You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Tomasz Kapuściński | -- | 2256 | 2023-06-15 14:48:17 | | | |

| 2 | Lindsay Dong | Meta information modification | 2256 | 2023-06-16 04:40:04 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kasyk, L.; Wolnowska, A.E.; Pleskacz, K.; Kapuściński, T. Marine Safety in Relation to Human Errors. Encyclopedia. Available online: https://encyclopedia.pub/entry/45660 (accessed on 26 December 2025).

Kasyk L, Wolnowska AE, Pleskacz K, Kapuściński T. Marine Safety in Relation to Human Errors. Encyclopedia. Available at: https://encyclopedia.pub/entry/45660. Accessed December 26, 2025.

Kasyk, Lech, Anna Eliza Wolnowska, Krzysztof Pleskacz, Tomasz Kapuściński. "Marine Safety in Relation to Human Errors" Encyclopedia, https://encyclopedia.pub/entry/45660 (accessed December 26, 2025).

Kasyk, L., Wolnowska, A.E., Pleskacz, K., & Kapuściński, T. (2023, June 15). Marine Safety in Relation to Human Errors. In Encyclopedia. https://encyclopedia.pub/entry/45660

Kasyk, Lech, et al. "Marine Safety in Relation to Human Errors." Encyclopedia. Web. 15 June, 2023.

Copy Citation

As in any industry exposed to risk, human and organizational factors are the main stakes of maritime safety. Understanding the causes and risks of maritime accidents is integral to the sustainability of shipping. The investigation of marine accidents is a crucial tool for their identification in areas related to operations and ships.

safety

navigation

marine accidents

1. Marine Safety as a Goal of Formal Organizations

Safety is one of the primary goals of multiple organizations around marine space. The most prominent one—The International Maritime Organization (IMO)—has adopted Resolution A.850(20), defining its vision, principles, and goals for the human element [1]. It was updated by Resolution A.947(23), which was adopted in 2003 [2] and assumes that human factors are a complex, multidimensional issue that impacts maritime safety, security, and marine environment protection. Additionally, effective remediation following maritime casualties requires a solid understanding of the human factor’s contribution to causing accidents; that adequate safeguards be put in place; that rules and regulations are simple, clear, and comprehensive; and that communication is flawless. It also recognizes that crew endurance is a function of many complex variables, including personal knowledge, management principles, cultural factors, experience, training, professional skills, and work environment. The resolution has several objectives:

-

Implement a structured approach to the proper consideration of the human element.

-

Conduct a comprehensive review of selected existing IMO instruments.

-

Promote and communicate a maritime safety culture across the marine environment.

-

Encourage the development of non-regulatory solutions.

-

Implement a system to identify and disseminate human factor analysis and research.

-

Provide educational material for seafarers on human factor issues.

Thus, not only is the human factor being recognized as a key contributor to marine safety but there is also an understanding of how much culture can influence the practical application of formal rules. Another essential organization regulating maritime labor is the International Labour Organisation (ILO). Together with the IMO, they attempt to solve problems regarding the human factor in the marine sector. The result of this cooperation is the Seafarers’ Employment Agreements from 2006, updated in 2016 [3][4].

Other organizations, such as the International Association of Ship Classification Societies (IASCS), are also contributing to improvements in safety on all ships by introducing their set of rules, regulations, and requirements. Also worth mentioning is the International Safety Management (ISM) Code, one of the most robust tools to prevent human errors in shipping, adopted by the IMO by Resolution A741(18), which became effective on 1 July 1998 as Chapter IX of the SOLAS Convention on the management of the safe operation of ships.

Every country has its own framework for ensuring that accidents are analyzed and learning applied. In Poland, for example, the body investigating the causes of incidents is the State Marine Investigation Commission (SMAIC), while in the UK, it is the Marine Accident Investigation Branch (MAIB). However, despite the ongoing detailed inspections of all ships sailing on the seas and oceans, and the detention of non-compliant ships, accidents happen almost every day due to the failure of safety mechanisms, and their number must be reduced. As systems improve, new and convenient technologies are introduced, resulting in excessive human reliance on them. [5]. Unfortunately, safety management systems are often over-regulated, too detailed, and too time-consuming [6]. Sometimes, such procedures are difficult to apply in real life, with multiple conflicting priorities around timeliness, cost, and efficiency [7]. While good practices exist to improve safety on every vessel, it is a common practice in the marine industry to purchase a standard, off-the-shelf safety management system designed and developed for a certain group of vessels or companies. This makes safety audits easier on the one hand, but these systems sometimes do not match the specific profile of a given ship [8][9]. For many seafarers, managing safety is an additional workload (documentation, procedures) requiring their concentration and distracting them from delivering their basic tasks [10][11]. Some researchers claim that managing safety takes time and may decrease seafarers’ levels of concentration [12]. As displayed in multiple publications [13][14][15], safety procedures across many industries have been evaluated as too complex and requiring documentation that is too broad, which in itself could potentially lead to incidents. This leads to the conclusion that simply having formal organizations, regulations, and documented practices might not lead to an increase in safety. The marine industry must more actively adopt a safety culture by better analyzing past incidents and driving improvements to educational and training programs.

2. Human Errors as Causes of Incidents

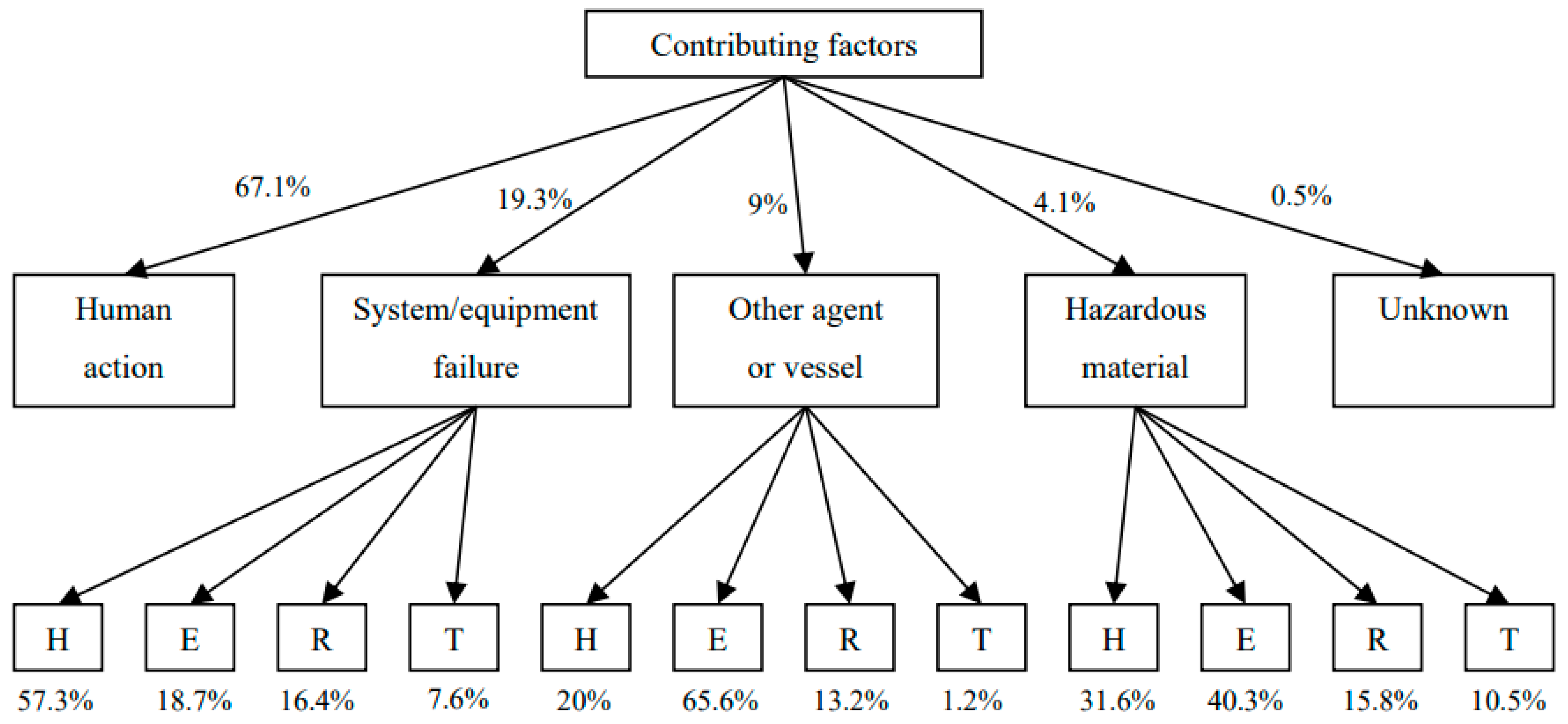

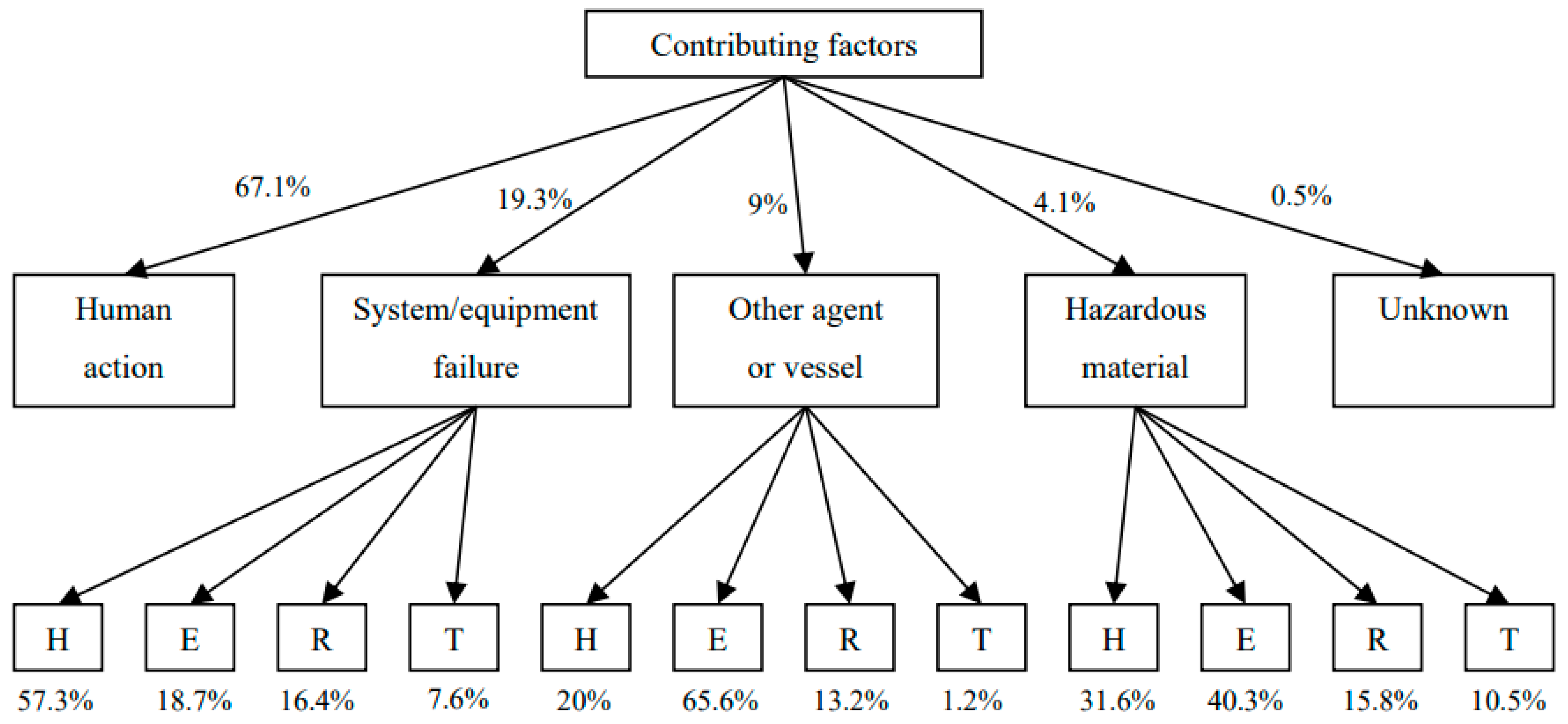

Every marine accident may have one or more causes. More than one accident may be associated with one incident. The five categorized causes are human action, system or equipment failure, other agent or vessel, hazardous material, and unknown. Each accident can also have one or more contributing factors, which are divided into three main categories: external environment, shore management, and ship operation. Studies have shown [15] that human error contributes to the following:

Contemporary sources [19] show the following breakdown of accidents and contributing factors:

-

Cargo ships—in more than 80% of cases, the human factor was the leading cause or at least a component.

-

Fishing vessels—56.5% of accidents were related to human factors.

-

Passenger ships—65.4%.

-

Specialist, service vessels—65.5%.

-

Other ships—71.1%.

As shown in Figure 1, considering the 67.1% of human action in the basic breakdown of accident factors and the corresponding human–related percentages in the groups of: system/equipment failure, other agent or vessel, and hazardous material, there is in total more than 81% impact of the human factor on causes of accidents. It is evident, that the human factor is a direct or indirect cause of almost all marine accidents; thus, a proper analysis of the components that influence such errors can positively influence safety at sea.

Figure 1. Tree of events of contributing factors to accidents. Source: own study based on [19]. H—Human behavior, E—Environment, R—Rules, procedures, and training, T—Tools and equipment.

3. Marine Safety in Relation to Human Errors

A lot of documented research on the influence of the human factor on marine accidents is based on modelling techniques and focuses on the identification and quantification of the probability of human and organizational errors [20][21][22][23]. The HFACS method, being widely used, defines four cause categories: organizational influence, insufficient supervision, initial conditions for risky actions, and risky actions. In order to solve defined problems from a marine area, Chen et al. [24] proposed the HFACS—Maritime Accident (HFACS—MA) method. It uses a SHEL model, which stands for Software (S), Hardware (H), Environment (E), and Liveware (L), to describe initial conditions in a traditional HFACS environment. Another method based on a similar idea, HFACS for passenger vessels (HFACS—PV), has been proposed by Ugurlu et al. [25]. It treats operational conditions as a new HFACS category. The authors of this method believe that operational conditions are not a hidden fault but rather a result of a higher-level component that then leads to the accidental results of dangerous actions. Another modification of the original method is HFACS Fuzzy Cognitive Mapping (HFACS—FCM), proposed by Soner et al. [26], where a fuzzy cognitive map is used to identify and quantify definitions of causes that are initiated in HFACS. It is mainly used to strengthen organizational safety measures for fire accidents and collisions [27]. Other documented techniques that are a modification of HFACS include FAHP [28] and ANP [29], which use a process of fuzzy analytical hierarchy to identify causes contributing to HFACS; HFACS and Chi-square test [30]; HFACS and FTA [31]; and fuzzy FTA, ANN, and HFACS [32].

Another source [33] shows that human-related factors play a significant role in shipboard accidents. For example, in 2020, 63% of accidents were caused by human error and 37% of accidents had a technical cause. Therefore, this problem should still be presented and possible solutions proposed; all components of a ship’s operation should be carefully analyzed, cataloged, and broken down into specific parts along with their source and a set of recommendations provided on how to counteract their negative effects on the safety of life at sea. An essential element is social and situational systems [34][35][36].

Looking further into significant causes of marine accidents, refraining from proper visual observation, over-reliance on GPS, fatigue, commercial pressures, and distraction are other significant causes of accidents. In an archive issue of The Navigator, David Patraiko, project director at The Nautical Institute, argued that new technologies and changing regulations can generate unknown direct causes of accidents [37]. A similar analysis can be found in another report from Acejo [38].

Nevertheless, shipping has maintained a long-term positive safety trend over the past year. Still, the recent COVID-19 pandemic and Russia’s invasion of Ukraine are major impact factors on global supply chain routes and capacity that have placed enormous stress on the system, with potentially detrimental outcomes: loss of life, loss of ships, exacerbated crew crisis, trade disruption, sanctions burden, and increased cost and reduced availability of bunker fuel. The main places of incidents are Southern China, Indochina, Indonesia, and the Philippines. The increasing number of costly problems may be associated with manning larger ships, the challenges of port congestion due to the shipping boom, and managing ambitious decarbonization goals. Port congestion puts pressure on crews and facilities, meaning there is no room for complacency [37]. Additionally, the increased use of non-container ships to carry containers, despite bulk carriers not being designed to carry containers, can affect their maneuverability in bad weather, and crews may need assistance in responding appropriately to incidents.

All the mentioned components result in a situation where crew demand is high; however, many skilled and experienced seafarers are leaving the industry. A serious shortage of qualified staff is expected over the next five years. Among those who remain, morale is low as commercial pressures, cargo operations responsibilities, and workloads are high. The work situation is prone to error, with 75% of incidents involving human error, according to an AGCS analysis [39].

A Dutch study of 100 victims of navigation accidents [40] showed that the number of causes of accidents ranged from 7 to 58, with a median of 23. Therefore, half of the accidents had 7–23 causes and the other half had 23–58. Sometimes, small things go wrong or small mistakes may seem harmless. However, when these seemingly minor events come together, the result is a casualty. The study found that human error contributed to 96 of 100 accidents. In 93 accidents, there were multiple human errors, usually by two or more people, each making approximately two mistakes.

The key finding was that each human error was identified as a precondition for accidents. This means that if only one of these human errors had not occurred, the chain of events would have been broken, and the accident would not have happened.

There are many demanding aspects of shipping, such as the inability of employees to leave the workplace, extreme weather conditions, long periods away from home, and workplace traffic. Some of these are immutable and reflect the nature of the field. Sometimes, very ordinary situations, such as using the toilet, lead to a procedure breach (rest hours) when, for example, there is only a captain and an officer on duty on board the ship.

Nonetheless, it is possible to modify, supplement, and introduce new strategies or interventions to reduce the impact of these factors on the health and well-being of individual seafarers [41].

Maritime transport has a safety level that is comparable to rail transport and much higher than road transport. In the case of passenger transport in Europe, the risk of a fatal accident is estimated to be 1.1 for road transport and 0.33 for ferry transport [42]. In this context, accident risk and, more precisely, the place of the human factor in this risk, are central issues. Indeed, the human factor appears to be the leading cause of accidents at sea [43]. Among the factors that contribute to incidents are productivity loss (fatigue, stress, health problems), insufficient technical and cognitive skills, insufficient interpersonal competencies (communication difficulties, difficulty in mastering a common language), and organizational aspects (safety training, team management, safety culture) [28][43]. Following this, the article “On your watch automation on the bridge” took a closer look at issues of human–machine collaboration and the role of automation in marine accidents [44]. In the case of a collaborative crew or team, a shared mental representation is one of the key elements behind every safe action. Methods developed in cognitive psychology to analyze this mental structure can be used to assess its impact [45] on crew performance. A study of this type was conducted some years ago [45]. However, as presented in [46], this research remains marginal in maritime transport. Since human error (and usually multiple errors by multiple people) contributes to most marine accidents, preventing human error is essential to reduce the number and severity of maritime accidents. Many types of human error have been described, most of which are not the fault of the human operator. Instead, most of these errors occur due to technology, working environments, and organizational factors that do not account for the capabilities and limitations of the people interacting with them, thus setting up the operator for failure.

In general, there are ways to prevent some human errors or at least increase the chance that such errors will be noticed and corrected by improving the safety culture through better education and training for the better analysis of human factor causes of accidents. As such, we can achieve greater safety at sea and fewer casualties. Summarizing the available data, in the years 2014–2020 there were 6921 injuries, which corresponded to 6211 incidents, and crew members accounted for 81% of the victims [47]. These numbers are very high and should be a call to action for the marine industry.

References

- International Maritime Organization. Human Element Vision, Principles and Goals for the Organization, Resolution A.850(20). 1997. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/AssemblyDocuments/A.850(20).pdf (accessed on 20 February 2023).

- International Maritime Organization. Human Element Vision, Principles and Goals for the Organization, Resolution a.947(23). 2004. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/AssemblyDocuments/A.947(23).pdf (accessed on 20 February 2023).

- IMO Website on Legal Affairs. IMO/ILO Work on Seafarer Issues. Available online: https://www.imo.org/en/OurWork/Legal/Pages/JointIMOILOWorkingGroupsOnSeafarerIssues.aspx (accessed on 3 August 2022).

- International Labour Conference, Maritime Labour Convention, 2006, Consolidated Text Established by the International Labour Office, Including the Amendments of 2014 and 2016 to the Code of the Convention. 2016. Available online: https://www.ilo.org/wcmsp5/groups/public/---ed_norm/---normes/documents/normativeinstrument/wcms_554767.pdf (accessed on 10 September 2022).

- Kaber, D.B.; Endsley, M.R. Out-of-the-loop performance problems and the use of intermediate levels of automation for improved control system functioning and safety. Process Saf. Prog. 1997, 16, 126–131.

- Oltedal, H.A.; McArthur, D.P. Reporting practices in merchant shipping, and the identification of influencing factors. Saf. Sci. 2011, 49, 331–338.

- Bye, R.J.; Aalberg, A.L. Why do they violate the procedures?—An exploratory study within the maritime transportation industry. Saf. Sci. 2020, 123, 104538.

- Størkersen, K.V.; Thorvaldsen, T.; Kongsvik, T.; Dekker, S. How deregulation can become overregulation: An empirical study into the growth of internal bureaucracy when governments take a step back. Saf. Sci. 2020, 128, 104772.

- Mišković, D.; Jelaska, I.; Ivče, R. Attitudes of experienced seafarers as predictor of ISM code. Promet-Traffic Transp. 2019, 31, 569–579.

- Österman, C.; Hult, C. Administrative burdens and over-exertion in Swedish short sea shipping. Marit. Policy Manag. 2016, 43, 569–579.

- Bailey, N. Risk perception and safety management systems in the global maritime industry. Policy Pract. Health Saf. 2006, 4, 59–75.

- Rae, A.J.; Provan, D.; Weber, D.; Dekker, S. Safety clutter: The accumulation and persistence of ‘safety’ work that does not contribute to operational safety. Policy Pract. Health Saf. 2018, 16, 194–211.

- Bieder, C.; Bourrier, M. Trapping Safety into Rules: How Desirable or Avoidable Is Proceduralization? 1st ed.; Ashgate: Farnnham, UK, 2013.

- Dekker, S. Safety Differently: Human Factors for a New Era, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2015.

- Størkersen, K.V.; Antonsen, S.; Kongsvik, T.Ø. One size fits all? Safety management regulation of ship accidents and personal injuries. J. Risk Res. 2017, 20, 1154–1172.

- Working Paper on Tankers Involved in Shipping Accidents 1975–1992; Transportation Safety Board of Canada: Ottawa, ON, Canada, 1993.

- Cormier, P.J. Towing Vessel Safety: Analysis of Congressional and Coast Guard Investigative Response to Operator Involvement in Casualties Where a Presumption of Negligence Exists. Master’s Thesis, University of Rhode Island, Kingston, RI, USA, 1994.

- Bryant, D.T. The Human Element in Shipping Casualties; Report; Department of Transport, Marine Directorate: London, UK, 1991.

- Annual Overview of Marine Casualties and Incidents 2021. Available online: www.emsa.europa.eu/ (accessed on 9 September 2022).

- Wu, B.; Yip, T.L.; Yan, X.; Guedes Soares, C. Review of techniques and challenges of human and organizational factors analysis in maritime transportation. Reliab. Eng. Syst. Saf. 2022, 219, 108249.

- Graziano, A.; Teixeira, A.P.; Guedes Soares, C. Classification of human errors in grounding and collision accidents using the TRACEr taxonomy. Saf. Sci. 2016, 86, 245–257.

- Isaac, A.; Shorrock, S.T.; Kirwan, B. Human error in European air traffic management: The HERA project. Reliab. Eng. Syst. Saf. 2002, 75, 257–272.

- Ung, S. Evaluation of human error contribution to oil tanker collision using fault tree analysis and modified fuzzy Bayesian Network based CREAM. Ocean Eng. 2019, 179, 159–172.

- Chen, S.; Wall, A.; Davies, P.; Yang, Z.; Wang, J.; Chou, Y. A Human and Organisational Factors (HOFS) Analysis Method for Marine Casualties Using HFACS-Maritime Accidents (HFACS-MA). Saf. Sci. 2013, 60, 105–114.

- Ugurlu, O.; Yildiz, S.; Loughney, S.; Wang, J. Modified human factor analysis and classification system for passenger vessel accidents (HFACS-PV). Ocean Eng. 2018, 161, 47–61.

- Soner, O.; Asan, U.; Celik, M. Use of HFACS–FCM in Fire Prevention Modelling on Board Ships. Saf. Sci. 2015, 77, 25–41.

- Chauvin, C.; Lardjane, S.; Morel, G.; Clostermann, J.; Langard, B. Human and organisational factors in maritime accidents: Analysis of collisions at sea using the HFACS. Accid. Anal. Prev. 2013, 59, 26–37.

- Celik, M.; Cebi, S. Analytical HFACS for investigating human errors in shipping accidents. Accid. Anal. Prev. 2009, 41, 66–75.

- Akyuz, E. A marine accident analysing model to evaluate potential operational causes in cargo ships. Saf. Sci. 2017, 92, 17–25.

- Yildirim, U.; Basar, E.; Ugurlu, O. Assessment of collisions and grounding accidents with human factors analysis and classification system (HFACS) and statistical methods. Saf. Sci. 2017, 119, 412–425.

- Zhang, M.; Zhang, D.; Goerlandt, F.; Yan, X.; Kujala, P. Use of HFACS and fault tree model for collision risk factors analysis of icebreaker assistance in ice-covered waters. Saf. Sci. 2019, 111, 128–143.

- Qiao, W.; Li, Y.; Ma, X.; Liu, Y. A methodology to evaluate human factors contributed to maritime accident by mapping fuzzy FT into ANN based on HFACS. Ocean Eng. 2020, 197, 106892.

- Galieriková, A. The human factor and maritime safety. Transp. Res. Procedia 2019, 40, 1319–1326.

- Porathe, T.; Hoem, Å.S.; Rødseth, Ø.J.; Fjørtoft, K.; Johnsen, S.O. At Least as Safe as Manned Shipping? Autonomous shipping, safety and “human error”. In Safety and Reliability—Safe Societies in a Changing World; Haugen, S., Barros, A., Gulijk, C.V., Kongsvik, T., Vinnem, J., Eds.; CRC Press: London, UK, 2018.

- Endsley, M.R. Toward a theory of situation awareness in dynamic systems. Hum. Factors 1995, 37, 32–64.

- Hollnagel, E. Safety-I and Safety-II: The Past and Future of Safety Management; Ashgate: Farnham, UK, 2014.

- Patraiko, D. Into the Future, the Technology of Tomorrow, The Navigator, Issue 24. The Nautical Institute. 1 June 2020. Available online: https://www.nautinst.org/resources-page/into-the-future-the-technology-of-tomorrow.html (accessed on 21 September 2022).

- Acejo, I.; Sampson, H.; Turgo, N.; Ellis, N.; Tang, L. The Causes of Maritime Accidents in the Period 2002–2016; Seafarers International Research Centre (SIRC), Cardiff University: Cardiff, UK, 2018.

- Covid-19 losses settle, but pandemic effects linger. In Global Claims Review 2022; Available online: www.agcs.allianz.com/ (accessed on 8 July 2022).

- Wagenaar, W.A.; Groeneweg, J. Accidents at sea: Multiple causes and impossible consequences. Int. J. Man-Mach. Stud. 1987, 27, 587–598.

- Parker, A.W.; Huhinger, L.M.; Sargent, L.; Boyd, R. Health Stress and Fatigue in Shipping; Australian Maritime Safety Agency: Brisbane, Australia, 2002.

- Maekay, M. Safer Transport in Europe: Tools for Decision-Making; European Transport Safety Council Lecture; The European Transport Safety Council: Etterbeek, Belgium, 2000.

- Hetherington, C.; Flin, R.; Mearns, K. Safety in shipping: The human element. J. Saf. Res. 2006, 37, 401–411.

- Lülhoft, M.; Dekker, S. On your watch automation on the bridge. J. Navig. 2002, 55, 83–96.

- Brun, W.; Johnsen, B.; Iabertg, J.C.; Ekomas, B.; Kobbeltvedt, T. Bridge resource management training enhancing shared mental models and task performance. In How Professionals Make Decisions; CRC Press: Boca Raton, FL, USA, 2004; pp. 183–193.

- Salas, E.; Wilson, C.A.; Burke, C.S.; Wighlman, D.C. Does crew resource management training work? An update, an extension, and some critical needs. Hum. Factors 2006, 48, 392–412.

- Kobylinski, L. Risk analysis and human factor in prevention of CRG casualties. Int. J. Mar. Navig. Saf. Sea Transp. 2009, 3, 443–448.

More

Information

Subjects:

Transportation

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.7K

Revisions:

2 times

(View History)

Update Date:

16 Jun 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No