Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Paweł Węgierek | -- | 1600 | 2023-03-21 21:21:26 | | | |

| 2 | Peter Tang | Meta information modification | 1600 | 2023-03-22 02:13:27 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Węgierek, P.; Kostyła, D.; Lech, M. Vacuum Switching Devices in Medium-Voltage Networks. Encyclopedia. Available online: https://encyclopedia.pub/entry/42406 (accessed on 08 February 2026).

Węgierek P, Kostyła D, Lech M. Vacuum Switching Devices in Medium-Voltage Networks. Encyclopedia. Available at: https://encyclopedia.pub/entry/42406. Accessed February 08, 2026.

Węgierek, Paweł, Damian Kostyła, Michał Lech. "Vacuum Switching Devices in Medium-Voltage Networks" Encyclopedia, https://encyclopedia.pub/entry/42406 (accessed February 08, 2026).

Węgierek, P., Kostyła, D., & Lech, M. (2023, March 21). Vacuum Switching Devices in Medium-Voltage Networks. In Encyclopedia. https://encyclopedia.pub/entry/42406

Węgierek, Paweł, et al. "Vacuum Switching Devices in Medium-Voltage Networks." Encyclopedia. Web. 21 March, 2023.

Copy Citation

The development of power grid infrastructure and increasingly stringent environmental regulations have intensified work, carried out by researchers and electrical equipment manufacturers, to develop innovative gas-insulated, environmentally neutral devices. The emergence of new designs of circuit breakers and disconnectors, in which the resulting electric arc is extinguished in a vacuum environment, requires the development of appropriate techniques for diagnosing the chambers responsible for the dielectric parameters of the device.

vacuum technology

vacuum degree

pressure level

vacuum condition

vacuum measurement

dielectric strength

real-time monitoring

vacuum interrupter

1. Introduction

Electricity is one of the basic utilities used in today’s world. It is essential in almost every area of our lives, from powering large manufacturing plants to protecting human health and life. The ever-increasing amount of electricity consumed by consumers and the increased demands placed on networks in terms of continuity and quality of energy supply have led to the development of energy infrastructures [1][2][3], which is constantly being improved to meet the challenges posed. Innovative technologies are being applied to modern networks and have prompted the development of appropriate control and measurement techniques to verify the condition of the power network in operation [4]. The development of the electricity network has led to an increase in the importance of gas-insulated apparatus, particularly the importance of vacuum interrupter technology (VI—Vacuum Interrupters), whose main aspect of suitability for operation is the pressure inside the extinguishing chamber. Given the paramount importance of the pressure level in a vacuum chamber, the power industry faced another challenge of developing a real-time pressure measurement system to enable chamber diagnostics and thus predict potential damage and thus power outages.

2. Switching Devices in Medium-Voltage Networks

The VI technology, especially modern vacuum circuit breakers (VCBs—Vacuum Circuit Breakers) are of enormous importance in the power system, enabling switching processes to be carried out autonomously or with negligible dispatcher intervention. Vacuum circuit breaker technology is widely known and used in network infrastructure, mainly through the VD 4 series from ABB [5] and the SION series from SIEMENS [6]. Vacuum circuit-breakers practically dominate the switchgear in transformer substations due to their small size and excellent mechanical durability of up to 30,000 switching cycles, as well as the fact that no maintenance is required during normal operation.

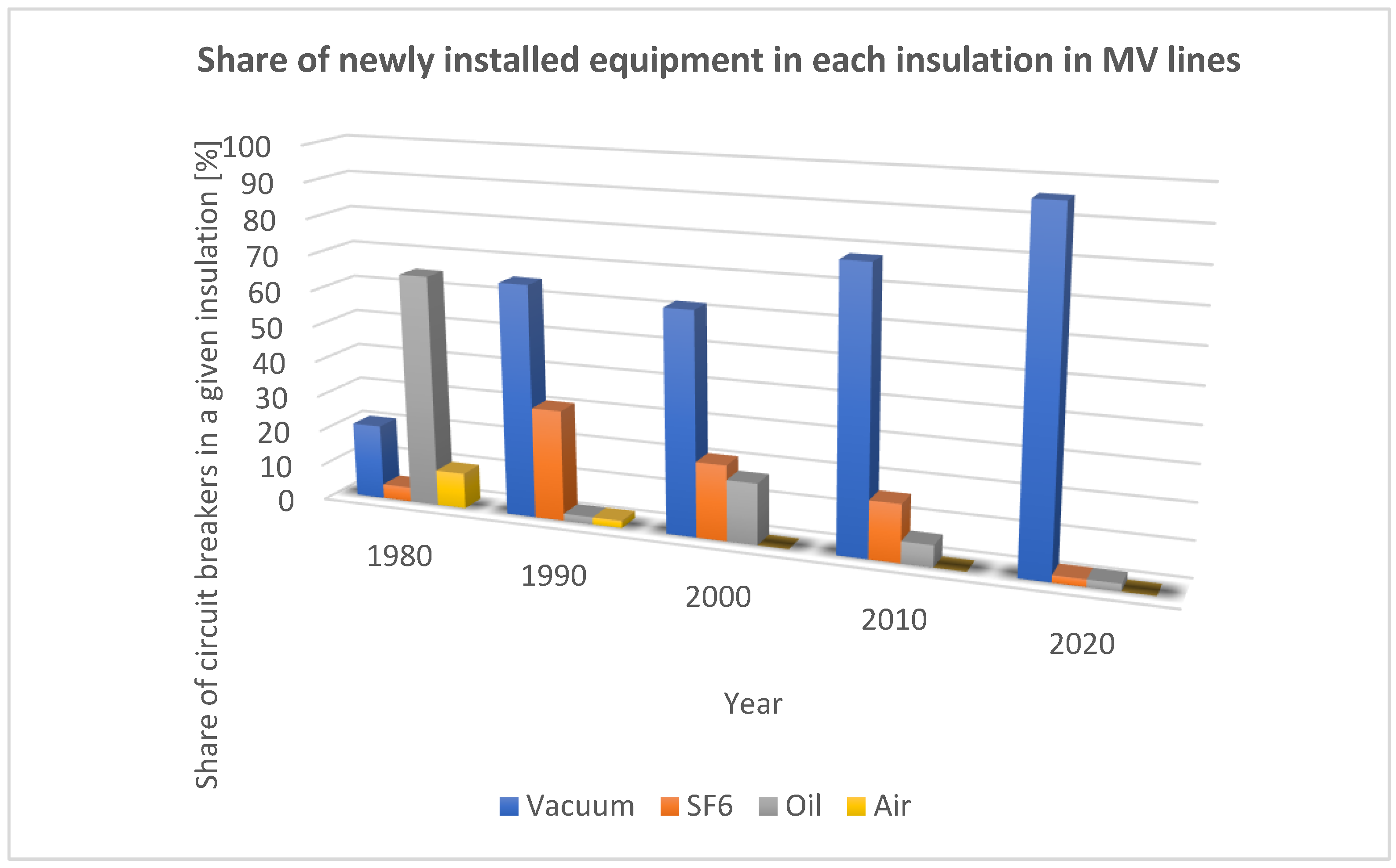

Over the decades, the market for arc extinguishing agents has been dominated by vacuum, this was not always the case, as shown in Figure 1 below.

Figure 1. Proportion of each type of equipment in the total number of installed apparatuses [7].

As can be seen from the diagram above, oil, air, sulfur hexafluoride (SF6) and vacuum have played the role of insulating medium in switchgear over more than four decades [8].

In the 1980s, oil-insulated circuit breakers were the most trusted. The entire circuit breaker unit was immersed in a tank filled with oil, whose function was to provide insulation and an arc extinguishing mechanism. These were usually located outside [9]. However, the great days of oil-insulated circuit breakers are already long gone and now they have been virtually eliminated from industrial applications in favour of vacuum circuit breakers.

Pneumatic air circuit breakers [10][11][12] have been used extensively in various types of circuits, especially conditions. They are equipped with blast coils, applicable for arc extinguishing by magnetic blast, and blast tubes that operate by forcing air down the tube from each nozzle of the contact assembly. They were completely displaced from the market in favour of vacuum units more than two decades ago.

Another type of gas-insulated apparatus encountered in networks are arc extinguishing switches in compressed SF6 [13][14]. In industrial environments where the use of oil circuit breakers was not possible due to fire hazards. The cool air created by convection enables them to operate at the correct temperature for the operating.

Sulfur hexafluoride and vacuum circuit breakers are similar in design. The main difference between these two apparatuses is the insulation, which is provided by different dielectric medium. The highly compressed gas is expelled from the arcs in the circuit breakers while the mechanism is operating and is then collected in a low-pressure container before being transported back to the high-pressure container for reuse. The effect of extinguishing the arc in SF6 is an extremely harmful residue from arc combustion. The fact that SF6 is a powerful greenhouse gas is also not insignificant. The pollutants released into the environment can have a very negative impact on the atmosphere. The technology used reduces the possibility of leakage from the circuit breaker during operation.

The most common adaptation of circuit breakers for more than four decades has been vacuum circuit-breakers [15][16]. This solution is nowadays widely used in various types of power systems. They are famous for their long service life and functionality and, above all, for their lack of negative environmental impact, which is extremely important in the context of an ongoing environmental policy. They provide a higher degree of reliability compared to air circuit breakers. Due to the fact that there is no ionizing agent and only the contact material is present, vacuum circuit breakers are characterized by low arc energy. The arc is extinguished already at a distance between contacts of 2–3 mm (typically 10 mm for MV networks). Near the point where the current passes zero, the discharge can no longer be maintained by the arc energy and the arc is extinguished.

As Figure 1 shows, for almost forty years there has been a constant increase in the amount of equipment in which vacuum technology is used, which has been reflected in the work of scientists and in the innovative designs of vacuum-insulated apparatus offered by manufacturers. in the work of researchers and in the innovative designs of vacuum-insulated apparatus offered by manufacturers. The dynamic development of the grid and stricter regulations on power outages have necessitated the development of new designs of vacuum equipment.

In countries with a low level of network cabling, such as Poland, medium-voltage overhead networks play a decisive role in shaping reliability factors. Inherent in these networks are disconnectors, which are typically installed in overhead lines, are responsible for connecting operating currents and are most often of open, less often of closed construction, but based on SF6 technology. It is only in the last decade that research work has been undertaken to develop a vacuum disconnector with a closed design, free of SF6, using vacuum technology.

The result of the work of researchers and manufacturers of switchgear intended for medium-voltage networks is EKTOS—an innovative medium-voltage overhead vacuum disconnector in a closed enclosure, dedicated to Smart Grids, which was developed in cooperation with researchers from Lublin University of Technology and a company EKTO from Białystok. The innovativeness of EKTOS lies primarily in the innovative, developed from scratch motor storage drive integrated with the contact system which is based on a DC motor, which has allowed the system’s dimensions and power requirements to be reduced to 90W. The place of contactors and limit switches has been taken by a starting system equipped with reed switches. In order to eliminate tie rods and thus simplify the design, the entire drive unit was located inside the disconnector structure. This form of drive system, to the authors’ knowledge, is not found in other devices of this type [17]. Bearing in mind that EKTOS is a device intended for use on overhead lines, its weight is not without significance. Components with reduced weight and size were used in the construction of the apparatus, which has resulted in the final weight of the device being approximately 1⁄5 that of known construction solutions. It is perfectly in line with global preferences in terms of the direction of network infrastructure development. It has based the operation on an emission-free medium such as vacuum, but there are still improvements in the dielectric resistance of the extinguishing medium through the use of noble gases or mixtures of these gases as an arc-extinguishing medium [18]. Another challenge faced by EKTOS is the need to provide real-time measurement of the gas pressure in the vacuum chamber so that potential damage resulting from unsealing of the extinguishing chambers can be predicted.

3. Pressure Control in Switchgear

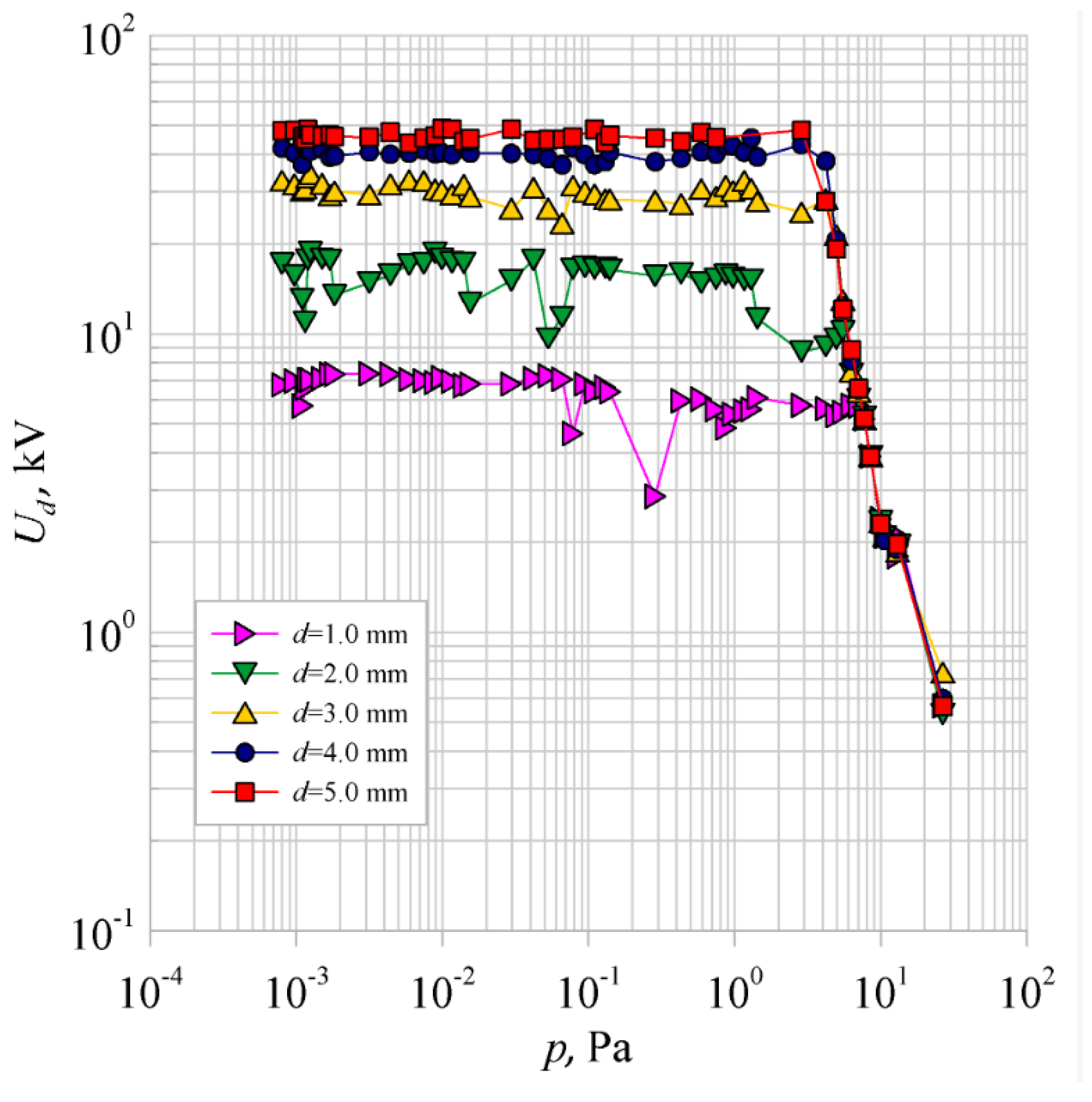

The control of the pressure level in gas-insulated apparatus is extremely important, as the vacuum retains its excellent insulating properties only up to a pressure level of 1 Pa, once the pressure increases beyond this value the breakdown voltage of the insulating gap drops dramatically [19][20][21]. This situation is shown in Figure 2 [18][22].

This is an extremely unfavorable situation, particularly given that the current switchgear used in the power industry is of enclosed construction, which makes it less susceptible to environmental factors and vandalism, but this is coupled with the inability to observe a safe insulation gap. The inability to determine what state the device is currently in poses a number of dangers, the greatest of which is the possibility of potential being transferred to the side that may be de-energized. This poses a serious risk to human health and even life, as maintenance crews carrying out maintenance work on a theoretically de-energized line can be electrocuted. This illustrates the magnitude of the problem of pressure control on gas-insulated equipment. The dielectric strength of the vacuum for different contact distances is shown in Figure 2 [18][22].

The problem of measuring the pressure in vacuum chambers and thus determining the technical condition of these apparatuses affects all equipment that uses vacuum as an extinguishing medium, but it is particularly acute for disconnectors which, due to the specific nature of the switching operations carried out, require knowledge of the pressure prevailing in the extinguishing chamber and thus the ability to determine the presence of a safe insulation gap.

References

- Colak, I.; Bayindir, R.; Sagiroglu, S. The Effects of the Smart Grid System on the National Grids. In Proceedings of the 2020 8th International Conference on Smart Grid (icSmartGrid), Paris, France, 17–19 June 2020; pp. 122–126.

- The EU in the World-Energy-Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=The_EU_in_the_world_-_energy#Electricity_generation (accessed on 11 August 2022).

- Mohanty, S.P.; Choppali, U.; Kougianos, E. Everything you wanted to know about smart cities: The Internet of things is the backbone. IEEE Consum. Electron. Mag. 2016, 5, 60–70.

- Morello, R.; de Capua, C.; Fulco, G.; Mukhopadhyay, S.C. A Smart Power Meter to Monitor Energy Flow in Smart Grids: The Role of Advanced Sensing and IoT in the Electric Grid of the Future. IEEE Sens. J. 2017, 17, 7828–7837.

- VD4-Medium Voltage Vacuum Circuit-Breakers. Available online: https://search.abb.com/library/Download.aspx?DocumentID=1VCP000001_A&LanguageCode=pl&DocumentPartId=&Action=Launch (accessed on 28 November 2022).

- Totally Integrated Power-SION Wyłączniki Próżniowe SION Typu 3AE5 i 3AE1 Aparaty Łączeniowe Średniego Napięcia. Available online: https://publikacje.siemens-info.com/pdf/115/Wy%C5%82%C4%85czniki%20pr%C3%B3%C5%BCniowe%20SION.pdf (accessed on 8 September 2022).

- Slade, P.G. The Vacuum Interrupter, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2020.

- Alsumaidaee, Y.; Yaw, C.; Koh, S.; Tiong, S.; Chen, C.; Ali, K. Review of Medium-Voltage Switchgear Fault Detection in a Condition-Based Monitoring System by Using Deep Learning. Energies 2022, 15, 6762.

- Yeckley, R.; Perulfi, J. Oil circuit breakers: A look at the earlier generation . IEEE Power Energy Mag. 2018, 16, 86–97.

- Pei, X.; Cwikowski, O.; Vilchis-Rodriguez, D.S.; Barnes, M.; Smith, A.C.; Shuttleworth, R. A review of technologies for MVDC circuit breakers. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 3799–3805.

- Park, W.; Kim, Y.K.; Lee, S.; Ahn, K.-Y.; Kim, Y.-G. Arc phenomena and method of arc extinction in air circuit breaker. In Proceedings of the 25th International Conference on Electricity Distribution (CIRED 2019), Madrid, Spain, 3–6 June 2019.

- Air Circuit Breaker: Construction, Types, Working & Its Applications. Available online: https://www.elprocus.com/air-circuit-breaker-acb-working-principle-application/ (accessed on 12 November 2022).

- Tian, S.; Zhang, X.; Xiao, S.; Zhang, J.; Chen, Q.; Li, Y. Application of C6F12O/CO2 mixture in 10 kV medium-voltage switchgear. IET Sci. Meas. Technol. 2019, 13, 1225–1230.

- Seeger, M.; Smeets, R.; Yan, J.; Ito, H.; Claessens, M.; Dullni, E.; Falkingham, L.; Franck, C.M.; Gentils, F.; Hartmann, W.; et al. Recent Trends in Development of High Voltage Circuit Breakers with SF6 Alternative Gases. Plasma Phys. Technol. 2017, 4, 8–12.

- Xemard, A.; Jurisic, B.; Rioual, M.; Olivier, A.; Sellin, E. Interruption of small, medium-voltage transformer current with a vacuum circuit breaker. Electr. Power Syst. Res. 2020, 187, 106502.

- Moore, T.; Schmid, F.; Tricoli, P. Voltage transient management for Alternating Current trains with vacuum circuit breakers. IET Electr. Syst. Transp. 2021, 12, 1–14.

- Węgierek, P.; Staszak, S.; Pastuszak, J. EKTOS—Innowacyjny napowietrzny rozłącznik próżniowy średniego napięcia w obudowie zamkniętej przeznaczony do sieci smart grids. Wiadomości Elektrotechniczne 2019, 1, 23–27.

- Węgierek, P.; Lech, M.; Kostyła, D.; Kozak, C. Study on the Effect of Helium on the Dielectric Strength of Medium-Voltage Vacuum Interrupters. Energies 2021, 14, 3742.

- Martins, P.; Silva, C.; Oliveira, J.; Marques, A. Preliminary Tests with Screen-Printed Piezoresistive Pressure Sensors on PET and Textile Substrates. In Proceedings of the 2022 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Vienna, Austria, 10–13 July 2022; pp. 1–4.

- Kumar, S.; Rathore, P.K.; Rangababu, P. Implementation of operational amplifier for the designing of novel piezoresistive pressure sensor. In Proceedings of the 2018 2nd International Conference on Smart Sensors and Application (ICSSA), Kuching, Malaysia, 24–26 July 2018; pp. 126–129.

- Pan, L.; Chortos, A.; Yu, G.; Wang, Y.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun. 2014, 5, 3002.

- Bang, S.; Lee, H.W.; Lee, B.W. Real-time monitoring of the vacuum degree based on the partial discharge and an insulation supplement design for a distribution class vacuum interrupter. Energies 2021, 14, 7891.

More

Information

Subjects:

Engineering, Electrical & Electronic

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

553

Revisions:

2 times

(View History)

Update Date:

22 Mar 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No