You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ronald George Kander | -- | 1716 | 2023-06-20 14:22:29 | | | |

| 2 | Sirius Huang | Meta information modification | 1716 | 2023-06-21 03:59:38 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kaur, G.; Kander, R. Industrial Hemp Plant. Encyclopedia. Available online: https://encyclopedia.pub/entry/45864 (accessed on 24 December 2025).

Kaur G, Kander R. Industrial Hemp Plant. Encyclopedia. Available at: https://encyclopedia.pub/entry/45864. Accessed December 24, 2025.

Kaur, Gurinder, Ronald Kander. "Industrial Hemp Plant" Encyclopedia, https://encyclopedia.pub/entry/45864 (accessed December 24, 2025).

Kaur, G., & Kander, R. (2023, June 20). Industrial Hemp Plant. In Encyclopedia. https://encyclopedia.pub/entry/45864

Kaur, Gurinder and Ronald Kander. "Industrial Hemp Plant." Encyclopedia. Web. 20 June, 2023.

Copy Citation

Industrial hemp is a versatile, sustainable plant with several applications of its various forms, including fiber obtained from hemp stalks, food obtained from hemp seeds, and oil obtained from hemp flowers and seeds. Industrial hemp has the potential to offer a solution to the crisis of climate change, since it is a viable energy source that satisfies the three pillars of sustainability, namely economy, environment, and society.

industrial hemp

cannabis

1. Introduction

The recent climate changes on Earth, which are a significant result of human activities, are causing global environmental problems. Overpopulation, global warming, and biodiversity destruction are some of the impacts of these problems. The literature supports that these processes are the result of natural resources being used in an unsustainable way [1][2][3][4]. To sustain the environment, sustainable agriculture, economy, and ecology are critical and must cooperate [5]. Recently, sustainable agricultural opportunities have been of considerable interest to United States (U.S.) farmers. One crop that has gained attention for its sustainability potential is industrial hemp. In the U.S., hemp production has been virtually nonexistent since the 1950s. Previously, the U.S. was a prominent producer of hemp [6], and it played an important role in U.S. history. However, because of its association with marijuana, hemp was banned in the U.S. after the passage of the Marijuana Tax Act of 1937 [7][8]. Along with other varieties of cannabis, it fell under the Controlled Substances Act’s (CSA) Schedule I classification [9].

Under U.S. law, hemp and marijuana have different legal definitions. Congress defined industrial hemp as “the plant Cannabis sativa L. and any part of such plant, whether growing or not, with a delta-9 tetrahydrocannabinol concentration of not more than 0.3 percent on a dry weight basis” as part of a 2014 farm bill [9]. Prior to this bill, the U.S. hemp market could not meet demand and was heavily dependent on imports [9]. Under a federal action after the bill was passed, state agriculture departments were authorized to cultivate hemp as a pilot project [10]. In a 2018 amendment to the farm bill, Congress expanded the definition to “the plant Cannabis sativa L. and any part of that plant, including the seeds thereof and all derivatives, extracts, cannabinoids, isomers, acids, salts, and salts of isomers, whether growing or not, with a delta-9 tetrahydrocannabinol (THC) concentration of not more than 0.3 percent on a dry weight basis” [9].

In the past ten years, the U.S. business community, including state governments, private researchers, and companies, has shown great interest in industrial hemp. According to advocates supporting its legalization, hemp is a viable alternative cash crop for U.S. farmers due to its sustainability potential, including its environmental benefits, its versatile adaptability to various agronomical conditions, and its manifold applications. Studies have claimed that if industrial hemp is allowed to develop in the same manner as other commercial agricultural enterprises, it could be lucrative [11].

2. Industrial Hemp Plant

A cannabis plant (species Cannabis sativa L.) grown for fiber, hurd, and oilseed/grain, is known as industrial hemp [12]. Cannabis sativa L., including industrial hemp, is an upright, yearly plant that grows up to 1–6 m tall and is primarily a dioecious herb [13][14].

The Cannabis sativa L. species produces many plants, including hemp and marijuana. It has more than 100 recognized cannabinoids, which are chemical compounds that have different physiological effects on humans [15][16]. The two most notable and researched cannabinoids of the Cannabis sativa L. plant are cannabidiol (CBD), a safe, non-addictive, and non-hallucinogenic compound known for its therapeutic profile, and tetrahydrocannabinol (THC), the psychoactive element causing the “high” with which cannabis is commonly associated [9][15][17]. CBD is marketed and sold in bud, oil, and tinctures to soothe swelling and promote relaxation [17]. THC is frequently used for medicinal purposes and for recreational use; because of its psychoactive effects, it is illegal in many countries [18].

The primary difference between industrial hemp and marijuana is the concentration of THC. Industrial hemp typically has less than 1% of THC on a dry-weight basis, while marijuana has 3% to 15% [19][20]. The perceived legitimacy of industrial hemp varies between countries. To discourage its recreational use, the European Union (EU) and countries around the globe only allow production of hemp with low THC, thereby reducing or eliminating its psychoactive effects [18][21]. The EU limits THC content to 0.2%, the strictest regulation in the world, while Mexico limits it to 1.0%; Malaysia to 0.5%; and the U.S., Canada, and East Asia to 0.3% [22]. In the U.S., industrial hemp cannot legally have more than 0.3% of THC in any part of the plant in any condition or growth stage [23].

3. Parts and Uses for the Industrial Hemp Plant

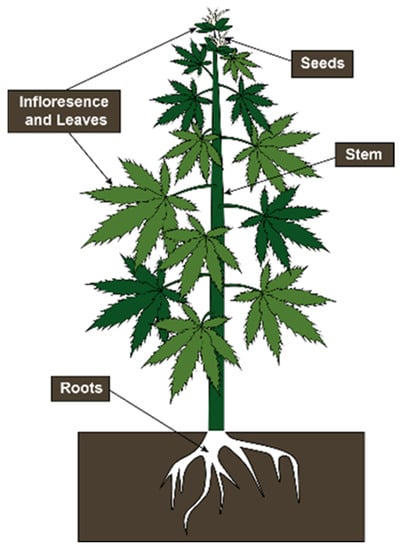

Cannabis plant parts include seeds, stem/stalk, inflorescence, leaves, and roots (Figure 1) [16].

Figure 1. Various parts of the cannabis plant; derived from, (CC BY 4.0) [16].

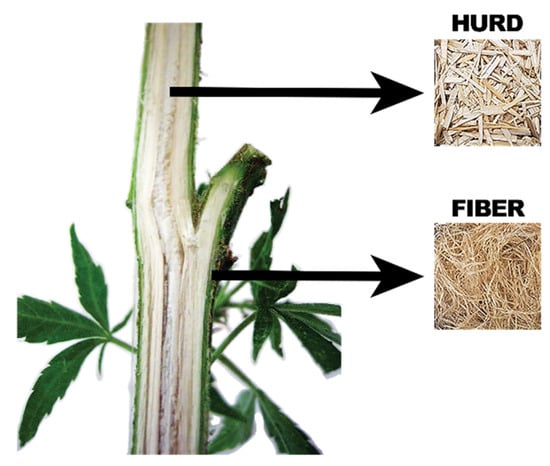

Industrial hemp plants harvested for their stem/stalk provide hemp fiber. To produce hemp fiber, branching and flowering of the plant is discouraged. The plant is planted densely, averaging 35 to 50 plants per square foot. The harvest height of plants for fiber is 10 to 15 feet [9]. A hemp stem/stalk is composed of two sublayers, the outer layer consists of more valuable bundles of fiber, called bast fiber, and the inner layer consists of a less valuable woody (xylem core body) component, called hurd or shive fiber (Figure 2) [24][25][26][27]. A hemp stem’s xylem core/hurd constitutes 85% of its biomass compared to bast fiber’s 15% contribution [28]. To produce fiber, core fibers are mechanically separated from bark (using a decorticator) or by retting, or by a combination of the two. After being separated, dried and baled hemp fibers can be further processed by additional mechanical separation (such as cottonizing, shredding into smaller lengths, and spinning into yarn).

Figure 2. Raw materials obtained from hemp stems/stalks.

Industrial hemp plants harvested for seeds provide oilseeds. The process of growing plants to produce hemp seeds is similar to that of growing plants to produce hemp fiber. The harvest height of plants for seed/grains is 6 to 9 feet [9]. A hemp seed/grain measures approximately one-eighth to one-fourth of an inch in length and has a smooth surface [29]. In seed processing, the shell is removed from the hulled seed kernels [30].

Industrial hemp plants are harvested for their flower buds and floral materials, which provide CBD and other oils. To produce flower buds and floral materials, wide branches and leaves are encouraged. The hemp is planted more sparsely, approximately three to five feet apart, so the plant can branch more widely [9]. The harvest height of industrial hemp plants grown for flowers is four to eight feet. To produce oil, an assortment of extraction methods is required, including lipid infusion, CO2 extraction, and solvent-free extraction [9].

According to a Congressional Research Service report [9], hemp grown for fiber yields 2000 to 11,000 pounds of whole dry stems per acre, while hemp grown for seeds and grain yields 800 to 1000 pounds per acre. Hemp grown for flowers yields about one pound of dried flower buds per plant [9].

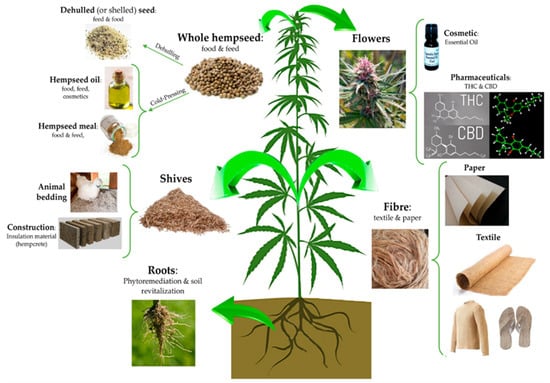

Almost all parts of the industrial hemp plant can be used [16]. Industrial hemp is not only one of the fastest growing plants [31], but is also a versatile, sustainable plant with several applications, including the use of the fiber, seeds, and oil [32]. As shown in Figure 3, the seeds, dehulled or whole, can be utilized as a food source, as feed for animals, and in cosmetics, or they can be made into oil through a cold press process. Shives (hurd) and fiber that are obtained from the stem can be used for animal bedding, building materials, paper, or textiles. The hemp flower can be used to produce cosmetic and pharmaceutical products, including essential oils (Figure 3) [33]. Recently, the global industrial hemp market has been growing [34], resulting in the production of more than 25,000 products across the globe in various subsectors: paper, construction and insulation materials, fabrics and textiles, yarns and spun fibers, biocomposites, carpeting, and home furnishings (Figure 4) [29][30][32].

Figure 3. The many applications of the industrial hemp plant, (CC BY 4.0) [33].

Figure 4. Modern uses of industrial hemp plant raw material, (CC BY 4.0) [35].

Each of the Cannabis sativa L. categories, (a) fiber and hurd, (b) seed or grain, (c) products for medicinal markets, and (d) products for recreational markets, has many modern uses.

- a.

-

Fiber products: Numerous industrial applications use hemp fiber as a natural source of bast fiber [36]. Known for their strength, durability, and length (fiber bundles can reach 1–5 m), hemp fibers have long been valued for serving many purposes including making rope, paper, and textiles [37][38][39]. The life cycle assessment (LCA) of hemp fibers, from cradle to grave, reveals that hemp fibers perform better than glass fiber by weight [40]. LCA assesses the environmental impact and resource usage of a product, including its raw material acquisition, manufacturing, and disposal phases [41][42][43][44]. The increased global demand for eco-friendly natural products and sustainable systems has increased the market share for textiles, fabrics, and clothing made from hemp fiber [12][45]. Hemp fiber is also used to make biodegradable mulch, horticultural planting materials, pressed fiber products, paper and pulp products, building-construction materials, insulation materials, animal bedding made of hurd, plastic bio composites, and compressed cellulose plastics [12].

- b.

-

Seed or grain products: Hemp seed has historically served as a vital food source [46][47]. It consists of 20 to 30% edible oil, 20 to 30% protein, 20 to 25% fiber, 20 to 30% carbohydrates, and many other important nutrients and vitamins recommended for humans [12]. Hemp seed oil and grain products include whole and dehulled hemp seeds, hemp seed oil, hemp seed flour, hemp seed cake (a byproduct of mechanical oil pressing), hemp seed meal, hulls of hemp, and hemp protein isolates and concentrates (Figure 5) [48]. Hemp seeds are used to produce olive oil and salad dressing, and seeds of hemp contain omega 3 fats and proteins. In addition to being used in cosmetics, hemp seed oil can be used as a substitute for industrial oils [12].

Figure 5. Processing to generate the main types of hemp seed-based food ingredients (CC BY 4.0) [48].

Figure 5. Processing to generate the main types of hemp seed-based food ingredients (CC BY 4.0) [48].

- c.

-

Products for the medicinal market: CBD oil is a nonintoxicating cannabinoid compound produced using industrial hemp; unlike THC, it is not addictive. Because it is non-addictive and may offer health benefits, many states have recently made CBD oil legal [49]. Although CBD is used in various products, such as sparkling water, lotions, and pharmacological substances, its purported health benefits have not been scientifically verified. These areas offer an exciting opportunity for further research [12].

- d.

-

Products for the recreational market: Because industrial hemp does not include high THC, it is not used for recreational purposes.

References

- Letcher, T.M. Global warming—A complex situation. In Climate Change; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–17.

- Al-Delaimy, W.; Ramanathan, V.; Sánchez Sorondo, M. Health of People, Health of Planet and Our Responsibility: Climate Change, Air Pollution and Health; Springer Nature: Berlin/Heidelberg, Germany, 2020.

- Singh, R.L.; Singh, P.K. Global environmental problems. In Principles and Applications of Environmental Biotechnology for a Sustainable Future; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–41.

- McMichael, A.J.; Lindgren, E. Climate change: Present and future risks to health, and necessary responses. J. Intern. Med. 2011, 270, 401–413.

- Agrawal, D.C.; Kumar, R.; Dhanasekaran, M. Cannabis/Hemp for Sustainable Agriculture and Materials; Springer: Berlin/Heidelberg, Germany, 2022.

- Pal, L.; Lucia, L.A. Renaissance of industrial hemp: A miracle crop for a multitude of products. BioResources 2019, 14, 2460–2464.

- Thedinger, S. Prohibition in the United States: International and US regulation and control of industrial hemp. Colo. J. Int’l Envtl. L. Pol’y 2005, 17, 419.

- Musto, D.F. The marihuana tax act of 1937. Arch. Gen. Psychiatry 1972, 26, 101–108.

- Johnson, R. Defining hemp: A fact sheet. Congr. Res. Serv. 2019, 44742.

- NCSL. State Industrial Hemp Statutes. 2020. Available online: https://www.ncsl.org/agriculture-and-rural-development/state-industrial-hemp-statutes (accessed on 8 June 2022).

- Fortenbery, T.R.; Bennett, M. Is Industrial Hemp Worth Further Study in the US? A Survey of the Literature. 2001. Available online: https://doi.org/10.22004/ag.econ.12680 (accessed on 8 June 2022).

- Jeliazkov, V.D.; Noller, J.S.; Angima, S.; Rondon, S.I.; Roseberg, R.J.; Summers, S.; Jones, G.B.; Sikora, V. What is Industrial Hemp? Oregon State University Extension Service: Corvallis, OR, USA, 2019.

- Miller, N.G. The genera of the Cannabaceae in the southeastern United States. J. Arnold Arbor. 1970, 51, 185–203.

- Agate, S.; Tyagi, P.; Naithani, V.; Lucia, L.; Pal, L. Innovating generation of nanocellulose from industrial hemp by dual asymmetric centrifugation. ACS Sustain. Chem. Eng. 2020, 8, 1850–1858.

- Atakan, Z. Cannabis, a complex plant: Different compounds and different effects on individuals. Ther. Adv. Psychopharmacol. 2012, 2, 241–254.

- Simiyu, D.C.; Jang, J.H.; Lee, O.R. Understanding Cannabis sativa L.: Current Status of Propagation, Use, Legalization, and Haploid-Inducer-Mediated Genetic Engineering. Plants 2022, 11, 1236.

- Iseger, T.A.; Bossong, M.G. A systematic review of the antipsychotic properties of cannabidiol in humans. Schizophr. Res. 2015, 162, 153–161.

- Bridgeman, M.B.; Abazia, D.T. Medicinal cannabis: History, pharmacology, and implications for the acute care setting. Pharm. Ther. 2017, 42, 180.

- Rupasinghe, H.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial hemp (Cannabis sativa subsp. sativa) as an emerging source for value-added functional food ingredients and nutraceuticals. Molecules 2020, 25, 4078.

- USDA. Industrial Hemp in the United States: Status and Market Potential; USDA: Washingtion, DC, USA, 2000; p. 182773. Available online: https://www.ers.usda.gov/webdocs/publications/41740/15867_ages001e_1_.pdf?v=42087 (accessed on 8 June 2022).

- Sgrò, S.; Lavezzi, B.; Caprari, C.; Polito, M.; D’Elia, M.; Lago, G.; Furlan, G.; Girotti, S.; Ferri, E.N. Delta9-THC determination by the EU official method: Evaluation of measurement uncertainty and compliance assessment of hemp samples. Anal. Bioanal. Chem. 2021, 413, 3399–3410.

- Zhao, H.; Xiong, H.; Chen, J. Regional Comparison and Strategy Recommendations of Industrial Hemp in China Based on a SWOT Analysis. Sustainability 2021, 13, 6419.

- Arnall, B.; Bushong, J.; Lofton, J. Agronomic Considerations for Industrial Hemp Production; Oklahoma Cooperative Extension Service: Stillwater, OK, USA, 2019.

- Marsh, G. Next step for automotive materials. Mater. Today 2003, 4, 36–43.

- Ouajai, S.; Shanks, R. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym. Degrad. Stab. 2005, 89, 327–335.

- John, F.; Williams, D.; Trey, R.; Jared, N.; Patrick, F.; Jeff, K.; Williams, D.; Williams, R.; Brian, C.; Dong, Z. Industrial Hemp as a Modern Commodity Crop; American Society of Agronomy: Madison, WI, USA, 2019.

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014, 7, 8131–8150.

- Li, X.; Wu, N.; Morrell, J.J.; Du, G.; Tang, Z.; Wu, Z.; Zou, C. Influence of hemp plant eccentric growth on physical properties and chemical compounds of hemp hurd. BioResources 2018, 13, 290–298.

- Johnson, R. Hemp as an Agricultural Commodity; Library of Congress Washington DC Congressional Research Service: Washington, DC, USA, 2014.

- Johnson, R. Production, Marketing, and Regulation of Hemp Products; IF11860; Congressional Research Service: Washington, DC, USA, 2021. Available online: https://crsreports.congress.gov/product/pdf/IF/IF11860 (accessed on 8 June 2022).

- Deitch, R. Hemp: American History Revisited: The Plant with a Divided History; Algora Publishing: New York, NY, USA, 2003.

- Kraenzel, D.G. Industrial Hemp as an Alternative Crop in North Dakota: A White Paper Study of the Markets, Profitability, Processing, Agronomics and History; North Dakota State University: Fargo, ND, USA, 1998.

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp (Cannabis sativa L.): Nutritional quality and potential functionality for human health and nutrition. Nutrients 2020, 12, 1935.

- FAOSTAT FAO. Available online: https://www.fao.org/faostat/en/#home (accessed on 14 August 2022).

- Zimniewska, M. Hemp fibre properties and processing target textile: A review. Materials 2022, 15, 1901.

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441.

- Small, E.; Pocock, T.; Cavers, P. The biology of Canadian weeds. 119. Cannabis sativa L. Can. J. Plant Sci. 2003, 83, 217–237.

- Sen, T.; Reddy, H.J. Various industrial applications of hemp, kinaf, flax and ramie natural fibres. Int. J. Innov. Manag. Technol. 2011, 2, 192.

- Fan, M. Characterization and Performance of Elementary Hemp Fibres: Factors Influencing Tensile Strength. Bioresources 2010, 5, 2307–2322.

- Anderson, J.; Jansz, A.; Steele, K.; Thistlethwaite, P.; Bishop, G.; Black, A. Green Guide to Composites: An Environmental Profiling System for Composite Materials and Products; BRE Press: Berkshire, UK, 2004.

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21.

- Rosenbaum, R.K.; Hauschild, M.Z.; Boulay, A.-M.; Fantke, P.; Laurent, A.; Núñez, M.; Vieira, M. Life cycle impact assessment. In Life Cycle Assessment: Theory and Practice; Springer: Cham, Switzerland, 2018; pp. 167–270.

- Curran, M. Encyclopedia of ecology. Encycl. Ecol. 2008, 2168–2174.

- Duda, M.; Shaw, J.S. Life cycle assessment. Society 1997, 35, 38–43.

- GrandViewResearch. Eco Fiber Market Size, Share & Trends Analysis Report By Product (Organic, Manmade/Regenerated, Recycled) By Application (Textiles/Apparel, Industrial, Medical), By Region, And Segment Forecasts, 2023–2030. 2020. Available online: https://www.grandviewresearch.com/industry-analysis/eco-fiber-market (accessed on 8 June 2022).

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 2004, 140, 65–72.

- Crescente, G.; Piccolella, S.; Esposito, A.; Scognamiglio, M.; Fiorentino, A.; Pacifico, S. Chemical composition and nutraceutical properties of hempseed: An ancient food with actual functional value. Phytochem. Rev. 2018, 17, 733–749.

- Burton, R.A.; Andres, M.; Cole, M.; Cowley, J.M.; Augustin, M.A. Industrial hemp seed: From the field to value-added food ingredients. J. Cannabis Res. 2022, 4, 1–13.

- Mead, A. The legal status of cannabis (marijuana) and cannabidiol (CBD) under US law. Epilepsy Behav. 2017, 70, 288–291.

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

2 times

(View History)

Update Date:

21 Jun 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No