Video Upload Options

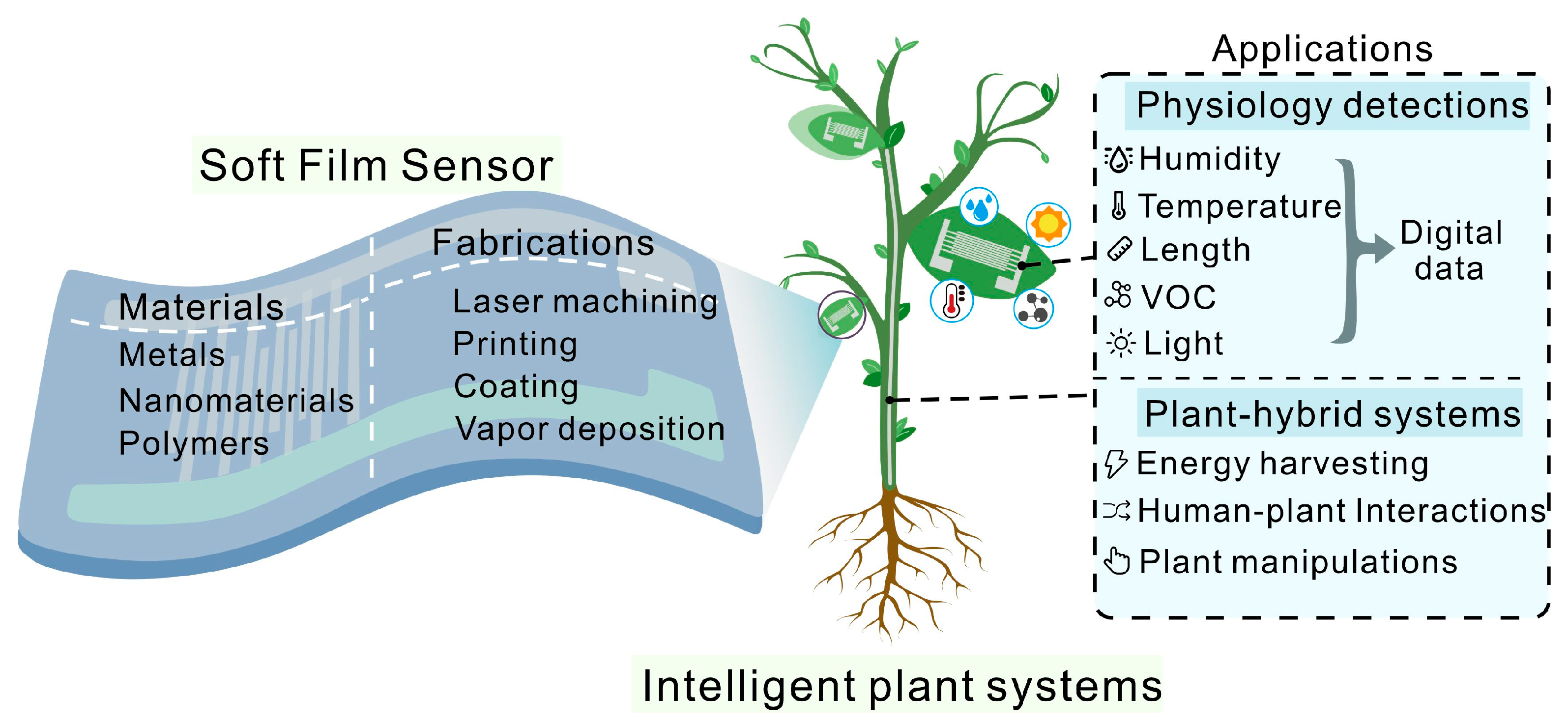

Being abundant as natural intelligence, plants have attracted huge attention from researchers. Soft film sensors present a novel and promising approach to connect plants with artificial devices, helping researchers to investigate plants’ intelligence further. For micro/nano soft film sensors that can be used for establishing intelligent plant systems are summarized, including essential materials, fabrications, and application scenarios.

1. Introduction

Researchers will review soft film-based micro/nano sensors for developing intelligent plant systems (Figure 1). To build such a system technically, researchers first overview the essential materials of soft film sensors, including metals, nanomaterials, and polymers. To be compatible with plants, specific materials of soft film sensors need to be selected and modified properly. Then, typical fabrication techniques for soft film sensors are presented, major including laser machining, printing, coating, and vapor deposition. Furthermore, researchers highlight two application scenarios of intelligent plant systems, including plant physiological detections and plant-hybrid systems. Finally, the existing challenges and new opportunities are discussed.

Figure 1. Overview of micro/nano soft film sensor for establishing intelligent plant systems.

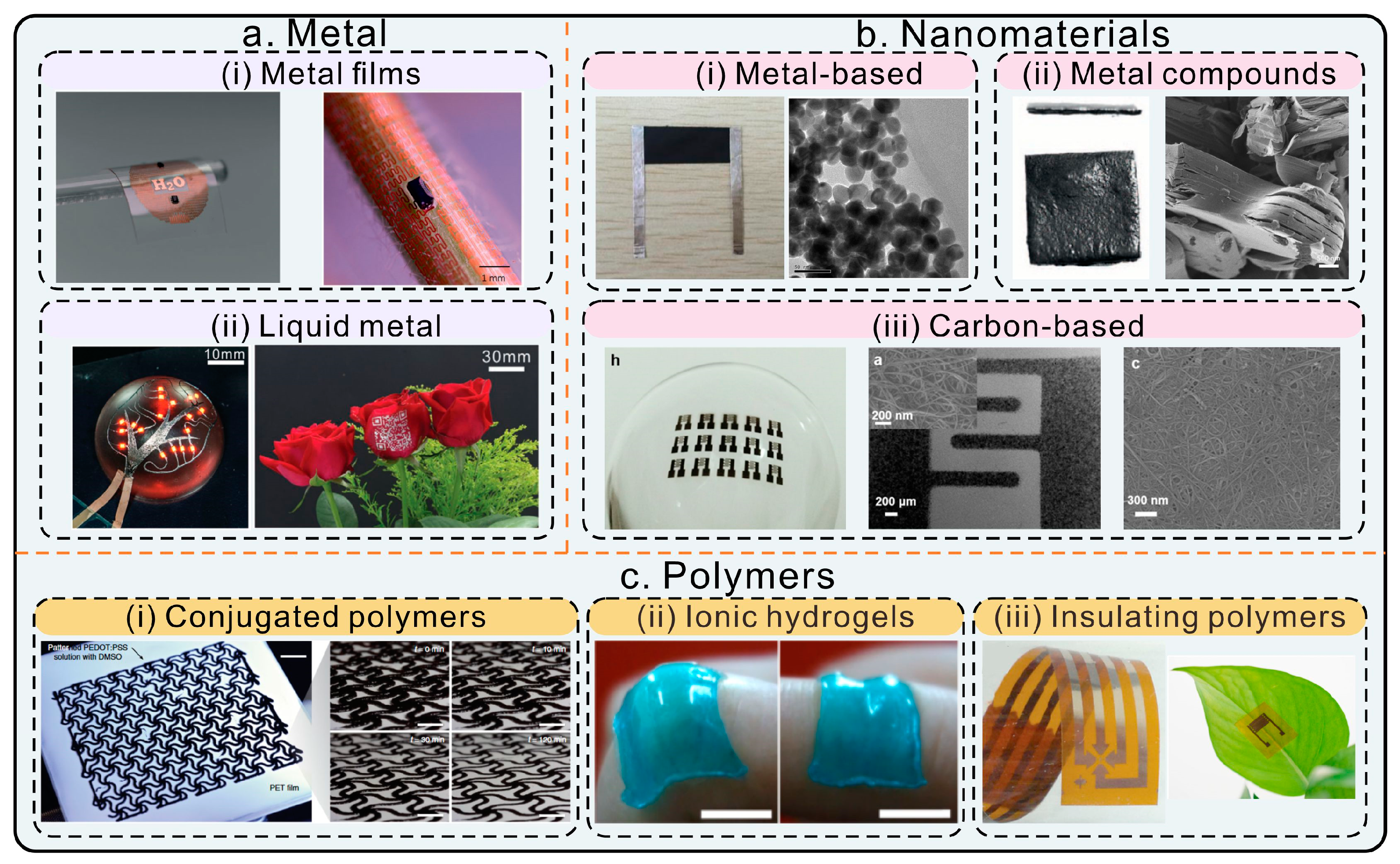

2. Materials

3. Fabrication

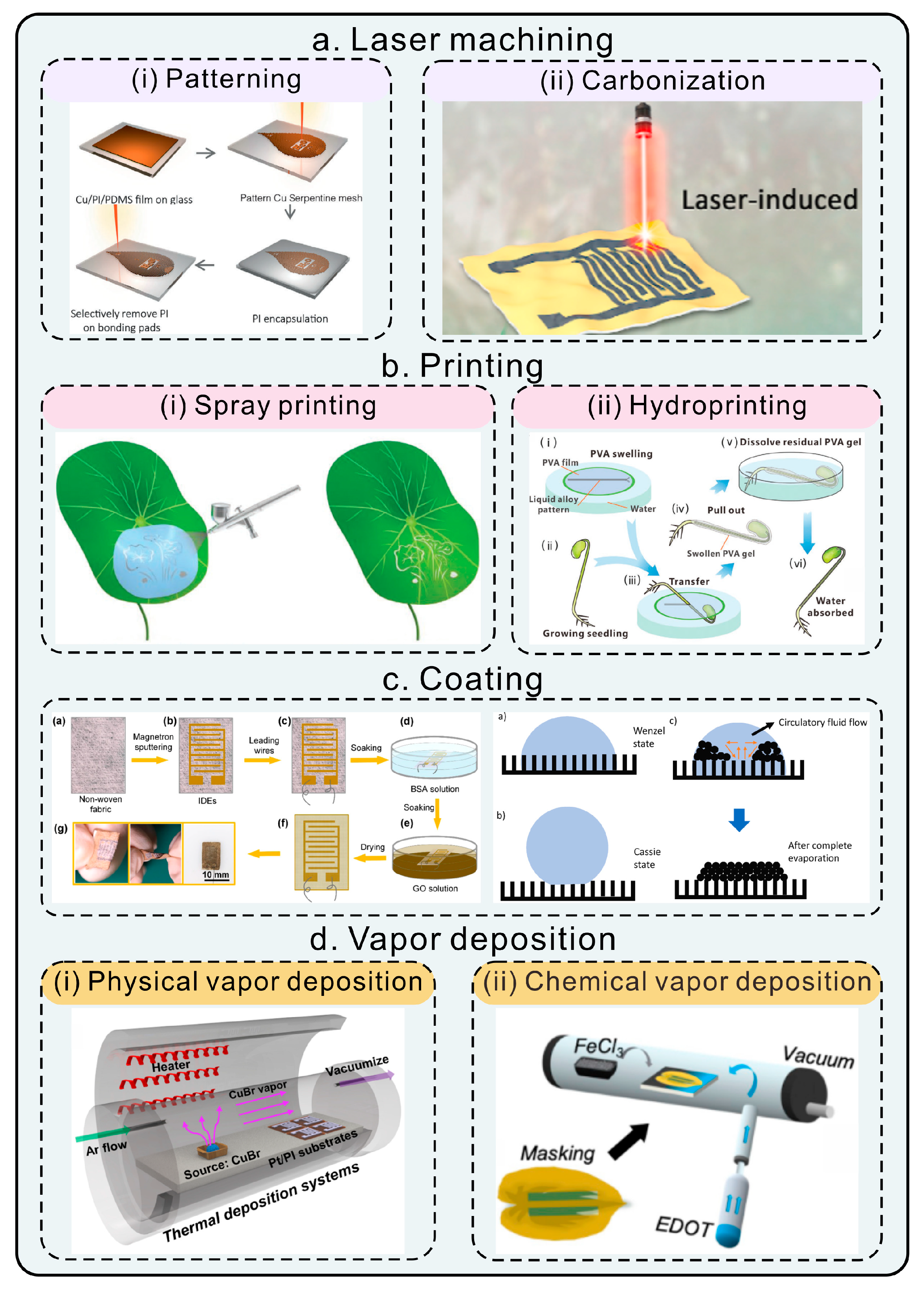

Based on the materials discussed earlier, the technical analysis of their corresponding fabrication techniques is also necessary. Only with proper fabrication processes will these materials function well as a part of sensors. Researchers introduce the fundamental working principle and their applicability. Some specific techniques can directly fabricate soft thin film sensors on fragile plants. Generally, several fabrication processes should be performed consecutively to achieve the final sensors, Figure 3.

Figure 3. Various fabrication processes of soft film sensors. a) Laser machining. i) Patterning Cu Serpentine mesh. (Reproduced with permission from. ii) Flexible humidity sensor fabricated by laser-induced carbonization. (Reproduced with permission from. b) Printing. i) liquid metal wires on lotus leaf by spray printing. ii) Hydroprinting liquid-alloy-based morphing electronics on living bean sprouts. c) Coating. Left, Flexible humidity sensor coated with graphene oxide. Right, a schematic diagram showing the whole process of coating. d) Vapor deposition. i) Schematic diagram of CuBr deposited on Pt/PI substrate by high-temperature airflow. ii) PEDOT-based plant sensors fabricated by chemical vapor deposition.

4. Applications

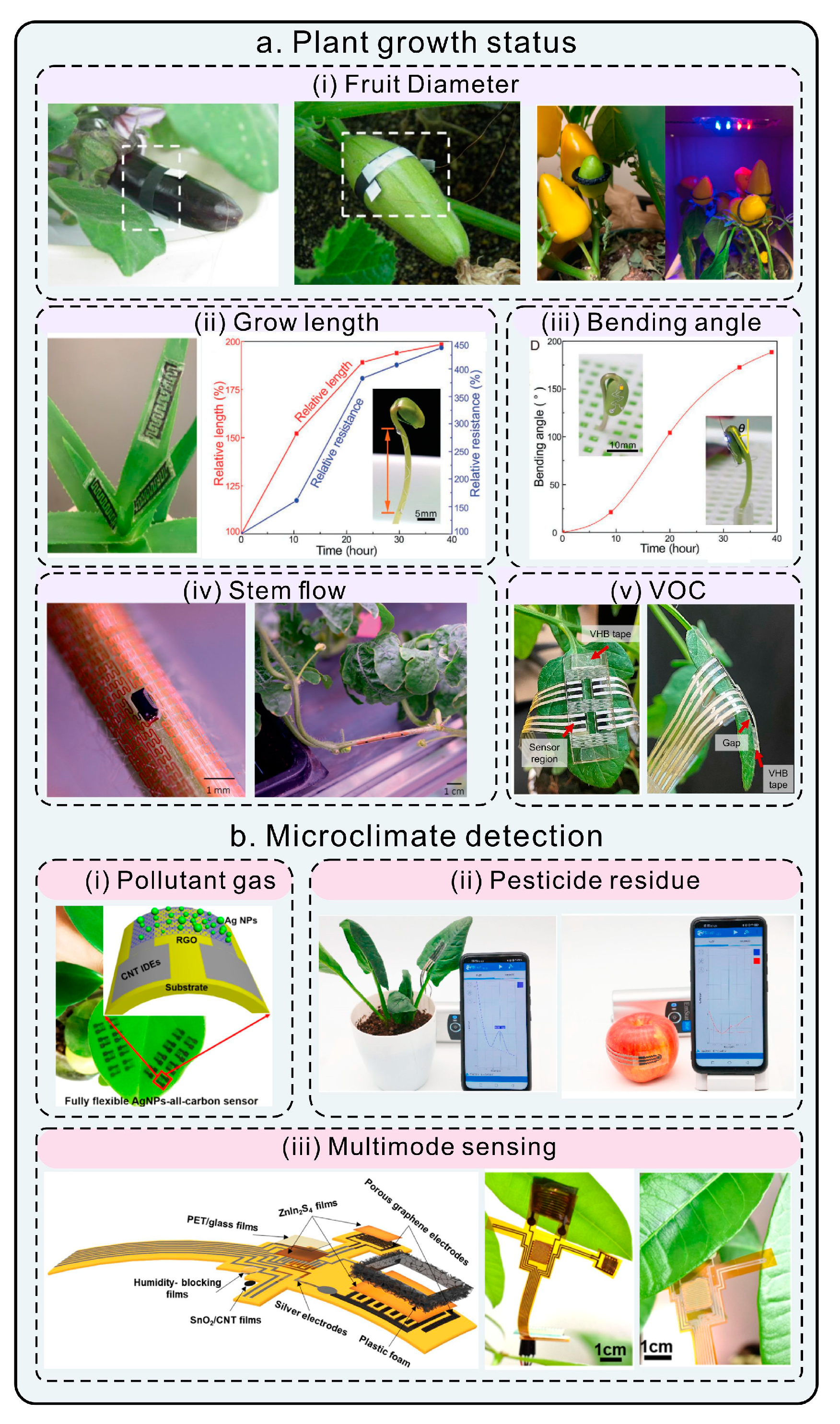

4.1 Physiological detection

Wearable soft film sensors can directly attach to the plant’s surface and provide a precise and gentle sensing approach. This technique can detect various on-time data for plant growth and living microclimate. Thus, these soft film sensors can help researchers investigate plant physiology. This technology can be generalized in intelligent and precise agriculture, smart horticulture, botanical research, and so on, see Figure 4.

Figure 4. Soft film sensors for plant physiological detection. a) Detections of plant growth status. i) Fruit diameter detection. Ii) Grow length detection. iii) Monitoring the sprout’s bending angle. iv) Sensors for recording plant stem flow. v) Detection of leaf’s releasing VOC. B) The detection of microclimate around plants. I) Detection of pollutant gas surrounding leaves. ii) In situ analysis of pesticide residue of crop surfaces. iii) Multimode sensing for diverse environment parameters, including light, temperature, and humidity.

4.2 Intelligent Plant-hybrid system

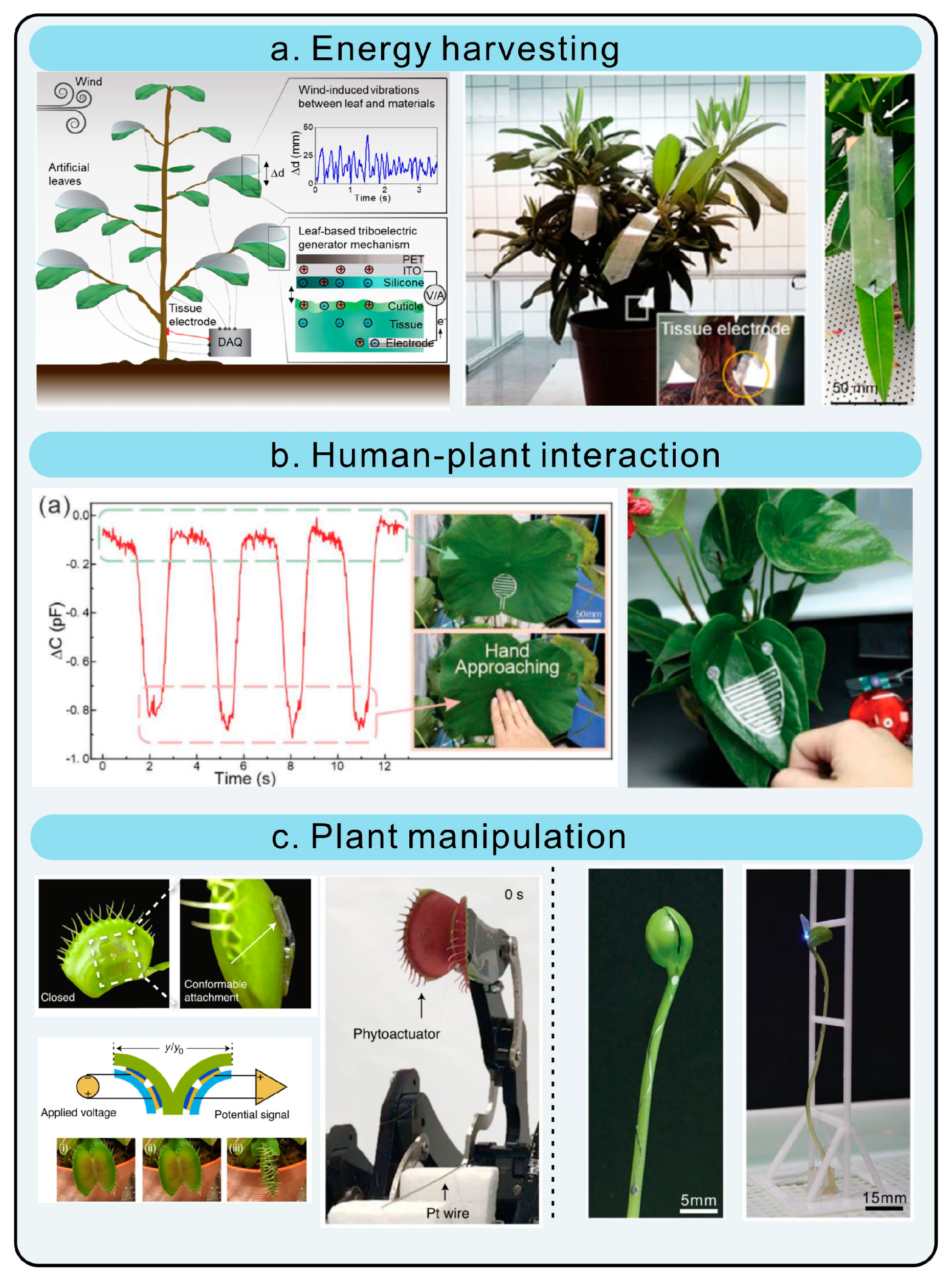

In recent years, researchers have been trying to combine soft sensors with plants to generate intelligent plant-hybrid systems. As mentioned above, plants have abundant natural intelligent abilities, yet researchers still have not fully explored them. To cope with this challenge, the soft film sensor acts as a bridge to connect with plants and artificial intelligent systems. Researchers currently conclude intelligent plant-hybrid systems into three aspects: energy harvesting, human-plant interaction, and plant manipulation, Figure 5.

Figure 5. Plant-hybrid systems. a) Energy harvesting system that converts wind energy into electricity. b) A human-plant interaction system that can sense hand approaching. c) Living plant manipulation systems. Left: Manipulating a flytrap to grasp a thin Pt wire. Right: Manipulating a bean sprout to climb a ladder.

5. Conclusions and Perspectives

Plants are amazing biological systems that have abundant natural intelligence. Based on soft film sensors that can be directly attached to plants, various plants’ biological information can be precisely transferred to digital signals. Moreover, with the help of soft film sensors, artificial intelligence technology can be closely connected with plants’ natural intelligence, forming intelligent plant systems. As mentioned above, soft film sensors have broad applications in monitoring plant physiological information, such as microenvironments, growth status, and crop yield and quality. The information collected from plants can be used as indicators for setting intelligent plant management systems, enabling a new level of precision agriculture, botanical research, and intelligent forestry. Furthermore, plants can be seen as integral machines and combine with soft film sensors to establish intelligent plant-hybrid systems, including energy harvesting, plant-human interactions, and plant manipulations. There are still several grand challenges and opportunities to be explored.

1) Reliable interface matching between soft film sensors and plants. Most existing soft film sensors process soft substrates to adhere to plant surfaces. However, such a bonding strategy can bring a mismatch or detachment caused by plants' rapid and continuous growth. Moreover, tightly attached sensors would hinder plant growth. Therefore, developing a reliable and stable interface between sensors and plants is vital for achieving long time (months and years) wearable detection. LM provides one of the solutions, which can be directly printed on plant surfaces without carrier films. As LM has unique fluidity and ductility, the LM-based sensors can conformally morph with plant growth. Thus, researchers look forward to further developing the next generation of soft film sensors with a stable attachment interface, lower stiffness, and compatibility with plant growth.

2) Multi-sensor fusion. Until now, multimode soft film sensors have been developed to monitor diverse physiological information (such as temperature, light intensity, and water transport). However, these sensors always are placed on a single part of plants (e.g., leaves), where information is very limited. Multi-sensor fusion systems that can be integrated into various plant parts (such as leaves, stems, and roots) may provide more comprehensive and rich physiological information than ever.

3) Higher intelligent plant-hybrid system. In the current stage, plant-hybrid systems have shown the potential for taking full advantage of plant intelligence in different parts, such as energy, interaction, and manipulation. Researchers expect comprehensively integrate these functional parts and thus forming high intelligent plant-hybrid system. The next generation of plant-hybrid systems would possess a high-efficient transforming mechanism, which could harvest various energy from nature (such as wind, rain, light, and temperature). Furthermore, plants can interact intimately with humans, for instance, behaving like “plant pets”, where plants can sense human stress and react friendly to comfort humans by releasing pleasant smells.

With the continuous development of essential materials, advanced fabrication technologies, and cross-disciplinary fields, these goals will definitely be achieved soon with the advent of the era of intelligent plant systems.

References

- Gougoulias, C.; Clark, J.M.; Shaw, L.J. The Role of Soil Microbes in the Global Carbon Cycle: Tracking the below-Ground Microbial Processing of Plant-Derived Carbon for Manipulating Carbon Dynamics in Agricultural Systems. J. Sci. Food Agric. 2014, 94, 2362–2371.

- Laforest-Lapointe, I.; Paquette, A.; Messier, C.; Kembel, S.W. Leaf Bacterial Diversity Mediates Plant Diversity and Ecosystem Function Relationships. Nature 2017, 546, 145–147.

- Juroszek, P.; Von Tiedemann, A. Potential Strategies and Future Requirements for Plant Disease Management under a Changing Climate. Plant Pathol. 2011, 60, 100–112.

- Trewavas, A. Plant Intelligence: Mindless Mastery. Nature 2002, 415, 841.

- Trewavas, T. Plant Intelligence: An Overview. Bioscience 2016, 66, 542–551.

- Trewavas, A. Plant Intelligence. Naturwissenschaften 2005, 92, 401–413.

- Christie, J.M.; Murphy, A.S. Shoot Phototropism in Higher Plants: New Light through Old Concepts. Am. J. Bot. 2013, 100, 35–46.

- Hodge, A.; Berta, G.; Doussan, C.; Merchan, F.; Crespi, M. Plant Root Growth, Architecture and Function. Plant Soil 2009, 321, 153–187.

- Huynh, T.P.; Haick, H. Learning from an Intelligent Mechanosensing System of Plants. Adv. Mater. Technol. 2019, 4, 1–11.

- Meder, F.; Baytekin, B.; Del Dottore, E.; Meroz, Y.; Tauber, F.; Walker, I.; Mazzolai, B. A Perspective on Plant Robotics: From Bioinspiration to Hybrid Systems. Bioinspir. Biomim. 2022, 18, 015006.

- Hölker, F.; Wolter, C.; Perkin, E.K.; Tockner, K. Light Pollution as a Biodiversity Threat. Trends Ecol. Evol. 2010, 25, 681–682.

- Qu, C.C.; Sun, X.Y.; Sun, W.X.; Cao, L.X.; Wang, X.Q.; He, Z.Z. Flexible Wearables for Plants. Small 2021, 17, 1–25.

- Dufil, G.; Bernacka-Wojcik, I.; Armada-Moreira, A.; Stavrinidou, E. Plant Bioelectronics and Biohybrids: The Growing Contribution of Organic Electronic and Carbon-Based Materials. Chem. Rev. 2022, 122, 4847–4883.

- Lee, G.; Wei, Q.; Zhu, Y. Emerging Wearable Sensors for Plant Health Monitoring. Adv. Funct. Mater. 2021, 31, 2106475.