The main advantages of metallic wire are the full use of raw materials free of waste, and the easy handling and storage without any special conditions or requirements, except for a closed packing to keep the surface clean since the surface of metallic wire must be free of impurities. The main disadvantage is the lack of commercial wire with different compositions, as is the case with many high-strength aluminum alloys that are not commercially available as wire. Additionally, the chemical composition of the wire used cannot be modified, in contrast to powder feedstock, that can be mixed with alloying elements. Consequently, only a few compositions can be employed in the final part.

2. Processes to Produce Metal Wires for AM

Production of wires is achieved by different techniques, such as casting, extrusion, and drawing. The most conventional process is casting, which uses ingots of metallic alloys. It is an elementary method that has been used for many years.

Drawing produces wires from rods, bars or plates. By means of a pulling force, the material goes through a die (a rigid tool with a wear-resistant surface), changing and reducing the cross-section. The process requires cleaning and lubrication before going through a die. Kabayama and Taguchi

[9][10] defined the most important features of the drawing process as follows:

-

Lubricant (friction coefficient, viscosity, surface treatment)

-

Wire properties (yield stress, elastic modulus, strain rate, strain-hardening)

-

Die geometry (reduction angle, bearing region length, reduction area, material).

The extrusion process is also an alternative for producing wires. Friction extrusion uses a heat source generated by the rotating friction between the raw material and the dies used in the process under load. When the material exhibits plastic behavior, it is forced to flow through the die.

Researchers at the University of South Carolina (USC) obtained 2050 and 2195 aluminum wires. They used friction extrusion to obtain the preliminary rod, followed by drawing, giving the wires a length range between 1.7 and 2.3 m

[11]. They also showed that 15 drawing steps can be needed to obtain the final wire with a 1.6 mm diameter. The 0.1 mm step size was used to reduce 2.7 mm starting diameters to 1.6 mm. Annealing and reannealing can alleviate work hardening caused by drawing to prevent wire breaking in the posterior drawing

[12]. The purpose of this work was to design wires by wire arc additive manufacturing (WAAM) and explore the possibility of modifying the characteristics and initial compositions to obtain a specific final wire. This research concluded that post-extrusion drawing could improve the applicability of extruded wires in the following ways:

Moreover, powder consolidation in the wires is possible. The direct extrusion of powders, which is a simple metal-forming process, is being developed to obtain preliminary rods. In the subsequent step, these rods can be drawn to obtain wires. Some studies have already been carried out for this purpose, obtaining high-strength Al alloy rods by direct extrusion processes

[13][14].

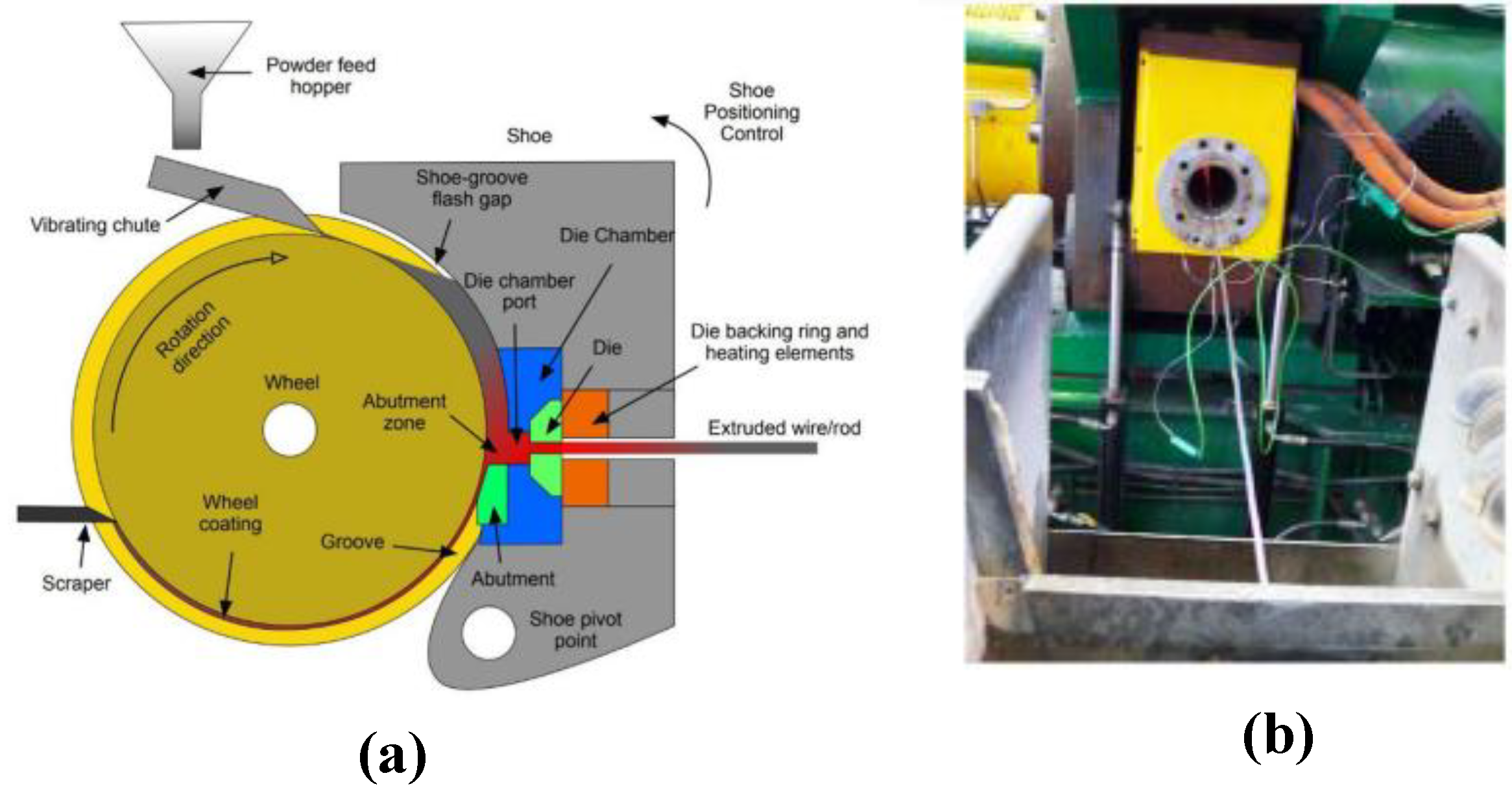

Another process to produce wires from powders is the Conform™ process (Figure 1). Continuous extrusion or Conform™ is used to transform powders, particulates, or waste products, such as machining swarf, into a rod/wire, by means of severe plastic deformation processes. It is possible to obtain a diameter wire of < 5 mm by means of cold drawing with 100% of the material used.

Figure 1. (

a) Scheme of the Conform machine. (

b) Extruded wire exiting from the Conform machine and entering the water trough for quenching

[15].

WAAM, whose classification is explained below, has been established as a potential technology for the large-scale production of aluminum alloy parts; however, its application is currently limited by the porosity and low mechanical properties attained.

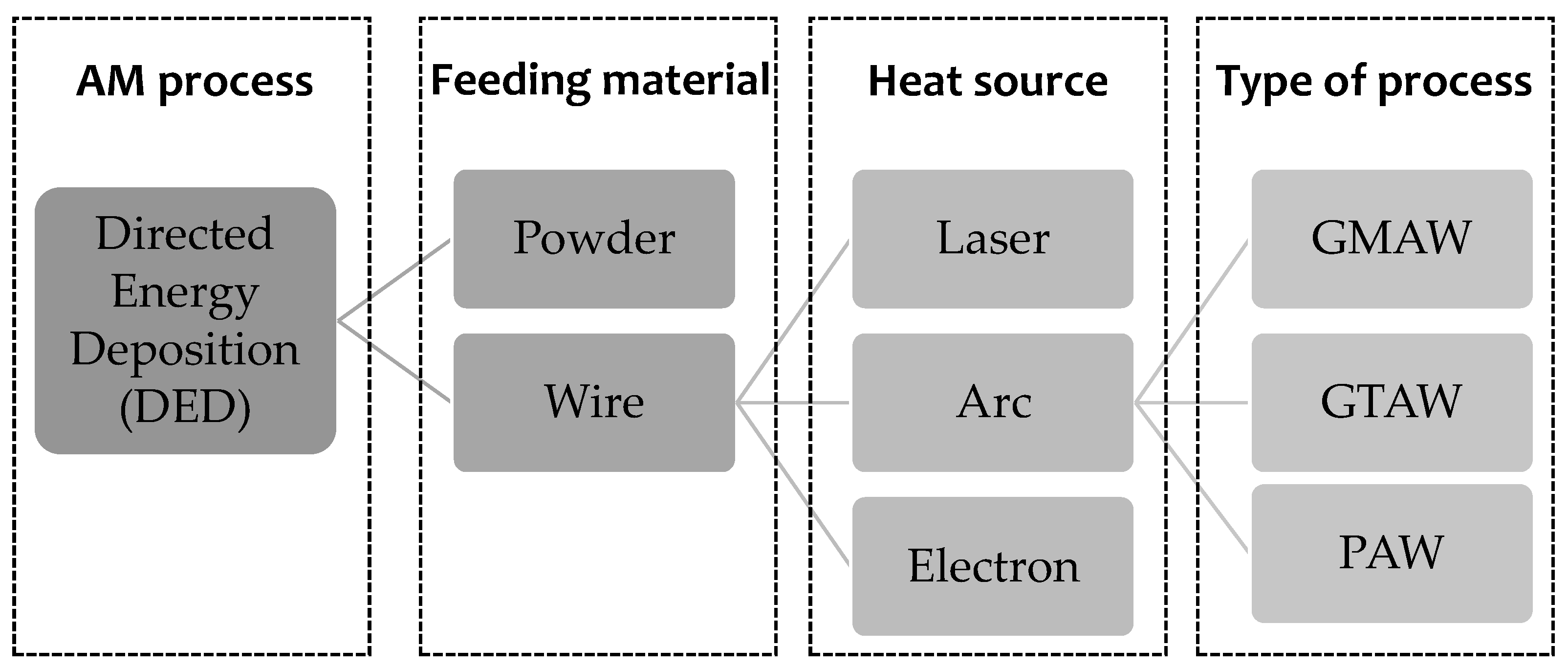

3. Classification of the WAAM Techniques and Their Characteristics

The classification of the WAAM techniques based on the type of welding technique used is shown in

Figure 2: gas metal arc welding (GMAW), plasma arc welding (PAW), and non-consumable tungsten electrode welding (gas tungsten arc welding, GTAW)

[16].

Figure 2. Classification of the DED process

[3].

GMAW generates an electric arc as the heat source between the consumable metal electrode and the workpiece. GMAW has two variants: metal inert gas (MIG) and metal active gas (MAG). It is ideal for producing parts on a large scale in short periods of time. These techniques basically consist of an electric arc established between the tip of a consumable wire and the part under the protection of an inert or active gas that protects the weld pool and the adjacent material. The deposition rate is 15–160 g/min

[17], which is higher compared to GTAW and PAW.

GTAW and PAW generate an electric arc between the nonconsumable tungsten electrode and the workpiece. The difference with GMAW is that GTAW and PAW require a wire feed that is externally provided. The orientation and the wire feeding direction determine the characteristics and quality of the deposited material

[7]. PAW and GTAW have features in common, such as a nonconsumable electrode to establish the electric arc and using an inert shielding gas without filler material

[16][17]. However, PAW is a higher energy density process, where excellent stability is achieved due to the arc passing through an orifice between the cathode and anode. Consequently, the weld bead obtained by PAW tends to be narrow since it allows the welding speed to be controlled. The deposition rates are low, approximately 1 g/min, achieving a high-quality surface finish.

On the other hand, the deposition rate for the GTAW technique can be as high as 30 g/min, and the total wall width is thicker (4–15 mm) than the one obtained by PAW (2 mm). The beam’s penetration is higher with PAW, causing the fusion of the previously deposited layers and compromising the wall’s stability

[17].

New techniques have been developed to improve the method according to the material used. A variation of the GMAW process, also known as a modified metal inert gas (MIG), is a cold metal transfer (CMT). CMT, known as the freezing process, compared to the other welding techniques

[3], alternates cooling and heating based on a short circuit with high and low current and voltage. It applies noticeably less heat input than traditional GMAW and differs from the latter in its excellent control over penetration, a high wire melting efficiency, and a high deposition rate. Another variant is GMAW in tandem. A tandem uses two independent welding systems, synchrony, and two wires. The energy input and deposition rates are higher.

4. Overview of WAAM

In 1925, Baker

[18] carried out studies using an electric arc as a heat source and metal wire as feedstock, but the earliest research into WAAM dates back to 1926, when Baker patented “the use of an electric arc as a heat source to generate 3D objects depositing molten metal in superimposed layers”

[19]. Baker used a new technique to build a 3D object using welding, the oldest known attempt to use welding technology in additive manufacturing. The same year, Eschholz

[20] used an electric arc to deposit metal to create a variety of ornamentation using only a single layer and identified the primary process variables, such as arc current, depth of penetration, travel speed, substrate material, bead width, and height.

In 1935, an electric arc was covered beneath a bed of granulated flux known as SAW (submerged arc welding). The process patented by Jones, Kennedy, and Rothermund

[21] required a continuously fed consumable solid or tubular (metal-cored) electrode. In 1947, 20 years later, Carpenter et al.

[22] patented the method for metal coating of metal pipes by electric fusion. This invention was used in the production of magnesium retorts, having a carbon steel base clad with a high chromium, high nickel steel alloy coating of one-half inch and a base metal thickness of one inch.

Numerous patents were accepted as the first steps in wire and arc additive manufacturing. In 1950, a process for additive manufacturing with wire deposition was described by Muller Albert et al.

[23]. In 1971, Ujiie (Mitsubishi) fabricated a pressure vessel using SAW, electroslag, and TIG, and also employed different wires to provide functionally graded walls. In 1983, Kussmaul

[24] used shape welding to manufacture high-quality, large, nuclear structural steel parts with a deposition rate of 80 kg/h and a total weight of 79 tons

[25].

In recent years, WAAM techniques have progressed, incorporating post-processing such as heat treatment of parts and research into corrosion behavior. In addition, the integration of rapid prototyping using CMI-WAAM allows bimetallic materials to be obtained and memory alloys to be shaped.

Recent studies have also focused on increasing the deposition rate. Project development by Stewart Williams at Cranfield University has made considerable contributions to the fields of aluminum and WAAM

[26][27][28]. The researchers developed the WAAM process capable of creating the most significant part, a six-meter-long, 300-kg, double-sided spar created from aerospace-grade aluminum

[29].

5. Overview of Al-Cu-Li Alloys

5.1. Introduction to Al-Li Alloys

The most widely used aluminum alloys in the aerospace industry are the precipitation-hardening Al-Cu alloys (2xxx series) and Al-Zn alloys (7xxx series) due to their high strength-to-weight ratio. Al-Cu-Li alloys are lightweight and ideal for reducing weight and achieving lighter and stronger parts

[30]. However, Al-Cu-Li alloys are expensive compared to other aluminum alloys, with a cost that is three to five times higher than the others.

Research into Al-Cu-Li alloys began in the U.S. and Germany in the early 1920s. Although this research was interrupted for many years, in 1980, researchers developed the second generation of Al-Cu-Li alloys

[31]. These alloys clearly have improved mechanical properties compared to the first-generation ones. However, the properties still could not meet most aircraft specifications in terms of thermal stability, corrosion resistance, isotropy, and weldability. The third generation of Al-Li alloys was then developed to overcome these issues

[30], and some of them were finally used in the aerospace industry. For instance, AA2060 and AA2050 alloys present excellent properties, such as thermal stability, corrosion resistance, and high specific strength

[32].

5.2. Al-Cu-Li Alloys and Their Applications

Despite the fact that the development of third-generation alloys has led to new applications in the aerospace industry, their high cost has not allowed them to be fully exploited and implemented in new applications.

Conventional aluminum alloys, such as 2024 and 7055, are still widely used. The most common aluminum alloys for aerospace are 2014, 2024, 5052, 6061, 7050, 7068, 7075, 2219, 6063, and 7475. However, the alloys that are being employed for additive manufacturing techniques are mainly 2524, 7055, 7150, and AA2024, which are currently employed in the Boeing 777.

Nevertheless, some Al-Li alloys, such as 8090, have been proposed to replace AA2014, AA7010, AA2024, and AA7075 in various locations of the EH101 helicopters for structural and nonstructural applications. In particular, in floor installations, brackets, stiffeners, longerons, bulkheads, tail cone skins, flying control structures, door rails, and seat tracks

[33]. AA8090 has also been evaluated for cryogenic fuel tanks.

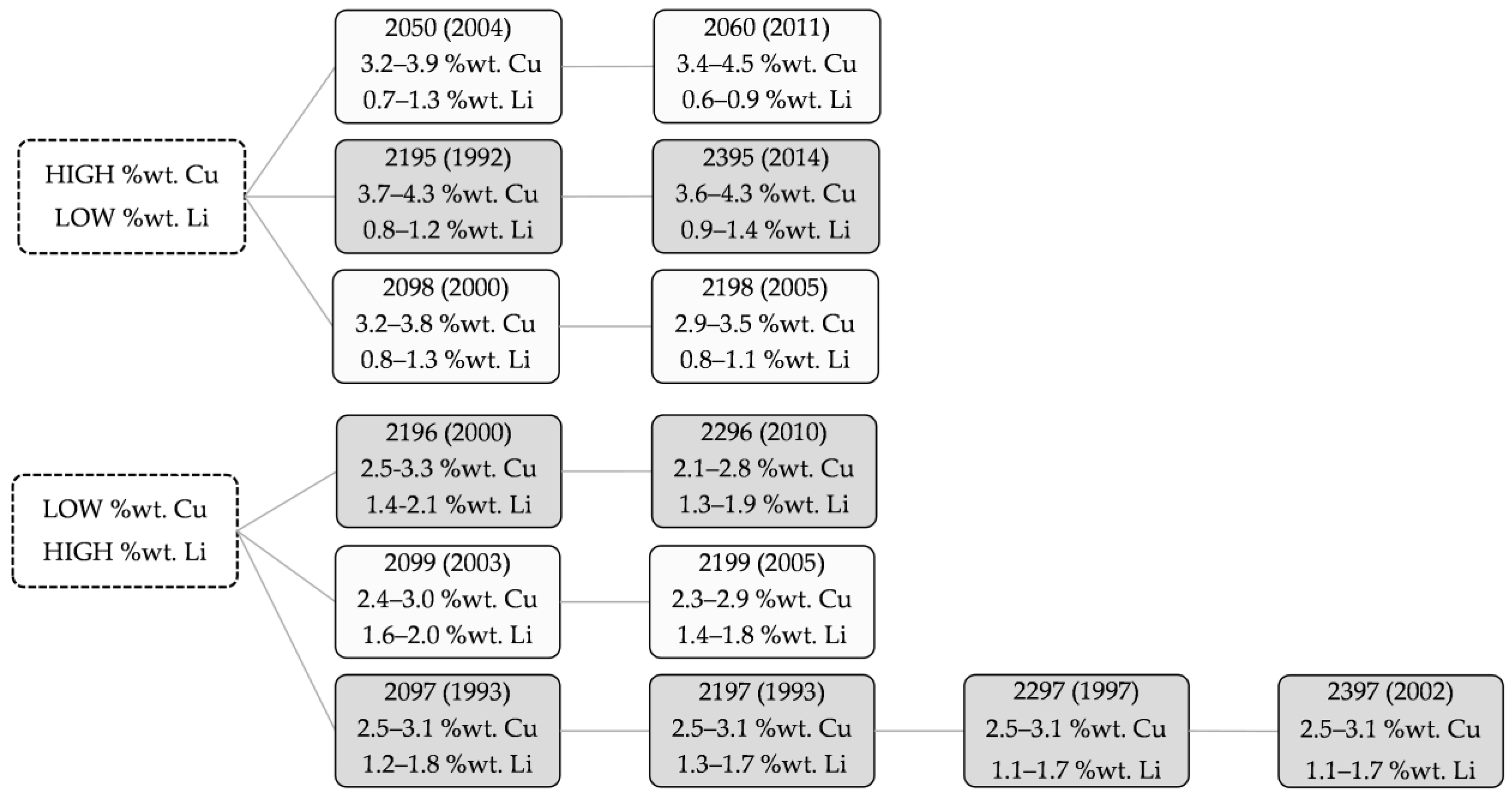

According to Al-Cu-Li alloys,

Figure 3 shows the most used Al-Cu-Li alloys. The compositions can be found in the Aluminum Association, revised in 2018

[34]. These alloys can be divided into two main groups: high-copper and low-lithium, and low-copper and high-lithium.

Figure 3. Scheme of the most used Al-Cu-Li alloys.

5.3. Influence of the Main Alloying Elements

The addition of lithium reduces the density of the alloy substantially while increasing its strength more than any other element added. Each increment of 1 wt.% of lithium decreases the density by 3% and increases the elastic modulus (E) by approximately 6%

[35][36][37]. Approximately 14–16 at.% (4.7 wt.%) of Li can be wholly dissolved in solid Al at 600 °C

[38].

In addition, the low atomic weight of Li (6.94 g/mol) gives it the highest heat capacity compared to any other metal (in terms of J/kg·K). These properties and its relatively good thermal conductivity make Li an appealing high-temperature heat transfer material

[38]. It can be a disadvantage because aluminum also presents high thermal conductivity, making it challenging in some undercooling processes.

Al-Li precipitates tend to nucleate heterogeneously on grain boundaries in slowly cooled and overheated alloys. The precipitates sequence can be described as a solid solution α + δ’ + δ → α + δ where δ is the equilibrium phase (AlLi) and δ’ metastable phase (Al

3Li). They can also easily nucleate homogeneously in the matrix, forming spherical precipitates, thanks to their low interfacial energy with the matrix (approximately 14 MJ/m

2) and low precipitation activation energy

[39].

The addition of copper improves strength and hardness and reduces corrosion resistance. During aging, the precipitates, solute-rich domains produce the strengthening effect in the alloy. These areas are fully coherent with the matrix, but the atomic spacings are different enough to distort the crystal lattice without discontinuity in the matrix. When the movement of dislocations is obstructed, an increase in strength is attained. Al-Cu systems follow this sequence during heating, where GP corresponds to Guinier–Preston zones

[40]:

Super saturated solid solution → Cu clustering → G.P.1 → G.P. 2 (θ’’) → θ’ → θ

θ’’ is an intermediate precipitate, with a tetragonal structure, which maintains coherency with the Al matrix. When θ’ appears, the strengthening is reduced. Further heating causes the transformation from θ’ to θ, an equilibrium precipitate, with the composition Al2Cu.

The addition of magnesium increases strength due to solid solution strengthening. Additions greater than 1.6 wt.% Mg in Al-Cu alloys promote the formation of the metastable, incoherent S’ (Al

2CuMg) phase near grain boundaries

[41].

The addition of silver and Mg stimulates the nucleation of a fine and uniform dispersion of T1 phase

[42]. However, it is essential to take into account that adding elements, such as Ag, makes the alloy more expensive.

The addition of manganese promotes the formation of precipitates of the Al

20Cu

2Mn

3 phase, which controls grain size and texture during the thermomechanical processing

[43]. This helps improve creep resistance and damage tolerance in fracture toughness and fatigue.

Titanium interacts with the Al matrix to form Al

3Ti intermetallic, strengthening in addition to conventional precipitation hardening (such as in the θ’ (Al

2Cu) phase). A study shows that adding 0.6% Ti to an Al-Cu-Mg-Ag alloy promotes the precipitation of finer and denser θ’ (Al

2Cu) phase. It also promotes the formation of the intermetallic phase Al

3Ti. In contrast, if the addition of Ti is increased to 1.1%, no improvements are observed; the results reveal that a high volume of Al

3Ti phase is likely detrimental to strengthening

[44].

Furthermore, it is widely used as a grain refiner. In particular, and regarding the WAAM techniques, Wang, L. et al.

[45] studied the Al-Mg alloy for WAAM, using ER5356 as the filling wire and adding Ti powder between layers as a grain refiner. This study reports that the Al3Ti phase provides heterogeneous nucleation cores. The addition of Ti powder during WAAM can promote effective transformation from columnar to equiaxed grains at the interlayer interface. The ultimate tensile strength and elongation increase by 20.25 MPa and 3.13% in the horizontal direction, and by 25.89 MPa and 6.97% in the vertical direction. This study highlights the addition of Ti as a grain refiner as an excellent strategy to obtain isotropic and improved mechanical properties in the WAAM technique.

The addition of zirconium promotes the formation of coherent dispersoid β’ (Al

3Zr) and θ’ and T1 phases and reduces the solubilities of lithium and magnesium in Al alloys

[46]. Zr inhibits recrystallization and grain growth at elevated temperatures

[47].

The small additions of Scandium act as a core for the formation of very refined grain microstructures. At the same time, its influence has led to the development of a new alloy, Scalmalloy (AlMgSc), developed by the Airbus Group Innovations

[48]. The addition of Sc results in high mechanical properties, good ductility, and specific resistance.

6. General Welding Problems for Aluminum Alloys

The most relevant concerns related to aluminum alloys applied to additive manufacturing techniques are: the oxidation of the material surface due to the formation of Al

2O

3, the solidification shrinkage (compared to ferrous metallic materials) due to the wide solidification temperature range, the high coefficient of thermal expansion (CTE), which leads to cracking phenomena due to high solidification stresses and shrinkage, high reflectivity, high thermal conductivity (which leads to rapid dissipation of heat from the scanned area and requires greater source heat), and the high solubility of hydrogen in liquid aluminum (which leads to pore formation)

[49].

7. Suitable WAAM Techniques for Al-Cu-Li Alloys

There is scant use of WAAM in Al-Cu-Li alloys. The first research study carried out focused on post-WAAM treatments to improve properties, such as removing porosity and increasing strength. However, other problems, such as the surface oxide film (alumina), which has a higher melting point than Al, cannot be addressed by those post-treatments. For this purpose, the most recent studies have focused on a variant of the WAAM technique that works with alternating current (AC).

AC mode allows the current waveform (frequency and balance) to be modified. In one half of the cycle, the electrode will be negative (with the base plate positive), and in the next half, the electrode tip will be positive (with the base plate negative). The balance represents the relationship between the penetration (EN, electrode negative) and cleaning action (EP, electrode positive) in the percentage of the cycle. The AC mode is necessary for Al-Li alloys since it allows both actions to be worked on: cleaning the oxide layer and heating a weld bead

[50]. During the cleaning, the electrons remove the oxide layer from the aluminum surface, and the shielding gas prevents new oxide from being formed during the welding process.

VP-GTAW (variable polarity gas tungsten arc welding) was applied successfully on an Al-Cu-Li alloy, in particular 2050 wire, and a thin straight wall was deposited

[51]. The results showed that the inner layers consisted of refined, equiaxed grains, compared to the interlayers, which consisted of coarse, columnar grains. The secondary phases were θ (Al

2Cu) and δ’ (Al

3Li) phases, which were dispersed along the grain boundaries after post-deposited heat treatment. The mechanical properties, such as microhardness, in the heat-treated sample were 141HV, which showed an increase of 98.6% compared to that of the deposited one (71HV), and 55% compared to that of the wire (91HV).

Other variants of GMAW, such as cold metal transfer (CMT), are of particular interest for Al-Cu-Li alloys: CMT-P, CMT-ADV, and CMT-PADV. The CMT-P refers to pulsing recurrent, in which the high pulse current results in a higher heat input compared to the conventional CMT-ADV. The advanced path involves a polarity reversal in the short circuit; and the combination of both is CMT-PADV and pulse-advanced. CMT-PADV, developed by Fronius

[17], greatly improves porosity due to the control of the polarity and the pulse cycles

[52]. The most significant characteristics are the low thermal heat input, the high deposition rate, and the low spatter, which have been shown to eliminate gas pores due to an oxide cleaning effect.

To evaluate the applicability of the alloy to WAAM techniques, it is necessary to carry out numerous weldability tests. No alloy should be discarded due to its chemical composition or the possibility of the evaporation of elements with low vapor pressure, such as Li or Zn.

The combined effect of CMT, interlayer rolling, and heat treatment on the porosity and oxide cleaning surfaces of aluminum alloy by WAAM is an area of interest for many researchers. The interlayer rolling contributes to reducing porosity and greatly influences the grain structure. When rolling is applied, depending on the load, precipitates break into smaller sizes. After heat treatment, a uniform distribution of refined, smaller grains is attained. For the 2024 alloy, a preliminary study by Fixter et al.

[53] showed that, with adequate control of porosity and subsequent heat treatment, the tensile properties could be improved through the WAAM process to levels comparable to those of the standard wrought products. By rolling each added layer, the interpass deformation was found to lead to further refinement in grain size and improved ductility.

New pulse technologies, such as PMC (pulse multicontrol) and PMC mix, are based on pulse-controlled spray arcs optimized by tight control algorithms. The company Fronius has managed to modify the power source platform (TPS) to obtain better welding results. Process stability is improved, heat input is reduced compared to MIG, and there is almost no spatter. Consistently, good penetration is guaranteed, there is less undercutting, and it is possible to weld more quickly and more cost-effectively. PMC Mix technology combines this pulse-controlled transfer to cycles controlled short-circuit, generating a colder phase and reducing the heat input even more

[54][55].

Gomes et al.

[54] also compared the PMC and CMT techniques for Al alloys. The porosity was smaller than 175 µm in diameter and was dispersed in both cases. Samples by PMC and PMC mix showed a pore fraction of 0.21% and 0.80%, respectively, much lower compared to those by CMT and CMT-P techniques, which showed 0.54% and 1.16%, respectively. These results are particularly interesting for Al-Cu-Li alloys. Regarding mechanical properties, nearly isotropic properties were obtained with a difference of 13 MPa higher in the longitudinal direction of the deposition. Therefore, the small pore fractions and the regularity of the deposits obtained with PMC and PMC Mix, compared with CMT and Pulsed-MIG, point to the benefits of these techniques.

Synchro-feed welding

[56] is the most advanced technology and produces a high-quality and high-speed weld without requiring a post-weld cleanup. It incorporates a driven wire feeder within the torch body, advancing the welding wire forward to create an arc. It then retracts the wire while synchronizing with a specialized weld current waveform that extinguishes the arc to make consistent droplet transfer with virtually zero weld spatter. This way, it combines a speedy wire feed control and ultra-low spatters with ultra-low heat input and ultra-low smut. Finally, it results in a very neat, precise weld laid down at a rate of up to 100 inches (254 cm) per minute using a welding current of up to 300 amps

[56].

Another improvement was found by Zhang et al.

[57] y means of the workpiece vibrating in combination with the VP-CMT technique. The most conclusive results were the refined grain and the homogenized grain distribution with increased vibration. The average grain size decreased due to the over-threshold bending stresses induced by workpiece vibration, breaking the dendrite arms and evolving into more nuclei. In this way, the workpiece vibration was able to significantly reduce the porosity from 6.66% to 1.52% and improve the mechanical properties; the workpiece vibration induced the molten pool stirring, which removed the fine grain zone of the interlayers and the pore defects

[57]. Therefore, the combination of vibration and WAAM techniques will help to significantly reduce porosity in Al-Cu-Li alloys.