1. The World Grape Industry

The grapevine is one of the main cultivated fruit plants in the world and occupies fourth place in the world ranking, behind only bananas, watermelons, and apples

[1]. In the 2021 harvest season, grapes occupied an area of approximately 7.3 million hectares, with a production of 74.8 million tons. Of the total produced, 52% was destined to the elaboration of wine, must, and juice; 41% to the consumption of table grapes; and 7% to the production of raisins. China currently concentrates 36% of world production, and together with India (12%) and Turkey (6%), they are responsible for more than 50% of the world production of table grapes

[2].

Countries in the Southern Hemisphere, especially those in South America, such as Chile, Peru, and Brazil, reached in the 2021–2022 season a new export record of 1.5 million tons of fresh grapes, an increase of 0.3 million tons in a decade. In Chile, the current main table grape exporter, the trend towards red and licensed seedless cultivars continues with 43% of grapes exported. White seedless grape cultivars accounted for 24% of the exports, and black grapes, also mainly seedless, accounted for 12%. ‘Red Globe’, a traditional red seeded grape, continues to contribute 20% to the Chilean exports, mainly sent to Asia, Latin America, and the EU. Export destinations remain balanced with just over 50% of the shipments going to the US, 22% to Asia, 16% to the EU, and 7% to Latin America. On the other hand, Peru’s export volumes have significantly increased (five-fold) over the year, jumping from 150,000 tons exported 10 years ago to 530,000 tons this season. At this moment, licensed table grape cultivars account for 50% of the shipments, especially ‘Sweet Globe

TM’ (syn. IFG Ten) developed by International Fruit Genetics

®. In addition, there has been a strong shift towards the US, with 45% sent for North America this season. Brazil has been regaining exports with 63,000 tons being exported in the last season, and there has been an escalating move towards licensed cultivars as well. From the strong predominance of traditional white grapes, there is an expressive shift to licensed seedless whites and reds. The EU continues to be by far the main destination of the Brazilian exports, although its dependence has decreased in recent years. In the last season, the EU, North America, and Latin America received 78%, 15%, and 7% of the Brazilian exports, respectively

[1].

2. Factors That Impact the Table Grape Quality

For the production of high-quality table grapes, it is necessary to pay attention both to the performance of the vine (harvest time, resistance to pathogens, plant yield, and berry size) and to the sensory characteristics (color, flavor, aroma, and firmness) and nutrition (fibers, vitamins, minerals, phenolic compounds, and antioxidant activity) of grape berries

[3]. All these quality attributes can vary depending on a complex combination of factors that include preharvest, such as the choice of scion and rootstock cultivars, the incidence of pests or diseases, the climatic conditions of the region, and the agricultural practices adopted. In the vineyard, such as the type of pruning, thinning, and the use of pesticides and plant growth regulators

[4].

The harvest time is also essential to obtain a high-quality end product, as it is a non-climacteric fruit with relatively low respiratory activity; it should only be harvested when it presents the appropriate characteristics for consumption

[5] (that is, when it meets the requirements demanded by the consumer market)

[4]. Thus, during maturation, the berries lose rigidity, there is an increase in anthocyanin and sugar contents, and there is a pronounced decrease in acidity

[6].

Postharvest management is also essential so that the consumer can enjoy a fruit with the same quality as the one that had just been harvested. Increasingly, consumer expectations, whether in the domestic or foreign markets, are that the product to be consumed is fresh and keeps its functional characteristics preserved (changes in their physicochemical properties during handling, transport, and storage)

[7].

Table grapes are manually harvested and properly handled to ensure a high fruit quality. Bunches are harvested when fully ripe because they do not ripen after being detached from vines. Injured berries are removed, and the bunches are packed in most cases right after harvesting on the field or in a nearby facility to avoid further handling. Depending on the growing conditions, when this practice is not feasible, the bunches are transported to a packinghouse and cleaned and packed there. Usually, bunches are stored and shipped in cardboard boxes of 5.0, 7.5, or 10 kg capacity, and as soon as possible, they are pre-cooled at 0–1 °C to minimize water loss. Depending of the grape cultivar, bunches tolerate storage temperature down to −2 °C without significant damage from freezing. To ensure a fast cooling of grapes, the cardboard boxes should provide a sufficient air movement over the berries, and it can be reached by the perforations of the packaging material. Washing or cooling with water or other chemical compounds is not recommended for grapes due to the risk of spreading disease, especially gray mold caused by

Botrytis cinerea [8], which is considered the biggest threat during the cold storage of grapes.

Each country or commercial area has specific regulations regarding the standards that exporters must follow and strictly respect. For instance, the marketing standard of the EU for fresh fruits and vegetables regulates the quality requirements for table grapes for fresh consumption after preparation and packaging, as described in the standard 543/2011; Part 9. According to this regulation, berries and grapes must be sound without rotting or deterioration and clean and free of visible foreign matter. In addition, it is required that berries and grapes must be practically free from pests and pest damage, abnormal external moisture, and foreign smell or taste. The berries must be intact, well-formed, and normally developed according to the cultivar characteristics. A peduncle no more than 5 cm long may be left on the rachis (stem) of the bunch. In addition, according to the EU Directive 2000/29 (Annex III.A.15), the introduction of ‘plants of

Vitis, other than fruits’ from Third countries other than Switzerland, is not allowed. ’Plants’ are defined as “all living plant parts including seeds, cut flowers, branches with foliage, bud-wood, cuttings, scion tubers, bulbs, rhizomes, cut trees retaining foliage, live pollen and leaves and foliage”

[9].

3. Postharvest Conservation of Table Grapes

3.1. Cold Storage

As it is a very perishable fruit, the grape is susceptible to the occurrence of various types of damage, such as rot, dehydration, drying of the rachis, shattered berries and darkening, and softening of the berries during post-harvest handling, resulting in increased losses

[10][11]. The use of postharvest conservation technologies, such as storage in a refrigerated chamber, where temperature and humidity are controlled, is essential to mitigate the effects of degradation and increase the marketing period and fruit quality

[12].

Usually, table grapes are cold stored at −1 °C to 2 °C, depending on the cultivar and its soluble solids content at a high relative humidity (95–98%), to avoid several disorders. Under certain conditions, at least for a long storage time and for shipment, table grapes can be fumigated with sulfur dioxide (SO

2) to devitalize

B. cinerea as well as to prevent the browning of cluster stems and fruit decay. During shipments exceeding 10 days, SO

2-generating pads ensure constant concentration of the gas depending on the amount of the active ingredient (sodium metabisulfite)

[13]. The treatment allows table grape storage for several weeks or even months. Depending of the grape sensitivity to the SO

2, the gas can cause damages of the berries, fruit bleaching

[8] and blocking of the product from some markets

[14]. In general, the treatment with SO

2 and the low storage temperatures should kill most arthropod pests as well as several microorganisms (e.g., spores of

Botrytis on the surface of the berry skin), and a proper packaging material should be used to ensure that the gas has a good diffusion and reaches every fruit in sufficient concentrations

[13].

SO

2 is a colorless, non-flammable gas with a strong, pungent, suffocating odor and intensely irritating to the eyes, throat, and upper respiratory system. It can be detected by taste at concentrations of 0.35–1.05 ppm (µg·g

−1) and at an odor threshold of 0.67–4.75 ppm (µg·g

−1). In addition, sulfites are recognized as allergens by many international regulatory bodies on food safety, and for these reasons, it must be used considering the lowest concentrations that promote good conservation of table grapes with a low risk for consumers

[13][14].

The duration of storage and transport is very variable. The transport time from South Africa, from Chile, and from India (Mumbai) to the Netherlands with container vessels averages each three weeks

[15], but table grapes are also transported via airfreight within less than a day

[16].

When grape bunches are stored under conditions of high temperatures and low relative humidity, usually a significant mass loss occurs

[17][18]. For this reason, after harvesting, the bunches must be pre-cooled as soon as possible in order to remove the “field heat”. This process aims to reduce the loss of mass caused by excessive respiration of the fruit since the temperature is high, in addition to avoiding injuries due to the cold if the grapes were stored directly at a temperature around 0 °C

[19][20].

The cooling process after removing the “field heat” is considered the most suitable physical method to prolong the shelf life and maintain the desirable characteristics of the fruit (

Figure 1)

[6][21]. Therefore, the bunches must be stored at a temperature ranging from −1 °C to 1 °C with a relative humidity of 90 to 95%, as in this condition table grapes can be preserved for long periods

[22]. However, the interruption of the cold chain associated with the high and constant humidity required to avoid the severe action of dehydration can lead to the development of fungal diseases, such as gray mold.

Figure 1. Postharvest conservation of grapes in a cold room. (A) Stacks of table grapes packaged in cardboards; (B) Preparation of table grapes for overseas shipment.

3.2. Gray Mold Disease

The gray mold disease is caused by the fungus

B. cinerea Pers., which is the only species of this genus with a wide spectrum of hosts. The fungus is primarily responsible for causing postharvest diseases in fruit trees, such as the blackberry, blueberry, strawberry, among others, significantly reducing yield and fruit quality

[23]. In grapevines, it is also responsible for the main postharvest disease of table grapes

[24]. An infection by this fungus can occur during crop blossom, at harvest, or during handling operations. It can develop in the vineyard and even more after harvest and during long-distance transport, cold storage, and shelf-life

[20][22].

B. cinerea is characterized as a necrotrophic fungus; however, it can live saprophytically from the production of mycelium and resistance structures, called sclerotia. Under favorable conditions, the sclerotia produce conidia, which constitute the main inoculum of the pathogen for infection, which is easily disseminated by wind and rain

[21]. On the other hand, under unfavorable conditions, the fungus can remain in the form of dormant mycelium, in plant remains, or in dead parts of plants

[25]. When the temperature is between 15 °C and 20 °C with the presence of water or relative humidity above 90%, the fungus reproduces again; however, the conidia can germinate in a wide temperature range, which varies between −1 °C and 33 °C

[26]. The germination of conidia can occur at different stages of production, whether during fruit maturation, during refrigerated storage, commercialization, or even after purchase by the consumer

[27][28][29].

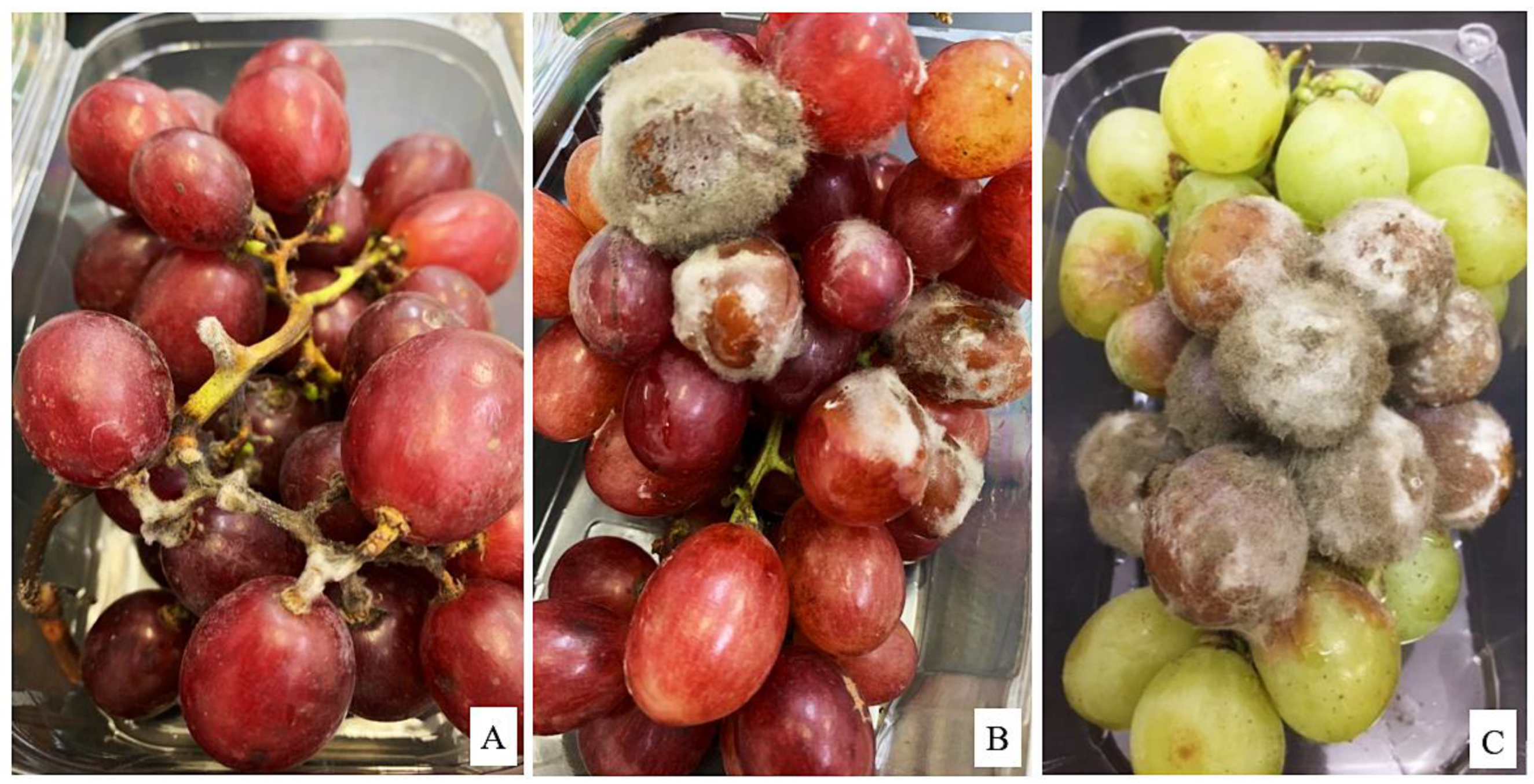

The symptoms caused by a B. cinerea infection can be observed in the whole plant, but mainly in bunches (Figure 2).

Figure 2. Grapes with symptoms of gray mold caused by Botrytis cinerea. (A) Gray sporulation on rachis; (B,C) Gray sporulation on berry surface.

On leaves, symptoms occur in the form of dark brown lesions; however, they are infrequent under field conditions. In berries, the fungus grows through cracks caused by natural openings or wounds, and then, a brown to reddish circular darkening is observed, followed by the loosening of the skin. As the most characteristic infection of the fungus is through the direct penetration of the mycelium through the epidermis of the berries, white mycorrhization, and abundant gray sporulation are seen that cover the surface of the berries and the rachis, giving the appearance of gray mold

[22].

The fungus

B. cinerea can be spread from a single or a few infected berries to all the berries in the bunch, forming a cluster of rotten berries, and it can also rapidly progress to still healthy bunches, resulting in an extensive loss of yield and quality

[24][30].

Control of

B. cinerea is a difficult task, as pre-harvest fungicide applications are not always effective in preventing and controlling an infection during cold storage

[31] since the fungus can survive in less favorable conditions for long periods and due to the emergence of fungicide-resistant isolates

[30][32]. In addition, many countries do not allow the treatment of fruit after harvesting with synthetic fungicides, and few active ingredients are allowed against postharvest diseases, making their control even more difficult

[33][34]. Therefore, efforts to minimize gray mold are extremely important in all stages of vine development and especially in the harvest and post-harvest stages, requiring the search for alternative measures

[35][36].

3.3. Packaging Materials

Cold storage is considered the main technique in the postharvest management of table grapes; for this reason, strategies that work in combination with cooling are essential

[12]. The use of proper packaging as a complementary method allows for prolonging the shelf life of the bunches, as it aims to reduce injuries caused by berry decay and disorders of a physiological nature, such as mass loss, darkening of the berries, and dryness of the rachis, almost always caused during refrigerated storage

[37][38].

The choice of packaging requires a careful analysis and should be based on the needs of the fruit, the packaging method, resistance, cost, and availability, in addition to market requirements that vary according to the standards defined by them

[39][40]. The set of packages in which table grapes are usually packaged include cardboard boxes, vented plastic clamshells, perforated plastic bags, perforated plastic liners (

Figure 3), among others

[18][41] (

Table 1).

Figure 3. Different packaging materials for table grapes. (A1) Carton box not assembled; (A2) Carton box assembled; (B1) Vented plastic clamshell; (B2) Grape bunched in a plastic clamshell; (C) Perforated plastic bags; (D) Perforated plastic liners.

Table 1. Examples of postharvest packaging materials, SO2-generating pads, perforated SO2-generating plastic liners, perforated plastic liners, and laser perforated bio-based liners used to extend the conservation of table grapes.

The outer packaging used to pack the table grapes consists of corrugated cardboard boxes with double walls and a single piece of the tray type, with a capacity for 4.5 to 10 kg of grapes. This material must be easy to assemble, resistant to wetting, and adjustable to the handling and accommodation of the bunches. It must have holes that allow for air circulation in order to promote the rapid cooling of the fruits, in addition to having fins on the sides that facilitate their stacking and allow them to be palletized

[55].

The vented plastic clamshells are internal packaging whose main purpose is to individually accommodate bunches of approximately 0.5 kg, avoiding physical contact of the grape with the external environment. In addition, they reduce the mechanical impacts that occur during transport, minimize the loss of fruit mass, and provide a modified atmosphere, slowing down the physiological processes harmful to the quality of the grapes, as well as acting in the indirect control of fungi

[6][56]. Clamshells used in the food industry are usually made out of polyethylene terephthalate plastic, so they are highly recyclable. For these reasons, clamshells have become an innovative alternative, which not only offers greater convenience to the consumer, but also enables greater integrity of the bunch until its final destination is reached

[42][57].

Grape bunches, whether or not they are accommodated in plastic clamshells, must be packed in perforated plastic films that line the inside of cardboard boxes

[52]. The films have perforations that provide different areas of ventilation; the aim is to further reduce the loss of mass resulting from dehydration of the fruit, in addition to allowing a better efficiency in the use of the SO

2 gas by using the SO

2-generating pads

[43].

3.4. SO2-Generating Pads and SO2 Fumigation

The association of packages with SO

2-generating pads has been used to extend the refrigerated storage of table grapes. The purpose of this gas is to inhibit fungal growth, allowing for the fruits to be stored in environments with a high humidity

[58]. In addition to controlling the development of microorganisms, it has an antioxidant action, influencing the physiological processes of the fruit itself, such as maintaining the green color of the rachis

[22][59][60]. The use of SO

2 is a commonly used sanitary practice for the conservation of table grapes in refrigerated storage, which can be carried out through fumigation in the packing-houses or from the use of SO

2-generating pads, which are placed on the clamshells inside from cardboard boxes and packaged with perforated plastic liners (

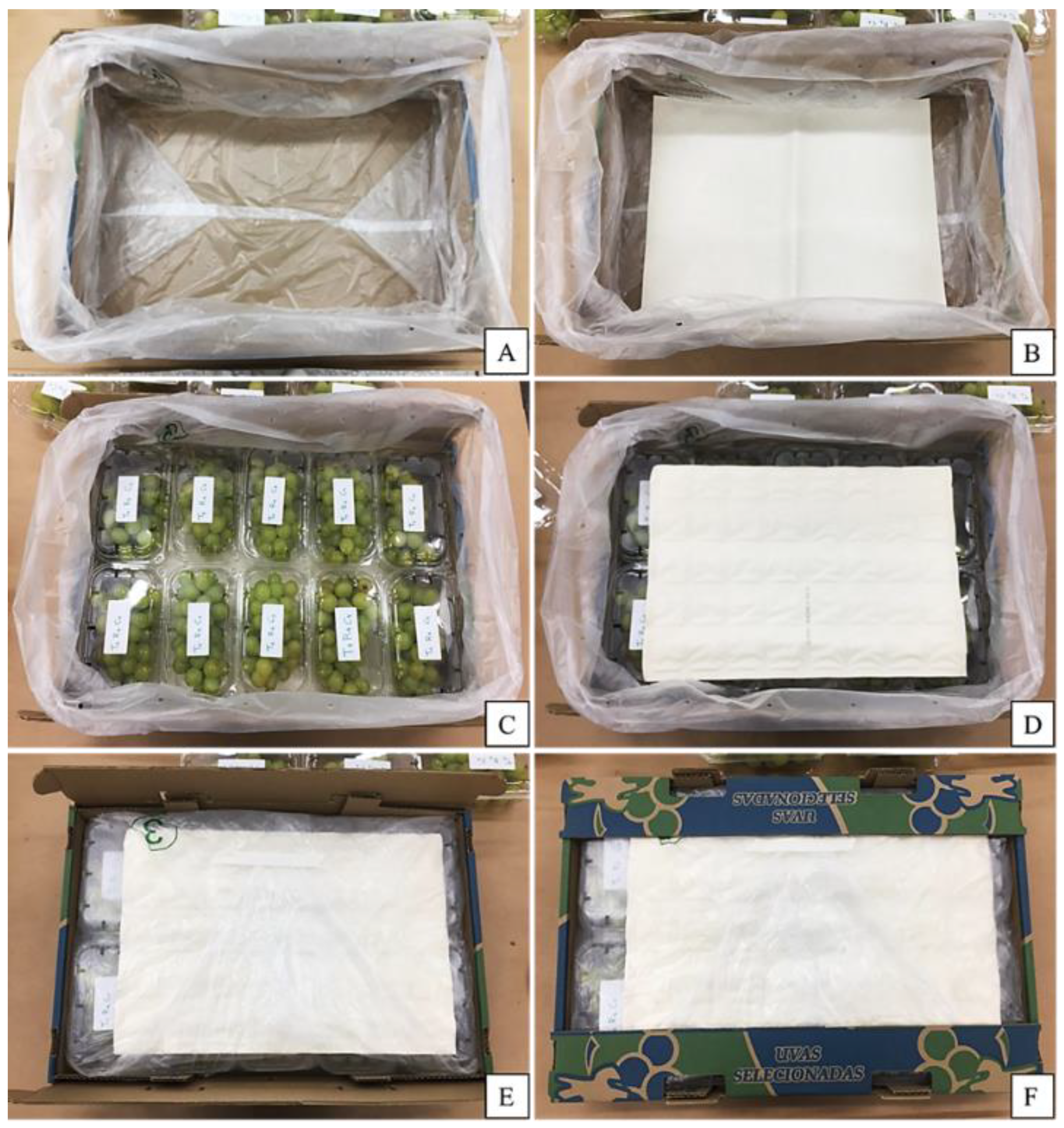

Figure 4)

[61][62].

Figure 4. Packaging steps of table grape. (A) Carton box and perforated plastic liners; (B) Sheet of moisture-absorbing paper on the bottom of the box; (C) Placement of vented plastic clamshells with grapes; (D) SO2-generating pad on top of clamshells; (E) Sealing of the liners with adhesive tape; (F) Carton box ready to be placed under cold storage.

SO

2 fumigation is a practice that has been used for over 90 years to export table grapes that are shipped in refrigerated maritime containers

[63]. Some countries, such as the US, usually demands that grapes are SO

2-fumigated to avoid the entry of some specific pests in their territory. Thus, before shipment, the fruits are selected, sorted, and packed in boxes, then transported to the packaging machine, pre-cooled, treated with SO

2 gas, and kept at about 0 °C and a high relative humidity until the container is loaded. It is recommended to perform, when possible, the pre-cooling and initial SO

2 fumigation simultaneously in a forced-air precooling room under the total utilization system because this method uses about 75% less SO

2 than traditional initial fumigations

[64].

Table grapes can be fumigated with SO

2 at high concentrations, such as 100 ppm (µg·g

−1) for a short period of time (1 h) and/or are exposed to low concentrations of 20–30 ppm (µg·g

−1) throughout the entire storage/shipment time to eradicate the spores of

B. cinerea, prevent the stem browning of the bunches and the decomposition of the fruit

[8][14]. In most cases, loaded containers are re-fumigated on shipment to ensure their safe arrival.

The action of SO

2 during fumigation is described in terms of the toxic concentration and the amount of time that the gas remains in contact with the target organism. These factors are multiplied, and the gas doses are expressed by the CT product (concentration × time)

[64]. Products that contain sulfur dioxide as the active ingredient are formulated as a liquid under pressure, which forms a gas upon release for grape fumigation. These products are stored in steel cylinders (

Figure 5) and applied to the treatment area via a hose system with a detector tube at a maximum rate of 1% concentration (based on measured volume of the fumigation chamber) for the initial fumigation and up to 0.5% gas concentration for maintenance fumigations. Grapes are fumigated on a 7–10 day interval and may be treated up to 20 times. Fumigation may occur in various types of cold-storage warehouses or in truck trailers, vans, and railcars

[64].

Figure 5. Sulfur dioxide (SO2) cylinders containing pressurized liquid gas for table grapes fumigation.

Residues of sulfites and symptoms of phytotoxicity in grapes are the main problems associated with sulfur dioxide fumigations

[64]. Thus, the use of SO

2 must be done with care, as the gas in high concentration can cause darkening of the rachis, affect the physicochemical and sensory characteristics of the grapes, in addition to being harmful to man and the environment in high doses

[51][65]. Thus, aiming at greater protection, the main markets for importing fresh grapes, such as the European Union and the United States, established a maximum tolerance of 10 ppm (µg·g

−1) in the postharvest management of table grapes

[66].

When the SO

2 fumigation is used, the active spores of

B. cinerea on berry skins are eradicated

[44]. On the other hand, the SO

2-generating pads release the gas in a controlled manner and enough to inhibit the latent inoculum of the fungus throughout the entire period of cold storage

[22].

The pads, when absorbing the water vapor that originates from the respiration of the fruit and the high relative humidity of the air present in the cold chamber, react with the active ingredient sodium metabisulfite (Na

2S

2O

5), releasing SO

2 gas

[22][60][67]. Commercially, there are SO

2-generating pads of a slow-release and dual-release of the gas (fast and slow), with different active ingredients while emitting a continuous concentration of SO

2, and they can be stored for up to 60 days or even longer. The dual-release pads have different permeability, resulting in the fast release of gas in the first 48 h of storage, providing an eradicating effect of fungi spores from berry skin in this phase and a subsequent slow and continuous release of gas for up to 60 days

[4][47].

However, the efficiency of SO

2-generating pads in the packaging of table grapes can be influenced by several factors, such as the cultivar, the temperature, the relative humidity of the air, the concentration of SO

2, the time of contact of the gas with the fruit, in addition to the use of packaging, since the distribution and retention of SO

2 depend on the type of material chosen and the amount of fruit stored

[18][41][68]. Therefore, even with the use of SO

2 in a cold chamber, depending on the conditions in which the grapes were grown, symptoms of gray mold may still appear, especially when the grapes are stored for long periods (more than a month).

To overcome these difficulties, the ultra-fast SO2-generating pad was developed, which is used before packing the grapes in the packing house (i.e., right after bunches are harvested) along a perforated plastic liner in a 20 kg capacity harvesting box (Figure 6).

Figure 6. Field ultra-fast SO2-generating pad treatment right after harvesting. (A) Cellulose sheet to avoid impact placed at the bottom of the plastic harvest box of 20 kg capacity; (B) Harvest box lined with a plastic liner with 0.3% of ventilation area; (C) Table grapes placed inside the box; (D) Passive dosimeter tube to quantify the amount of SO2 released; (E): Laying of a field ultra-fast SO2-generating pad above grapes; (F) Sealing of the liner.

The SO

2 gas is released in about 4–6 h, approximately the same time it takes to start the packing of the grapes in the packing house. This technique aims to further reduce the risk of gray mold occurring in the postharvest period because the ultra-fast release of SO

2 has an eradicating effect on

Botrytis spores and can potentiate the effect of SO

2-generating pads used for packing grapes during cold storage

[45][46].

However, the use of SO

2-generating pads, both in the harvesting box and in the cold chamber, cannot occur indiscriminately, as the excess gas may cause damage to the grapes, such as bleaching, premature stem browning, shattered berries, and unpleasant changes in fruit flavor

[22]. Thus, the SO

2-generating pads should be used in order to allow for the adequate protection of the fruit without compromising the end quality of the product

[48][69].

3.5. Perforated Plastic Liners

As previously mentioned, to improve the efficiency of SO

2-generating pads, it is necessary to use them, combined with perforated plastic coatings, to facilitate gas circulation in the packaging

[55]. In addition to maintaining humidity and preventing the loss of fruit mass, the perforations of the liners prevent moisture from causing water condensation (droplets) on the grapes, and materials with different ventilation areas are available from 0.2% to 2.6%

[43][48].

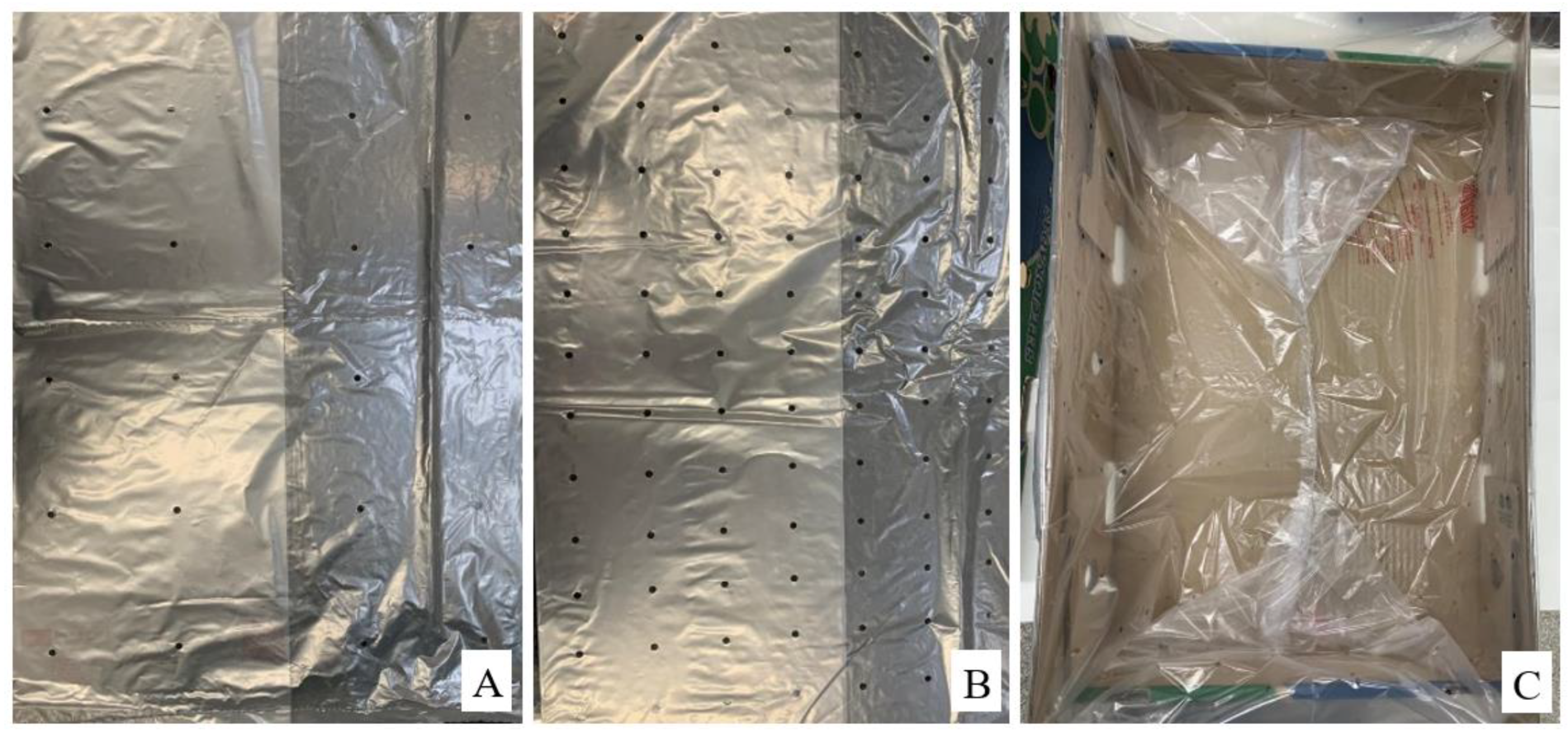

Recently, a new packaging material was developed known as a perforated SO

2-generating plastic liner containing Na

2S

2O

5 (

Figure 7)

[49]. This material is advantageous because it combines the liner and the generator of SO

2 in a single unit, maintaining the same efficiency as SO

2-generating pads used together with perforated plastic liners, and it saves time during the packaging process

[50][57]. This liner has been improved with the use of different amounts of the active principle and different ventilation areas for use according to the demand of the grape cultivar, including a perforated plastic liner with a slow- or dual-release (fast and slow) of SO

2 [46].

Figure 7. Perforated SO2-generating plastic liners with different ventilation areas. (A) SO2-generating plastic liners with 3 g of active ingredient and 0.3% of ventilation area; (B) SO2-generating plastic liners with 7 g of active ingredient and 0.9% of ventilation area; (C) Perforated SO2-generating plastic liner placed in a carton box.

It is known that plastic materials have been widely used in food packaging due to their low cost, high strength and stability, lightness, and impermeability to gases and numerous solvents, allowing for sterilization without affecting the quality of food. However, plastic products can become problematic due to their high pollution rates since the polymeric compounds that form these plastic products do not degrade over time and are of a fossil origin

[70]. Therefore, there is a need to search for more sustainable bio-based packaging materials for the preservation of fruits and vegetables

[53][71]. These materials could alleviate the environmental, public health, and economic burdens caused by traditional materials, especially those made from plastic

[53][54].

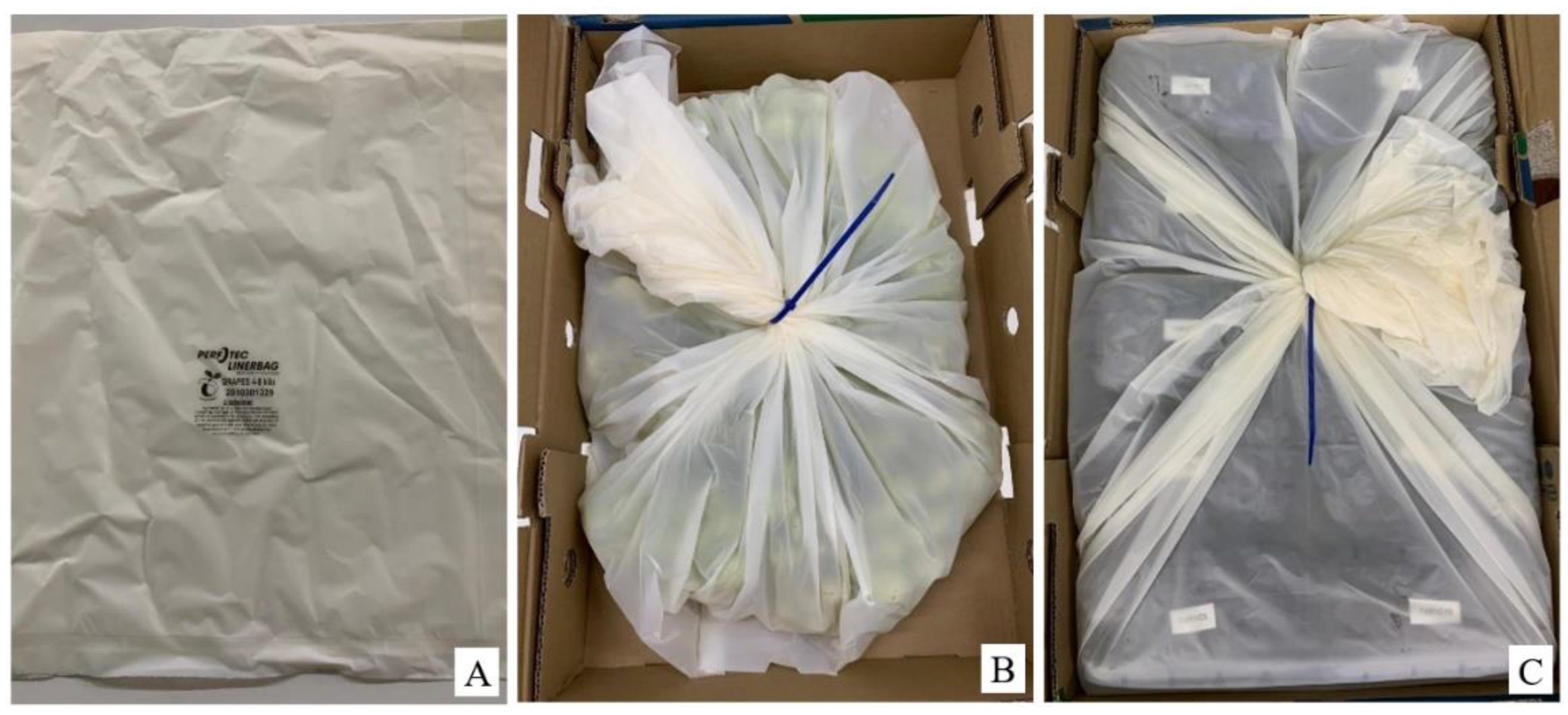

More recently, bio-based liners made of potato starch have been developed to improve the storage and the transport of fresh produce, including table grapes and vegetables. This liner has with microscopic holes (laser perforated) and are made with starch and other polymers of a biological origin (

Figure 8). In addition, this liner has an adequate water vapor transmission rate that prevents water condensation (droplets) inside the package. This bio-based liner is also compostable, which is in agreement with global trends to reduce the use of non-biodegradable, fossil-based plastics

[46].

Figure 8. Laser perforated bio-based liners. (A) Starch bio-based liner; (B) Grape bunches packaged by using bio-based liners; (C) Clamshell-packaged grapes by using bio-based liners.

The potato starch bio-based liner does not contain any chemical compounds such as sodium metabisulfite in its constitution to control gray mold; however, the liner can be helpful in several growing conditions where this grape disease is not a major concern, keeping the product fresh and free of water droplets for a longer period.

The high quality of the ‘Benitaka’ table grape packaged with starch bio-based liner was significantly extended when in combination with the field ultrafast SO

2-generating pad, keeping the incidence of berry decay at low levels during cold storage. Because of the high-water vapor permeability of this liner, the ‘Benitaka’ grapes remained dry throughout the period of cold storage with a significantly reduced chance of decay

[46]. Furthermore, the field ultrafast SO

2-generating pad applied before the packaging of the grapes, during which a high amount of the active ingredient is released in a short period of time (i.e., within 6 h); this also may have helped to prevent the disease incidence due to its eradicative effect of fungal spores from the berry skin and thus effectively controlled the disease

[45]. The bio-based liner alone may also decrease the sulfite residues on grape berries by avoiding the use of SO

2-generating pads during cold storage. Thus, the authors concluded that combining the bio-based liner during cold storage with the field ultrafast SO

2-generating pad before packaging may be advantageous because these materials are compostable and allow for the reduction of the use of non-biodegradable, fossil-based plastics

[46].

3.6. Biodegradable and Edible Coatings

Biodegradable edible coatings preserve the quality of the produce and enhance their appearance by forming a film coating over the bunches that serves as a partial barrier to CO

2 and O

2, water vapor, and aroma compounds, creating a modification and decreasing the respiration rate of the fruit and the water loss. These coatings are also useful as carriers of several food additives that may help to preserve or even improve the quality of the produce

[72]. The most important characteristic of any coating is its permeability properties, which are determined by its composition. Recently, a new natural edible coating based on

Aloe vera gel was developed to promote the quality of table grapes during cold storage. It was demonstrated that this natural coating is very effective in decreasing mass loss and delaying the natural development of other ripening-related attributes, but the most important benefits to treat grapes with this compound is the reduction of the rachis dehydration and the control of berry decay

[73].

3.7. Alternatives to the Use of SO2 and New Trends

Alternatives to the use of SO

2 in table grapes have also been reported by several authors, including the use of low doses of far ultraviolet irradiation (UV-C), treatments with gaseous ozone (O

3), ozone in water or storage in ozonated atmospheres, hot water or vapor heat treatments, carbon dioxide (CO

2) or oxygen (O

2) shocks, and eco-friendly nanocomposites treatments before harvesting

[74][75][76][77][78]. However, its efficacy to control gray mold and to keep the freshness of the grapes relies on several factors, including growing conditions, grape cultivars, among others.

In recent years, new table grape cultivars have been released by several research institutions as well by private breeding programs. Although there is a demand for table grapes with different characteristics in world markets, the demand for seedless, larger berry, and disease-tolerant or resistant varieties is much higher. However, some of these new cultivars are sensitive to SO2 treatments as well to rachis dehydration, mass loss, and other physiological disorders during cold storage. Thus, the combination of different packaging materials and SO2 treatments for each cultivar grown under different conditions is needed to extend the postharvest conservation of table grapes for both domestic and export markets.