.; Williams, B.W. Nanocrystalline Cored Transformer Design and Implementation for a High Current and Low Voltage DC/DC Converter. In Proceedings of the 5th IET International Conference Power Electronics, Machines and Drives (PEMD), Brighton, UK, 19–21 April 2010; pp. 1–6.

- Seltzman, A.H.; Nonn, P.D.; Anderson, J.K. Design and Modeling of Nanocrystalline Iron Core Resonant Transformers for Pulsed Power Applications. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1153–1160.

- Sefa, I.; Balci, S.; Bayram, M.B. A Comparative Study of Nanocrystalline and SiFe Core Materials for Medium-Frequency Transformers. In Proceedings of the 6th International Conference Electronics, Computers and Artificial Intelligence (ECAI), Bucharest, Romania, 23–25 October 2014; pp. 43–48.

- Balci, S.; Sefa, I.; Altin, N. Design and Analysis of a 35 kVA Medium Frequency Power Transformer with the Nanocrystalline Core Material. Int. J. Hydrogen Energy 2017, 42, 17895–17909.

- Kauder, T.; Hameyer, K. Iron Loss Comparison of Standard SiFe and Nanocrystalline Materials for Power Transformers in a Dual Active Bridge Converter. In Proceedings of the 18th European Conference Power Electronics and Applications (EPE’16 ECCE Europe), Karlsruhe, Germany, 5–9 September 2016; pp. 1–10.

- Jiang, X.; Xu, J.; Cui, B.; Zeng, Y.; Li, Z. Evaluations and Measurements of a High Frequency Nanocrystalline Core Transformer for Power Converters. In Proceedings of the 41st Annual Conference IEEE Industrial Electronics Society (IECON), Yokohama, Japan, 9–12 November 2015; pp. 3660–3664.

- Warnakulasuriya, K.; Nabhani, F.; Askari, V. Development of a 100 kW, 20 kHz Nanocrystalline Core Transformer for DC/DC Converter Applications. In Proceedings of the International Exhibition and Conference Power Electronics, Intelligent Motion, Renewable Energy and Energy Management (PCIM Europe), Nuremburg, Germany, 10–12 May 2016; pp. 1439–1446.

- Li, H.; Yuan, D.; Wang, S.; Wang, S.H.; Zhu, J. Core Losses Calculation of Nanocrystalline Alloy High Frequency Transformer Considering Magnetic Hysteresis Effects. In Proceedings of the 20th International Conference Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; pp. 1–4.

- Grybos, D.; Leszczynski, J.; Swieboda, C.; Kwiecien, M.; Rygal, R.; Soinski, M. Magnetic Properties of Composite Cores Made of Nanocrystalline Material for High Frequency Inductors and Transformers. In Proceedings of the Innovative Materials and Technologies in Electrical Engineering (i-MITEL), Sulecin, Poland, 18–20 April 2018; pp. 1–6.

- Ruiz-Robles, D.; Venegas-Rebollar, V.; Anaya-Ruiz, A.; Moreno-Goytia, E.L.; Rodriguez-Rodriguez, J.R. Design and Prototyping Medium-Frequency Transformers Featuring a Nanocrystalline Core for DC-DC Converters. Energies 2018, 11, 2081.

- Ruiz-Robles, D.; Ortiz-Marin, J.; Venegas-Rebollar, V.; Moreno-Goytia, E.L.; Granados-Lieberman, D.; Rodriguez-Rodriguez, J.R. Nanocrystalline and Silicon Steel Medium-Frequency Transformers Applied to DC-DC Converters: Analysis and Experimental Comparison. Energies 2019, 12, 2069.

- Liu, X.; Wang, T.; Hu, L.; Chen, X.; Liu, N.; Chen, L. Design and Optimization of High Frequency Transformer with Nanocrystalline Core. In Proceedings of the International Conference Intelligent Green Building and Smart Grid (IGBSG), Yichang, China, 6–9 September 2019; pp. 246–249.

- Chen, B.; Liang, X.; Wang, N. Design Methodology for Inductor-Integrated Litz-Wired High-Power Medium-Frequency Transformer With the Nanocrystalline Core Material for Isolated DC-Link Stage of Solid-State Transformer. IEEE Trans. Power Electron. 2020, 35, 11557–11573.

- Li, X.; Jiang, C.; Zhao, H.; Wen, B.; Jiang, Y.; Long, T. Novel Flexible Nanocrystalline Flake Ribbons for High-Frequency Transformer Design. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Online, 14–17 June 2021; pp. 2891–2896.

- Luo, Z.; Li, X.; Jiang, C.; Long, T. Characterization of Nanocrystalline Flake Ribbon for High Frequency Magnetic Cores. IEEE Trans. Power Electron. 2022, 37, 14011–14016.

- Milkovic, M.; Luborsky, F.E.; Chen, D.; Tompkins, R.E. Electronic Transformer Using Amorphous Material. IEEE Trans. Magn. 1977, 13, 1224–1226.

- Yamamoto, M.; Mori, T.; Kawasaki, T.; Tsutsui, K.; Itoh, T.; Yagisawa, T. A Design Study of Amorphous Core Transformer. IEEE Trans. Magn. 1984, 20, 1771–1773.

- Alexandrov, N.; Schulz, R.; Roberge, R. Amorphous Alloys for Distribution Transformers: Design Considerations and Economic Impact. IEEE Trans. Power Deliv. 1987, 2, 420–424.

- Lee, J.-K.; Kim, W.-S.; Hahn, S.-Y.; Choi, K.-D.; Cha, G. Development of a Three Phase 100 kVA Superconducting Power Transformer with Amorphous Cores. IEEE Trans. Appl. Supercond. 1999, 9, 1293–1296.

- Wang, Y.; Zhao, X.; Han, J.; Li, H.; Guan, Y.; Bao, Q.; Xiao, Y.; Lin, L.; Xu, X.; Song, N.; et al. Development of a 630 kVA Three-Phase HTS Transformer With Amorphous Alloy Cores. IEEE Trans. Appl. Supercond. 2007, 17, 2051–2054.

- Islam, M.R.; Lei, G.; Guo, Y.; Zhu, J. Optimal Design of High-Frequency Magnetic Links for Power Converters Used in Grid-Connected Renewable Energy Systems. IEEE Trans. Magn. 2014, 50, 2006204.

- Islam, M.R.; Guo, Y.; Jafari, M.; Malekjamshidi, Z.; Zhu, J. A 43-level 33 kv 3-phase Modular Multilevel Cascaded Converter for Direct Grid Integration of Renewable Generation Systems. In Proceedings of the IEEE Innovative Smart Grid Technologies—Asia (ISGT Asia), Kuala Lumpur, Malaysia, 20–23 May 2014; pp. 594–599.

- Islam, M.R.; Guo, Y.; Zhu, J. A Multilevel Medium-Voltage Inverter for Step-Up-Transformer-Less Grid Connection of Photovoltaic Power Plants. IEEE J. Photovolt. 2014, 4, 881–889.

- Islam, M.R.; Guo, Y.; Zhu, J. A High-Frequency Link Multilevel Cascaded Medium-Voltage Converter for Direct Grid Integration of Renewable Energy Systems. IEEE Trans. Power Electron. 2014, 29, 4167–4182.

- Jafari, M.; Malekjamshidi, Z.; Lei, G.; Wang, T.; Platt, G.; Zhu, J. Design and Implementation of an Amorphous High-Frequency Transformer Coupling Multiple Converters in a Smart Microgrid. IEEE Trans. Ind. Electron. 2017, 64, 1028–1037.

- Islam, M.R.; Muttaqi, K.M.; Sutato, D.; Zhu, J. Design and Implementation of Amorphous Magnetic Material Common Magnetic Bus for the Replacement of Common DC Bus. IEEE Trans. Magn. 2018, 50, 2002004.

- Islam, M.R.; Mahfuz-Ur-Rahman, A.M.; Islam, M.M.; Guo, Y.G.; Zhu, J.G. Modular Medium-Voltage Grid-Connected Converter With Improved Switching Techniques for Solar Photovoltaic Systems. IEEE Trans. Ind. Electron. 2017, 64, 8887–8896.

- Xu, Y.; Chen, L.; Guo, W.; Shangguan, C.; Zuo, J.; He, K. Optimal Design of Medium-Frequency Fe-Based Amorphous Transformers Based on Genetic Algorithm. IEEE Trans. Plasma Sci. 2018, 46, 3240–3248.

- Kiran, M.R.; Farrok, O.; Islam, M.R.; Zhu, J. Characterization of the Optimized High Frequency Transformer Using Nanocrystalline and Amorphous Magnetic Materials. In Proceedings of the 22nd International Conference Electrical Machines (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–4.

- Kiran, M.R.; Farrok, O.; Islam, M.R.; Zhu, J. Increase in the Power Transfer Capability of Advanced Magnetic Material Based High Frequency Transformer by Using a Novel Distributed Winding Topology. IEEE Trans. Ind. Appl. 2021, 57, 6306–6317.

- Liu, D.; Zhong, W.; Zhou, C. Optimization Design of Amorphous Metal Distribution Transformer Based on Improved Quantum Particle Swarm Optimization Algorithm. In Proceedings of the 18th International Conference AC and DC Power Transmission (ACDC), Online, 2–3 July 2022; pp. 1–4.

- Zhang, S.; Chen, D.; Bai, B. Study of a High-Power Medium Frequency Transformer Using Amorphous Magnetic Material. Symmetry 2022, 14, 2129.

- Denis, N.; Inoue, M.; Fujisaki, K.; Itabashi, H.; Yano, T. Iron Loss Reduction in Permanent Magnet Synchronous Motor by Using Stator Core Made of Nanocrystalline Magnetic Material. IEEE Trans. Magn. 2017, 53, 8110006.

- Yao, A.; Sugimoto, T.; Odawara, S.; Fujisaki, K. Core Loss Properties of a Motor With Nanocrystalline Rotor and Stator Cores Under Inverter Excitation. IEEE Trans. Magn. 2018, 54, 8203205.

- Mischler, W.R.; Rosenberry, G.M.; Frischmann, P.G.; Tompkins, R.E. Test Results on a Low Loss Amorphous Iron Induction Motor. IEEE Trans. Power Appar. Syst. 1981, PAS-100, 2907–2911.

- Johnson, L.A.; Cornell, E.P.; Bailey, D.J.; Hegyi, S.M. Applications of Low Loss Amorphous Metals in Motors and Transformers. IEEE Trans. Power Appar. Syst. 1982, PAS-101, 2109–2114.

- Fukao, T.; Chiba, A.; Matsui, M. Test Results on a Super-High-Speed Amorphous-Iron Reluctance Motor. IEEE Trans. Ind. Appl. 1989, 25, 119–125.

- Jensen, C.C.; Profumo, F.; Lipo, T.A. A Low-Loss Permanent-Magnet Brushless dc Motor Utilizing Tape Wound Amorphous Iron. IEEE Trans. Ind. Appl. 1992, 28, 646–651.

- Liew, G.S.; Ertugrul, N.; Soong, W.L.; Gayler, J. Investigation of Axial Field Permanent Magnet Motor Utilizing Amorphous Magnetic Material. In Proceedings of the Australasian Universities Power Engineering Conference (AUPEC), Hobart, Australia, 25–28 September 2005; pp. 1–6.

- Wang, Z.; Enomoto, Y.; Ito, Y.; Masaki, R.; Morinaga, S.; Itabashi, H.; Tanigawa, S. Development of an Axial Gap Motor With Amorphous Metal Core. In Proceedings of the International Conference Electrical Machines and Systems (ICEMS), Tokyo, Japan, 15–18 November 2009; pp. 1–6.

- Kolano, R.; Krykowski, K.; Kolano-Burian, A.; Polak, M.; Szynowski, J.; Zackiewicz, P. Amorphous Soft Magnetic Materials for the Stator of a Novel High-Speed PMBLDC Motor. IEEE Trans. Magn. 2012, 49, 1367–1371.

- Fan, T.; Li, Q.; Wen, X. Development of a High Power Density Motor Made of Amorphous Ally Cores. IEEE Trans. Ind. Electron. 2014, 61, 4510–4518.

- Dems, M.; Komeza, K. Performance Characteristics of a High-Speed Energy-Saving Induction Motor With an Amorphous Stator Core. IEEE Trans. Ind. Electron. 2014, 61, 3046–3055.

- Okamoto, S.; Denis, N.; Kato, Y.; Ieki, M.; Fujisaki, K. Core Loss Reduction of an Interior Permanent-Magnet Synchronous Motor Using Amorphous Stator Core. IEEE Trans. Ind. Appl. 2016, 52, 2261–2268.

- Li, T.; Zhang, Y.; Liang, Y.; Ai, Q.; Dou, H. Multiphysics Analysis of an Axial-Flux In-Wheel Motor with an Amorphous Alloy Stator. IEEE Access 2020, 8, 27414–27425.

- Simuzu, S.; Byerly, K.; Schneider, K.; Kim, H.; Nations, M.; Narasimhan, S.; Beddingfield, R.; Bhattachayara, S.; McHenry, M.E. Flux Switching Permanent Magnet Motor with Metal Amorphous Nanocomposite Soft Magnetic Material and Rare Earth Free Permanent Magnets. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Online, 10–14 October 2021; pp. 3866–3872.

- Fan, Z.; Yi, H.; Xu, J.; Xie, K.; Qi, Y.; Ren, S.; Wang, H. Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor. Energies 2021, 14, 2468.

- Chai, F.; Hu, M.; Li, Z.; Geng, L. Vibration Characteristic Analysis and Comparison of High-Speed Switched Reluctance Motor With Amorphous Alloy Core. In Proceedings of the International Power Electronics Conference 2022, Himeji, Japan, 15–19 May 2022; pp. 1536–1541.

- Sarker, P.C.; Guo, Y.; Lu, H.Y.; Zhu, J.G. Two Dimensional Measurement of Magnetic Field and Core Loss Using a Square Specimen Tester. IEEE Trans. Magn. 2021, 57, 8402008.

- Guo, Y.; Zhu, J.G.; Watterson, P.A.; Wu, W. Comparative Study of 3-D Flux Electrical Machines With Soft Magnetic Composite Cores. IEEE Trans. Ind. Appl. 2003, 39, 1689–1696.

- Yang, Q.; Li, Y.; Zhao, Z.; Zhu, L.; Luo, Y.; Zhu, J. Design of a 3-D Rotational Magnetic Properties Measurement Structure for Soft Magnetic Materials. IEEE Trans. Appl. Supercond. 2014, 24, 8200804.

- Guo, Y.; Liu, L.; Ba, X.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. Measurement and Modeling of Magnetic Materials under 3D Vectorial Magnetization for Electrical Machine Design and Analysis. Energies 2023, 16, 417.

More

Information

Subjects:

Engineering, Electrical & Electronic

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.9K

Revisions:

2 times

(View History)

Update Date:

05 Jul 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No