Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | LEONIE ASFORA SARUBBO | -- | 2045 | 2023-05-24 16:41:06 | | | |

| 2 | Lindsay Dong | Meta information modification | 2045 | 2023-05-25 02:58:19 | | | | |

| 3 | Lindsay Dong | Meta information modification | 2045 | 2023-05-25 02:58:45 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Batista, R.M.; Converti, A.; Pappalardo, J.; Benachour, M.; Sarubbo, L.A. Tools for Optimization of Biomass-to-Energy Conversion Processes. Encyclopedia. Available online: https://encyclopedia.pub/entry/44787 (accessed on 06 March 2026).

Batista RM, Converti A, Pappalardo J, Benachour M, Sarubbo LA. Tools for Optimization of Biomass-to-Energy Conversion Processes. Encyclopedia. Available at: https://encyclopedia.pub/entry/44787. Accessed March 06, 2026.

Batista, Ranielly M., Attilio Converti, Juliano Pappalardo, Mohand Benachour, Leonie A. Sarubbo. "Tools for Optimization of Biomass-to-Energy Conversion Processes" Encyclopedia, https://encyclopedia.pub/entry/44787 (accessed March 06, 2026).

Batista, R.M., Converti, A., Pappalardo, J., Benachour, M., & Sarubbo, L.A. (2023, May 24). Tools for Optimization of Biomass-to-Energy Conversion Processes. In Encyclopedia. https://encyclopedia.pub/entry/44787

Batista, Ranielly M., et al. "Tools for Optimization of Biomass-to-Energy Conversion Processes." Encyclopedia. Web. 24 May, 2023.

Copy Citation

Biomasses are renewable sources used in energy conversion processes to obtain diverse products through different technologies. The production chain, which involves delivery, logistics, pre-treatment, storage and conversion as general components, can be costly and uncertain due to inherent variability. Optimization methods are widely applied for modeling the biomass supply chain (BSC) for energy processes.

biomass supply chain

optimization models

mathematical programming

1. Introduction

The search for energy solutions to replace fossil fuels includes a set of technologies aimed at sustainable development [1]. Dependence on the oil industry is huge, but the finite nature of petroleum and its inherent environmental impacts underscore the need for ecologically friendly processes that can compete economically. Therefore, it is necessary to pay attention to the optimization of alternative processes and systems [2].

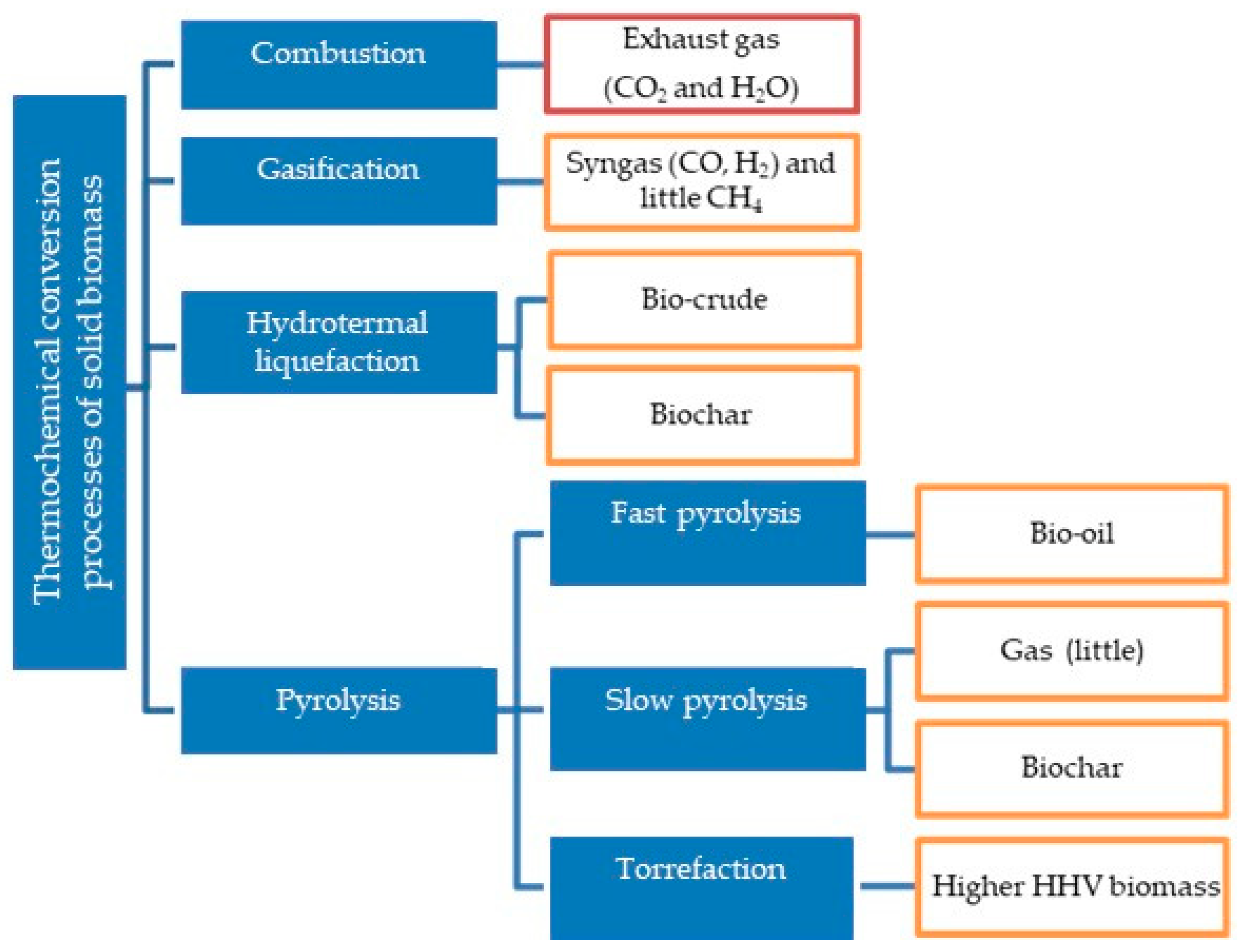

Different thermochemical technologies are used for the conversion of biomass, such as pyrolysis, gasification and direct combustion (Figure 1) [3]. Pyrolysis can occur in three forms. Torrefaction produces enhanced biomass with greater calorific power and lesser density and hygroscopicity [4], slow pyrolysis produces charcoal, and fast pyrolysis produces bio-oil. Direct combustion for the generation of thermal energy is the oldest and most consolidated technology [5][6]. The use of biomass is justified by its carbon-neutral status, i.e., the emissions of carbon dioxide are compensated by its fixation during the process of photosynthesis. As a result, an overall increase has recently been observed in the use of biofuels for electricity generation [7]. From a practical standpoint, however, this balance is not completely neutral due to the emissions involved in biomass transport and the disproportion between the replanting of native species and consumption that leads to deforestation [8]. For this reason, residual biomass (i.e., second-generation biomass) is preferable in most cases. To reduce emissions and costs, all aspects of the supply chain—planting, transporting, pre-treatment and final use—can be improved with different types of optimizations [4].

Figure 1. Thermochemical processes for production of fuels or chemical products (orange rectangles) and thermal energy (red rectangles) from solid biomass.

Optimization may involve the thermochemical processes indicated in Figure 1 or the supply chain and management processes. One of the lines of thermochemical process optimization is that concerning the combustion process itself. Improvements in combustion efficiency generally take into consideration aspects intrinsic to the reaction, such as composition, stoichiometric proportion of reagents (fuel and air), interaction of phases (liquid–gas, solid–gas) and geometry of the combustion chamber and accessories (grills, heat exchangers, etc.). Other thermodynamic processes concerning the conversion system (boiler, steam generator, etc.) can also be optimized [9]. Such measures enable the entire lower calorific power of biomass to be converted into heat for use in different processes.

From the global standpoint, the optimization of the supply chain as a whole involves supply (quality and variability of biomass), logistics, pretreatment, storage and burning. Complex logistics relating to the transport of biomass and its economic, energy use and environmental implications may be a barrier to the development of the sector due to the variations in the calorific power and density of biomass as well as its high moisture content [10][11][12][13].

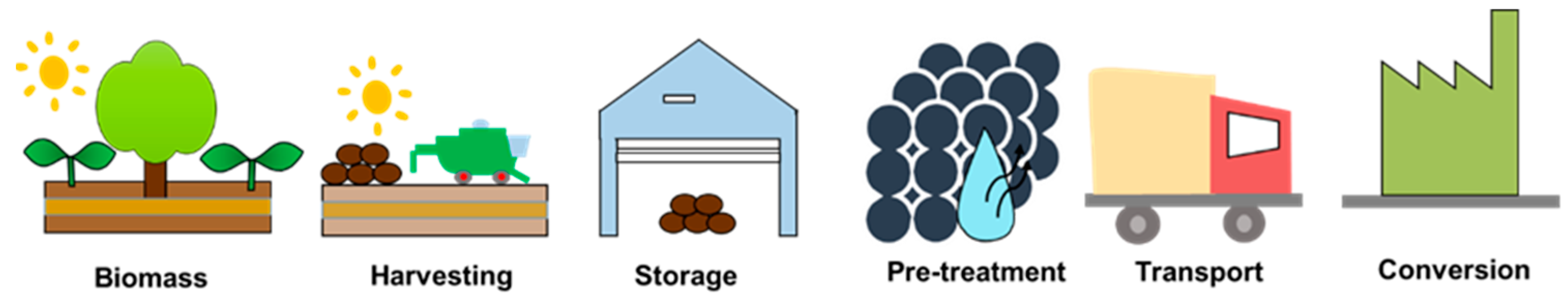

The steps of the biomass supply chain (BSC) involve the harvesting of planted biomass or the provision of residual biomass, bagging, storage in warehouses, pretreatment (fragmentation, lixiviation, drying, mixing and densification), loading, conversion in the boiler and energy distribution. Changes can occur in the order in which the steps occur, such as treatment prior to harvesting (genetic improvement, fertilization, pest control, etc.). The number of warehouses, boilers and plants depends on the process in question and logistics relating to the region, while the availability and variability of biomass depend on the endemic and adaptable species as well as the inherent seasonality. Figure 2 summarizes the basic steps.

Figure 2. General steps of biomass supply chain.

1.1. Biomass Characteristics Influencing the Supply Chain

Biomass is defined as organic material derived from plants and organic (agricultural, forest, industrial, human, animal and municipal) waste [14]. The main constituents of plant biomass are cellulose, hemicellulose and lignin, along with lipids, proteins, simple sugars, starch, inorganic compounds and moisture [15]. Biomass, such as wood, grass, agricultural waste, animal and human waste, algae, etc., is a natural, renewable source produced sustainably in large quantities in many parts of the world [16].

The composition of biomass influences the process yield and determines the need for pretreatment for cofiring. Such characteristics vary with the species and seasonal crop conditions and should be considered along with the boiler properties. A high moisture content (mass of water in the biomass per unit of dry mass or mass of water in relation to total mass) requires biomass drying, while a high concentration of inorganics, such as chlorine and potassium, suggests a lixiviation step. Steps such as pelleting and briquetting should also be evaluated. However, the greater the need for preliminary biomass treatment, the higher the costs. Moisture confers variability to the calorific power, increases transport costs due to the indirect purchasing of water, can cause obstruction of biomass in lines, and reduces the efficiency of the firing process due to the increase in time for moisture vaporization. The cause of reduced combustion efficiency due to solid biomass moisture is mainly related to a longer time required before biomass begins its combustion process (evaporation of water, volatilization, pyrolysis and combustion—Figure 3) and poorly established residence time in the boiler or furnace.

Figure 3. Biomass combustion process.

2. Modeling and Biomass Supply Chain

The use of modeling of the biomass supply chain for energy purposes has been widely explored in the literature and can assist in strategic, tactical and operational decision making. Differences exist in the comprehensiveness of the levels of decision. Regarding long-term aspects (e.g., annual), strategic decisions include the design of the boiler itself, investments, selection of suppliers, allocation of installations, etc. Medium-term aspects involving transport routes and seasonal inventories are tactical decisions. Operational problems require more frequent adjustments and involve transport planning and short-term demands [17].

According to Sun and Fan [18], the BSC problems relating to the harvesting process are those regarding scheduling forest and crop harvest, as well as the necessary equipment. There are location and shipping scheduling problems (related to storage), while network design with material flows and vehicle routes is expected to generate transport problems.

In general, there is a preponderance of the economic focus in optimization of the biomass supply chain, with limited attention given to the reduction in the carbon emissions of this chain [19].

Modeling of the biomass supply chain could be single-objective or multi-objective, with various goals to be optimized at the same time [20]. According to Albashabsheh and Stamm [21], the use of deterministic methods presupposes prior knowledge of all parameters. In contrast, other researchers take into consideration uncertainties and more realistic random parameters relating to the supply, transport and demand for biofuels as well as the prices of biofuels and biomass, thus characterizing a stochastic or hybrid model when combined with the deterministic model. The need emerges to make the optimal solution feasible, independently of the uncertainty (distributions of probability), and sensitivity analysis could be performed with variation in the input parameters [21][22].

2.1. Geographic Information Systems—GISs

Geographic information systems (GISs) use interactive maps for managing geographic and spatial data, helping decision makers analyze processes. Geographical issues are a factor that can affect the feasibility of a project due to the location provided by longitude and altitude parameters [23][24].

GISs are a useful tool for identifying, selecting and optimizing locations of bioenergy plants considering physical, biological, social and economic criteria [11]. GIS systems enable superimposing data from different disciplines, such as vegetation cover and demographic density, on useful maps for BSC managers of BSC. According to Kim et al. [25], GISs have been used for the precise analysis of transport distances, costs and impacts of different projects; facilitating the selection of sites as sources of biomass and their yields; determining suitable areas to build facilities (strategic decisions); calculating changes in routes (road network) and regions of demand and high densities; and considering factors such as water flows, electricity networks for infrastructure, and population for labor. They are used to help design, plan and manage problems in the BSC [18][24]. This type of consideration and simulation helps to achieve, for example, minimization of costs in the BSC.

2.2. Neural Networks

Neural networks are mathematical models of stochastic nature composed of units or nodes called neurons that can predict system outputs with high precision, low cost, and short processing time [26]. They are based on two stages: training and validation. A set of input data and respective output data are provided in the training step. The modeled neural network is formed by a set of layers and weights. The input layer receives the input data, the output layer provides the result, and the hidden layers enable the neural network to operate through activation functions [27].

A neural network needs data collection, pre-processing of data, optimizing of the network design (number of hidden layers, neurons and activated transfer functions, algorithm selection). The linear transfer functions (Purelin and Poslin), Log-Sigmoid function (Logsig), and Tan-Sigmoid function (Tansig) are often reported in the literature. To train the network and obtain the best weights of neurons, algorithms such as quasi-Newton (QN), sealed conjugate (SC) and Levenberg–Marquardt (LM) are cited by Yatim et al. [26] and Güleç et al. [28].

Neural networks can be applied in the context of seasonal variability in the composition and supply of biomass for production chain situations in which the volume of data enables computational algorithms to learn from varied examples.

As “machine learning” establishes, the program is capable of providing outputs based on new inputs—like a human brain would do—after having learned to relate inputs and outputs that are related in a highly nonlinear, complex way. In this regard, artificial neural networks were utilized to predict biomass pyrolysis behavior without known reaction mechanisms [29]. Zhang et al. [30] reported the use of neural networks to predict HHV, enthalpies of combustion and other exergetic data based on biomass composition.

2.3. Linear Programming

The optimization method known as linear programming is widely employed because it also helps in decision making with regards to production planning. This mathematical model of deterministic origin involves an objective function to be either maximized or minimized (the objective function generally regards the overall operating cost of a plant when applied to the optimization of biomass supply chains for energy purposes) and a set of restrictions (mathematical expressions, such as linear equations or inequations) that address the selected decision variables (outputs) and parameters (inputs) [31][32].

The objective may be to understand the maximization of profit, minimization of operating costs, environmental impact or fuel consumption. The general restrictions of a supply chain model regard the availability of biomass, processing capacities and market demands, establishing limits to be met [20].

Table 1 summarizes some applications of mathematical modeling relating to biomass, especially linear programming, which is often used with other tools and techniques. Through these models, there has been a broad approach to programming, with most of them minimizing the global cost. It can be noted that at this stage, the biorefinery or plant does not have a large enough volume of data to allow it to use other techniques. In general, the previous integrated use of GIS makes it possible to indicate the vegetation cover and its space–time variability, supporting the definition of locations for the installation of thermoelectric conversion plants and biorefineries.

Table 1. Summary of studies involving the use of mathematical modeling of biomass supply chain.

| Authors | Type of Modeling/Solver | Factors Considered | Objective |

|---|---|---|---|

| Cundiff et al. [33] | Linear programming (LP) optimization software package CPLEX | Storage Transport Losses with storage and handling Production uncertainty due to weather |

Minimize costs relating to transport and expansion capacity in warehouses |

| Nienow et al. [34] | Linear programming (LP) | Cofiring Production of wood biomass Transport Use |

Minimize cost of production of particular demand for electricity while meeting environmental regulations |

| Bruglieri and Liberti [35] | Mixed integer nonlinear programming (MINLP) Mixed integer linear programming (MILP) optimization software package CPLEX |

Different biomass transformation processes Commodities Transport Processing |

Minimize costs of commodities, transport and processing |

| Rocco and Morabito [36] | Mixed Integer linear programming (MILP) | Purchasing Transport Storage Multiple boilers with different aspects (switch on, heating and switch off) |

Minimize costs of biomass supply chain for steam production: purchasing, fuel transport, storage and switching on and heating of boilers |

| Saghaei et al. [37] | Stochastic programming MINLP Metaheuristics Genetic algorithms (GAs) Chaos theory Tent maps CE (ICE) algorithm |

Suppliers Storage Energy plants Consumers |

Minimize costs; identify optimal size and location, flow between sectors, volumes of stored and converted materials, and distribution strategy |

References

- Sikkema, R.; Proskurina, S.; Banja, M.; Vakkilainen, E. How can solid biomass contribute to the EU’s renewable energy targets in 2020, 2030 and what are the GHG drivers and safeguards in energy—And forestry sectors? Renew. Energy 2021, 165, 758–772.

- Lora, E.S.; Andrade, R.V. Biomass as energy source in Brazil. Renew. Sustain. Energy Rev. 2009, 13, 777–788.

- Zhang, X.; Brown, R.C. Introduction to Thermochemical Processing of Biomass into Fuels, Chemicals, and Power. In Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and Power, 2nd ed.; Brown, R.C., Ed.; John Wiley & Sons: Chichester, UK, 2019; ISBN 9781119417576.

- Basu, P. Biomass Gasification and Pyrolysis: Practical Design and Theory; Academic Press: Boston, MA, USA, 2010; ISBN 9780123749888.

- Kumar, R.P.; Bharathiraja, B.; Kataki, R.; Moholkar, V.S. (Eds.) Biomass Valorization to Bioenergy; Springer: Singapore, 2020; ISBN 9789811504105.

- Siwal, S.S.; Sheoran, K.; Saini, A.K.; Vo, D.N.; Wang, Q.; Thakur, V.K. Advanced thermochemical conversion technologies used for energy generation: Advancement and prospects. Fuel 2022, 321, 124107.

- Renewables—Fuels & Technologies—IEA. Available online: https://www.iea.org/fuels-and-technologies/renewables (accessed on 15 April 2022).

- Gemechu, E.D.; Oyedun, A.O.; Norgueira, E., Jr.; Kumar, A. Life Cycle Assessment of the Environmental Performance of Thermochemical Processing of Biomass. In Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and Power, 2nd ed.; Brown, R.C., Ed.; John Wiley & Sons: Chichester, UK, 2019; ISBN 9781119417576.

- Silva, J.P.; Teixeira, S.; Grilo, E.; Peters, B.; Texeira, J.C. Analysis and monitoring of the combustion performance in a biomass power plant. Clean. Eng. Technol. 2021, 5, 100334.

- Schnorf, V.; Trutnevyte, E.; Bowman, G.; Burg, V. Biomass transport for energy: Cost, energy and CO2 performance of forest wood and manure transport chains in Switzerland. J. Clean. Prod. 2021, 293, 125971.

- Wang, Y.; Wang, J.; Schuler, J.; Hartley, D.; Volk, T.; Eisenbies, M. Optimization of harvest and logistics for multiple lignocellulosic biomass feedstocks in the northeastern United States. Energy 2020, 197, 117260.

- Brand, M.A.; Rodrigues, T.M.; Da Silva, J.P.; De Oliveira, J. Recovery of agricultural and wood wastes: The effect of biomass blends on the quality of pellets. Fuel 2021, 14, 6486.

- Paolucci, N.; Bezzo, F.; Tugnoli, A. A two-tier approach to the optimization of a biomass supply chain for pyrolysis processes. Biomass Bioenergy 2016, 84, 87–97.

- Narnaware, S.L.; Panwar, N.L. Biomass gasification for climate change mitigation and policy framework in India: A review. Bioresour. Technol. Rep. 2021, 17, 100892.

- Mandø, M. Direct combustion of biomass. In Biomass Combustion Science, Technology and Engineering; Rosendahl, L., Ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 61–83. ISBN 9780857091314.

- Liu, W.; Liu, C.; Gogoi, P.; Deng, Y. Overview of Biomass Conversion to Electricity and Hydrogen and Recent Developments in Low-Temperature Electrochemical Approaches. Engineering 2020, 6, 1351–1363.

- Cao, J.X.; Zhang, Z.; Zhou, Y. A location-routing problem for biomass supply chains. Comput. Ind. Eng 2021, 152, 107017.

- Sun, O.; Fan, N. A Review on optimization methods for biomass supply chain: Models and algorithms, sustainable issues, and challenges and opportunities. Process. Integr. Optim. Sustain. 2020, 4, 203–226.

- Yahya, N.S.M.; Ng, L.Y.; Andiappan, V. Optimisation and planning of biomass supply chain for new and existing power plants based on carbon reduction targets. Energy 2021, 237, 121488.

- Ng, W.P.Q.; How, B.S.; Lim, C.H.; Ngan, S.L.; Lam, H.L. Biomass supply chain synthesis and optimization. In Value-Chain of Biofuels: Fundamentals, Technology, and Standardization; Yusup, S., Rashidi, N.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 445–479. ISBN 9780323858991.

- Albashabsheh, N.; Stamm, J.L.H. Optimization of lignocellulosic biomass-to-biofuel supply chains with densification: Literature review. Biomass Bioenergy 2020, 144, 105888.

- Sowlati, T. Modeling of forest and wood residues supply chains for bioenergy and biofuel production. In Biomass Supply Chains for Bioenergy and Biorefining; Holm-Nielsen, J.B., Ehimen, E.A., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 167–190. ISBN 9781782423669.

- Balaman, Ş.Y. Modeling and Optimization Approaches in Design and Management of Biomass-Based Production Chains. In Decision-Making for Biomass-Based Production Chains: The Basic Concepts and Methodologies; Balaman, Ş.Y., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 185–236. ISBN 9780128142783.

- Vukašinović, V.; Gordić, D. Optimization and GIS-based combined approach for the determination of the most cost-effective investments in biomass sector. Appl. Energy 2016, 178, 250–259.

- Kim, J.; Realff, M.J.; Lee, J.H.; Whittaker, C.; Furtner, L. Design of biomass processing network for biofuel production using an MILP model. Biomass Bioenergy 2011, 35, 853–871.

- Yatim, F.E.; Boumanchar, I.; Srhir, B.; Chhiti, Y.; Jama, C.; Alaoui, F.E.M. Waste-to-energy as a tool of circular economy: Prediction of higher heating value of biomass by artificial neural network (ANN) and multivariate linear regression (MLR). Waste Manag. 2022, 153, 293–303.

- Pappalardo, J.R. Future Perspective on Micro Gas Turbines Associated with Biogas Production. Master’s Thesis, University of Genoa, Genoa, Italy, 2017.

- Güleç, F.; Pekaslan, D.; Williams, O.; Lestera, E. Predictability of higher heating value of biomass feedstocks via proximate and ultimate analyses—A comprehensive study of artificial neural network applications. Fuel 2022, 320, 590–603.

- Zhong, Y.; Ding, Y.; Jiang, G.; Lu, K.; Li, C. Comparison of Artificial Neural Networks and kinetic inverse modeling to predict biomass pyrolysis behavior. J. Anal. Appl. Pyrolysis 2023, 169, 105802.

- Zhang, Y.; Ji, Y.; Qian, H. Progress in thermodynamic simulation and system optimization of pyrolysis and gasification of biomass. GreenChE 2021, 2, 266–283.

- Matoušek, J.; Gärtner, B. Understanding and Using Linear Programming; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 9783540307174.

- Belfiore, P.; Fávero, L.P. Pesquisa Operacional Para Cursos de Engenharia; Elsevier: Rio de Janeiro, Brazil, 2013; ISBN 9788535248937.

- Cundiff, J.S.; Dias, N.; Sherali, H.D. A linear programming approach for designing a herbaceous biomass delivery system. Bioresour. Technol. 1997, 57, 47–55.

- Nienow, S.; Mcnamara, K.T.; Gillespie, A.R. Assessing plantation biomass for co-firing with coal in northern Indiana: A linear programming approach. Biomass Bionergy 2000, 18, 125–135.

- Bruglieri, M.; Liberti, L. Optimal running and planning of a biomass-based energy production process. Energy Policy 2008, 36, 2430–2438.

- Rocco, C.D.; Morabito, R. Um modelo de otimização para as operações de produção de vapor em caldeiras industriais. Gest. Prod. 2012, 19, 273–286.

- Saghaei, M.; Ghaderi, H.; Soleimani, H. Design and optimization of biomass electricity supply chain with uncertainty in material quality, availability and market demand. Energy 2020, 197, 117165.

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

3 times

(View History)

Update Date:

25 May 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No