Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mladen Bošnjaković | -- | 3648 | 2023-05-18 03:06:31 | | | |

| 2 | Peter Tang | Meta information modification | 3648 | 2023-05-18 03:08:20 | | | | |

| 3 | Peter Tang | Meta information modification | 3648 | 2023-05-18 03:09:34 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Bošnjaković, M.; Katinić, M.; Santa, R.; Marić, D. Wind Turbine Technology Trends. Encyclopedia. Available online: https://encyclopedia.pub/entry/44461 (accessed on 01 March 2026).

Bošnjaković M, Katinić M, Santa R, Marić D. Wind Turbine Technology Trends. Encyclopedia. Available at: https://encyclopedia.pub/entry/44461. Accessed March 01, 2026.

Bošnjaković, Mladen, Marko Katinić, Robert Santa, Dejan Marić. "Wind Turbine Technology Trends" Encyclopedia, https://encyclopedia.pub/entry/44461 (accessed March 01, 2026).

Bošnjaković, M., Katinić, M., Santa, R., & Marić, D. (2023, May 18). Wind Turbine Technology Trends. In Encyclopedia. https://encyclopedia.pub/entry/44461

Bošnjaković, Mladen, et al. "Wind Turbine Technology Trends." Encyclopedia. Web. 18 May, 2023.

Copy Citation

The rise in prices of traditional energy sources, the high dependence of many countries on their import, and the associated need for security of supply have led to large investments in new capacity of wind power plants. Although wind power generation is a mature technology and levelized cost of electricity low, there is still room for its improvement.

wind turbine

development trend

electricity

renewable energy sources

1. Introduction

Environmental problems, air pollution and major climate changes are being solved by the use of renewable energy sources, with wind energy playing a leading role. In Europe, this is further accentuated by the difficult procurement of classic sources of energy, oil and natural gas, due to the war in Ukraine and disrupted trade relations with Russia. The technology for using wind energy has made great progress in the last two decades and is now mature. Large investments in the future capacity of wind turbines have also encouraged investment in further improving wind turbine technology to make electricity generation as reliable, efficient and cost-effective as possible.

Due to the pandemic of the COVID-19 virus, there was a delay in the installation of new renewable energy capacity and difficulties in procuring traditional energy sources. Hence, many countries are rapidly increasing their investments in their own renewable energy sources. In addition to this negative aspect, the COVID-19 pandemic has initiated an analysis of project delays and opportunities to increase productivity and shorten manufacturing times of plant components [1]. Europe, as the world’s leading region for wind turbine manufacturing with extensive experience in this field, should continue on the path of wind turbine development and technological improvement. According to IRENA (International Renewable Energy Agency, Masdar City, Abu Dhabi), the total capacity of onshore wind farms is expected to triple by 2030 and quadruple by 2050 [2].

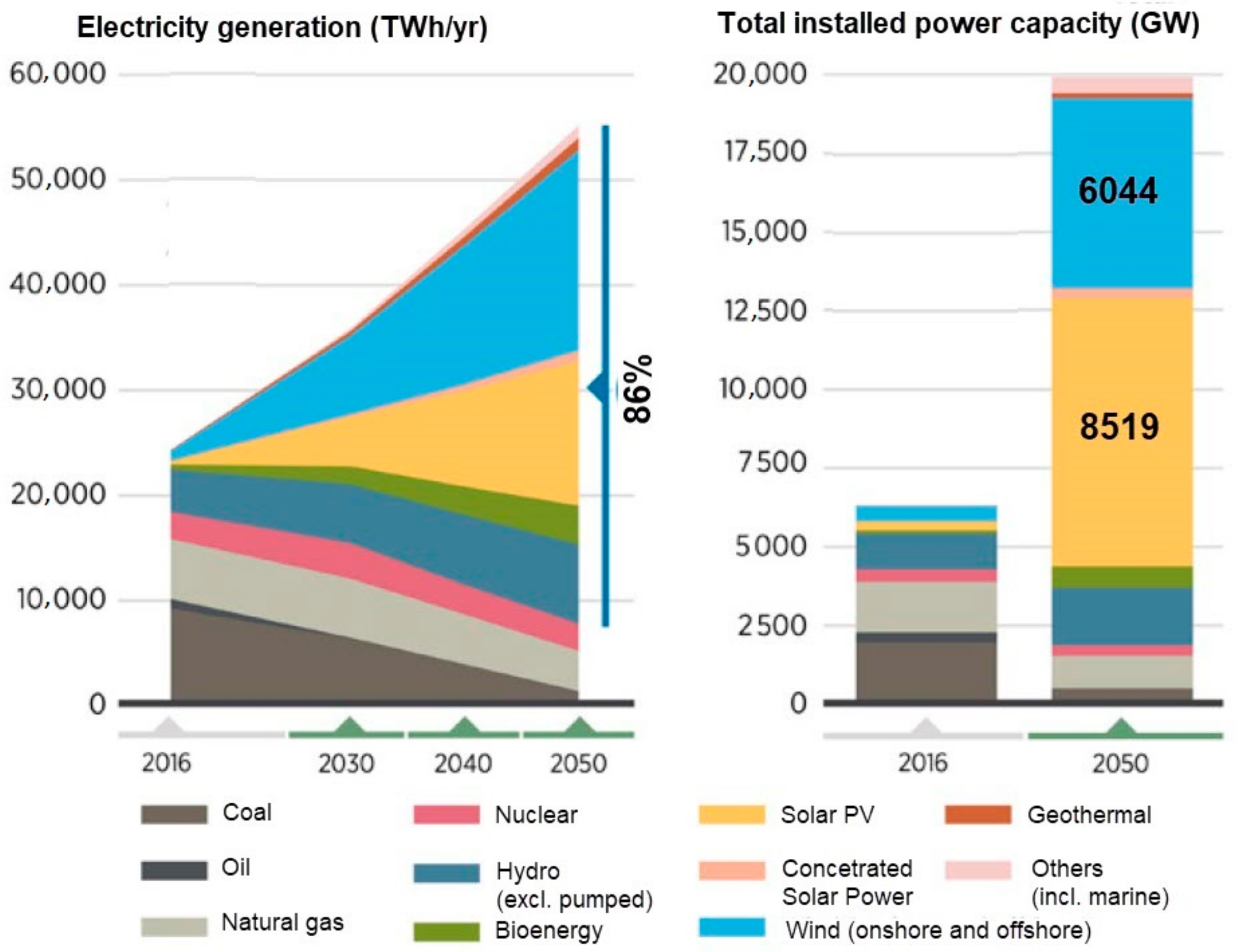

The Russian invasion of Ukraine has led to a sharp increase in the prices of basic products, especially fuel. Security of energy and food supplies is a growing concern in Europe and around the world. From the second half of 2021, energy prices in Europe and the world increased. The situation has also been affected by Russia’s decision to suspend gas supplies to some European Union member states. The leaders of the 27 European Union (EU-27) member states have agreed on the need to reduce dependence on Russian fossil fuels and accelerate the transition to renewable energy sources. This could mean shortening the planned dates for the installation of wind turbines, which would lead to a sharp increase in electricity production. In other words, the energy projections for 2030 and 2050 could be realized earlier (Figure 1) [2]. However, this will require a major effort, as 17 GW of new wind energy capacity was installed in Europe in 2021, including 11 GW in the EU-27, which is less than half of the EU’s plan to meet its climate and energy targets by 2030.

Figure 1. Predictions about the method of power generation [2].

Onshore wind farms account for 81% of new capacity in Europe in 2021, with Sweden, Germany, and Turkey making the largest contributions. In terms of new offshore global wind capacity, 21.1 GW was commissioned 2021, three times more than in 2020, making 2021 the best year in the history of offshore wind. At the same time, China accounted for 80% of the global offshore wind capacity added in 2021. In onshore wind farms, China has overtaken Europe to become the largest onshore wind market, accounting for nearly one-third of the world’s installed capacity [2].

The installation of a planned 6044 GW of wind energy can generate more than one-third of the total electricity demand in 2050. This would reduce energy-related carbon emissions by 6.3 gigatons of CO₂, which is more than a quarter of the total emissions reduction potential from renewable energy sources and energy efficiency measures.

At the same time, it is predicted that the price of electricity generated by wind farms will decrease (Table 1), as will investment costs (Table 2) [2].

Table 1. Levelized cost of electricity from wind energy [2].

|

2010 |

2018 |

2030 |

2050 |

|

|---|---|---|---|---|

|

Onshore wind ($/kWh) |

0.08 |

0.06 |

0.03–0.05 |

0.02–0.03 |

|

Offshore wind ($/kWh) |

0.16 |

0.13 |

0.05–0.09 |

0.03–0.07 |

Table 2. Total installation cost * [2].

|

2010 |

2018 |

2030 |

2050 |

|

|---|---|---|---|---|

|

Onshore wind ($/kWh) |

1913 |

1497 |

800–1350 |

650–1000 |

|

Offshore wind ($/kWh) |

4572 |

4353 |

1700–3200 |

1400–2800 |

* IRENA takes inflation into account in levelized cost of electricity and installation cost.

2. Onshore Wind Turbine Development

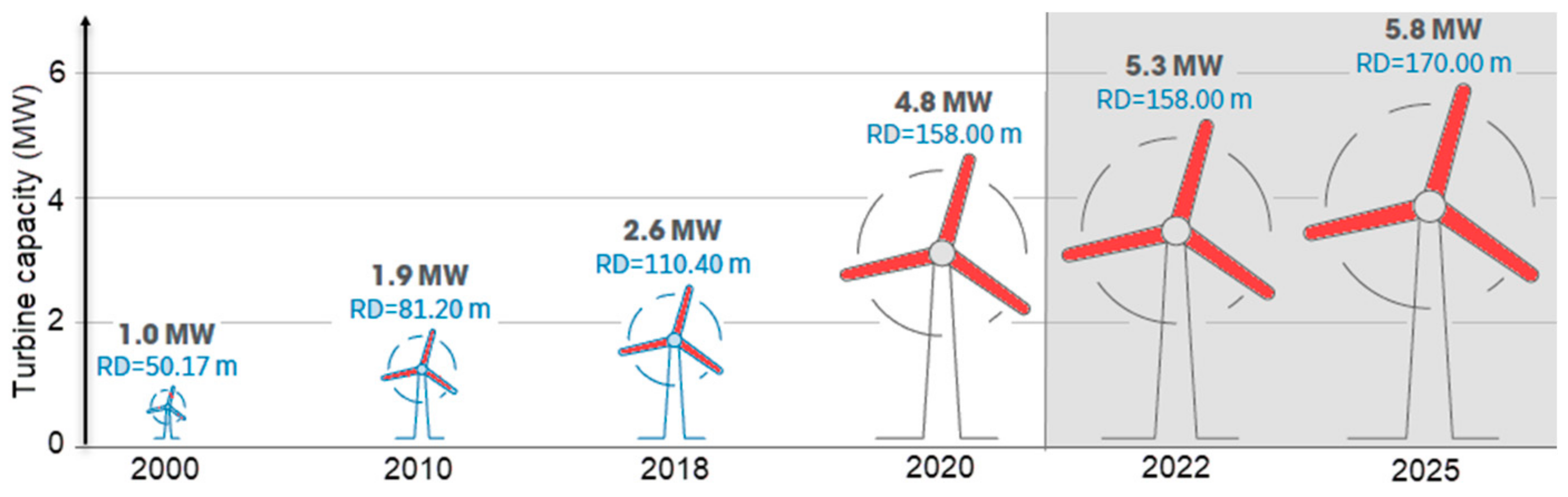

Based on available literature, it was determined that wind turbine development in the coming decade will be based on increasing wind turbine power and thus dimensions, as well as minor design improvements (Figure 2 and Figure 3).

Figure 2. Power and rotor diameters of existing and planned onshore wind farms [2].

Figure 3. Power and rotor diameters of existing and planned offshore wind farms [2].

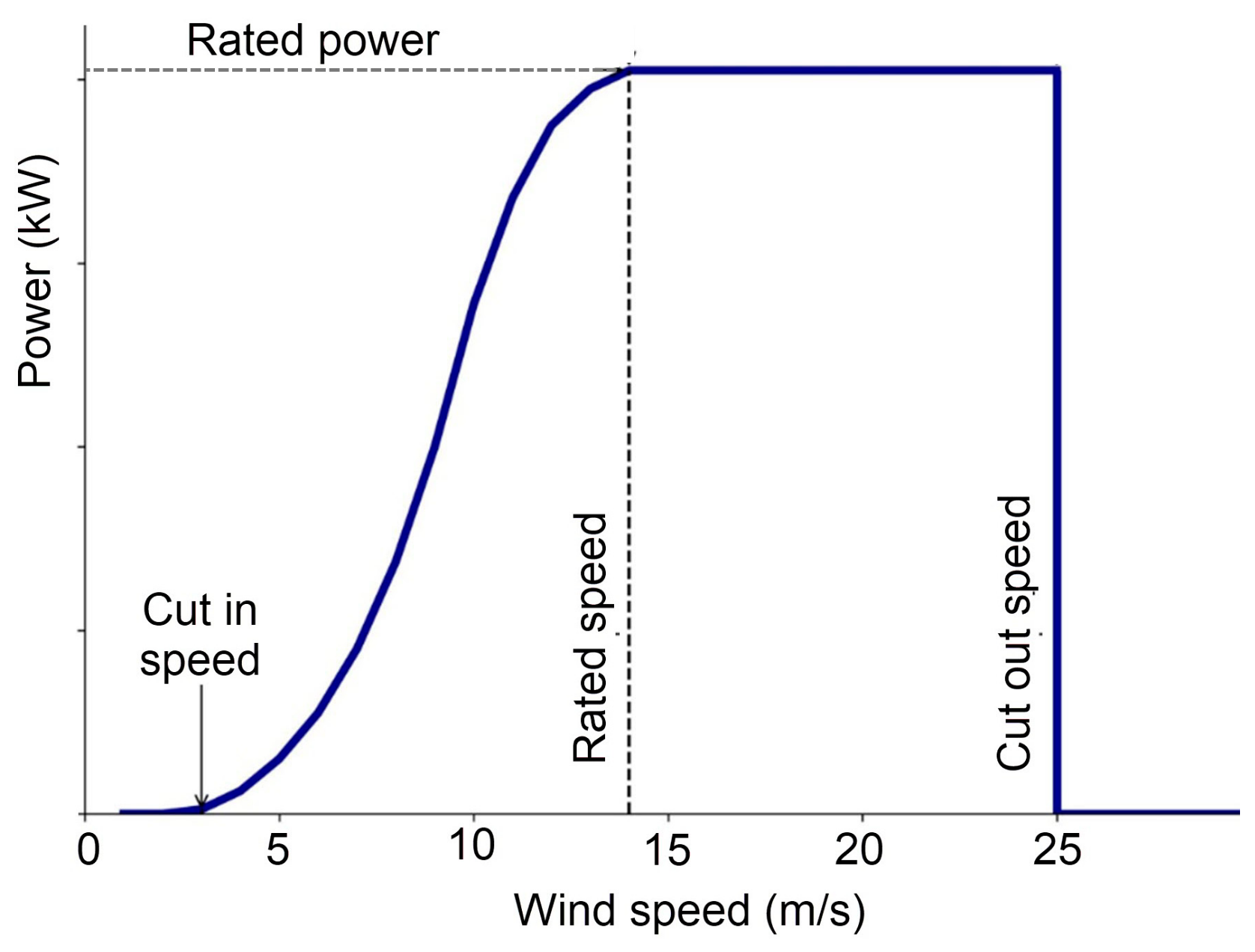

These improvements include further enhancements to the rotor blade aerodynamics, wind farm operational management system, and maintenance and fault diagnosis system, resulting in improved wind farm efficiency, reliability, and availability [3]. The power curve of a wind turbine (Figure 4) shows the output power of the turbine at different wind speeds. The annual electricity production of a wind turbine depends, among other things, on two important points on the power curve: the wind speed at which the wind turbine is turned on, and the wind speed at which the wind turbine is turned off, so that there is no excessive stress and damage to the parts of the wind turbine if the wind speed continues to increase.

Figure 4. Typical wind turbine power curve.

The lower the cut-in speed and the higher the cut-out speed, the more energy the wind turbine will produce on an annual basis. The development of wind turbines that generate energy at low wind speeds theoretically expands the possibility of constructing wind farms in areas with lower average annual wind speeds. Therefore, the researchers analyze at what electricity price such a wind turbine (e.g., with a capacity of 3.4 MW and a rotor diameter of 208 m) would be competitive in the European electricity system. Although the electricity price of such a power plant is currently 45% higher than that of a conventional onshore wind turbine with the same hub height, it has been shown that this technology could yield more than twice as much as conventional turbines in the future European electricity system in areas where lower wind speeds prevail [4].

Similarly, Figure 4 shows that it is desirable to design wind turbines so that they can still produce electricity in extremely strong winds (shifting the boundary to the right). Even for existing wind turbines, it is possible to improve the power curve of the wind turbine by updating the control system. In doing so, the wind turbine may be subjected to severe vibration and stress on the one hand, but on the other hand, the increase in production energy is significant [5].

Currently, various mechanical and aerodynamic braking systems are implemented to control the overspeed of wind turbines at extreme wind speeds. A recent approach attempts to aerodynamically control the overspeed of wind turbines by placing chord slots (openings). By placing the slots, the pressure distribution on the blade surface is altered and the wind turbine speed is reduced within allowable limits. In this way, the excessive speed of the turbine rotor is effectively reduced without affecting energy production. In the work of Kumar et al. [6], the effects of various slot parameters on the chord, such as the position and length of the slot, on power generation were analyzed and the slot parameters were optimized experimentally and computationally.

3. Offshore Wind Turbine Development

Offshore wind turbine design is challenging due to the wide and complex range of design parameters, as well as varying operational requirements and harsh environmental conditions. The service life of offshore wind turbines is typically 50 years, although the foundations are designed to last longer. The tower must be able to withstand static, dynamic, and cyclic loads and their critical combinations, so proper material fatigue analysis is required [7]. To solve these challenges, various optimization techniques are used. With them, it is possible to obtain optimized parameters for different designs of offshore wind turbines while balancing the effects on energy production and wind turbine lifetime. The work of Chen and Kim [8] gives an overview of the basic principles of various critical optimization techniques and their application in the design process of offshore wind turbines. The work of Sunday and Brennan [9] and Trojnar [10] provides a concise overview of important technical aspects, recent improvements in the design of offshore wind turbines on monopiles, and the challenges of future monopile designs with respect to increasing monopile size and turbine performance. The analysis focuses primarily on foundation-tower connections, damping for monopile structural analysis, modeling of soil-monopile interaction, and corrosion. The calculations performed have confirmed that the displacement of the hybrid monopile is 40–70% lower compared to a standard monopile with similar dimensions. An important part of foundation costs relates to protection against scouring, as drifting of material can lead to instability and collapse of the structure. Research by Fazeres-Ferrados [11] shows that scour protection in foundations is a very challenging area of research that still leaves many questions open.

Numerous other works also address the issue of structural optimization considering structural stresses [12][13], the stresses in large diameter flanges in the primary load path of wind turbine foundations, usually found at the base of turbine towers [14]. The new design of floating hybrid platforms will reduce the cost of the overall system due to faster erection and less amount of steel. The project of floating wind farm “Salamander” of Ocergy in 2021 allowed insights into the technology of substructures.

Increasing the rated power of the wind turbine is one of the most important ways to reduce the cost of electricity generation from offshore wind farms. Manufacturers prefer one larger wind turbine to building several smaller wind turbines for the same output, which lowers the cost per installed kilowatt of power [15].

The largest operating wind turbine in the world is the prototype GE Haliade-X in Rotterdam, which by increasing the output of the generator has a capacity of 13 MW. The practice of increasing the power output of an existing turbine by increasing the generator and drivetrain capacity with the same rotor is common among OEMs (Original Equipment Manufacturer) in offshore wind markets. It is a way to increase the power output of the wind turbine on the same platform without making changes to the blade design. Increasing the output of the generator can produce more power and improve efficiency, but increased material fatigue due to increased loading and reduced life must be carefully considered [16].

The benefits of increasing performance by scaling dimensions are potentially even greater than for land-based turbines. In the work of Papi et al. [17], a critical analysis of the technical implications of upscaling was given, focusing on the aerodynamics of the blades and the stress and elasticity of the structure. The study is based on the reference floating wind turbines NREL 5 MW and IEA 15 MW.

Vibration control of a floating wind turbine becomes increasingly important as the size of the wind turbine increases. Therefore, a new three-branch mooring system for Spar-type floating wind turbines is proposed in the work of Liu et al. [18]. The sway, pitch and yaw motions of the wind turbine in regular and irregular waves are calculated to quantify the performance of the mooring system. In the work of Jahani et al. [19], the main issues related to the structural dynamics of offshore wind turbines were analyzed, including modal alignment, aeroelasticity, hydroelasticity, bottom interaction, mooring cable-float interaction, drivetrain vibration, and others.

Offshore wind turbines can be sized larger because their transportation is not as problematic as onshore wind turbines. Vestas plans to develop a 15 MW wind turbine, with a prototype expected to enter service in 2022. With a rotor diameter of 236 m, this wind turbine will have a larger wind-swept area than any other turbine in operation. Series production is planned for 2024 [16].

Floating wind farms are a major breakthrough in ocean energy technology. Floating foundations offer two important opportunities:

-

they provide access to sites with water depths greater than 60 m, and

-

they facilitate turbine installation even in intermediate water depths (30–50 m) and could ultimately provide a lower-cost alternative to fixed foundations. In general, floating foundations have environmental benefits compared to fixed foundations because less seabed intervention is required during installation.

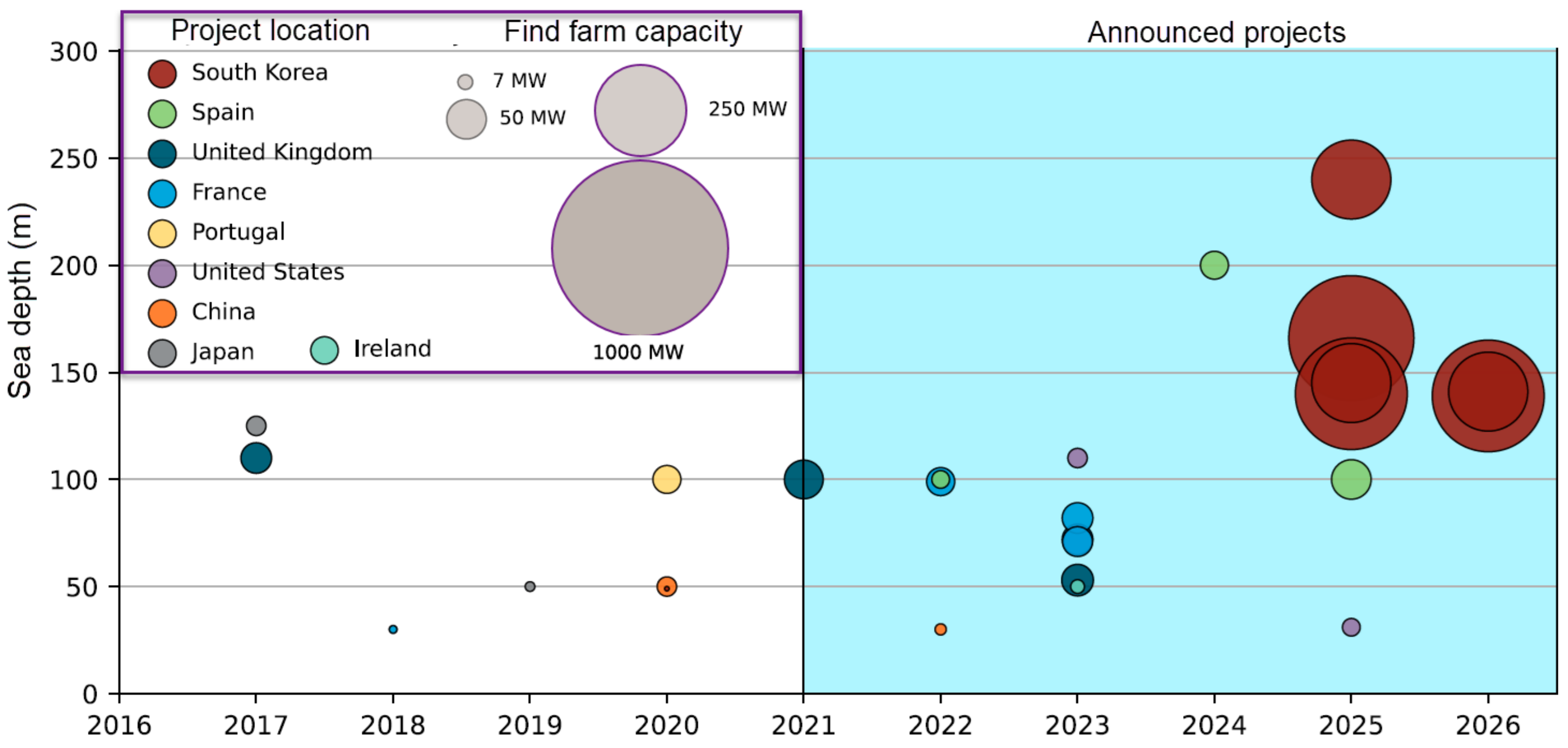

Floating wind turbines can be installed far offshore and in deep waters. The shift to offshore will increase the use of offshore wind farms. There are plans to install more floating wind turbines in Southeast Asia, Oceania, and Northern Europe (Figure 5).

Figure 5. Global floating offshore wind energy projects by depth, country, and project size [16].

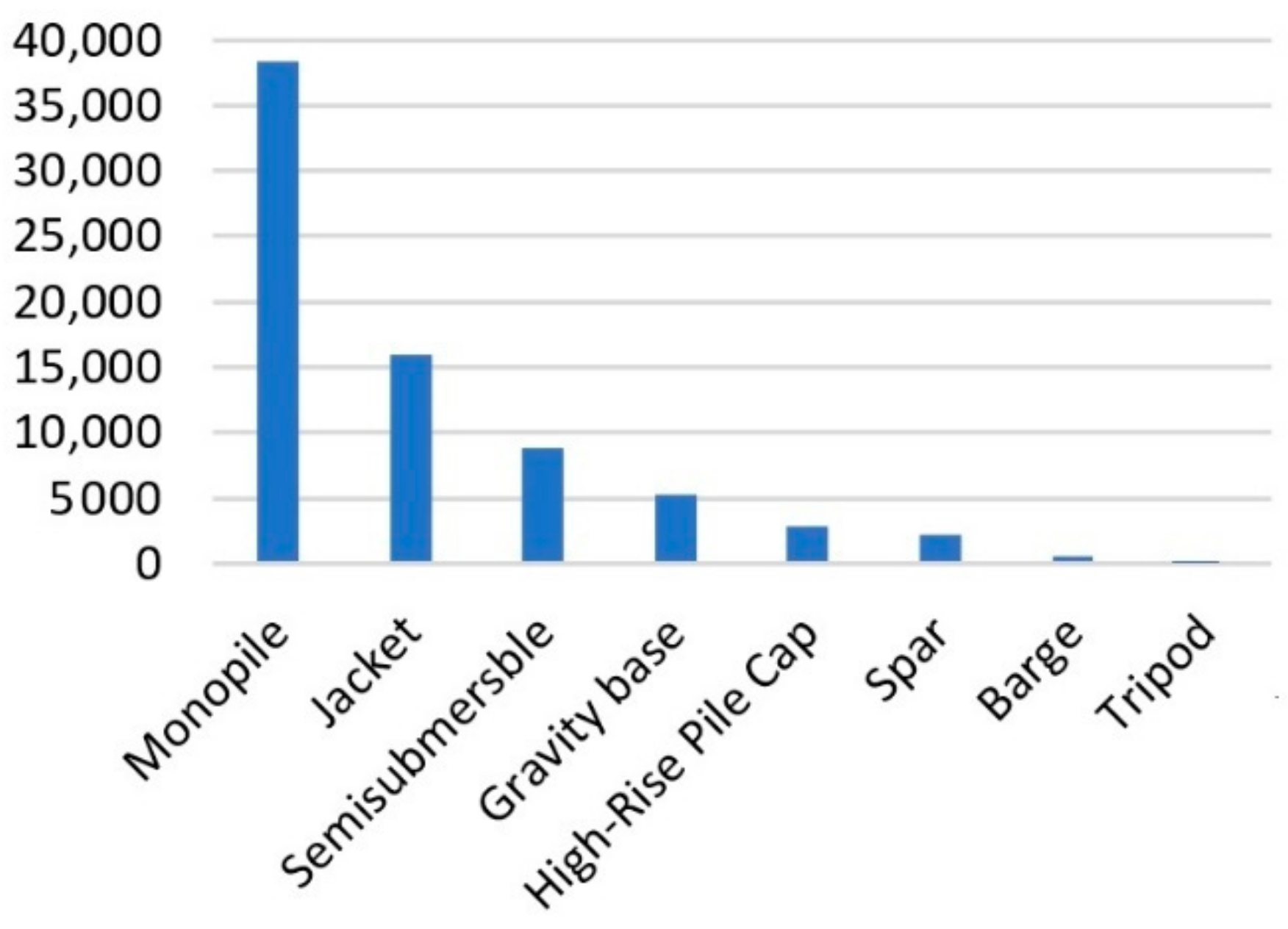

The most common foundation type for offshore wind turbines (OWT) is the monopile: a single pile six to eight meters in diameter and 20 to 30 m long below the seabed. It accounts for about 80% of the installed OWT foundations.

Figure 6 shows the technology of offshore wind substructure for future projects. The use of jacket foundations will be more than quadruple in future projects. In addition, the share of monopiles will decrease to 51.6% of the market. This change is due to the fact that projects are planned for deeper waters and increasing manufacturing capabilities for jackets. The share of floating foundations is also increasing. However, the industry’s ability to adapt monopiles to deeper waters while maintaining low costs could result in monopiles remaining the dominant foundation type for some time. Based on information about planned projects, gravity foundations will increase their market share because they are better suited to rocky soils where it can be difficult to drive monopiles.

Figure 6. Announced offshore wind foundation types in future projects [16].

Most floating wind farm projects provide for a semi-submersible substructure. The advantage of this type of substructure is a relatively shallow draft and hydrodynamic stability during operation of the wind turbine. This allows for dockside installation and towing to the site without the use of heavy lift vessels.

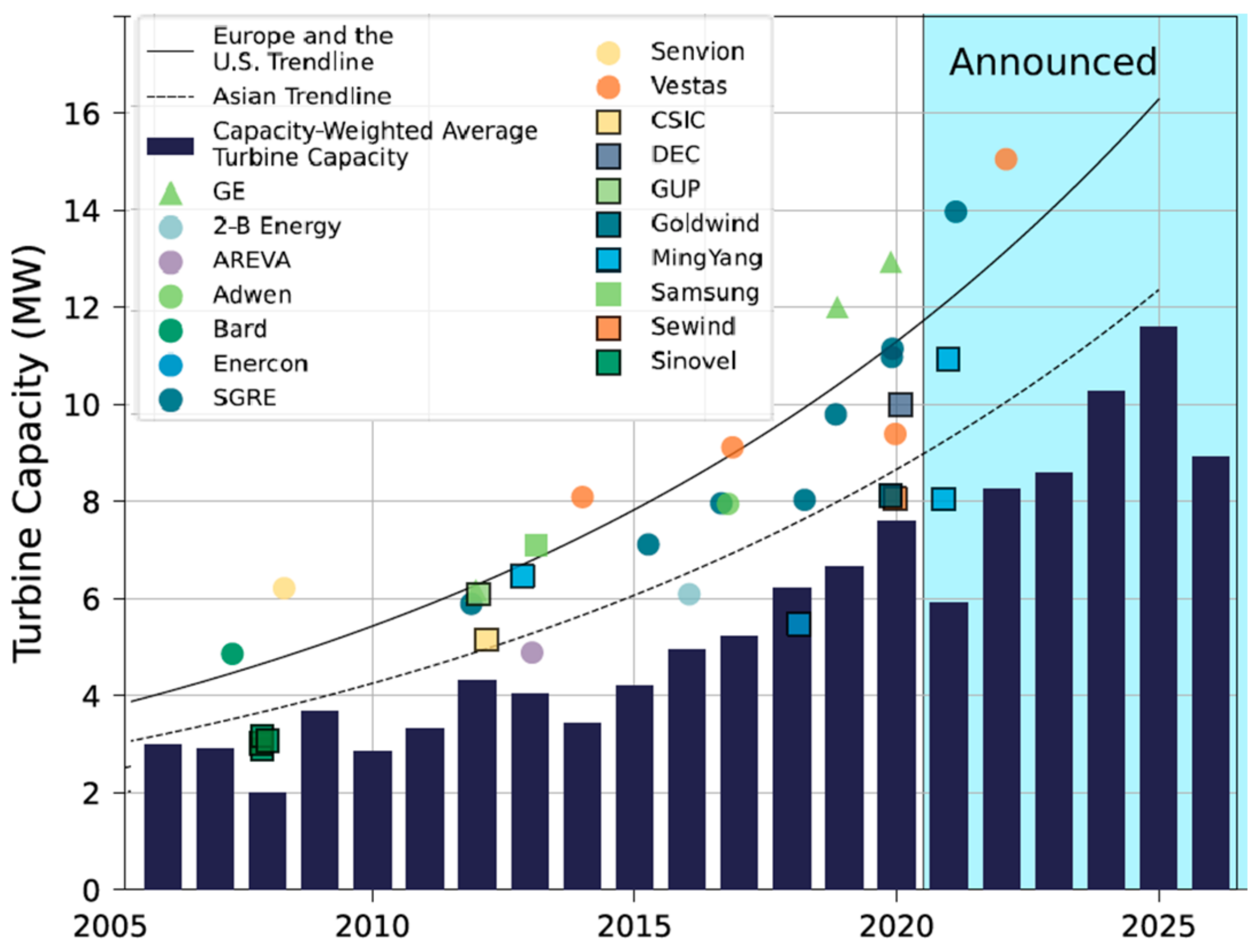

Figure 7 shows the steady increase in global offshore wind turbine capacity. This continuous growth in rated capacity is one of the factors that has led to a reduction in the cost of offshore wind farms [20]. The significant growth of large offshore wind farms in Europe is also due to improvements in wind turbines and basic structures [21].

Figure 7. Installed and planned new annual capacities of offshore turbines until 2025 [16].

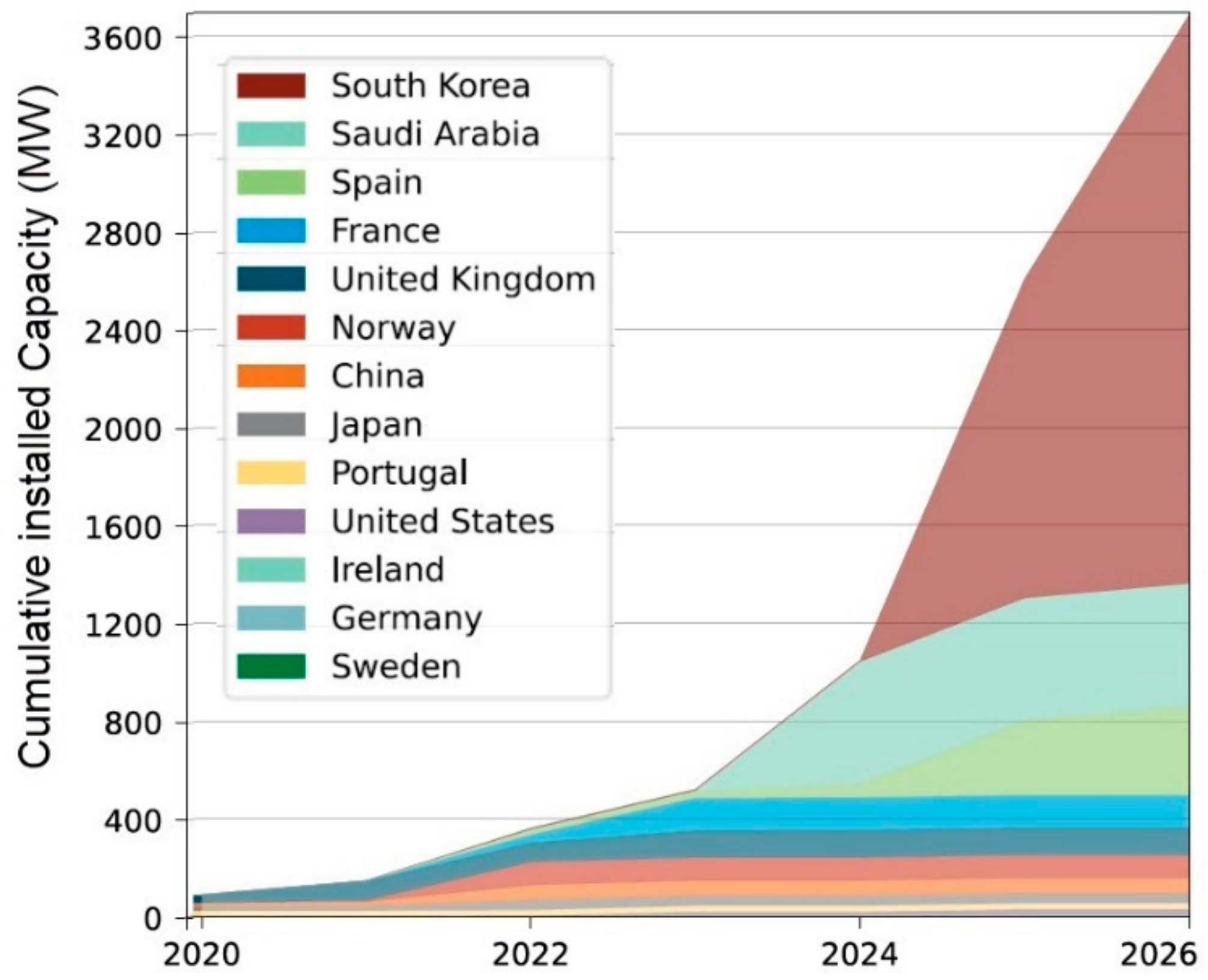

Figure 8 shows the cumulative deployment of floating offshore wind turbines. Of the 3,688 MW floating offshore wind turbines that will be installed by 2026, most will be located in South Korea (2300 MW), Saudi Arabia (500 MW), Spain (365 MW), and France (132 MW). Other wind farms will be evenly distributed in Europe, some of which are still in the planning phase [16].

Figure 8. Cumulative floating offshore wind capacity [16].

Wind turbine floating structures must withstand harsh conditions. The combined effects of high winds and waves cause vibration, material fatigue, and severe loads on the elements of the wind turbine. These problems lead to increased maintenance efforts and increase the risk of failures [22].

Therefore, maintenance is very important as it reduces the number of repairs required. Improved maintenance scheduling can reduce costs and increase turbine availability. The possibility of remote maintenance has also developed. This includes remote monitoring, which allows early detection of problems and preventive maintenance. Subsea equipment has also been developed for inspection and repair of components that are difficult to access [16].

Improving and upgrading the power grid is necessary in many countries to accommodate large amounts of renewable energy, including energy from offshore wind farms. Policymakers urgently need to mobilise more public and private investment in secure, smart, and flexible grids that can accommodate an ever-increasing share of renewable energy. Otherwise, the availability of appropriate grid connections, capacity, and transmission lines may be a significant bottleneck to the growth of new utility-scale wind and solar energy projects. Grids need to be comprehensively modernised not only in terms of physical infrastructure, but also in terms of intelligence. The grid in the future energy system is likely to be a data network grafted onto a physical grid, enabling multidirectional energy and information flow with effective and precise controls.

In addition, the development of ports and vessels is accelerating to keep pace with the increasing production of offshore wind turbines and the increase in their dimensions [23].

A sharp increase in offshore wind farm projects leads to a rise in demand for submarine cables. The market is divided into cables connecting an offshore substation to the onshore station and cables connecting adjacent wind turbines and offshore substations. It is estimated that the need for offshore cables in Europe will be about 2000 km per year. In addition, there are efforts to install cables with a voltage of 66 kV, compared to the current 33 kV [16].

The work of Turnbull et al. [24] examines the market trends for offshore technologies in Europe and provides a detailed overview of installed and planned capacity. There is a clear shift from smaller reduction gear turbines to larger direct drive turbines. To investigate the impact of this shift on wind farm reliability, the failure rates of 39 wind farms in Europe and South America with direct drive and geared turbines were analyzed. The analysis revealed several key similarities between the configurations, with the electrical system responsible for the majority of turbine failures in both cases. When considering the total downtime due to failure of all components, the direct drive wind turbine had the highest value, primarily due to the relatively higher downtime associated with the electrical system, generator, and control system. This indicates that further improvements are needed for direct-drive power plants.

It is estimated that the cost of electricity for floating offshore wind turbines will decrease from $160/MWh (2010) to $50–105/MWh (2030), i.e., it can be said that technological progress in the design of floating wind turbines will lead to a significant reduction in costs [2][25]. In this way, the predictions for the year 2050 (Figure 1) could come true that most of the electricity generation will come from wind turbines.

Hydrogen will play a key role in Europe’s carbon-neutral economy, as many current scenarios show. Hydrogen produced by electrolysis of electricity from wind turbines is an emerging technology. It could potentially contribute to system flexibility by acting as “seasonal storage” to help integrate various renewable energy sources. Hydrogen contributes to the “sectoral connection” between the electric power system and industry, construction, and transportation. Due to the existence of an extensive gas infrastructure that can be used to transport hydrogen-natural gas mixtures and also converted to transport pure hydrogen, the EU is well positioned to become a leading region in the global hydrogen economy [26]. In its report [2], IRENA forecasts a 19 exajoule increase in the global economic potential of hydrogen from renewable energy sources in total final energy consumption by 2050. This would represent 5% of total final energy consumption, and 16% of the electricity generated would be used for hydrogen production by 2050.

Governments, energy consuming companies (chemical companies, steel producers, etc.), and end users are increasingly interested in offshore wind as an energy source for the production of green hydrogen (produced by electrolysis from renewable energy sources) that can be used in various sectors of the economy (e.g., transportation, heating, industry, grid storage) as a fuel with zero pollutant emissions. Several early-stage global projects are being planned by Shell, RWE, Equinor, Gasunie, Gascade, Ørsted, and Boskalis. These producers plan to install 10 GW of wind power to obtain hydrogen as part of the AquaVentus/AquaDuctus project. Hydrogen can thus play a key role in implementing the EU’s offshore renewable energy strategy. The goal is to obtain up to 1 million tons of hydrogen from 2035 [26]. POSCO, as one of the largest South Korean steel producers, plans to use the 1.6 GW Ørsted offshore wind farm to produce the hydrogen needed for further steel production. Neptune Energy’s PosHydon project plans to use the produced hydrogen for Dutch utilities Gasunie, Eneco, Noordgastransport and Northern Offshore Gas Transfer. Ørsted’s H2RES hydrogen production project will use two 3.6 MW offshore wind turbines at Avedøre Holme to obtain one ton of hydrogen per day for “green” road transport in the urban area of Copenhagen [5].

Finally, it is worth noting that some research has addressed the analysis and improvement of vertical axis wind turbines, although they are very little used compared to horizontal axis wind turbines. In the work of Shouman et al. [27], a modification of Savonius wind turbines is considered. The proposed modification consists of a curtain arrangement with additional fins on the blade. The effect of the proposed modification was predicted by CFD simulation using ANSYS FLUENT software. It was found that the maximum power coefficient of the Savonius rotor with the optimal curtain arrangement (curtain blade lengths 1000 mm and 1150 mm and curtain blade angles 30 and 50) together with the addition of only one fin increased by about 42%.

The rotation induced by the flow through a modified Savonius rotor, in which the blade consists of a semicircular profile and an elliptical shape, is studied in the work of Le et al. [28] using unsteady flow simulations (CFD). The modified rotor provides excellent performance at a tip speed ratio (TSR) of more than 0.8, and the new peak power coefficient Cp is achieved at TSR = 1.4, which is the typical operating condition of wind turbines in urban areas. Thus, their study not only contributes to the basic understanding of the flow mechanism around the rotor, but also suggests a good practical application of this type of rotor for power generation in urban areas. In the work of Tian et al. [29], a new vertical axis wind turbine (VAWT) with side-by-side overlapping Savonius rotors was designed and analyzed. The new VAWT consists of multiple Savonius rotors with a distance between adjacent rotor axes smaller than the rotor diameter. It was found that the new VAWT has an incredible efficiency improvement of 46.95% at TSR = 0.4. The improvement of aerodynamic performance of a Savonius wind turbine using the Taguchi optimization method is addressed by Kaya and Acir [30]. The work of Ahmad et al. [31] addresses the design optimization of a double Darrieus hybrid vertical axis wind turbine. Moreover, Al-Ghriybah et al. [32] analyze the aerodynamics and productivity of a Savonius rotor with additional blades. Although many other papers analyze possible improvements in vertical axis wind turbine design, this approach is not expected to make a significant contribution to power generation.

References

- Lerche, J.; Lorentzen, S.; Enevoldsen, P.; Neve, H.H. The impact of COVID-19 on offshore wind project productivity—A case study. Renew. Sust. Energ. Rev. 2022, 158, 112188.

- IRENA. Future of Wind Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects. Available online: https://www.irena.org (accessed on 20 July 2022).

- Enevoldsen, P.; Xydi, G. Examining the trends of 35 years growth of key wind turbine components. Energy Sustain. Dev. 2019, 50, 18–26.

- Swisher, P.; Leon, J.P.M.; Gea-Bermudez, J.; Koivisto, M.; Madsen, H.A.; Munster, M. Competitiveness of a low specific power, low cut-out wind speed wind turbine in North and Central Europe towards 2050. Appl. Energy 2022, 306 Pt B, 118043.

- Astolfi, D.; Castellani, F.; Lombardi, A.; Terzi, L. About the Extension of Wind Turbine Power Curve in the High Wind Region. J. Sol. Energy Eng. Trans. ASME 2019, 141, 014501.

- Kumar, B.N.; Rajendran, S.; Vasudevan, A.; Balaji, G. Aerodynamic braking system analysis of horizontal axis wind turbine using slotted airfoil. Mater. Today Proc. 2020, 33 Pt 7, 3970–3979.

- Basack, S.; Dutta, S.; Saha, D.; Das, G. Power Generation by Offshore Wind Turbines: An Overview on Recent Research and Developments. WSEAS Trans. Power Syst. 2021, 16, 254–261.

- Chen, J.; Kim, M.-H. Review of Recent Offshore Wind Turbine Research and Optimization Methodologies in Their Design. J. Mar. Sci. Eng. 2022, 10, 28.

- Sunday, K.; Brennan, F. A review of offshore wind monopiles structural design achievements and challenges. Ocean Eng. 2021, 235, 109409.

- Trojnar, K. Simplified design of new hybrid monopile foundations for offshore wind turbines. Ocean Eng. 2021, 219, 108046.

- Fazeres-Ferradosa, T.; Chambel, J.; Taveira-Pinto, F.; Rosa-Santos, P.; Taveira-Pinto, F.V.C.; Giannini, G.; Haerens, P. Scour Protections for Offshore Foundations of Marine Energy Harvesting Technologies: A Review. J. Mar. Sci. Eng. 2021, 9, 297.

- Li, Q.; Prendergast, L.J.; Askarinejad, A.; Gavin, K. Influence of Vertical Loading on Behavior of Laterally Loaded Foundation Piles: A Review. J. Mar. Sci. Eng. 2020, 8, 1029.

- Jiang, Z.; Hu, W.; Dong, W.; Gao, Z.; Ren, Z. Structural Reliability Analysis of Wind Turbines: A Review. Energies 2017, 10, 2099.

- Mehmanparast, A.; Lotfian, S.; Vipin, S.P. A Review of Challenges and Opportunities Associated with Bolted Flange Connections in the Offshore Wind Industry. Metals 2020, 10, 732.

- Shields, M.; Beiter, P.; Nunemaker, J.; Cooperman, A.; Duffy, P. Impacts of turbine and plant upsizing on the levelized cost of energy for offshore wind. Appl. Energy 2021, 298, 117189. Available online: https://www.nrel.gov/docs/fy21osti/78126.pdf (accessed on 10 July 2022).

- Musial, W.; Spitsen, P.; Beiter, P.; Duffy, P.; Marquis, M.; Cooperman, A.; Hammond, R.; Shields, M. Offshore Wind Market: 2021 Edition. Available online: https://www.energy.gov/sites/default/files/2021-08/Offshore%20Wind%20Market%20Report%202021%20Edition_Final.pdf (accessed on 6 August 2022).

- Papi, F.; Bianchini, A. Technical challenges in floating offshore wind turbine upscaling: A critical analysis based on the NREL 5 MW and IEA 15 MW Reference Turbines. Renew. Sustain. Energy Rev. 2022, 162, 112489.

- Liu, S.; Yang, Y.; Wang, C.Y.; Tu, Y.G.; Liu, Z.Q. Proposal of a Novel Mooring System Using Three-Bifurcated Mooring Lines for Spar-Type Off-Shore Wind Turbines. Energies 2021, 14, 8303.

- Jahani, K.; Langlois, R.G.; Afagh, F.F. Structural dynamics of offshore Wind Turbines: A review. Ocean Eng. 2022, 251, 111136.

- Wind Energy Technologies Office. Top Trends in Offshore Wind. 2021. Available online: https://www.energy.gov/eere/wind/articles/top-trends-offshore-wind (accessed on 20 July 2022).

- Soares-Ramos, E.P.P.; de Oliveira-Assis, L.; Sarrias-Mena, R.; Fernández-Ramírez, L.M. Current status and future trends of offshore wind power in Europe. Energy 2020, 202, 117787.

- Salic, T.; Charpentier, J.-F.; Benbouzid, M.; Boulluec, M. Control Strategies for Floating Offshore Wind Turbine: Challenges and Trends. Electronics 2019, 8, 1185.

- Ekstrand, L. Zero-Waste Turbines by 2040. Vestas Wind Systems. Available online: https://www.vestas.com/en/media/blog/sustainability/Zero-waste-turbines-by-2040 (accessed on 20 July 2022).

- Turnbull, A.; McKinnon, C.; Carrol, J.; McDonald, A. On the Development of Offshore Wind Turbine Technology: An Assessment of Reliability Rates and Fault Detection Methods in a Changing Market. Energies 2022, 15, 3180.

- Wiser, R.; Rand, J.; Seel, J.; Beiter, P.; Baker, E.; Lantz, E.; Gilman, P. Expert elicitation survey predicts 37% to 49% declines in wind energy costs by 2050. Nat. Energy 2021, 6, 555–565.

- Chatzimarkakis, J.; Levoyannis, C.; van Wijk, A.; Wouters, F. Hydrogen Act: Towards the creation of The European Hydrogen Economy. Hydrog. Eur. 2021, 39. Available online: https://profadvanwijk.com/hydrogen-act-towards-the-creation-of-the-european-hydrogen-economy/ (accessed on 20 July 2022).

- Shouman, M.R.; Helal, M.M.; El-Haroun, A.A. Numerical prediction of improvement of a Savonius rotor performance with curtaining and fin addition on blade. Alex. Eng. J. 2022, 61, 10689–10699.

- Le, A.D.; Minh Duc, B.; Van Hoang, T.; The Tran, H. Modified Savonius Wind Turbine for Wind Energy Harvesting in Urban Environments. ASME J. Fluids Eng. 2022, 144, 081501.

- Tian, W.; Ni, X.; Mao, Z.; Wang, Y.-F. Study on the performance of a new VAWT with overlapped side-by-side Savonius rotors. Energy Convers. Manag. 2022, 264, 115746.

- Kaya, A.F.; Acır, A. Enhancing the aerodynamic performance of a Savonius wind turbine using Taguchi optimization method. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 5610–5626.

- Ahmad, M.; Shahzad, A.; Akram, F.; Ahmad, F.; Ali Shah, S.I. Design optimization of Double-Darrieus hybrid vertical axis wind turbine. Ocean Eng. 2022, 254, 111171.

- Al-Ghriybah, M.; Hdaib, I.I.; Al-Omari, Z.; Al-Husban, Y. The Study of Aerodynamics and Productivity of the Savonius Rotor with Supplementary Blades. Int. J. Renew. Energy Res. 2022, 12, 1167–1174.

More

Information

Subjects:

Energy & Fuels

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.9K

Revisions:

3 times

(View History)

Update Date:

18 May 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No