2. Trench-Isolated LGAD

In trench-isolated LGADs (TI-LGADs)

[5], fine pitch n-electrodes are implanted close together and isolated by a trench. The approximately 1

μm wide trench replaces all the structures, such as p-stop and JTE, in the border region of a standard LGAD. Pixels, separated by trenches, are very close together which usually comes at the price of an increased interpixel capacitance. In TI-LGADs, this issue is mitigated by two factors: trenches, while electrically separating the pixel, also keep the interpixel capacitance lower than the case of the same geometry and different isolation (p-spray or p-stop). Second, interpixel capacitance becomes less important than the capacitance towards the back for thin substrates. This point applies also to standard LGADs. In TI-LGADs, JTE and p-stop are no longer needed, which benefits the fill factor. The doping profile of the shallow n

+ phosphorus implant and of the p

+ boron gain layer are unchanged with respect to the standard LGAD so that the breakdown voltage (and related operational point and gain factor) stays the same in the two cases. The devices have been fabricated by Fondazione Bruno Kessler (FBK, Trento, Italy), leveraging their experience in silicon etching and LGAD fabrications, and currently they are the only producer. Silicon etching is also used for 3D detectors, where columns are vertically etched into the substrate and doped by diffusion in furnaces. Aspect ratio (depth to diameter of columns) can be about 20:1; therefore, as the substrate thickness is about 100–150

μm, column diameters are in the order of 10

μm or just below. Trenches are used also in SiPMs

[6] to optically isolate the single photon avalanche diodes (SPADs) so that the photons induced in one avalanche do not trigger parasitic avalanches in nearby SPADs (cross talk). To serve this purpose, trenches need to be filled with metal; a depth of only a few microns is required, which makes these trenches much more shallow than the columns in a 3D sensor. In TI-LGAD, trenches are quite similar to the SiPM ones, except that they are filled with oxide. A 7

μm dead border, instead of the usual few tens of microns, has been measured on these devices for an outstanding 75% fill factor for a 50

μm pitch sensor. Current–voltage characteristics are identical to those measured in standard LGAD devices with the same doping profiles. However, the current generation of TI-LGADs do not completely solve the problem as they do not yet achieve 100% fill factor which means further optimization may still be possible. Other LGAD-based devices can achieve 100% fill factor, as detailed below.

3. Inverted LGAD

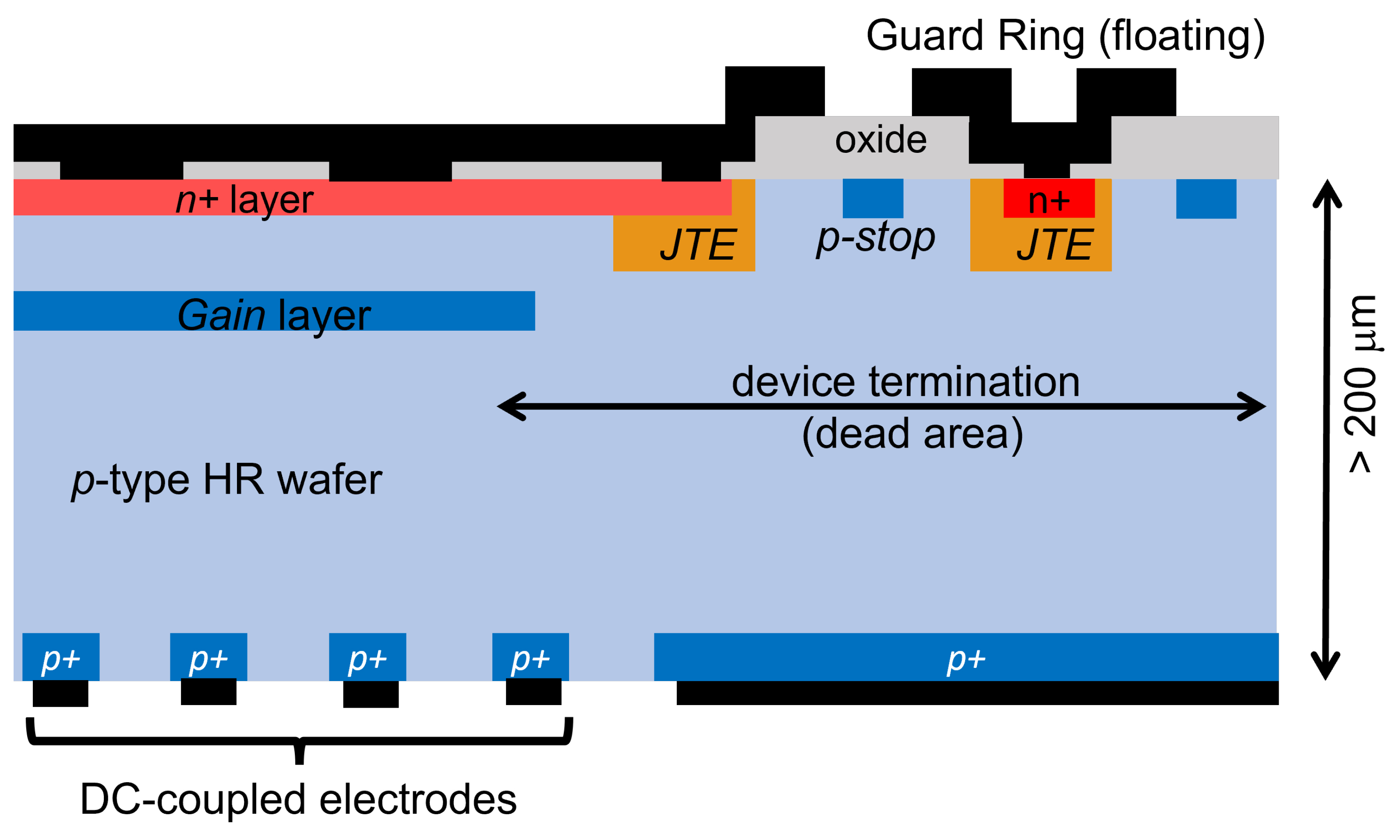

An attempt to obtain high spatial resolution with a structure based on LGADs is the inverted LGAD (i-LGAD)

[7]. It is based on keeping the n

+ and gain layer on one side of the wafer, while the hole collecting electrodes are on the opposite side of the wafer

[8][9] (a sketch is shown in

Figure 3). The n

+ and the gain layer will be uniformly implanted over a large area, interrupted only at the edge to allocate the proper termination for high voltage handling. The uniformity of the gain layer over a large area assures a 100% fill factor. On the opposite side, the hole collecting electrodes can be placed at a small pitch without detrimental effects on the uniform multiplication occurring at the opposite side of the wafer. A good spatial resolution is therefore achieved. However, the device, which operates in full depletion, requires double-sided processing of a high resistivity p-type wafer. To be processed in a standard clean room, wafers need to be about 200

μm thick for 4” wafers, and even thicker for 6” wafers. Such thicknesses, which will be entirely active as the device is fully depleted during operation, will spoil the timing capability of the LGAD. Timing resolution of only about 60 ps can be obtained for a 200

μm thick wafer. The i-LGAD can be used for imaging of particles that need some gain to be detected, for example soft X-ray, and only when timing information is not crucial. The researchers will finally consider sensors that truly deliver 100% fill factor, fast timing and good spatial resolution.

Figure 3. Sketch, not to scale, of a typical cross section of an i-LGAD, showing the main components as described in the text.

4. AC-LGAD

The capacitively coupled LGAD or AC-LGAD was the first LGAD-based sensor conceived to specifically address the issue of the dead region at the border of an LGAD pixel

[10][11]. An AC-LGAD is made of a large uniform gain layer implanted below the n-implant, as in the standard LGAD. Where the two devices differ is that these two layers are uniformly implanted over the entirety of the active area; there is no interruption in the layers (except at the device termination). The n-implant is covered by a thin dielectric layer of approximately 100 nm (oxide, nitride or a stack of both) which is subsequently covered with metal electrodes that are then used to connect to the read-out electronics. The n

+ is grounded at the edge, where the JTE is present as in the case of standard LGAD, and it is surrounded by the usual termination for the high voltage handling. A sketch is shown in

Figure 4. The n-implant, which can be 10 or 100 times less doped than the n

+ implant of a standard LGAD, has a sheet resistivity much larger than the n

+ in the conventional LGAD and can be seen as a resistive layer. The metal electrodes create coupling capacitances over the resistive n

+ in a similar fashion as in an AC-coupled silicon sensor. The whole device can be thought of as a distributed RC network, where R is given by the n

+ layer and C by the the capacitances towards the back and toward the metal electrodes. As the oxide is very thin, the coupling capacitance dominates over the capacitance towards the back.

Figure 4. Sketch, not to scale, of a typical cross section of an AC–LGAD, showing the main components as described in the text.

The signal develops as in a standard LGAD; the electrons generated by the MIP are multiplied in the high electric field between the n+ and the gain layer. As the two layers are uniform, so are the electric fields and a 100% fill factor is achieved with uniform multiplication and no dead areas. The multiplied holes generate most of the signal during their drift to the p+ contact. The electrons are collected by the n+ implant and slowly drift to the DC contact at the border. The overall movement of signal electrons and holes capacitively induces a signal to the metal electrodes over the dielectric. Since the metal electrodes are separated from the n-layer by an insulator, they do not collect charge, and the signal pulse is bipolar. The fast signal “sees” a low impedance across the coupling capacitors and is fed to the read-out electronics before being spread to the neighbors. Nevertheless, a certain amount of cross talk exists due to the finite value of the interpixel resistance introduced by the n layer.

The cross talk between pixels can be exploited to increase the position resolution by interpolation at the expense of an increase of occupancy.

Tests in a laboratory setup, such as a Transient Current Technique (TCT) and confirmed at test beams, show a 100% fill factor, a timing resolution comparable to LGADs and spatial resolution at a level of 5% of the pitch

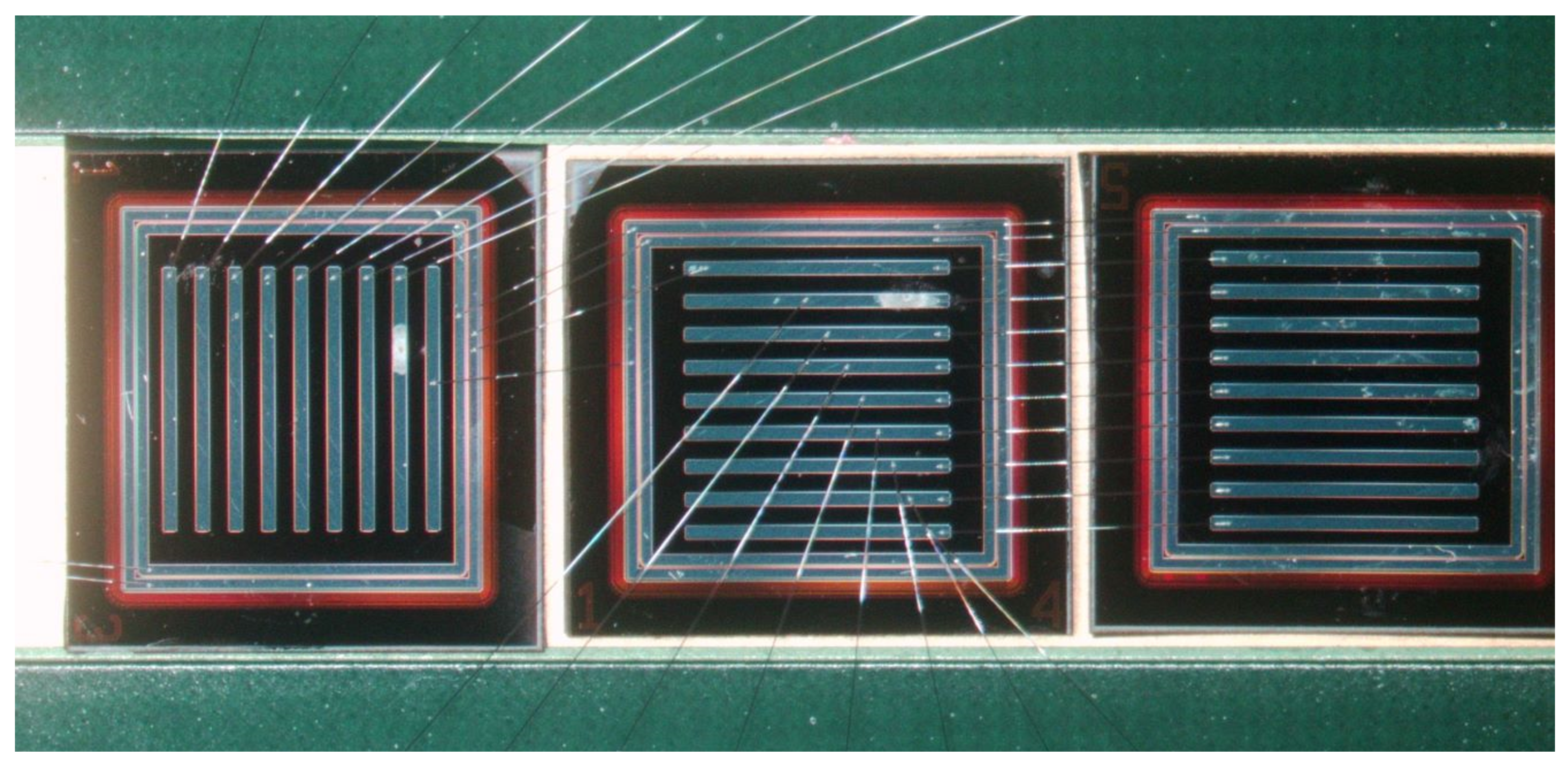

[12][13]. As previously mentioned, some limitations occur as a result of the cross talk. On one hand, this is necessary to achieve excellent spatial resolution; on the other hand, it increases the occupancy so that the device in not useful in high event environments. In addition, experimental results suggest that the capacitance of long strips is quite high (the value of this capacitance is difficult to measure as it needs to be measured at high frequency). At the present stage of development, AC-LGADs in the shape of pixels or up to 1 cm long strips are excellent 4D detector candidates in low event rate environments. Pictures of LGADs recently fabricated at BNL are shown in

Figure 5.

Figure 5. Picture of three 0.5 cm × 0.5 cm AC-LGAD devices, whose AC-coupled electrodes are in the shape of 0.5 cm long strips. Aluminum wire-bonds connect the metal electrodes to the read-out electronics (not shown) for testing purposes.

5. Deep-Junction LGAD

Another device that gives good 4D reconstruction is the deep-junction LGAD (DJ-LGAD) [14], which is currently under development. A sketch of a section of the device is shown in Figure 6. Its timing resolution is expected to be at the same level of an LGAD, while its spatial resolution is expected to be at the same level as a conventional strip or pixel detector. Therefore, it will not have the excellent spatial resolution of the AC-LGAD, but it can be used even in high rate of event environments. A deep junction, made by a large area of uniform n+ and p+ gain implants, sits a few microns from the surface where n+ DC coupled electrodes are placed.

In this new design, the multiplication region (where high electric fields are present) is contained between the buried n+ and p+ gain layer, while everywhere else the electric fields are well below the threshold for impact ionization. Electrons multiplied in this region then drift to be collected by the n+ electrodes at the interface; holes, as in any type of LGADs considered so far, drift toward the uniform back. Signal electrons generated by the MIPs in the few microns between the n+ electrodes and the n-gain layer do not cross the high field region and therefore do not get multiplied. On the other hand, signal holes generated here cross the high field region but contribute little to the signal, as they do not undergo significant multiplication. TCAD simulations suggest that the electric field within the gain layers just below the gap between pixels is slightly lower than below the pixels, but the effect can be mitigated by a proper design of the DC electrodes.

The DJ-LGAD can be fabricated by implanting both p+ and n+ gain layers on a 50-micron active layer and then by burying them under a few micron thickness of epitaxial layer. On the top of the layer, the DC coupled electrodes are finally defined. Another way is to implant the two gain layers on two different wafers which are then wafer-bonded together. The wafer carrying the n+ gain layer is then thinned down to a few microns and its surface processed to allocate the DC coupled electrodes. As the electric fields are low everywhere in the device except within the gain region, the JTE at the pixel border is no longer needed; p-spray or p-stop are instead still needed to isolate the n+ electrodes.

Figure 6. Sketch, not to scale, of a typical cross section of an DJ-LGAD, showing the main components as described in the text.