Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | OSMAN YASIR KOYUN | -- | 2118 | 2023-03-07 21:55:01 | | | |

| 2 | Conner Chen | Meta information modification | 2118 | 2023-03-09 04:17:44 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Koyun, O.Y.; Balta, I.; Corcionivoschi, N.; Callaway, T.R. Structure of the North American Beef Industry. Encyclopedia. Available online: https://encyclopedia.pub/entry/41947 (accessed on 07 February 2026).

Koyun OY, Balta I, Corcionivoschi N, Callaway TR. Structure of the North American Beef Industry. Encyclopedia. Available at: https://encyclopedia.pub/entry/41947. Accessed February 07, 2026.

Koyun, Osman Y., Igori Balta, Nicolae Corcionivoschi, Todd R. Callaway. "Structure of the North American Beef Industry" Encyclopedia, https://encyclopedia.pub/entry/41947 (accessed February 07, 2026).

Koyun, O.Y., Balta, I., Corcionivoschi, N., & Callaway, T.R. (2023, March 07). Structure of the North American Beef Industry. In Encyclopedia. https://encyclopedia.pub/entry/41947

Koyun, Osman Y., et al. "Structure of the North American Beef Industry." Encyclopedia. Web. 07 March, 2023.

Copy Citation

North America is a large producer of beef and contains approximately 12% of the world’s cattle inventory. Feedlots are an integral part of modern cattle production in North America, producing a high-quality, wholesome protein food for humans.

feedlot cattle

zoonoses

STEC O157:H7

1. Introduction

Cattle, along with other ruminants, have provided humanity a stable supply of meat and dairy products since their domestication. In 2021, the per capita consumption of beef was approximately 26.7 kg in the United States [1], 16.9 kg in Canada [2], and 14.8 kg in Mexico [3]. North America is a large producer of beef for both domestic and export purposes, with more than 119 million heads of cattle, which represents approximately 12% of the world’s cattle inventory [4][5]. The United States has the largest cattle inventory (approximately 98.8 million cattle and calves in both beef and dairy operations) in North America [4][5]. Feedlots have been an integral part of modern beef cattle production in North America for more than 60 years, producing wholesome, highly desirable and marketable carcasses throughout the course of the year at a low cost to produce a high-quality protein food for humans [6][7]. Feedlots are typically located in the Great Plains region of North America and are located near both grain production and stocker/backgrounding regions. Cattle are fed in feedlots to take advantage of the economies of scale related to having many cattle located in one facility.

Readily digestible, high-energy rations are provided to cattle through communal feed bunks or troughs (Figure 1) at feedlots (i.e., a confined area for growing or fattening cattle) during their final stage of growth, which is also known as finishing. It is at this point that marbling (i.e., intramuscular fat) is deposited in muscular tissues [6][7]. Feedlot rations mostly rely on corn (Zea Mays L.) supplemented with a protein source and often include by-products from other industries (e.g., dried distiller’s grains, brewer’s yeast) [6][8]. Cattle are usually fed 2–3 times per day in order to maximize feed consumption and growth efficiency. Feedlot cattle typically gain 1–2 kg/d and have a feed efficiency of approximately 5 to 6 kg feed/kg gain [9]. Commonly, these feedlot rations contain less than 10% forage (e.g., corn silage), and the feeding of such high-energy density rations can lead to the development of ruminal acidosis (low ruminal pH) [10]. When we feed cattle, we are actually feeding the microbial population of the rumen and hindgut (i.e., cecum, colon, and rectum), which ferment feedstuffs to produce Volatile Fatty Acids (VFAs) that cattle utilize for energy, and Microbial Crude Proteins (MCP), which ruminants use as their primary dietary protein source [11]. Feeding with starch has an advantage, as the microbial fermentation produces a greater proportion of propionate than when cattle are fed forage-based rations. Propionate is glucogenic and leads to intramuscular fat deposition (i.e., marbling) [12].

Figure 1. Cattle share communal feed bunks or troughs.

Despite ground-breaking advancements in the animal production and animal health aspects of feedlot systems, cattle can still have certain conditions and diseases that impact their health, growth performance, and carcass characteristics, and some of these can also impact human health [13][14][15][16]. Diseases are mostly transferred between cattle in a fecal–oral or direct contact fashion; however, they can originate from the environment and be spread by vectors (e.g., animals, rodents, or insects) or fomites (e.g., water, feed, surfaces, and soil), and pathogen carriage in the gastrointestinal tract (GIT) of cattle often leads to the direct or indirect contamination of feeds and the feedlot environment (e.g., water troughs and feed bunks, and feedlot pen surfaces) [14][15][17][18]. The circulation (and re-circulation) of pathogenic bacteria between different hosts, vectors, and the feedlot environment is ripe for the development of an on-farm endemic pathogen population that can impact both animal and human health.

Amongst zoonotic pathogenic bacteria, foodborne pathogens such as Salmonella spp., Shiga toxin-producing Escherichia coli (STEC), and Campylobacter spp. are commonly associated with animal-derived foods and can be transferred to humans through several routes: (i) contact with positive cattle or carcasses, (ii) the consumption of contaminated or infected meat, and/or (iii) the consumption or irrigation of crops with water contaminated with cattle manure [13][19].

2. Structure of the North American Beef Industry

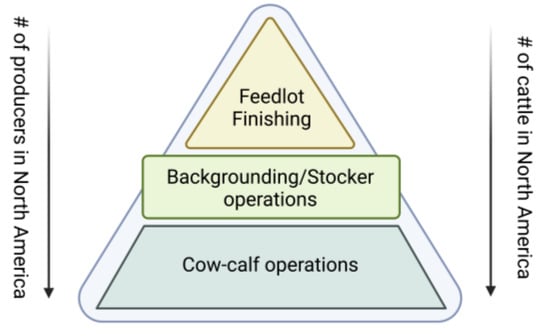

Beef cattle production in the United States is inextricably linked with the founding mythos of the Great Plains, or the “Old West”. Cattle ranchers from the frontier are often portrayed in movies and stories as independent and self-reliant heroes. Today’s North American cattle producers are heirs to this image and remain very independent and self-reliant. While increasing corporatization has impacted some segments of the cattle industry at the cow-calf production level, the beef industry of North America currently remains largely comprised of small producers. The beef industry has traditionally been highly decentralized and fragmented into five basic segments: cow-calf producers, stocker/backgrounder, feedlots, packers, and retail. The beef production continuum is shown in Figure 2 and is best visualized as a pyramid in terms of the number of producers involved at each phase. However, an increasing degree of consolidation and vertical integration at the packing and retail levels has entered the beef production industry because there are fewer participants who can implement the required/suggested practices on the farms. This means that many of the practices that can implemented at larger, more well-funded production locations may not be implemented due to the economic and logistical constraints faced by the small producers.

Figure 2. The beef production continuum visualized as a pyramid in terms of the number of producers involved at each phase.

2.1. Cow-Calf Producers

Cow-calf producers are the foundation of cattle in the U.S. and are the most de-centralized phase of cattle production with thousands of producers scattered across the country, raising approximately 30 million calves each year. Cow-calf producers are often not able to be full-time cattle producers but must often work a “traditional job” (i.e., off-farm/ranch employment to generate a stable, consistent income) and must perform all of the farm tasks in their in their spare time, and as a result, many of their production decisions are driven by necessity, time availability, and logistics. This often limits the type of animal care procedures, as well as the procedures aimed at improving production efficiency, that can be implemented on any single farm. A typical beef producer in the southeastern United States is almost 60 years of age and works cattle on weekends and evenings when the weather and day-length allow. While most producers desire to maximize their profitability, many do not use the most up-to-date production methodologies (e.g., artificial insemination and estrus synchronization) due to the expense, time, and lack of skills and/or facilities involved. In general, producers attempt to calve in the spring and some use artificial insemination to improve their herd genetics and have a calf crop within a specified time window, with the majority utilizing a herd bull for ease of breeding.

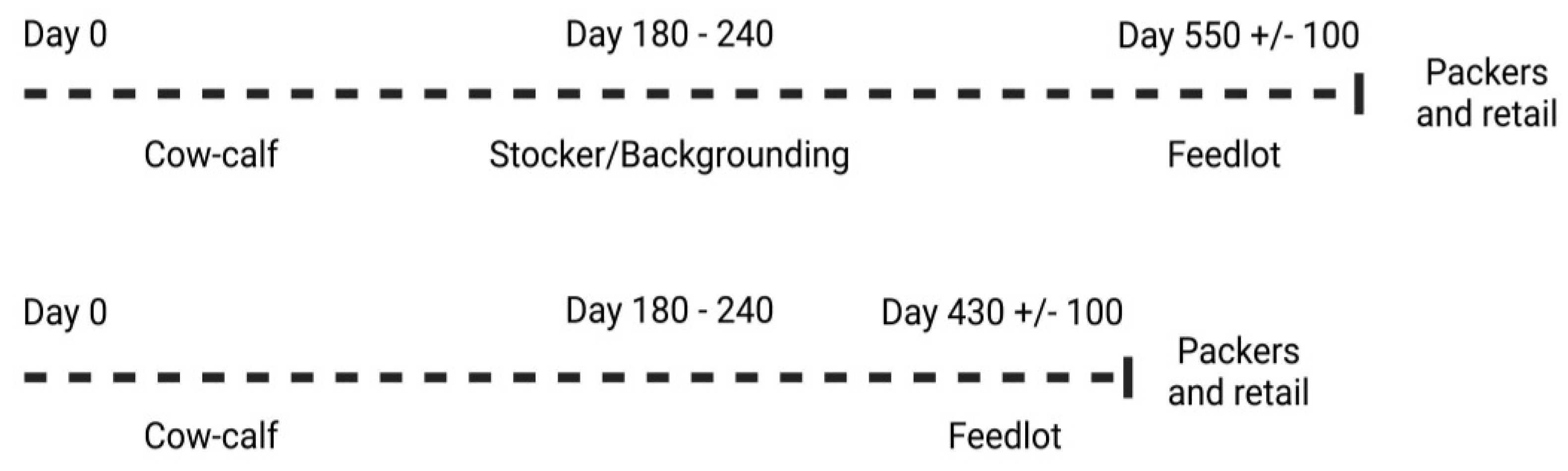

Most cow-calf herds contain fewer than 50 cows, and these producers maintain a fairly stable herd size over the course of the year, marketing their calves themselves (from 180–240d of age, see Figure 3), often through local auction markets or sale barns [20][21]. When calves leave their farm of origin, they bring an “internal record of exposure and vaccination” with them in the form of their immune systems, which means that that while the calves are less susceptible to pathogens that they have previously been exposed to, they remain susceptible to novel pathogens (bacterial, protozoal, and viral). Stress acts as an immunosuppressant and is cumulative in its impacts. Calves at auction markets can undergo multiple simultaneous stresses from weaning and transport, as well as social stresses, and can therefore be moderately to severely immunosuppressed when commingled with calves from other farms. Collecting calves from multiple farms in a close-quarters environment is a recipe for disease amplification in a population of susceptible calves, including the spread of zoonotic pathogens within these calves, commingled with calves that originated from across broad geographic origins.

Figure 3. The beef industry has traditionally been fragmented into five segments: cow-calf producers, stockers/backgrounders, feedlots, packers, and retail. Created with BioRender.com.

Calves (weighing approximately 120–360 kg) typically remain at an auction market for 24 to 48 h before they are shipped to either a backgrounder/stocker facility or directly to a feedlot. The decision as to which pathway is utilized depends on calf size/age, breed, owner marketing strategies, and packer demands for quality or type of beef to be produced. Larger and older calves may be sent straight to a feedlot instead of to a background/stocker facility in order to begin the finishing process, but smaller calves may instead be sent to backgrounding/stocking to allow for slower growth and development.

2.2. Backgrounders/Stockers and Feedlots

A tractor-trailer load of stressed and newly commingled calves is often transported for an additional 12 to 24 h (frequently transiting more than 1500 km in this time frame, whilst undergoing feed and water withdrawal, and often profound temperature changes) to a stocker or feedlot facility, which further exacerbates the susceptibility of these calves to disease exposure from cohorts. Upon arrival at either the feedlot or stocker facility, calves are typically rapidly vaccinated, identified, and allowed to rest and recuperate from the stresses of transport. These first days upon arrival are critical in setting cattle up for success as stresses can accumulate and result in the development of shipping fever in calves, which can impact morbidity and mortality among animals. Thus, it is critical to ensure that calves receive a ration designed to tempt them into beginning feed consumption quickly, in order to begin the supply of glucose, protein, and minerals to the immune system. Calves that are classified as “high risk” often require special care and added nutritional metaphylaxis and prophylaxis in the first few days after arrival in a stocker facility or feedlot. Stocker operators commonly feed native forages or crop residues (e.g., corn or wheat stubble) to cattle for 2–6 months in order to increase their growth and develop their frame (Figure 3). During backgrounding/stocking, cattle may consume protein or energy concentrates in their ration to increase their energy or protein intake; however, the amount of grain consumed in the stocker phase is typically much lower than that used in feedlots. The rations of stocker producers often contain by-products such as distiller’s grains, but mostly contain corn, with varying levels of processing (e.g., cracking or flaking) to improve its digestibility. When calves reach feedlot market weight (typically 270–370 kg), they are shipped to the feedlot for finishing or fattening prior to slaughter.

In the feedlot, cattle are segregated in pens based on body weight, breed, sex, and special program enrollment (e.g., No Antibiotics Ever) and eat from communal feed bunks at the front of each pen. Cattle often enter the feedlot at approximately 350 kg and are fed diets containing a high Net Energy for Gain (NEG) concentration, which is achieved by feeding them diets rich in starch until they reach approximately 625 kg, the current market weight. The feeding/finishing period can last 90–300 d, depending on the size of the cattle when they enter the feedlot.

Typically, according to the United States Department of Agriculture (USDA) animal census, there are more than 12 million cattle in U.S. feedlots at any time. While the vast majority of feedlot operations have a capacity of under 1000 heads, they only market a small percentage of the fed cattle to consumers. Feedlots with a capacity of more than 32,000 heads provide more than 40% of the fed cattle marketed [22]. Feedlots in the U.S. can reach a capacity of over 100,000 heads, which—assuming a 450 kg average weight for feedlot steers that consume 2% of their body weight (as dry matter (DM))—would require 9 kg (DM)/hd/d of feed, and a 50,000-head feedlot would require approximately 450,000 kg DM or 642,000 kg (as fed) of feed per day (approximately 7–8 train cars, or 20–25 tractor-trailer loads of feed). This typically requires feedlots to be largely self-contained facilities with an on-site feed mill (Figure 4). This means that many trucks bringing feed to each feedlot may take feed to other lots, and this represents a potential vector for zoonotic pathogens to be transmitted between feedlots. In addition, manure is often composted on site to mitigate the environmental impact and potentially generate a revenue stream by the sale of soil amendment for gardens; however, this can also carry zoonotic pathogens that can be transmitted to humans and other animals. It is clear that the infrastructure and activities needed to operate feedlots offer numerous opportunities for zoonotic pathogens to colonize and proliferate in cattle.

Figure 4. Aerial image of randomly chosen commercial feedyard. Feedmill is indicated by 1; silage pits are depicted by 2; manure/pen surface composting is tagged 3; 4 denotes water retention pond; 5 indicates cattle pens; and 6 highlights cattle working facilities. Image selected from Google Maps.

References

- National Chicken Council. Per Capita Consumption of Poultry and Livestock, 1965 to Forecast 2022, in Pounds. Available online: https://www.nationalchickencouncil.org/about-the-industry/statistics/per-capita-consumption-of-poultry-and-livestock-1965-to-estimated-2012-in-pounds/ (accessed on 28 November 2022).

- Shahbandeh, M. Consumption of Beef Per Capita in Canada from 1980 to 2023, by Type (in Pounds). Available online: https://www.statista.com/statistics/735166/consumption-of-milk-per-capita-canada/ (accessed on 28 November 2022).

- Estévez-Moreno, L.X.; Miranda-de la Lama, G.C. Meat consumption and consumer attitudes in México: Can persistence lead to change? Meat Sci. 2022, 193, 108943.

- Moyer, R.; Solano, P. 9. Commission for Environmental Cooperation (CEC). Yearb. Int. Environ. Law 2015, 26, 592–601.

- Trenda, E. Number of Cattle in Mexico from 2010 to 2021 (in Million Heads). Available online: https://www.statista.com/statistics/992638/catttle-number-heads-mexico/ (accessed on 28 November 2022).

- Wagner, J.J.; Archibeque, S.L.; Feuz, D.M. The modern feedlot for finishing cattle. Annu. Rev. Anim. Biosci. 2014, 2, 535–554.

- United States Department of Agriculture (USDA); Economic Research Service (ERS). Topics, Animal Products, Cattle & Beef. Sector at a Glance. Available online: https://www.ers.usda.gov/topics/animal-products/cattle-beef/sector-at-a-glance/ (accessed on 28 November 2022).

- Hales, K.; Lourenco, J.; Seidel, D.S.; Koyun, O.Y.; Davis, D.; Welch, C.; Wells, J.E.; Callaway, T.R. The use of feedlot/cereal grains in improving feed efficiency and reducing by-products such as methane in ruminants. In Improving Rumen Function; McSweeney, C., Mackie, R., Eds.; Burleigh Dodds Science Publishing Limited: Cambridge, UK, 2020; pp. 693–726.

- Lamb, G.C.; Maddock, T.; Feed Efficiency in Cows. Florida Beef Cattle Short Course. 2009; pp. 35–42. Available online: https://animal.ifas.ufl.edu/beef_extension/bcsc/2009/pdf/lamb.pdf (accessed on 28 November 2022).

- Nagaraja, T.G.; Lechtenberg, K.F. Acidosis in feedlot cattle. Vet. Clin. North Am. Food Ani. Prac. 2007, 23, 333–350.

- Hungate, R.E. The Rumen and Its Microbes; Academic Press: New York, NY, USA, 1966.

- Tokach, R.J.; Ribeiro, F.R.; Chung, K.Y.; Rounds, W.; Johnson, B.J. Chromium Propionate Enhances Adipogenic Differentiation of Bovine Intramuscular Adipocytes. Front. Vet. Sci. 2015, 2, 26.

- Pogue, S.J.; Kröbel, R.; Janzen, H.H.; Beauchemin, K.A.; Legesse, G.; de Souza, D.M.; Iravani, M.; Selin, C.; Byrne, J.; McAllister, T.A. Beef production and ecosystem services in Canada’s prairie provinces: A review. Agric. Syst. 2018, 166, 152–172.

- Rukambile, E.; Sintchenko, V.; Muscatello, G.; Kock, R.; Alders, R. Infection, colonization and shedding of Campylobacter and Salmonella in animals and their contribution to human disease: A review. Zoonoses Public Health 2019, 66, 562–578.

- Rahman, M.T.; Sobur, M.A.; Islam, M.S.; Ievy, S.; Hossain, M.J.; El Zowalaty, M.E.; Rahman, A.T.; Ashour, H.M. Zoonotic diseases: Etiology, impact, and control. Microorganisms 2020, 8, 1405.

- Jones, B.A.; Grace, D.; Kock, R.; Alonso, S.; Rushton, J.; Said, M.Y.; McKeever, D.; Mutua, F.; Young, J.; McDermott, J.; et al. Zoonosis emergence linked to agricultural intensification and environmental change. Proc. Natl. Acad. Sci. USA 2013, 110, 8399–8404.

- Callaway, T.R.; Edrington, T.; Anderson, R.C.; Byrd, J.A.; Nisbet, D.J. Gastrointestinal microbial ecology and the safety of our food supply as related to Salmonella. J. Anim. Sci. 2008, 86, E163–E172.

- McDaniel, C.J.; Cardwell, D.M.; Moeller, R.B.; Gray, G.C. Humans and cattle: A review of bovine zoonoses. Vector-Borne Zoonotic Dis. 2014, 14, 1–19.

- Dewey-Mattia, D.; Manikonda, K.; Hall, A.J.; Wise, M.E.; Crowe, S.J. Surveillance for foodborne disease outbreaks—United States, 2009–2015. MMWR Surveill Summ. 2018, 67, 1–11.

- McBride, W.D.; Kenneth, M., Jr. The Diverse Structure and Organization of U.S. Beef Cow-Calf Farms. United States Department of Agriculture (USDA), Economic Research Service (ERS). 2011. Available online: https://www.ers.usda.gov/publications/pub-details/?pubid=44532 (accessed on 28 November 2022).

- Feuz, D.M.; Umberger, W.J. Beef cow-calf production. Vet. Clin. N. Am. 2003, 19, 339–363.

- United States Department of Agriculture (USDA), National Agricultural Statistics Service (NASS), Census of Agriculture. 2017. Available online: https://www.nass.usda.gov/AgCensus/ (accessed on 28 November 2022).

More

Information

Subjects:

Agriculture, Dairy & Animal Science

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.1K

Revisions:

2 times

(View History)

Update Date:

09 Mar 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No