Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mingshan Wei | -- | 1494 | 2023-06-29 04:50:55 | | | |

| 2 | Fanny Huang | Meta information modification | 1494 | 2023-06-29 08:05:21 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Dan, D.; Zhao, Y.; Wei, M.; Wang, X. Electric Vehicle Thermal Management Requirements. Encyclopedia. Available online: https://encyclopedia.pub/entry/46197 (accessed on 07 February 2026).

Dan D, Zhao Y, Wei M, Wang X. Electric Vehicle Thermal Management Requirements. Encyclopedia. Available at: https://encyclopedia.pub/entry/46197. Accessed February 07, 2026.

Dan, Dan, Yihang Zhao, Mingshan Wei, Xuehui Wang. "Electric Vehicle Thermal Management Requirements" Encyclopedia, https://encyclopedia.pub/entry/46197 (accessed February 07, 2026).

Dan, D., Zhao, Y., Wei, M., & Wang, X. (2023, June 29). Electric Vehicle Thermal Management Requirements. In Encyclopedia. https://encyclopedia.pub/entry/46197

Dan, Dan, et al. "Electric Vehicle Thermal Management Requirements." Encyclopedia. Web. 29 June, 2023.

Copy Citation

The burgeoning electric vehicle industry has become a crucial player in tackling environmental pollution and addressing oil scarcity. As these vehicles continue to advance, effective thermal management systems are essential to ensure battery safety, optimize energy utilization, and prolong vehicle lifespan.

electric vehicle

thermal management

1. Introduction

Presently, the world is grappling with numerous environmental challenges, such as global warming and resource depletion [1]. Studies have indicated that the transportation sector significantly contributes to global energy consumption, with automotive energy consumption accounting for over 30% of total oil energy consumption in recent years [2]. The exhaustion of oil reserves and the harmful environmental consequences of burning fossil fuels have led the United Nations and governments globally to enforce restrictions on fuel vehicles to achieve sustainable development goals [3]. Consequently, many companies are vigorously developing more environmentally friendly and energy-efficient products, including electric vehicles (EVs).

EVs have surfaced as the most viable alternative to internal combustion engine vehicles (ICEVs) due to their zero-emission capabilities on the road and various power source options [4]. Depending on the power source, EVs can be categorized as battery electric vehicles (BEVs), fuel cell electric vehicles (FCEVs), or hybrid electric vehicles (HEVs) [5]. Despite their potential, the evolution of EVs faces substantial thermal challenges, such as ensuring cabin thermal comfort, battery thermal safety, electric motor heat resistance, and addressing thermal integration. These challenges necessitate the adoption of novel thermal management solutions to improve the safety, reliability, and performance of EVs.

The thermal management of EVs involves the management of heat generated by various components, including the cabin, battery, and motor. The EV thermal management systems (EVTMSs) encompass cabin thermal management (CTM), battery thermal management (BTM), and motor thermal management (MTM) [6]. Air conditioning (AC) systems are a crucial component of EVTMS as they provide the necessary cooling or heating capacity for the cabin or the entire system [7]. However, traditional AC systems employing the PTC heating method consume significant energy, reducing the EV range at low ambient temperatures as well as contributing to lower energy efficiency. Heat pump systems offer an alternative but face challenges such as low-temperature heat production capability [8]. Enhancing the efficiency of compressors, the heat transfer performance of heat exchangers, and other critical AC system components is an area of significant research focus to improve their overall performance. Meanwhile, traditional refrigerants such as R134a have high global warming potential (GWP) values, making them environmentally unfriendly. The roadmap for the phasing out of HFC refrigerants has been proposed and R134a will shortly be replaced by more friendly refrigerants [9]. With the emergence of more eco-friendly refrigerants, it is very essential to develop efficient AC systems to extend EV range and to address environmental concerns.

Another critical aspect of EVTMS is managing heat accumulation within battery packs, particularly at high ambient temperatures, to prevent thermal runaways and ensure driving safety [10]. Advanced cooling systems such as liquid cooling provide efficient heat dissipation and maintain optimal temperature ranges for EV components. Phase change materials (PCM) and heat pipes offer alternative cooling methods, which can provide advantages such as being lightweight and having high cooling efficiency [11]. The transition toward higher power densities, torque densities, and faster speeds in electric motors has resulted in increased heat generation within the windings and mechanical components during operation, ultimately leading to decreased performance and service life [12]. Various thermal management systems have been extensively investigated to address these issues. In summary, efficient EVTMS components are crucial for driving safety and the lifespan of EVs.

The EVTMS systems manage the heat generated by different components either independently or in an integrated manner. Stand-alone thermal management systems operate independently, which allows for the identification and optimization of heat transfer weaknesses within a particular system but does not consider the energy coupling between subsystems [13]. As battery and motor power densities increase, separate thermal management systems struggle to meet thermal management requirements. Several relevant review papers critically reviewed solutions for separate cabin [14][15][16], battery [17][18], and motor [19] thermal management systems, offering new perspectives. By contrast, integrated thermal management systems combine multiple subsystems to distribute heat appropriately, making them a popular trend in EVTMS due to their ability to increase energy density.

2. Electric Vehicle Thermal Management Requirements

2.1. Cabin Thermal Management Requirements

The cabin of a vehicle provides the environmental conditions for the driver during travel. Harsh driving conditions can cause driver fatigue and cognitive impairment, as demonstrated by existing literature [20], which highlights the importance of cabin thermal management in the automotive industry [21]. Achieving optimal thermal comfort in the cabin requires regulating various parameters, including temperature, humidity, and airflow, to maintain levels within the desired comfort range. It is essential to note that thermal management needs for the cabin may vary between summer and winter seasons [22].

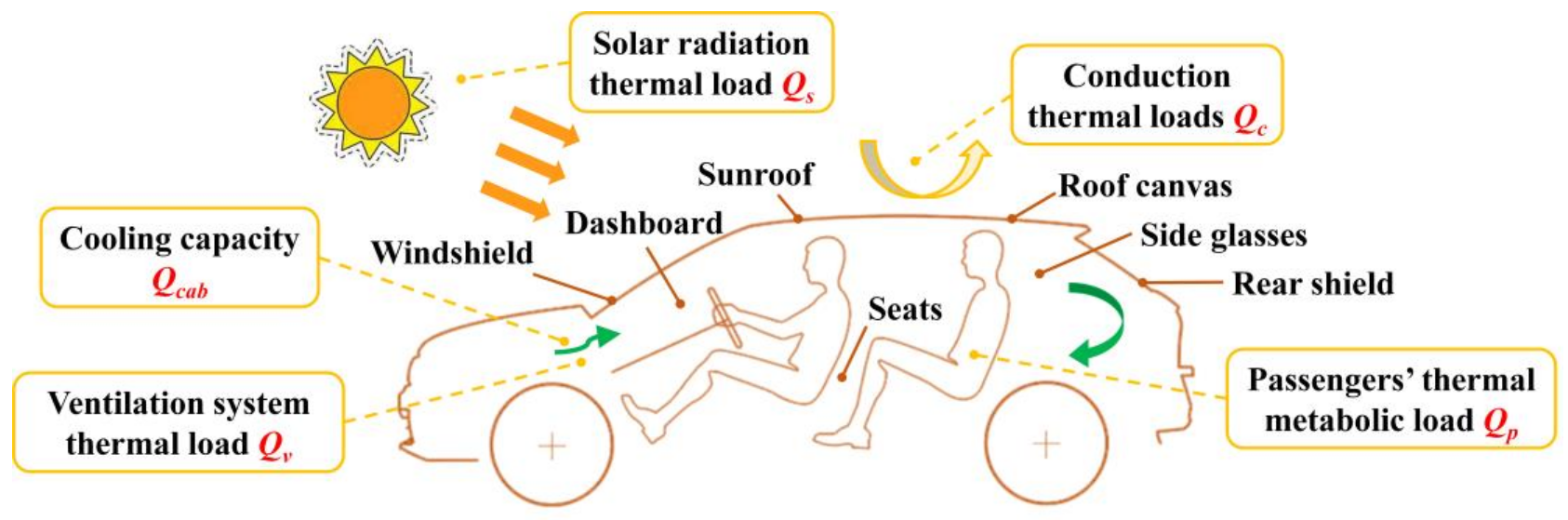

Recent studies have classified cabin thermal load calculation methods into three categories: steady-state heat transfer method, quasi-steady-state heat transfer method, and unsteady-state heat transfer method. Due to the complex nature of cabin thermal load, which involves various factors, as shown in Figure 1, the steady-state heat transfer method is commonly used for thermal load estimation in current investigations [23]. To simplify the modeling process of the electric vehicle cabin and improve the speed and accuracy of thermal simulation, models custom-built or pre-designed using multiphysics field simulation software such as MATLAB SimDriveline [24], MATLAB/Simulink [25], AMESim [26], and Dymola/Modelica [27] are employed.

Figure 1. Cabin thermal loads.

2.2. Power Battery Thermal Management Requirements

Li-ion batteries are considered the most suitable power source for electric vehicles due to their numerous advantages over other rechargeable technologies, such as high energy density, low self-discharge rates, extended cycle life, and lightness [18][28][29][30]. Studies have indicated that the theoretical operational temperature range of Li-ion batteries is between –10 °C and 50 °C [31]. However, investigations have demonstrated that the battery undergoes a capacity decay phenomenon at low temperatures, and aging is accelerated when the temperature exceeds 50 °C [32]. Operating at high temperatures can impact charge/discharge efficiencies, battery life, internal electrochemical reactions, and safety [33][34].

Various heat generation models have been proposed to accurately describe the thermal characteristics of batteries, including the electrochemical-thermal model [35], the electro-thermal model [36], and data-driven models based on intelligent algorithms [37]. The electrochemical-thermal model focuses on the internal structure of the cell, the thermal characteristics of the components, and the electrochemical reaction process. This model, based on electrochemical reaction kinetics and thermodynamics, describes the cell’s current, voltage, heat production, and heat transfer processes during electrochemical reactions, including the diffusion migration of lithium ions and changes in electrolyte concentration. The most commonly used electrochemical-thermal models are the single particle (SP) model [38] and the pseudo-two-dimensional (P2D) model [39]. However, from an engineering perspective, simplification of the models is necessary due to the inclusion of multiple coupled partial differential equations (PDEs) [40]. The electro-thermal model examines the electric and temperature fields inside a single cell from a macroscopic viewpoint. Based on the equivalent circuit approach, the model studies the battery’s heat production and temperature distribution based on the current density distribution and potential over the electrodes [41]. Hence, the physics-based equivalent circuit model has been considered the core of advanced safety and health management algorithms for next-generation battery thermal management systems [42]. Moreover, data-driven models based on intelligent algorithms make it feasible to estimate the electrical and thermal states of Li-ion batteries [43][44][45].

2.3. Electric Motor Thermal Management Requirements

To meet the increasing demand for electric vehicles, motors must exhibit higher power density, torque density, and speed [46][47]. This leads to a significant increase in loss density and temperatures that can cause short circuits, demagnetization of the magnet, and other issues [48]. Insufficient cooling of the motor will result in a rapid decrease in performance parameters of the electric motor, including power density, durability, and driving range per single charge [49]. For permanent magnet motors, high temperatures can also lead to demagnetization of the magnets embedded within the rotor [50][51]. The motor plays a crucial role in the energy output of electric vehicles and generates a considerable amount of heat during operation [19]. The most common electric vehicle motors include AC induction motors, switched reluctance motors, and permanent magnet synchronous motors [48]. Depending on the size of the electric vehicle motor, the heat generation power can range from 2.5–6 kW, 6–10 kW, and 10–15 kW, resulting in different thermal management requirements [52]. Two commonly used motor thermal management methods are air and liquid cooling [53][54][55]. Air cooling typically involves natural and forced air cooling and air impingement cooling [56]. On the other hand, liquid cooling mediums typically include coolant fluids and transformer oil, among others [57]. Numerous studies have been conducted to design various structural forms for both cooling methods to address the thermal management requirements of motors.

Several theoretical modeling methods have been proposed to provide academic support for meeting the thermal management requirements of electric motors. The primary theoretical modeling methods include the finite element method (FEM), lumped-parameter thermal network (LPTM) method, and computational fluid dynamics (CFD) method [58]. The FEM and CFD methods provide detailed information, such as heat flux, temperature, and pressure distribution in the motor domain under given boundary conditions. By contrast, the LPTM method can provide fast temperature prediction of the thermal nodes with lower accuracy [59].

References

- Zhang, X.; Li, Z.; Luo, L.; Fan, Y.; Du, Z. A review on thermal management of lithium-ion batteries for electric vehicles. Energy 2022, 238, 121652.

- Backe, S.; Korpås, M.; Tomasgard, A. Heat and electric vehicle flexibility in the European power system: A case study of Norwegian energy communities. Int. J. Electr. Power Energy Syst. 2021, 125, 106479.

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001.

- Zhao, Y.; Dan, D.; Zheng, S.; Wei, M.; Xie, Y. A two-stage eco-cooling control strategy for electric vehicle thermal management system considering multi-source information fusion. Energy 2023, 267, 126606.

- Lei, S.; Xin, S.; Liu, S. Separate and integrated thermal management solutions for electric vehicles: A review. J. Power Sources 2022, 550, 232133.

- Wawzyniak, M.; Wiebelt, A. Thermal Management for Electrified Vehicles. MTZ Worldw. 2016, 77, 38–43.

- Tan, L.; Yuan, Y. Computational fluid dynamics simulation and performance optimization of an electrical vehicle Air-conditioning system. Alex. Eng. J. 2022, 61, 315–328.

- Yu, X.; Jiang, R.; Lu, G.; Liu, H.; Tong, Y.; Qian, G.; Huang, R.; Li, Z. A novel energy-economic-environmental evaluation model for heat pump air conditioners integrated with waste heat recovery in electric vehicles. Case Stud. Therm. Eng. 2023, 41, 102605.

- Wu, J.; Zhou, G.; Wang, M. A comprehensive assessment of refrigerants for cabin heating and cooling on electric vehicles. Appl. Therm. Eng. 2020, 174, 115258.

- Dan, D.; Li, W.; Zhang, Y.; Xie, Y. A quasi-dynamic model and thermal analysis for vapor chambers with multiple heat sources based on thermal resistance network model. Case Stud. Therm. Eng. 2022, 35, 102110.

- Yu, Z.; Zhang, J.; Pan, W. A review of battery thermal management systems about heat pipe and phase change materials. J. Energy Storage 2023, 62, 106827.

- Du, G.; Xu, W.; Zhu, J.; Huang, N. Power Loss and Thermal Analysis for High-Power High-Speed Permanent Magnet Machines. IEEE Trans. Ind. Electron. 2020, 67, 2722–2733.

- Liang, K.; Wang, M.; Gao, C.; Dong, B.; Feng, C.; Zhou, X.; Liu, J. Advances and challenges of integrated thermal management technologies for pure electric vehicles. Sustain. Energy Technol. Assess. 2021, 46, 101319.

- Yang, D.; Huo, Y.; Zhang, Q.; Xie, J.; Yang, Z. Recent advances on air heating system of cabin for pure electric vehicles: A review. Heliyon 2022, 8, e11032.

- Lajunen, A.; Yang, Y.; Emadi, A. Review of Cabin Thermal Management for Electrified Passenger Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 6025–6040.

- Zhang, Z.; Wang, J.; Feng, X.; Chang, L.; Chen, Y.; Wang, X. The solutions to electric vehicle air conditioning systems: A review. Renew. Sustain. Energy Rev. 2018, 91, 443–463.

- Shahid, S.; Agelin-Chaab, M. A review of thermal runaway prevention and mitigation strategies for lithium-ion batteries. Energy Convers. Manag. X 2022, 16, 100310.

- Ghaeminezhad, N.; Wang, Z.; Ouyang, Q. A Review on lithium-ion battery thermal management system techniques: A control-oriented analysis. Appl. Therm. Eng. 2023, 219, 119497.

- Wang, X.; Li, B.; Gerada, D.; Huang, K.; Stone, I.; Worrall, S.; Yan, Y. A critical review on thermal management technologies for motors in electric cars. Appl. Therm. Eng. 2022, 201, 117758.

- Norin, F.; Wyon, D. Driver Vigilance—The Effects of Compartment Temperature; SAE: Warrendale, PA, USA, 1992.

- Warey, A.; Kaushik, S.; Khalighi, B.; Cruse, M.; Venkatesan, G. Data-driven prediction of vehicle cabin thermal comfort: Using machine learning and high-fidelity simulation results. Int. J. Heat Mass Transf. 2020, 148, 119083.

- Zou, H.; Tang, Z.; Yang, T.; Tian, C. Review of Research on Thermal Management Technology for Electric Vehicles. J. Refrig. 2022, 43, 15–27, 56. (In Chinese)

- Xie, Y.; Ou, J.; Li, W.; Li, K.; Liu, J.; Liu, Z.; Zhou, D.; Li, J. An intelligent eco-heating control strategy for heat-pump air conditioning system of electric vehicles. Appl. Therm. Eng. 2022, 216, 119126.

- Shin, H.; Park, S.; Kim, H.; Yang, I. Development of an integrated energy management strategy with cabin heating for plug-in hybrid electric vehicle. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 31 March–2 April 2015; pp. 1–10.

- Kiss, T.; Lustbader, J.; Leighton, D. Modeling of an Electric Vehicle Thermal Management System in MATLAB/Simulink; SAE Technical Paper; SAE: Warrendale, PA, USA, 2015.

- Piao, C.; Wang, W.; Liu, Z.; Wu, C.; Yuan, R. Research on vehicle cabin temperature and thermal comfort optimal control based on fuzzy PID. J. Phys. Conf. Ser. 2021, 1865, 032039.

- Cvok, I.; Ratkovic, I.; Deur, J. Optimisation of Control Input Allocation Maps for Electric Vehicle Heat Pump-based Cabin Heating Systems. Energies 2020, 13, 5131.

- Bernagozzi, M.; Georgoulas, A.; Miché, N.; Marengo, M. Heat pipes in battery thermal management systems for electric vehicles: A critical review. Appl. Therm. Eng. 2023, 219, 119495.

- Youssef, R.; Hosen, M.S.; He, J.; Al-Saadi, M.; Van Mierlo, J.; Berecibar, M. Novel design optimization for passive cooling PCM assisted battery thermal management system in electric vehicles. Case Stud. Therm. Eng. 2022, 32, 101896.

- Lander, L.; Kallitsis, E.; Hales, A.; Edge, J.S.; Korre, A.; Offer, G. Cost and carbon footprint reduction of electric vehicle lithium-ion batteries through efficient thermal management. Appl. Energy 2021, 289, 116737.

- Mi, C.; Li, B.; Buck, D.; Ota, N. Advanced electro-thermal modeling of lithium-ion battery system for hybrid electric vehicle applications. In Proceedings of the 2007 IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 107–111.

- Liu, P.; Wang, J.; Hicks-Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Finamore, P. Aging mechanisms of LiFePO4 batteries deduced by electrochemical and structural analyses. J. Electrochem. Soc. 2010, 157, A499.

- Zhao, G.; Wang, X.; Negnevitsky, M. Connecting battery technologies for electric vehicles from battery materials to management. iScience 2022, 25, 103744.

- Safdari, M.; Ahmadi, R.; Sadeghzadeh, S. Numerical and experimental investigation on electric vehicles battery thermal management under New European Driving Cycle. Appl. Energy 2022, 315, 119026.

- Zhang, Q.; Wang, D.; Yang, B.; Cui, X.; Li, X. Electrochemical model of lithium-ion battery for wide frequency range applications. Electrochim. Acta 2020, 343, 136094.

- Nejad, S.; Gladwin, D.T.; Stone, D.A. A systematic review of lumped-parameter equivalent circuit models for real-time estimation of lithium-ion battery states. J. Power Sources 2016, 316, 183–196.

- Wang, Y.; Yang, D.; Zhang, X.; Chen, Z. Probability based remaining capacity estimation using data-driven and neural network model. J. Power Sources 2016, 315, 199–208.

- Romero-Becerril, A.; Alvarez-Icaza, L. Comparison of discretization methods applied to the single-particle model of lithium-ion batteries. J. Power Sources 2011, 196, 10267–10279.

- Doyle, M.; Fuller, T.F.; Newman, J. Modeling of Galvanostatic Charge and Discharge of the Lithium/Polymer/Insertion Cell. J. Electrochem. Soc. 1993, 140, 1526.

- Han, X.; Ouyang, M.; Lu, L.; Li, J. Simplification of physics-based electrochemical model for lithium ion battery on electric vehicle. Part II: Pseudo-two-dimensional model simplification and state of charge estimation. J. Power Sources 2015, 278, 814–825.

- Xu, X.; Tang, S.; Ren, H.; Han, X.; Wu, Y.; Lu, L.; Feng, X.; Yu, C.; Xie, J.; Ouyang, M.; et al. Joint state estimation of lithium-ion batteries combining improved equivalent circuit model with electrochemical mechanism and diffusion process. J. Energy Storage 2022, 56, 106135.

- Yunlong, L.; Yingchun, L.; Haijing, Z.; Huichao, G. Analysis of factors influencing homogenization effect of microlens array in laser lighting system. In Proceedings of the International Conference on Laser, Optics and Optoelectronic Technology (LOPET 2021), Xi’an, China, 28–30 May 2021; p. 1188502.

- Wang, Q.-K.; He, Y.-J.; Shen, J.-N.; Ma, Z.-F.; Zhong, G.-B. A unified modeling framework for lithium-ion batteries: An artificial neural network based thermal coupled equivalent circuit model approach. Energy 2017, 138, 118–132.

- Dong, G.; Zhang, X.; Zhang, C.; Chen, Z. A method for state of energy estimation of lithium-ion batteries based on neural network model. Energy 2015, 90, 879–888.

- Li, S.; He, H.; Li, J. Big data driven lithium-ion battery modeling method based on SDAE-ELM algorithm and data pre-processing technology. Appl. Energy 2019, 242, 1259–1273.

- Arbab, N.; Wang, W.; Lin, C.; Hearron, J.; Fahimi, B. Thermal Modeling and Analysis of a Double-Stator Switched Reluctance Motor. IEEE Trans. Energy Convers. 2015, 30, 1209–1217.

- Ušakovs, I.; Mishkinis, D.; Galkin, I.A.; Bubovich, A.; Podgornovs, A. Experimental thermal characterization of the in-wheel electric motor with loop heat pipe thermal management system. Case Stud. Therm. Eng. 2023, 47, 103069.

- Zhang, X.; Yang, Q.; Ma, M.; Lin, Z.; Yang, S. A Switched Reluctance Motor Torque Ripple Reduction Strategy With Deadbeat Current Control and Active Thermal Management. IEEE Trans. Veh. Technol. 2020, 69, 317–327.

- Park, M.H.; Kim, S.C. Development and validation of lumped parameter thermal network model on rotational oil spray cooled motor for electric vehicles. Appl. Therm. Eng. 2023, 225, 120176.

- Tikadar, A.; Johnston, D.; Kumar, N.; Joshi, Y.; Kumar, S. Comparison of electro-thermal performance of advanced cooling techniques for electric vehicle motors. Appl. Therm. Eng. 2021, 183, 116182.

- Kim, S.; Lee, S.; Kang, D.G.; Kim, M.S. Motor cooling method using flow boiling of two-phase refrigerant and its analysis with lumped parameter thermal model. Int. J. Therm. Sci. 2023, 192, 108458.

- Li, B.; Kuo, H.; Wang, X.; Chen, Y.; Wang, Y.; Gerada, D.; Worall, S.; Stone, I.; Yan, Y. Thermal Management of Electrified Propulsion System for Low-Carbon Vehicles. Automot. Innov. 2020, 3, 299–316.

- Garud, K.S.; Hwang, S.-G.; Han, J.-W.; Lee, M.-Y. Performance characteristics of the direct spray oil cooling system for a driving motor of an electric vehicle. Int. J. Heat Mass Transf. 2022, 196, 123228.

- Garud, K.S.; Lee, M.-Y. Grey relational based Taguchi analysis on heat transfer performances of direct oil spray cooling system for electric vehicle driving motor. Int. J. Heat Mass Transf. 2023, 201, 123596.

- Park, J.; An, J.; Han, K.; Choi, H.-S.; Seouk Park, I. Enhancement of cooling performance in traction motor of electric vehicle using direct slot cooling method. Appl. Therm. Eng. 2022, 217, 119082.

- Chang, M.; Lai, B.; Wang, H.; Bai, J.; Mao, Z. Comprehensive efficiency analysis of air-cooled vs water-cooled electric motor for unmanned aerial vehicle. Appl. Therm. Eng. 2023, 225, 120226.

- Saleem, A.; Hyeon Park, M.; Ambreen, T.; Chul Kim, S. Optimization of oil flow distribution inside the in-wheel motor assembly of electric vehicles for improved thermal performance. Appl. Therm. Eng. 2022, 201, 117753.

- Shazly, J.; Wahsh, S.; Yassin, A. Thermal modeling of an AFPMSM: A review. J. Electr. Syst. Inf. Technol. 2015, 2, 18–26.

- Sciascera, C.; Giangrande, P.; Papini, L.; Gerada, C.; Galea, M. Analytical Thermal Model for Fast Stator Winding Temperature Prediction. IEEE Trans. Ind. Electron. 2017, 64, 6116–6126.

More

Information

Subjects:

Engineering, Electrical & Electronic

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

2 times

(View History)

Update Date:

29 Jun 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No