Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Jakub Pizoń | -- | 1485 | 2023-02-21 22:02:11 | | | |

| 2 | Dean Liu | Meta information modification | 1485 | 2023-02-22 04:22:19 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Pizoń, J.; Gola, A. Human–Machine Relationship. Encyclopedia. Available online: https://encyclopedia.pub/entry/41502 (accessed on 07 February 2026).

Pizoń J, Gola A. Human–Machine Relationship. Encyclopedia. Available at: https://encyclopedia.pub/entry/41502. Accessed February 07, 2026.

Pizoń, Jakub, Arkadiusz Gola. "Human–Machine Relationship" Encyclopedia, https://encyclopedia.pub/entry/41502 (accessed February 07, 2026).

Pizoń, J., & Gola, A. (2023, February 21). Human–Machine Relationship. In Encyclopedia. https://encyclopedia.pub/entry/41502

Pizoń, Jakub and Arkadiusz Gola. "Human–Machine Relationship." Encyclopedia. Web. 21 February, 2023.

Copy Citation

The human–machine relationship was dictated by human needs and what technology was available at the time. Changes within this relationship are illustrated by successive industrial revolutions as well as changes in manufacturing paradigms.

human–machine relationship

human–machine collaboration

human-oriented manufacturing

1. Introduction

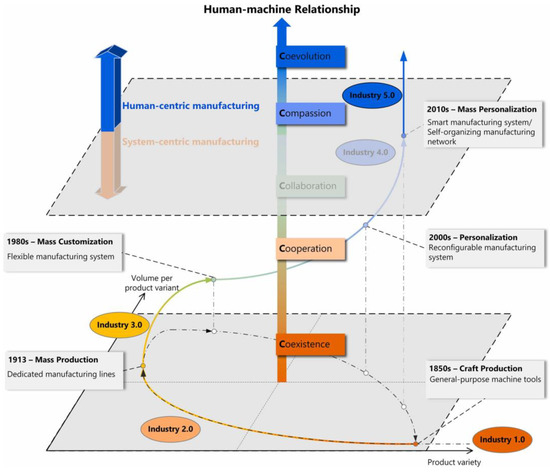

With successive industrial revolutions and accompanying changes in the production paradigm, an evolution of the human–machine relationship is practically taking place, referred to in the literature as the 5C model: Coexistence, Cooperation, Collaboration, Compassion, and Coevolution (Figure 1) [1].

Figure 1. Human–machine 5C relationship model [1].

The different stages signify the successive change that took place in the relationship. At the same time, the successive stages did not exclude the previous ones. Evolution rather than revolution in this respect means that constant change opens new perspectives. Thus, the man-machine relationship is undergoing constant change, which now, due to unprecedented technological developments, is entering a completely new level. Therefore, an extremely important question is the direction in which it will change.

What is important is that the above changes took place over the revolutions indicated in the previous chapter. Therefore, it should be noted that during the first and second industrial revolutions, machines were the equipment of factories. Thus, they formed a ‘cold’ coexistence relationship in which machines were simple tools for humans or worked independently under supervision.

Reconfigured machines and production lines forming dynamic cooperative human–machine teams in integrated production processes is a characteristic of the third industrial revolution. In this case, humans, and machines, depending on the process, temporarily share a workspace and share some of their physical, cognitive, and computational resources. At the same time, it should be noted that they are not working on the same task at the same time.

In the next, already the fourth industrial revolution, intelligent machines collaborate with humans in a shared workspace, with a specific goal of completing tasks through synchronized interactive joint actions of all parties within a common team identity [2].

In contrast, at the level of the fifth industrial revolution, workers together with robots (cobots) form teams to carry out production tasks [3]. Central to this relationship is how workers feel in this environment, how decisions are made, who makes them, and how such teams are formed. In the case of mixed human-cobot teams, there can be trust challenges. Particularly in the engineering industry, where the work requires not only good qualifications but the ability to work, many challenges arise. Methods and ways of developing trust in collaboration with the machine are needed. So that the worker knows that the machine is working towards the same goal and is not in danger from the machine. So that the worker can communicate effectively with the machine and understands the decision-making process when working with the machine. Depending on the manufacturing system, it is determined who ultimately makes the decisions.

Today, due to the development of advanced information technology and the transition to the Industry 4.0 era, the human–machine relationship is turning towards the human. Therefore, human-centered production systems need to be characterized by bidirectional empathy, proactive communication, and collaborative intelligence to establish reliable human–machine co-evolution relationships and thus lead to high-performance human–machine teams. Thus, on the one hand, the evolution of relationships and on the other hand a series of challenges [4] that need to be met to realize mass personalization (Figure 2).

Figure 2. Evolution of the human–machine relationship towards human-centric production [5].

To fully characterize the human–machine relationship, further characteristics for the types distinguished within the 5Cs are indicated below.

2. Human–Machine Coexistence

This type of relationship envisages that man and machine are in the same environment and share the same space. Within this case, one speaks of monitored coexistence, that is when a robot and a human work closely together without the need for mutual contact or coordination, thus requiring continuous opportunities for the robot controller to avoid obstacles [6].

Furthermore, the coexistence of machines and humans for the enterprise realizes the goal of balancing automation/productivity and flexibility/capability. For example, using the human–machine interface, the operator is associated with a set of behavioral roles as a supervisor of multiple semi-automated production processes. The proposed model can be used to design manufacturing systems at different levels of enterprise architecture, particularly at the machine level of the manufacturing system, where operators interact with semi-automated machines to realize the goal of human-enhanced automation [7].

The coexistence of machines and humans in the production space creates the risk of collisions. Therefore, there is a need to adopt appropriate policies that safeguard production efficiency using safety features such as emergency stops [8].

3. Human–Machine Cooperation

Human–machine cooperation is defined as a group of agents in a collaborative situation when two conditions are present. The first occurs when the agents pursue goals that may conflict with those of others, at the level of their own goals, sub-goals, processes, or resource. The second, on the other hand, is that each agent seeks to manage these interferences to facilitate its tasks and those of others on a common task [9].

Some research work has applied the principles of interpersonal cooperation to the dynamic sharing of tasks between human operators and automated systems. These shared tasks are decision-making tasks (e.g., conflict detection, problem-solving, diagnosis, or image analysis and retrieval) and may involve several organizational configurations of the human–machine system. In this mode of human-robot interaction, the human operator and the robot are placed at the same decision-making level. The two agents work together to achieve a common goal by initiating an interactive dialogue. In the approach presented in this thesis, this dialogue can take different forms depending on the collaborative situation. This dialogue is carried out using various forms of collaboration [10].

While considering the human–machine collaboration relationship, it should be noted that the inclusion of the human in this type of relationship, even if it integrates the machine, can be justified as contributing to solving part of the automation problems in terms of human–machine relationships [11].

4. Human–Machine Collaboration

Technological advances increasingly envisage the use of robots interacting with humans in everyday life. Human-robot collaboration (HRC) is an approach that explores the interaction between a human and a robot, while pursuing a common goal, at a cognitive and physical level [12].

The human–machine collaboration relationship is a key means of manufacturing. The system that results from it performs surveillance, prognostics, and health management is related to the safety and sustainability of manufacturing [13][14].

Human–machine collaboration has great potential for making risky decisions. Machines could be more helpful in gathering information and assessing uncertainty and communicating key information to human decision-makers to save cognitive resources. Moreover, human decision-makers could debate their judgments with the help of a machine and reduce emotional influences [15].

As machines become increasingly intelligent and can perform more complex functions, a new relationship between humans and automation is emerging. This relationship is changing from ‘master-servant’ to ‘master-collaborator’ and requires a different approach to system design, human–machine information exchange and interface, and the imposition of additional requirements on the machine [16].

Current technological trends are enabling more and more physical contact between humans and machines. Humans and machines act together and communicate with each other not only through gestures and speech but mainly through the haptic channel. This current phase of human–machine interaction can be referred to as human–machine collaboration [17].

This has resulted in the development of a new type of robot—cobot, collaborative robot— which is geared towards human collaboration [18]. This term describes a robot capable of working and collaborating with humans. These collaborative robots will be aware of human presence and will therefore take care of safety and risk criteria. They will be able to notice, understand and feel not only the human but also the goals and expectations of the human operator. Similar to a learner, cobots will observe and learn how to perform a specific task. Once learned, the task will be performed by the cobots as it would be performed by a human [19].

5. Human–Machine Compassion and Coevolution

In human-centered production, given the successes in cognitive science and personalized AI, it is conceivable that empathic machines that sense human emotions, needs, and preferences could provide situational assistance to humans in addition to situational cooperation.

In such circumstances, based on reciprocity, humans will willingly monitor and take care of the ‘health’ of empathic machines. At the same time, this machine’s health will be expressed in terms of quantitative measures related to workload, level of task fluctuation, etc. Such optics represent a whole new chapter in the human–machine relationship—human–machine empathy. It is also worth adding that intimate human–machine interactions will ultimately enable the growth of both human and machine capabilities, leading to continuous human–machine co-evolution in the future [2]. This mutual co-evolutionary development may lead to new forms of relationships no longer focusing on competition but on creating a better new future for machines and humans [20].

References

- Kumar, A. From mass customization to mass personalization: A strategic transformation. Int. J. Flex. Manuf. Syst. 2007, 19, 533–547.

- Lu, Y.; Zheng, H.; Chand, S.; Xia, W.; Liu, Z.; Xu, X.; Wang, L.; Qin, Z.; Bao, J. Outlook on human-centric manufacturing towards Industry 5.0. J. Manuf. Syst. 2022, 62, 612–627.

- Stączek, P.; Pizoń, J.; Danilczuk, W.; Gola, A. A digital twin approach for the improvement of an autonomous mobile robots (AMR’s) operating environment—A case study. Sensors 2021, 21, 7830.

- Pizoń, J.; Gola, A. The Meaning and Directions of Development of Personalized Production in the Era of Industry 4.0 and Industry 5.0. In Innovations in Industrial Engineering II.; Springer: Cham, Switzerland, 2023; p. 279569.

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10.

- Magrini, E.; Ferraguti, F.; Ronga, A.J.; Pini, F.; De Luca, A.; Leali, F. Human-robot coexistence and interaction in open industrial cells. Robot Comput. Integr. Manuf. 2020, 61, 101846.

- Cochran, D.S.; Arinez, J.F.; Collins, M.T.; Bi, Z. Modelling of human–machine interaction in equipment design of manufacturing cells. Enterp. Inf. Syst. 2016, 11, 969–987.

- Ishigooka, T.; Yamada, H.; Otsuka, S.; Kanekawa, N.; Takanashi, J. Symbiotic Safety: Safe and Efficient Human-Machine Collaboration by utilizing Rules. In Proceedings of the 2022 Design, Automation & Test in Europe Conference & Exhibition (DATE), Online, 14–23 March 2022; pp. 280–281.

- Habib, L.; Pacaux-Lemoine, M.P.; Millot, P. A method for designing levels of automation based on a human-machine cooperation model. IFAC-PapersOnLine 2017, 50, 1372–1377.

- Zieba, S.; Polet, P.; Vanderhaegen, F. Using adjustable autonomy and human–machine cooperation to make a human–machine system resilient—Application to a ground robotic system. Inf. Sci. 2011, 181, 379–397.

- Hoc, J.M. From human—Machine interaction to human—Machine cooperation. Ergonomics 2000, 43, 833–843.

- Semeraro, F.; Griffiths, A.; Cangelosi, A. Human–robot collaboration and machine learning: A systematic review of recent research. Robot Comput. Integr. Manuf. 2023, 79, 102432.

- Wang, T.; Li, J.; Kong, Z.; Liu, X.; Snoussi, H.; Lv, H. Digital twin improved via visual question answering for vision-language interactive mode in human–machine collaboration. J. Manuf. Syst. 2021, 58, 261–269.

- Simmler, M.; Frischknecht, R. A taxonomy of human–machine collaboration: Capturing automation and technical autonomy. AI Soc. 2021, 36, 239–250.

- Xiong, W.; Fan, H.; Ma, L.; Wang, C. Challenges of human—Machine collaboration in risky decision-making. Front. Eng. Manag. 2022, 9, 89–103.

- Trujillo, A.C.; Gregory, I.M.; Ackerman, K.A. Evolving Relationship between Humans and Machines. IFAC-PapersOnLine 2019, 51, 366–371.

- Inga, J.; Ruess, M.; Robens, J.H.; Nelius, T.; Kille, S.; Dahlinger, P.; Thomaschke, R.; Neumann, G.; Matthiesen, S.; Hohmann, S.; et al. Human-machine symbiosis: A multivariate perspective for physically coupled human-machine systems. Int. J. Hum. Comput. Stud. 2023, 170, 102926.

- Simões, A.C.; Pinto, A.; Santos, J.; Pinheiro, S.; Romero, D. Designing human-robot collaboration (HRC) workspaces in industrial settings: A systemic literature review. J. Manuf. Syst. 2022, 62, 28–43.

- Pizoń, J.; Gola, A.; Świć, A. The Role and Meaning of the Digital Twin Technology in the Process of Implementing Intelligent Collaborative Robots. In Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2022; pp. 39–49.

- Santosuosso, A. About coevolution of humans and intelligent machines: Preliminary notes. BioLaw J. Riv. Di BioDiritto 2021, 445–454.

More

Information

Subjects:

Engineering, Manufacturing

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

5.1K

Revisions:

2 times

(View History)

Update Date:

22 Feb 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No