1. Aluminum Alloy

Compared with many other SLM (Selective Laser Melting) candidate materials, the treatment of aluminum alloy is more complicated

[1]. This is mainly due to the lightweight nature and high fluidity of aluminum, which shows a high reflectivity wavelength range for typical SLM lasers, and has high thermal conductivity

[2]. The absorption of aluminum by laser is poor; this indicates that it is necessary to quickly dissipate the heat of parts after high laser power processing

[3]. Aluminum powder is very sensitive to oxidation

[4]. Therefore, when printing aluminum alloy, attention must be paid to the oxygen content to avoid oxidation by oxygen in the air, and passivation

[5]. Aluminum alloy is also the most widely used. It can be found in daily life and other fields

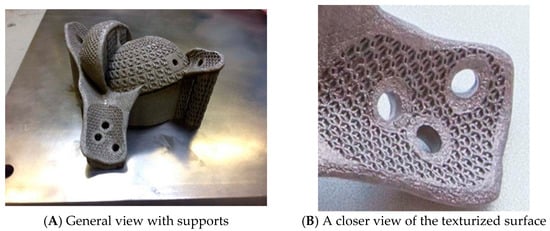

[6]. The SLM aerospace aluminum alloy specimen is shown in

Figure 1, The performance comparison of common aluminum alloy materials is shown in

Table 1.

Figure 1. Aluminum alloy parts produced by SLM

[6].

Zhao Xiaoming et al.

[7] studied the relationship between the structure and properties of SLM Al Si10Mg aluminum alloy. They found that the grain, internal design, and mechanical properties of SLM AlSi10Mg alloy are superior to those of traditional cast AlSi10Mg parts. Buchbinder et al.

[8] studied the influence of speed and scanning spacing on the hardness of AlSi10Mg. The research showed that the hardness of AlSi10Mg increased with an increase in scanning speed, and the best hardness was obtained when the laser scanning speed was 2500 mm/s. At the same time, the influence of scanning distance on the hardness of Al Si10Mg parts was determined. The results showed that the hardness of the samples obtained was independent of the scanning distance range used, and the optimal value was reached when the scanning distance was 0.15 mm. Currently, the optimal hardness value of AlSi10Mg parts processed by selective laser melting is twice that of die-cast AlSi10Mg parts. Rahman Rashet al.

[9] used selective laser melting technology to print AlSi12 alloy powder and obtain circular, triangular, and hexagonal lattice structures. The experimental results showed that the bending strength of the triangular frame was (175.80 ± 1) MPa, and the bending strength of the circular and hexagonal lattice powders were (151.35 ± 0.67) MPa and (143.16 ± 3.85) MPa, respectively. It can be seen that the triangular structure has better bending resistance than other reinforced members. Karg et al.

[10] studied the mechanical properties of 2219 aluminum alloy formed by selective laser melting. The results showed that the ultimate tensile strength of high-strength aluminum alloy after heat treatment is 384 MPa, and the elongation is 23%. Therefore, high-strength aluminum alloy formed by selective laser melting has good mechanical properties. Zhang

[11] and others successfully prepared an almost entirely dense Al-4.24Cu-1.97Mg-0.56M cubic sample using selective laser melting technology. Research shows that the selection has good mechanical properties. Dynin

[12] developed an advanced aluminum alloy, Al-10Si-0, 9Cu-0, 7Mg-0, 3Zr-0, 3Ce, for selective laser melting. The material showed a good speed build level in the SLM process, which allows for the formation of fine structures with low porosity levels. The microstructure characteristics of the alloy in the cast and T6 states were studied. The mechanical properties of Al Si Mg - (Cu) alloys produced by SLM exceeded those of such alloys produced by casting, which broadens their potential applications in aircraft, mechanical engineering, and other industrial fields. Hu et al.

[13] systematically studied the change rule of surface roughness of AlCu5MnCdVA aluminum alloy during SLM, and drew the following conclusions: during SLM, the top surface roughness experienced a complex evolution; for single channel samples, the ray first decreased and then increased with an increase in scanning speed; and for single layer samples, the ray increased with an increase in scanning speed and shadow spacing. In addition, this value was lower than that of single-track samples manufactured at the same scanning speed. With an increase in the number of layers, the surface roughness first increases, then decreases, and finally tends stabilize. An increase in fluid flow intensity and actual powder thickness affects the roughness in both directions on the contrary, leading to the evolution of surface roughness. This evolution shows that the surface quality improves itself during processing, but the ability of self-improvement is limited. Once the surface quality is too poor and the process is unstable, it is difficult for the process to improve itself.

Some scholars studied the oxidation phenomenon of aluminum alloy powder in the SLM process. In the SLM process of aluminum and its alloys, a large number of an oxide is combined into parts so that it will form oxide film, as in the traditional way. Due to the active chemical properties of aluminum, a kind of passivation and reduction in the surface tension of parts is generated on the surface

[14].

The low density, high strength, sufficient hardenability, good corrosion resistance, and excellent weldability of aluminum alloy make it suitable for a series of manufacturing industries, such as for automobiles, national defense, and aerospace equipment manufacturing

[15][16].

2. Magnesium Alloy

Magnesium alloys are mainly used to develop lightweight structures because of their low densities. In addition, due to their biocompatibility, they offer the potential to be used as bioabsorbable materials for biodegradable bone substitute implants.

To achieve this goal, the DFG German Research Foundation, a research project funded by Deutsche Bank in 2012, used skull replacement with SLM technology to manufacture biodegradable implants for people. Its leading alloy implant is a biodegradable magnesium alloy scaffold, which is pre-activated with human cells of patients to support bone growth on implants before implantation. Due to the biocompatibility of magnesium metal in the human body, when the magnesium stent is implanted in the human body, the stent will gradually become compatible with the human body over time; at the same time, the injured bone tissue will also close.

In 2010, Ng et al.

[17] studied selective laser melting magnesium to produce bone substitute scaffolding. Using the micro SLM system built by Hong Kong Polytechnic University, the experimental study was carried out in a protective gas environment. For the first test, coarse particles of 75–150 nm and fine spherical particles of 5–45 nm were produced, and satisfactory results were obtained.

Krause et al.

[18] conducted experiments on magnesium alloys. Their research showed that aluminum alloys with a calcium content of 8 ‰ had good human compatibility. Further research showed that the initial mechanical strength of magnesium alloys is insufficient when magnesium alloy stents are implanted into human bone joints. When low mechanical stability is necessary, it is appropriate to use these stents as the material of implants mixed with implants. WZ21 magnesium alloy contains biocompatible alloy, while rare earth elements show good biocompatibility, degrade slowly and homogenously in miniature abdominal cavities, and were shown to have stable mechanical integrity in the femur of experimental pigs and rats

[19][20]. WE43 alloy is a superb alloy for manufacturing biodegradable stents. Therefore, this material is often used as a magnesium alloy implant to treat patients. Yuan et al.

[21][22] used additive manufacturing technology to optimize the structure of MgNdZnZr magnesium alloy, and designed and prepared three magnesium scaffolds with the same porosity and average pore size using SLM technology. It was found that the SLM magnesium alloy stent presented a fully connected structure, appropriate compression performance, and moderate degradation behavior, indicating that the stent printed by SLM has good clinical application prospects.

Magnesium alloy biodegradable implants will be applied in the future of bone sutures.

In recent years, because of its good bearing capacity, magnesium alloys have been the preferred material for biodegradable polymers. SLM technology alloys of magnesium can be used to manufacture single biodegradable implants with complex shapes. Generally speaking, magnesium and its alloys are quite mature in SLM applications.

3. Titanium Alloy

Compared with other materials that can be used for SLM printing, titanium alloy is the ideal printing material because of its cleanness and high utilization rate in processing, and titanium can be used to print parts with complex shapes on the SLM platform.

Titanium alloy is widely used in biomedical implants

[23], among which Ti-45Nb is the primary material of implants, mainly due to its low Young’s modulus (~62Gpa) and high cooling rate. In addition, Ti-45Nb has excellent elasticity, good corrosion resistance, and good chemical resistance, mainly due to the passivation layer formed on the surface of titanium components

[24].

Huang et al.

[25] used SLM technology to conduct heat treatment research on TA15 titanium alloy style. The research shows that the microstructure of TA15 titanium alloy style after heat treatment is a typical basket structure, and the toughness of parts can be improved through heat treatment. Finally, with an increase in heat treatment time, the dimple size of the fracture increases. The failure mode changes from brittle fracture to semi ductile fracture, and finally to complete ductile fracture.

These results show that SLM technology is different from other manufacturing methods, and can make full use of the potential of solid titanium. In addition, porous titanium structure with the necessary characteristics can still be manufactured using SLM while retaining its biomechanical properties

[26]. However, the reliability of biomedical application parts of titanium alloy produced by SLM, especially its powder materials, its corrosion behavior, and the influence of fatigue properties, still needs further study. SLM parts of titanium alloy are shown in

Figure 2.

Figure 2. Titanium alloy hip implants produced by SLM

[26].

4. Stainless Steel

316L stainless steel, also known as titanium steel, is characterized by solid point corrosion resistance, excellent high-temperature strength, and non-magnetism. It is widely used in pipelines, the food industry, in marine and biomedical equipment, fuel cells, and other fields

[27][28][29]. In recent years, 316L stainless steel has gradually become the raw material of SLM 3D printing technology, and has been studied by many scholars

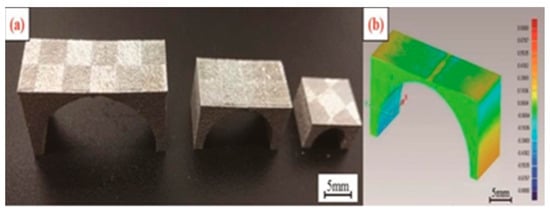

[30]. SLM bridge model of 316L stainless steel is shown in

Figure 3.

Figure 3. 316L Bridge model made by SLM: (

a) A sample of a bridge-shaped structure; (

b) the deformation diagram

[30].

Kruth et al.

[31] conducted many novel types of research on the SLM manufacturing of stainless steel. Soon after, Kruth

[32] proved that changes in process parameters play a vital role in SLM for forming parts. Since then, many scholars have researched this area and reached similar conclusions

[33][34][35]. However, the study showed that it is difficult to achieve the entire density state because there is a relatively fixed porosity in the metal powder. On the other hand, lack of a particular mechanical pressure will also make the total density unable to reach its highest

[36]. Casati et al.

[37] reported that a reduction in tensile strength would make the elongation break, attributing very different power of SLM 316L stainless steel, mainly because of partially melted powder particles in their microstructure. To solve this problem, laser remelting is the method applied; that is, before spraying the next layer, the powder layer is scanned twice. Yasa et al.

[38] proved that the density of stainless steel parts could be improved, and the surface roughness could be reduced by the secondary scanning method, thus improving the fatigue characteristics. Riemer et al.

[39] found that 316L stainless steel printed with SLM technology showed anisotropy in notched high-cycle fatigue behavior and fatigue crack. The research of Zhou Yuecheng et al.

[40] on 316L stainless steel showed that SLM is suitable for manufacturing small- and medium-sized parts, and that the mechanical properties of SLM products show obvious anisotropy and inhomogeneity due to epitaxial growth crystals, micro defects, weld pool boundaries, and residual stresses in the microstructure.

The research on 316L stainless steel by scholars from all over the world using SLM technology shows that due to certain porosity between stainless steel powders, the density state of stainless steel cannot be guaranteed, which can cause internal defects in the parts printed with 316L stainless steel, affecting the overall service life of the parts, and even leading to parts being scrapped. At the same time, scholars are also using methods to constantly improve the SLM process of stainless steel; the research on stainless steel is also maturing.

To sum up, the SLM process has shown strong developments in the printing of various metal materials. Although the material and application performance of parts still requires further exploration and verification, and the manufacturing process still needs to be improved, SLM metal printing technology has shown great application prospects in various fields: in the medical field, for patient specific implants and other high-value medical device components; in the field of automobile manufacturing, high-speed prototype design and customized components, or low volume, high-value applications; in the field of aerospace, conduits and other components. SLM metal printing is an exciting technology with many potential applications. With continued growth in uses and the maturity of technology, the process and materials are becoming cheaper. We should see SLM metal printing becoming increasingly common.