Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Houssein Al Attar | -- | 1327 | 2023-05-26 00:11:50 | | | |

| 2 | Catherine Yang | -4 word(s) | 1323 | 2023-05-26 04:49:36 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Al Attar, H.; Hamida, M.A.; Ghanes, M.; Taleb, M. Modeling and Control of Isolated DC–DC Converters. Encyclopedia. Available online: https://encyclopedia.pub/entry/44866 (accessed on 07 February 2026).

Al Attar H, Hamida MA, Ghanes M, Taleb M. Modeling and Control of Isolated DC–DC Converters. Encyclopedia. Available at: https://encyclopedia.pub/entry/44866. Accessed February 07, 2026.

Al Attar, Houssein, Mohamed Assaad Hamida, Malek Ghanes, Miassa Taleb. "Modeling and Control of Isolated DC–DC Converters" Encyclopedia, https://encyclopedia.pub/entry/44866 (accessed February 07, 2026).

Al Attar, H., Hamida, M.A., Ghanes, M., & Taleb, M. (2023, May 25). Modeling and Control of Isolated DC–DC Converters. In Encyclopedia. https://encyclopedia.pub/entry/44866

Al Attar, Houssein, et al. "Modeling and Control of Isolated DC–DC Converters." Encyclopedia. Web. 25 May, 2023.

Copy Citation

Bidirectional DC–DC converters are frequently chosen for applications requiring high power density such as in bidirectional electric vehicle (EV) chargers. Vehicle to Everything (V2X) technology makes the EV battery an electrical energy source.

electric vehicle charger

DC–DC LLC converter

V2X mode

1. Overview

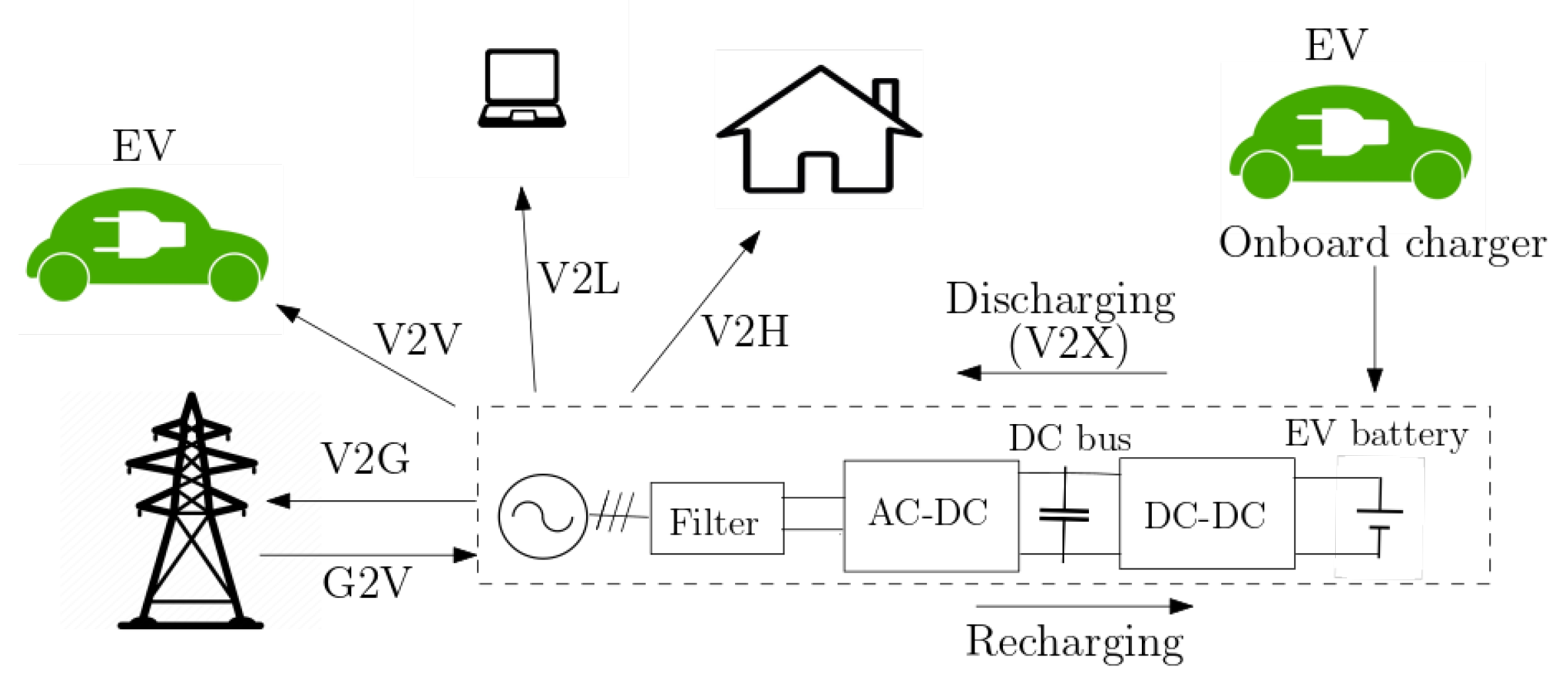

Understanding the advantages of electric mobility over the unsustainable usage of internal combustion engines (ICE) can clarify the reason why the popularity of electric vehicles (EVs) is increasing. The EV might have a huge impact on society. It represents the main support for e-mobility. Battery charging is an important element to take into account in the development of EVs. The onboard charger is generally embedded in the vehicle. The notion of Grid to Vehicle (G2V) describes how electric vehicle batteries are charged from the power grid. By integrating the bidirectional charger technology, it becomes possible to deliver energy in the other direction, from EV batteries to Grid (Vehicle to Grid or V2G) [1] or to Home/Load (V2H/L). The energy that has been stored in the battery can then be used as a source of current (in V2G) or voltage (in V2H/V2L). Vehicle to Everything (V2X) mode is the name given to the battery discharging operating mode. EVs, according to this concept, are not only electrical loads but also the electrical energy storage. Reactive and active power regulation, tracking of variable renewable energy sources, and load balancing are all features of an EV operating in V2X mode [2]. The battery charger must then be capable of ensuring the conversion of energy flow in both directions, becoming bidirectional and capable of both charging and discharging. As a result, EVs with bidirectional battery chargers [3] can be connected into the smart grid, dramatically transforming the energy market. As shown in Figure 1, the EV charger can be considered as the association of two conversion stages [4]: an AC–DC part followed by an isolated DC–DC converter.

Figure 1. Bidirectional EV charger synoptic and operating modes.

Both functions (charging or G2V and discharging or V2X) are provided by the charger, presented in Figure 1, composed of bidirectional AC–DC and DC–DC converters. The AC–DC converter is a Power Factor Correction (PFC), which is used to ensure the grid current control. Meanwhile, the DC–DC converter is used to maintain the DC bus voltage and guarantee battery charging/discharging without any voltage ripples.

2. Motivation

The construction of interface systems, such as bidirectional chargers, between the grid and vehicle energy storage is one of the most technologically challenging aspects of implementing energy management systems. Battery charging is an important element to take into account for the development of EVs. The choice of the topology of power converters (AC–DC and DC–DC converters) defines the characteristics of the EV charger. In order to guarantee the bidirectional charger operation, the converters should be able to operate in the two directions with a high efficiency.

Bidirectional DC–DC converters are frequently chosen for applications requiring high power density. The bidirectional EV charger is one of the main applications of the bidirectional isolated DC–DC converters. In this technology, the DC–DC converters are presented between a DC bus link connected to an AC–DC converter and a high voltage battery pack as shown in Figure 1. The control strategy of the EV charger consists of two control algorithms: AC–DC and DC–DC controllers. The controllers should be implemented in order to ensure the grid, DC bus and battery stability.

Model-Based Design (MBD) approaches have been developed in trying to best meet charging requirements. MBD can result in considerable quality improvements in the design and control of power converters [5][6]. The aim is to carry out an investigation on MBD and control strategies of the isolated DC–DC LLC converter implemented in a bidirectional EV charger toward improving the performance and efficiency.

3. Related Works on Modeling and Control of Isolated DC–DC Converters

In order to attain high efficiency throughout a broad operating range, Ref. [7] suggests a design optimization technique for a high-power off-board charger for EV applications. The electro-thermal modeling of the converter and control system design is the main emphasis of the design technique.

The design of a bidirectional onboard charger (OBC) for hybrid and electrified vehicles using a model-based approach is proposed in [8]. The design of a bidirectional single-phase OBC includes a DC–DC converter followed by an AC–DC converter. In order to assess the robustness of the implemented control algorithms, the produced models are tested under varied operating conditions.

Bidirectional DC–DC converters [9][10][11] are increasing in importance. Isolated DC–DC converters come in a variety of topologies and offer electrical isolation between the input and the output sides with a high-frequency transformer.

An interesting topology is Dual Active Bridge (DAB) converter [12][13]. Low device and component stresses, minimal switching losses (due to ZVS), high power density and efficiency, ad bidirectional power flow capabilities are all advantages of this topology.

Series resonant converters (SRCs) [14] also present different advantages. Because the resonant current and voltage are nearly sinusoidal due to the nature of resonance, those parameters can be approximated by merely its fundamental component without sacrificing too much precision for design purposes [14].

However, with the DAB and SRC topologies, soft-switching is impossible to maintain when the operating voltages at the ports are too high and under light load situations.

The isolated bidirectional DC–DC LLC resonant converter [15][16] is widely taken into account for control purposes in order to improve converter efficiency over a wide range of power and input/output voltages in industrial applications. On the other hand, because the resonant tank is not symmetric, there is a difference in the gain equation and the efficiency between the two operating modes (forward and reverse). Furthermore, while the DC–DC LLC converter is predicted to have a high efficiency in both operating modes, some of the unidirectional originator’s intrinsic advantages are lost (reduced ZVS zone in the reverse mode resulting in lower efficiency), and large switching losses occur at high output voltages.

Establishing a representative dynamic model of the DC–DC LLC converter is necessary to create an appropriate control method.

To build small signal models in PWM converters, the state space average approach is commonly used in modeling methodologies. However, because the operating frequency is not constant and the energy is largely conveyed through the fundamental components of the voltage and current waveforms, it is not appropriate for a frequency-controlled resonant converter [17].

In [18][19], an MBD approach enables for the creation of a LLC transfer function, making control simple. However, it fails to account for nonlinear and uncertain effects, such as the DC–DC LLC converter structure, which impacts the robustness of the control law in the face of system perturbations and results in a reduced operating zone. The large signal model based on Extending Describing Function (EDF) [20][21][22][23] is proposed for the DC–DC LLC converter. When big signal transient disruption occurs, these models give sufficient dynamic information of the DC–DC LLC converter. However, because these models are complex and nonlinear, design of the control is more difficult. Small signal modeling [15][17][24] consists of using harmonic approximation to obtain more simplified model. Small signal transfer functions can be derived that are more in accordance with the design of control strategies. Many control laws, such as for PID controllers and sliding mode control, have been proposed in the literature for the DC–DC LLC converter based on large or small signal models. In [17], a simple PI controller is used to regulate the resonant current flowing in the LLC resonant circuit by varying the phase shift. In [25], a combined sliding mode–PI control strategy is implemented to reduce the chattering phenomenon. By adjusting the DC bus voltage, a PI controller is implemented to ensure battery voltage regulation in [26]. In [20][27], sliding mode control is used to insure the battery voltage stability by varying the respective switching frequency and duty cycle.

References

- Garcés Quílez, M.; Abdel-Monem, M.; El Baghdadi, M.; Yang, Y.; Van Mierlo, J.; Hegazy, O. Modelling, Analysis and Performance Evaluation of Power Conversion Unit in G2V/V2G Application—A Review. Energies 2018, 11, 1082.

- Urcan, D.C.; Bica, D. Integrating and modeling the Vehicle to Grid concept in Micro-Grids. In Proceedings of the International Conference on ENERGY and ENVIRONMENT (CIEM), Timisoara, Romania, 17–18 October 2019; pp. 299–303.

- Jarraya, F.; Khan, A.; Gastli, A.; Ben-Brahim, L.; Hamila, R. Design considerations, modelling, and control of dual-active full bridge for electric vehicles charging applications. J. Eng. 2019, 2019, 8439–8447.

- Al-Ogaili, A.S.; Aris, I.B.; Verayiah, R.; Ramasamy, A.; Marsadek, M.; Rahmat, N.A.; Hoon, Y.; Aljanad, A.; Al-Masri, A.N. A Three-Level Universal Electric Vehicle Charger Based on Voltage-Oriented Control and Pulse-Width Modulation. Energies 2019, 12, 2375.

- Dini, P.; Saponara, S. Review on Model Based Design of Advanced Control Algorithms for Cogging Torque Reduction in Power Drive Systems. Energies 2022, 15, 8990.

- Dini, P.; Saponara, S. Model-Based Design of an Improved Electric Drive Controller for High-Precision Applications Based on Feedback Linearization Technique. Electronics 2021, 10, 2954.

- Rasool, H.; Verbrugge, B.; Zhaksylyk, A.; Tran, T.M.; Baghdadi, M.E.; Geury, T.; Hegazy, O. Design Optimization and Electro-Thermal Modeling of an Off-Board Charging System for Electric Bus Applications. IEEE Access 2021, 9, 84501–84519.

- Dini, P.; Saponara, S. Electro-Thermal Model-Based Design of Bidirectional On-Board Chargers in Hybrid and Full Electric Vehicles. Electronics 2022, 11, 112.

- Chub, A.; Vinnikov, D.; Kosenko, R.; Liivik, E.; Galkin, I. Bidirectional DC–DC Converter for Modular Residential Battery Energy Storage Systems. IEEE Trans. Ind. Electron. 2020, 67, 1944–1955.

- Wang, F.; Luo, Y. Modelling of a Power Converter with Multiple Operating Modes. World Electr. Veh. J. 2018, 9, 7.

- Krismer, F.; Biela, J.; Kolar, J. A comparative evaluation of isolated bi-directional DC/DC converters with wide input and output voltage range. In Proceedings of the Fourtieth IAS Annual Meeting. Conference Record of the Industry Applications Conference, Hong Kong, China, 2–6 October 2005; Volume 1, pp. 599–606.

- Shah, S.S.; Iyer, V.M.; Bhattacharya, S. Exact Solution of ZVS Boundaries and AC-Port Currents in Dual Active Bridge Type DC–DC Converters. IEEE Trans. Power Electron. 2019, 34, 5043–5047.

- Vieira, A.; Mazza, L.; Antunes, F.; Oliveira, D. Bidirectional dual-active-bridge DC-DC converter for vehicle-to-grid applications in DC microgrids. In Proceedings of the Simposio Brasileiro de Sistemas Eletricos (SBSE), Niteroi, Brazil, 12 May 2018; pp. 1–6.

- Li, X.; Bhat, A.K.S. Analysis and Design of High-Frequency Isolated Dual-Bridge Series Resonant DC/DC Converter. IEEE Trans. Power Electron. 2010, 25, 850–862.

- Al Attar, H.; Hamida, M.A.; Ghanes, M.; Taleb, M. LLC DC-DC Converter Performances Improvement for Bidirectional Electric Vehicle Charger Application. World Electr. Veh. J. 2022, 13, 2.

- Yildiran, N. Design Methodology and Implementation of Half-Bridge LLC Resonant Converter. In Proceedings of the International Conference on Electrical, Communication, and Computer Engineering (ICECCE), Istanbul, Turkey, 12–13 June 2020; pp. 1–6.

- Liu, C.; Liu, H.; Cai, G.; Cui, S.; Liu, H.; Yao, H. Novel Hybrid LLC Resonant and DAB Linear DC–DC Converter: Average Model and Experimental Verification. IEEE Trans. Ind. Electron. 2017, 64, 6970–6978.

- Zhang, G.; Zeng, J.; Yu, S.S.; Xiao, W.; Zhang, B.; Chen, S.Z.; Zhang, Y. Control Design and Performance Analysis of a Double-Switched LLC Resonant Rectifier for Unity Power Factor and Soft-Switching. IEEE Access 2020, 8, 44511–44521.

- Liu, F.; Ruan, X.; Huang, X.; Qiu, Y. Second Harmonic Current Reduction for Two-Stage Inverter With DCX-LLC Resonant Converter in Front-End DC–DC Converter: Modeling and Control. IEEE Trans. Power Electron. 2021, 36, 4597–4609.

- Ma, H.; Liu, Q.; Guo, J. A sliding-mode control scheme for llc resonant DC/DC converter with fast transient response. In Proceedings of the IECON—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 162–167.

- Wang, Y.; Liu, Q.; Ma, H. Discrete pulse frequency modulation control with sliding-mode implementation on LLC resonant DC/DC converter via input?output linearisation. IET Power Electron. 2014, 7, 1033–1043.

- Yao, L.; Li, D.; Liu, L. An improved large signal model of full-bridge LLC converter. PLoS ONE 2018, 13, e0205904.

- Fang, Z.; Wang, J.; Duan, S.; Liu, K.; Cai, T. Control of an LLC Resonant Converter Using Load Feedback Linearization. IEEE Trans. Power Electron. 2018, 33, 887–898.

- Al Attar, H.; Ghanes, M.; Hamida, M.; Taleb, M. Control strategies design and comparison of DC-DC LLC converter in V2X mode for electric vehicle charger application. In Proceedings of the 2021 IEEE Conference on Control Technology and Applications (CCTA), San Diego, France, 9–11 August 2021; pp. 1154–1159.

- Zheng, K.; Zhang, G.; Zhou, D.; Li, J.; Yin, S. Modeling, Dynamic Analysis and Control Design of Full-Bridge LLC Resonant Converters with Sliding-Mode and PI Control Scheme. J. Power Electron. 2018, 18, 766–777.

- Mansour, A.; Hajer, M.; Faouzi, B.; Jamel, G. Analysis and Modeling of LLC Resonant Converter Used in Electric Vehicle. In Proceedings of the International Conference on Advanced Systems and Emergent Technologies (IC_ASET), Hammamet, Tunisia, 19–22 March 2019; pp. 357–362.

- Ajmal, F.; Pan, H.; He, C.; Chen, G.; Chen, H. Pulse-width modulation control strategy for high efficiency LLC resonant converter with light load applications. IET Power Electron. 2014, 7, 2887–2894.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Revisions:

2 times

(View History)

Update Date:

26 May 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No