| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Urška Vrabič-Brodnjak | -- | 1324 | 2023-03-28 13:40:06 | | | |

| 2 | Catherine Yang | -8 word(s) | 1316 | 2023-03-30 08:19:58 | | |

Video Upload Options

Global economy depends on fossil resources, which provide raw materials for the production of a range of chemicals and materials for the manufacture of commercial products such as paper and packaging. Since there is growing environmental awareness and the need to reduce dependence on petroleum-based products, the attention has been paid to the possibilities of synthesizing polymeric materials from bio-based renewable resources. The paper and packaging segment dominates the market and is expected to grow further during the forecast period due to robust growth in demand for packaging materials from food and beverage manufacturers and e-retail companies. In the paper industry, biomass, such as wood and other species, is undergoing constant change due to countries' efforts to decarbonize, the rise of bio-based materials, and so on. The recent shortage of paper for various media, due to the shift from fiber to packaging applications, opens the space for alternative solutions. Recently, interest in the use of agricultural residues has increased. Environmentally friendly packaging, so called green packaging, based on biodegradable, recyclable or compostable materials, is currently attracting a great deal of attention in many disciplines because of its unique properties compared to traditional petrochemical-based plastics. Green packaging materials play an important role in preserving and protecting the product. To fulfil these benefits, the bio-based material for green packaging should be made from materials that enhance the biopolymer properties of the packaging material and meet the requirements of the global market. In addition, to ensure the recyclability or biodegradability of the above packaging, bio-based adhesives should be included in the packaging process. Lately, the adhesive production is still based on by-products of petroleum processing and with increasing concerns about environmental threats and sustainable development, the use of biomass and bio-based materials will play an important role.

1. Introduction

Currently, the adhesive production is still based on by-products of petroleum processing and with increasing concerns about environmental threats and sustainable development, the use of biodegradable and sustainable biomass to produce adhesives and other adhesives important to the industry is not only inevitable, but also a response to reducing the impact caused by formaldehyde adhesives. The global adhesives market grew fromth USD 77.15 billion in 2022 to a projected USD 83.99 billion in 2023 at a compound annual growth rate (CAGR) of 8.9% [1]. There are several ways in which renewable materials can be incorporated into adhesives. The adhesives used in paper and cardboard packages are adhesives that are applied at high temperatures or are as dispersion adhesives, that are applied as water-based dispersions. Water-based adhesives are usually emulsions of thermoplastic resins because their properties result from the polymer used and the system used to emulsify the polymer in water. As with solvent-based adhesives, the water carrier is evaporated by air or diffused into the porous structure. After drying, the resulting adhesive can be a brittle, hard resin or a flexible film, depending on the adhesive formulation. The most commonly used emulsion-based adhesive is the polyvinyl acetate-polyvinyl alcohol copolymer, which hardens to a relatively rigid solid when water diffuses through the substrate, such as packaging material. Water-based adhesives are considered as substitutes for solvent-based adhesives for the purpose of reducing volatile organic emissions in various packaging processes (sealing the package with goods, etc.). Starch based adhesives are the most used bio-based polymer in the paper industry. It has been proven that adhesives made from starch are not very stable when cooled during the production; moreover, the storage times of these adhesives are very short. Even with various modifications of starch, the limitation in terms of moisture barrier remains. Although the use of soy proteins and dextrin offers advantageous properties for the development of bioadhesives, they have disadvantages in terms of water resistance, stability and strength of the sheets, which are also the major drawbacks of the bio-based adhesives currently available on the market.

2. Overview of Bio-Based Adhesives such as Chitosan, Tannic Acid and Shellac in Packaging

Bio-based adhesives could be an important complement to dispersion and solvent-based adhesives due to increasing environmental and health requirements[2][3]. Innovative dry, wet and hot melt adhesives for packaging have been described in the scientific literature[4][5]. However, these are mostly based on synthetic polymers with a small addition of bio-based components. Among them are tannins, promising materials, which could be obtained from the plants. Tannin adhesives are of increasing interest, especially in the wood, auto-motive, cord and many other industries[6]. In particular, low resistance to moisture has led researchers to develop tannin-based adhesives blended or co-polymerized with resins and other additives. Tannin and other biopolymers such as chitosan and starch have also been used as packaging adhesives, as analyzed by Kaczmarek et.al.[6] The combination of tannins with other polymers has shown that tannins can be considered as additives for bio-based adhesives due to their potential effects ranging from adhesive properties to important water resistance. Mentioned adhesives also play an important role as underwater adhesives, which are an important multifunctional bonding solution for biological and engineering adhesive applications. Chitosan is known as non-toxic biopolymer, derived from the deacetylation of chitin. Due to its high crystallinity, hydrogen bonds between molecular chains, which exhibit great oxygen properties, has also attracted a lot of interest in packaging field and as an adhesive[7]. As a natural polymer, which is already used in many fields, as well as in packaging, is shellac. It is a natural polymer, obtained from purified resinous secretion, by the insects Kerria Lacca (Kerr) Lindinger (Coccideae). This species is the most important lac insect, being a main source of lac, for the production of shellac. Shellac’s chemical structure is composed of hard and soft resin of polyesters and single esters containing hydroxyl and carboxyl groups[8]. It is widely used as an adhesive, thermoplastics, insulating materials, sealants and as coatings in pharmaceutical and agronomical industries[9]. Shellac has excellent film forming and barrier properties.

3. Usage of Biobased Adhesives from Chitosan, Tannic Acid and Shellac

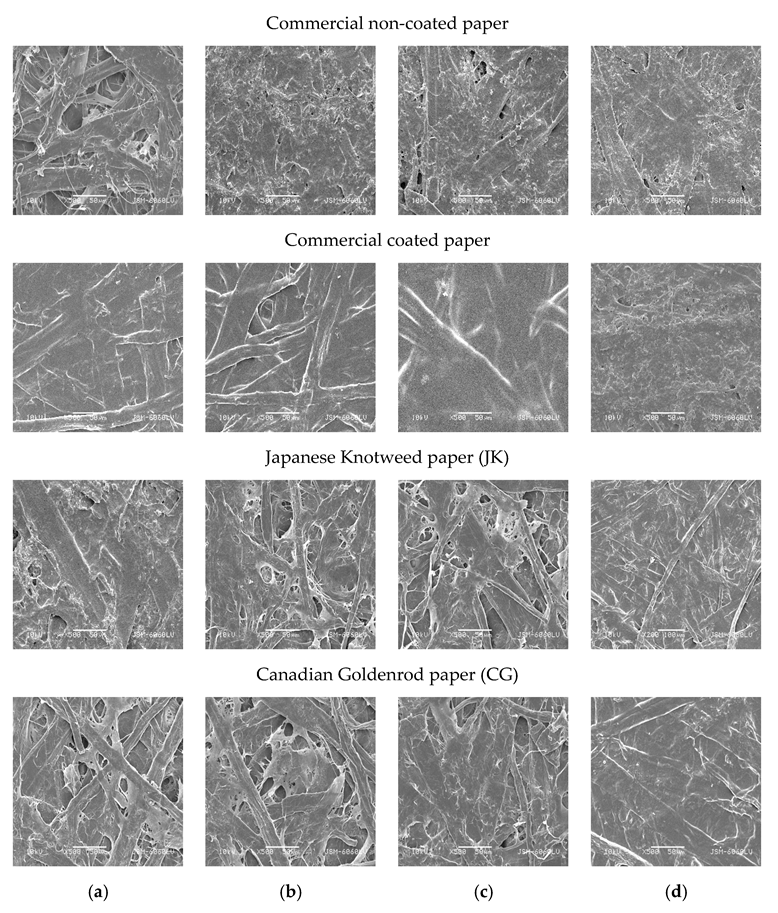

The bio-based adhesives produced from chitosan, shellac and tannic acid are adhesives for dry substrates. Namely, tannic acid was confirmed as a suitable additive among the prepared adhesives. Indeed, the addition of tannic acid increased the viscosity and the adhesive strength and the properties was better compared to commercial adhesive. Tensile strength with adhesives of tannic acid and chitosan was 30% better compared to commercial adhesives and 23% better with combinations of shellac and chitosan. In the bottom joint of papers, the shellac adhesive combinations with chitosan showed the best properties. Microscopic analysis showed good filling of the paper voids by the adhesives (Figure 1). This is an important contribution to other factors for adhesion of cellulosic materials to other polymers. The bio-based adhesives also exhibited a favorable thermal stability. In summary, these physical properties support the use of bio-based adhesives in different packaging applications. The combination of bio-based adhesives has shown that they can be compared to commercial adhesives, such as the commonly used packaging adhesive PVAc, under similar conditions. When comparing the data, they indicate that less tannic acid was needed to formulate strong adhesive. From the previous research and our results, tannic acid might be considered as a multifunctional crosslinking agent.

To evaluate the feasibility of adhesive applications for food packaging and pharmaceutical products, further experiments and different substrates (such as films and foils) under different conditions and environments should be investigated in the future. The bio-based adhesives used show potential for the development of many more products and even more environmentally friendly technologies. Future analyzes will focus on the biodegradability and/or recyclability of the adhesives investigated in this study. When using paper and bio-based adhesives, feasibility and commercial use in the future should answer questions about the environmentally friendly processing of the end products and their recyclability.

Figure 1. Scanning electron images of papers from commercial non-coated and coated papers and invasive plant species Japanese Knotweed and Canadian Goldenrod with different adhesives applied (a) 100% chitosan, b) 50% tannic acid + 50% chitosan; c) 50% shellac + 50% chitosan, d) 100% PVAc.

References

- Adhesives Global Market Report. 2023. . Adhesives Global Market Report. 2023.. Retrieved 2023-3-28

- Watcharakitti, J.; Win, E.E.; Nimnuan, J.; Smith, S.M. Modified starch-based adhesives: A review. Polymers 2022, 14, 2023.

- Amaraweera, S.M.; Gunathilake, C.; Gunawardene, O.H.; Fernando, N.M.; Wanninayaka, D.B.; Dassanayake, R.S.; Manipura, A. Development of starch-based materials using current modification techniques and their applications: A Review.. Molecules 2021, 26, 6880.

- Li, K.; Geng, X.; Simonsen, J.; Karchesy, J. Novel wood adhesives from condensed tannins and polyethylenimine. Int. J. Adhes. Adhes. 2004, 24, 327–333.

- Shirmohammadli, Y.; Efhamisisi, D.; Pizzi, A. Tannins as a sustainable raw material for green chemistry: A review.. Ind. Crops Prod. 2018, 126, 316–332.

- Kaczmarek, B.; Owczarek, A.; Nadolna, K.; Sionkowska, A. The film-forming properties of chitosan with tannic acid addition. . Mater. Lett. 2019, 245, 22-24.

- Improved mechanical, antibacterial and UV barrier properties of catechol-functionalized chitosan/polyvinyl alcohol biodegradable composites for active food packaging. Lei, Y.; Mao, L.; Yao, J.; Zhu, H.. Polymers 2021, 264, 117997.

- Jadhao, V.M.; Sathish Kumar, M.H.; Jayaraj Rao, K.; Matche, R.S. Evaluation of beeswax coated coconut shells for packaging of set-type dahi: An Indian fermented product. . JFST 2021, 58, 2019–2027.

- Bar, H.; Bianco-Peled, H. The unique nanostructure of shellac films. . Prog. Org. Coat. 2021, 157, 106328.