Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Shaker Mahmood | -- | 2241 | 2023-02-07 15:22:55 | | | |

| 2 | Conner Chen | -4 word(s) | 2237 | 2023-02-08 07:17:37 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Abdal, S.; Mansour, W.; Agwa, I.; Nasr, M.; Abadel, A.; Özkılıç, Y.; Akeed, M.H. Development of Ultra-High-Performance Concrete. Encyclopedia. Available online: https://encyclopedia.pub/entry/40935 (accessed on 08 February 2026).

Abdal S, Mansour W, Agwa I, Nasr M, Abadel A, Özkılıç Y, et al. Development of Ultra-High-Performance Concrete. Encyclopedia. Available at: https://encyclopedia.pub/entry/40935. Accessed February 08, 2026.

Abdal, S., Walid Mansour, Ibrahim Agwa, Mohammed Nasr, Aref Abadel, Yasin Özkılıç, Mahmoud H. Akeed. "Development of Ultra-High-Performance Concrete" Encyclopedia, https://encyclopedia.pub/entry/40935 (accessed February 08, 2026).

Abdal, S., Mansour, W., Agwa, I., Nasr, M., Abadel, A., Özkılıç, Y., & Akeed, M.H. (2023, February 07). Development of Ultra-High-Performance Concrete. In Encyclopedia. https://encyclopedia.pub/entry/40935

Abdal, S., et al. "Development of Ultra-High-Performance Concrete." Encyclopedia. Web. 07 February, 2023.

Copy Citation

Ultra-high-performance concrete (UHPC) is a form of cementitious composite that has been the most innovative product in concrete technology. Ultra-high-performance concrete has been broadly employed for the design of numerous forms of construction owing to its excellent mechanical characteristics and durability.

UHPC

applications

bridge engineering

1. Introduction

Ultra-high-performance concrete (UHPC) is an improved cementitious and fibrous concrete with high compressive strength (CS) (120–250 MPa) [1], tensile strength (15–20 MPa) [2], particle packing density (0.825–0.855) [3], and exceptional durability [4]. UHPC has three hundred times the energy absorption and ductility of high-performance concrete and three to sixteen times the compressive strength of normal concrete [5]. Owing to its excellent toughness and ductility under strain, as well as its remarkable mechanical characteristics, UHPC is often recognized as the material of choice for seismic design reasons [6]. UHPC is a viable alternative for improving infrastructure and the long-term viability of construction facilities [7].

Ultra-high-performance concrete is prepared with a low w/c ratio, often between 0.15 and 0.25 [8]. Owing to the low water volume, high-range water reducer agents are necessary to enhance the packing of the particles in the composite material, leading to a higher workability and fluidity of the mix [9]. As cementitious binders, PC and silica fume are often employed in UHPC production scenarios [10]. The worldwide ultra-high-performance concrete market is predicted to increase at a multifactor yearly growth rate of nearly seven percent between 2018 and 2022. As the high greenhouse gas inventory of PC has become a global issue, the need for more sustainable cementing binders has advanced significantly [11][12][13].

The mechanical characteristics of UHPC make it an ideal material for applications (apps) where strength is a fundamental design objective, and concrete structural component sizes can be reduced to make them thinner, smaller, and more visually appealing [14][15]. It is typically made up of PC, silica fume, fine aggregate, a higher-range water-reducing ingredient, and fibers. UHPC could be an appropriate material for concrete structures exposed to harsh environments [16]. UHPC is commonly employed in ultra-high-rise buildings, BE design, and long-span structures [17]. In harsh climate exposure or outdoor conditions, UHPC reduces service cycles, and the enhanced durability and longevity extends the lifecycle [18]. By utilizing synthetic fibers in UHPC, it is feasible to attain ultra-high CS and high tensile ductility in concrete materials [15][19]. Although UHPC progress and tech have been comprehensively studied and recognized from the micro- to the macro-level, its wide marketing remains difficult due to the high costs and complicated production process [12][20][21][22]. The problematic production process is mostly because of the usage of too many components, which leads to high prices and difficult handling. UHPC tech provides a different product that allows infrastructure developers to broaden their service offerings and product [4]. This tech’s main concept is the introduction of systematic ways to solve the inherent shortcomings in traditional concrete; for example, one of the sustainable ways to produce UHPC can be performed using geopolymer technology [23][24]. This innovative concrete is superior since it is more ductile, with a high capability to deform and support flexural and tensile loads even after initial cracking forms [25][26][27][28]. UHPC’s improved performance characteristics are the consequence of the improved bonding optimization and mineral matrix microstructural characteristics among the concrete matrix elements [29][30].

Since its inception more than two decades ago, UHPC has attracted increasing attention from the construction industry, with attention on the following: construction BEs [31], damaged concrete components [32], skyscrapers, unique architectural designs [33], offshore constructions, facilities related to the oil and gas industry apps [34], vertical elements (for instance, windmill towers and wind turbines) [7], overlay materials [35], and hydraulic structures [36]. UHPC is widely utilized in all of these industries, as well as road and BE construction [16]. UHPC is especially well suited for BE construction in difficult situations since its composites need less repair throughout their lifecycle and have excellent strength [37]. Ultra-high-performance concrete is also a preferred strategy for BE construction in high-traffic locations since it supports stronger and longer spans, leading to more usable space. However, the quality of the materials utilized and the accuracy with which they are produced have a considerable impact on the functioning of ultra-high-performance concrete [38]. Another factor that leads to carbon dioxide emissions is the high cement volume of ultra-high-performance concrete, which raises ecological concerns [3][39][40][41][42]. As a cement substitute, SF with fillers (for example, limestone and quartz powder) can substantially increase the workability of ultra-high-performance, fiber-reinforced concrete and the efficacy of the steel fibers in the material [43]. Moreover, fillers can lower the volume of the microsilica needed, which is essential for ultra-high-performance, fiber-reinforced concrete in terms of energy, costs, and ecological effect [43]. As SF has a broad-range of chemical and physical characteristics, depending on its source, more standardization and study are required [43][44].

Furthermore, UHPC provides a diverse product range that can be employed in big projects and infrastructure, including highways, federal roads, BEs, marine facilities, water conservation facilities, pre-cast buildings, and military facilities [45]. As several service infrastructures and facilities around the world deteriorate, innovative UHPC strategies, such as prefabricated BE components [46], UHPC BE overlays, seismic columns [47], piles [48], BE girders [49], link slabs [50], cladding [51], and waffle deck panels [52], are achieving acceptance and popularity in the construction industry. Owing to UHPC’s advanced progress, architects and designers can now introduce structural and decorative punctured facades in mesh designs or lattice styles, ultrathin [53], lightweight panels [31], and full facades with multifaceted forms, textures, curvatures, and puncture levels exceeding 50 percent [25]. This substantial advancement seems to be limited, though, by a lack of knowledge of the manufacturing processes and raw materials, the restricted design codes, and the high production costs [54].

Nonetheless, the usage of UHPC as a prospective and novel material is earning traction across a wide range of stakeholders, including scientists and construction companies [49]. Nevertheless, numerous hurdles limit the widespread utilization of UHPC. Some examples include significant spalling and shrinkage strains, large volume production techniques with limited workability, and undetermined durability following the progress of long-term concrete cracks [55][56][57]. Because of a lack of knowledge in the industry, ultra-high-performance concrete experts confront extra hurdles in imparting hands-on expertise to concrete industry professionals so that they can be well versed in the implementation of complex concrete techniques [58].

2. Development of UHPC

Concrete is the world’s most frequently utilized human-made product, and it will carry on being highly popular in the near future. The world’s manufacture of concrete is expected to be over six bcm/year, with China currently accounting for almost 40 percent of global concrete manufacturing [59][60]. Concrete’s outstanding characteristics, including its durability and strength, low costs, and capacity to be poured into different shapes, have made it the most well-known and important construction material. Concrete is often utilized owing to its strong CS [61][62]. Substantial progress has been achieved in the area of concrete construction during the last several years. In the 1930s, significant scientific efforts to enhance concrete CS started [63][64][65][66].

During the 1960s, concrete tech evolved slowly, with maximum CSs varying from 15 MPa to 20 MPa. Concrete’s CS grew from 45 MPa to 60 MPa over a ten-year period. Because of the technical obstacle of the present water reducer, concrete strength peaked at roughly 60 MPa in the early 1970s. The present water reducer was unable to further lower the w/b ratio at the time [67][68]. It was found in the 1980s that high-range water reducers, known as superplasticizers, could be utilized to progressively lower the w/b to 0.30. Lowering the w/b below 0.16 was supposed to be unlawful until Bache [69] demonstrated that it was possible to do so with large dosages of silica fume and superplasticizers. A concrete CS of up to 280 MPa was attained by utilizing compacted granular materials by regulating the grain size distribution of the granular skeleton. As a consequence, a material with the fewest flaws, such as interconnected pore spaces and micro-fractures, was advanced to attain maximum durability and strength.

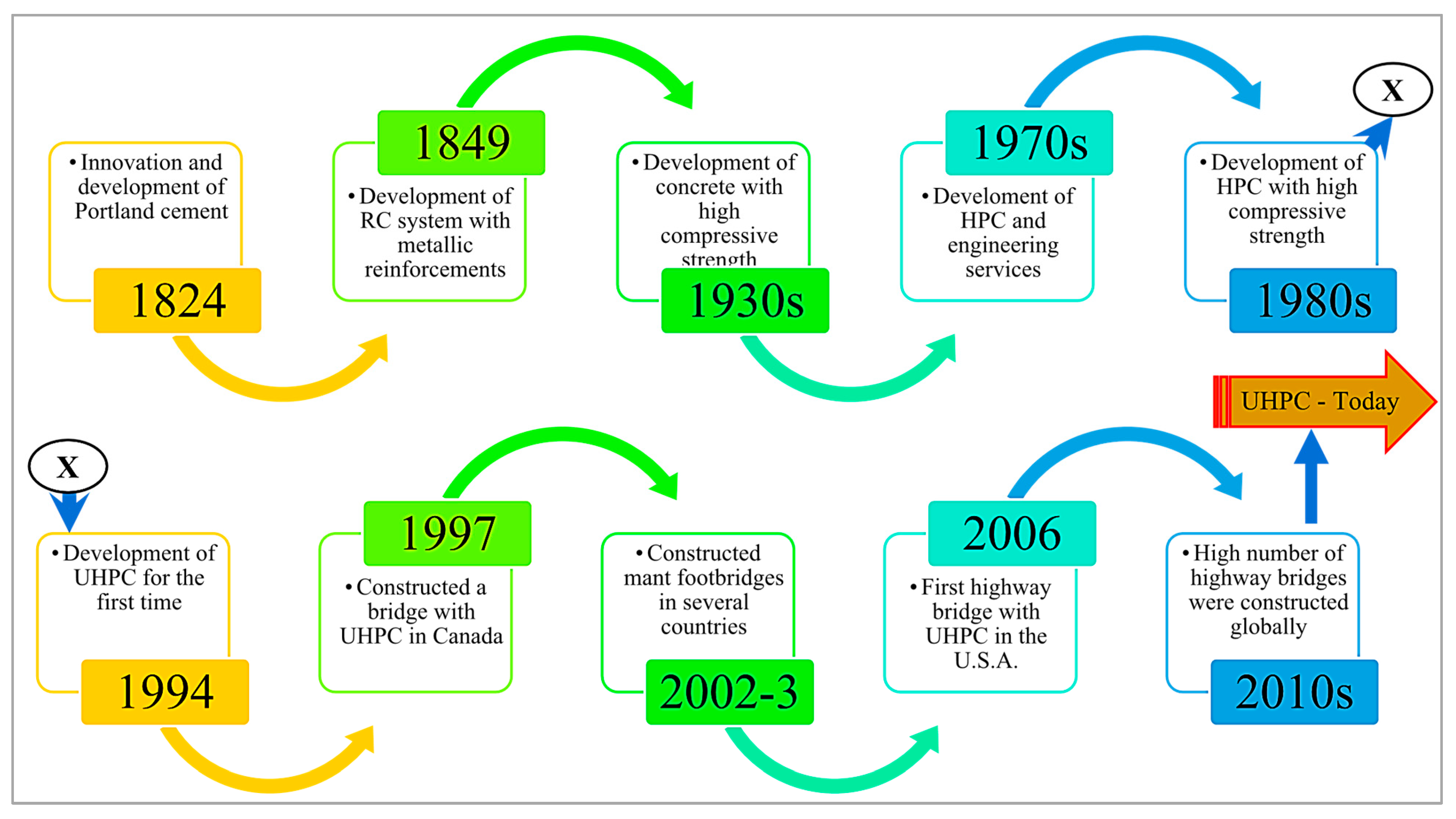

These technical breakthroughs, together with a fundamental understanding of low porous materials, have led to the formation of ultra-high-performance Portland composition materials with enhanced mechanical properties. Usually, the progress of UHPCs can be categorized into four stages: before the 1980s, after the 1980s, after the 1990s, and after the 2000s. Moreover, Figure 1 presents a summary of the historical progress patterns of UHPC.

Due to a lack of the current tech prior to the 1980s, UHPC production was restricted to the lab and needed specialized techniques such as heat curing and vacuum mixing. During this time, scientists experimented with several methods to produce more compact and denser concrete in order to boost its strength. Vacuum mixing coupled with temperature curing has been shown to raise the CS of concrete to 510 MPa [70][71]. Although a high CS of concrete was obtained, the preparation was energy-intensive and time-consuming [72][73][74][75].

In the early 1980s, microdefect-free cement was advanced [76]. In the microdefect-free cement process, polymers are employed to seal the pores and eliminate any flaws in the cement paste. Specific production conditions, such as the material being laminated by passing it through rollers, are required for this technique. Microdefect-free cement concrete has a CS of 200 MPa. Nevertheless, its apps have been restricted owing to the complicated preparation procedure, the high costs of the raw ingredients, the brittleness, and the substantial creep [76]. Following the launch of microdefect-free cement, Bache [69] advanced dense silica particle cement (dense silica particle cement). Dense silica particle cement, unlike microdefect-free cement, does not need rigorous manufacturing conditions to be produced. Dense silica particle cement faults were eliminated by increasing the particle packing density. Dense silica particle cement concrete is cured with pressure and heat and has a high concentration of SF and SP. Dense silica particle cement has a maximum CS of 345 MPa. These materials grow increasingly brittle as their ultra-high strength increases. Steel fibers were added to dense silica particle cement concretes in the 1980s to assist in enhancing their brittleness. This form of steel fiber-augmented concrete is a completely different material. It possesses ultra-high strength, a very thick microstructure, excellent ductility, and excellent durability. Slurry-infiltrated fiber concrete (SIFCON) and compact reinforced composites (CRC) are two significant instances of what transpired immediately after dense silica particle cement. Both slurry-infiltrated fiber concrete and compact reinforced composites offer remarkable durability and mechanical characteristics. Nevertheless, both slurry-infiltrated fiber concrete and compact reinforced composite slurry-infiltrated fiber concrete have workability issues that limit in situ implementations due to a lack of efficient high-range water reducers [77][78].

In the 1990s, Richard and Cheyrezy [79] utilized components with reactivity to produce reactive powder concrete (RPC) and higher fineness via thermal treatment. Reactive powder concrete is a key advancement in the progress of UHPCs. Its idea depended on the very dense arrangement of numerous particles. Reactive powder concrete is the most often utilized kind of UHPC in the field and laboratory experiments owing to its very high cement content, high binder concentration, extraordinarily low water-to-cement ratio, and utilization of fine quartz powder, SF, SP, quartz sand, and steel fibers [42]. To increase the matrix’s consistency, the coarse particles are eliminated. The CSs of reactive powder concrete range from 200 MPa to 800 MPa. Table 1 illustrates the typical mechanical parameters and reactive powder concrete composition provided by Richard and Cheyrezy [79]. Unlike its predecessors, reactive powder concrete is very consumer-oriented. This property of workability is an advantage and the most significant criterion for large-scale cementitious material apps. The first reactive powder concrete UHPC, known as Ductal+, was released in the late 1990s. The world’s first reactive powder concrete structure was developed in 1997 for a pedestrian BE in Sherbrooke, Canada [80]. It was the first time reactive powder concrete was employed to build the complete framework. Despite the effectiveness of reactive powder concrete structures, the apps are still restricted owing to the production costs and the prohibitively high cost of the materials.

Table 1. Typical mechanical parameters and reactive powder concrete composition of UHPC were provided by Richard and Cheyrezy [79].

| Ingredient in the Manufacture (kg/m3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PC | Ground Quartz (d50 = 10 mm) | Fine Sand (150–600 mm) | Total Water | Silica Fume | Steel Fibers | Superplasticizer (Polyacrylate) | Heat Treatment | CS (MPa) | Flexural Strength (MPa) | |

| reactive powder concrete 200 | 955 | / | 1051 | 162 | 239 | 168 | 15 | 20 C/90 C | 170–230 | 25–60 |

| reactive powder concrete 800 | 1000 | 390 | 500 | 190 | 230 | 630 | 19 | 250 C–400 C | 490–680 | 45–102 |

Since the year 2000, wide development has occurred in the progress of UHPCs. The engineers recognized that as concrete tech grew, advanced concrete should have more useful functions than high strength, which resulted in the names UHPC and ultra-high-performance, fiber-reinforced concrete [81]. A broad range of novel concrete formulations has been advanced to meet an increasing number of apps. Several scientists are now developing sustainable UHPC formulations with the goal of lowering both the initial and the material costs [82]. Supplementary cementitious materials such as SF, fly ash, rice husk ash, ground granulated blast furnace slag, and others [40][78][83], are employed to substitute part of the cement in the progress of sustainable UHPC and to minimize its current cement consumption. It has also been reported that UHPC could be synthesized by utilizing conventional temperature curing without compromising its characteristics. UHPC apps are becoming more common as ecologically friendly UHPC becomes more affordable. Since the early 2000s, numerous nations have been interested in different UHPC apps. UHPC has been employed to build several structures in France, including BEs, slabs, and facades [84]. UHPC is also being employed to repair and maintain transportation infrastructure in the United States [49]. Considerable efforts have been made in Australia to produce UHPC for BE construction [85]. UHPCs have mostly been employed for in situ structural reinforcement in Switzerland [86]. UHPC BE projects have been erected in Spain and the Netherlands [87]. In Malaysia, UHPC has been employed for BE construction as part of a sustainable BE building plan. Since 2010, a total of 113 UHPC BEs have been completed or advanced in Malaysia [88].

Figure 1. UHPC’s historical progress patterns [89].

References

- ASTM C1856/C1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Mishra, O.; Singh, S. An overview of microstructural and material properties of ultra-high-performance concrete. J. Sustain. Cem.-Based Mater. 2019, 8, 97–143.

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-obeidah, A.; Nassif, H.; Wang, H. New development of ultra-high-performance concrete (UHPC). Compos. Part B Eng. 2021, 224, 109220.

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of silica powder and cement type on durability of ultra high performance concrete (UHPC). Cem. Concr. Compos. 2016, 66, 47–56.

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377.

- Yoo, D.-Y.; Kang, S.-T.; Yoon, Y.-S. Enhancing the flexural performance of ultra-high-performance concrete using long steel fibers. Compos. Struct. 2016, 147, 220–230.

- Schmidt, M.; Fehling, E. Ultra-high-performance concrete: Research, development and application in Europe. ACI Spec. Publ. 2005, 228, 51–78.

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751.

- Hirschi, T.; Wombacher, F. Influence of different superplasticizers on UHPC. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; Kassel University Press: Kassel, Germany, 2008; pp. 77–84.

- Azreen, N.; Rashid, R.S.; Haniza, M.; Voo, Y.; Amran, Y.M. Radiation shielding of ultra-high-performance concrete with silica sand, amang and lead glass. Constr. Build. Mater. 2018, 172, 370–377.

- Park, S.; Lee, N.; An, G.-H.; Koh, K.-T.; Ryu, G.-S. Modeling the Effect of Alternative Cementitious Binders in Ultra-High-Performance Concrete. Materials 2021, 14, 7333.

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941.

- Khan, M.; Cao, M.; Chu, S.; Ali, M. Properties of hybrid steel-basalt fiber reinforced concrete exposed to different surrounding conditions. Constr. Build. Mater. 2022, 322, 126340.

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Xiao, X.; Zhang, X.; Wang, Y.; He, Y. Low carbon design of an Ultra-High Performance Concrete (UHPC) incorporating phosphorous slag. J. Clean. Prod. 2019, 240, 118157.

- Murali, G.; Venkatesh, J.; Lokesh, N.; Nava, T.R.; Karthikeyan, K. Comparative experimental and analytical modeling of impact energy dissipation of ultra-high performance fibre reinforced concrete. KSCE J. Civ. Eng. 2018, 22, 3112–3119.

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of ultra-high performance concrete—A review. Constr. Build. Mater. 2020, 255, 119296.

- Wu, C.; Li, J.; Su, Y.D. Development of Ultra-High Performance Concrete against Blasts: From Materials to Structures; Woodhead Publishing: Sawston, UK, 2018.

- Andrade, C.; Torres, J. Long term carbonation of UHPC. In Proceedings of the Proceedings of International Symposium on Ultra-High Performance Fiber-Reinforced Concrete, Marseille, France, 1–3 October 2013.

- Dai, J.-G.; Huang, B.-T.; Shah, S.P. Recent advances in strain-hardening UHPC with synthetic fibers. J. Compos. Sci. 2021, 5, 283.

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of ultra high performance hybrid fiber reinforced concrete. Cem. Concr. Compos. 2012, 34, 172–184.

- Khan, M.; Lao, J.; Dai, J.-G. Comparative study of advanced computational techniques for estimating the compressive strength of UHPC. J. Asian Concr. Fed. 2022, 8, 51–68.

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2021, 22, 535–549.

- Arunothayan, A.R.; Nematollahi, B.; Ranade, R.; Bong, S.H.; Sanjayan, J. Development of 3D-printable ultra-high performance fiber-reinforced concrete for digital construction. Constr. Build. Mater. 2020, 257, 119546.

- Kathirvel, P.; Sreekumaran, S. Sustainable development of ultra high performance concrete using geopolymer technology. J. Build. Eng. 2021, 39, 102267.

- Association, N.P.C. Ultra High Performance Concrete (UHPC) Guide to Manufacturing Architectural Precast UHPC Elements; National Precast Concrete Association: Carmel, CA, USA, 2013.

- Qaidi, S.; Yahia, A.; Tayeh, B.A.; Unis, H.; Faraj, R.; Mohammed, A. 3D printed geopolymer composites: A review. Mater. Today Sustain. 2022, 20, 100240.

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222.

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis. Materials 2022, 15, 7098.

- Wille, K.; Naaman, A.E. Pullout Behavior of High-Strength Steel Fibers Embedded in Ultra-High-Performance Concrete. ACI Mater. J. 2012, 109, 479–487.

- Manohar, T.; Suribabu, C.; Murali, G.; Salaimanimagudam, M. A novel steel-PAFRC composite fender for bridge pier protection under low velocity vessel impacts. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; pp. 765–777.

- Ghasemi, S.; Zohrevand, P.; Mirmiran, A.; Xiao, Y.; Mackie, K. A super lightweight UHPC–HSS deck panel for movable bridges. Eng. Struct. 2016, 113, 186–193.

- Habert, G.; Denarié, E.; Šajna, A.; Rossi, P. Lowering the global warming impact of bridge rehabilitations by using Ultra High Performance Fibre Reinforced Concretes. Cem. Concr. Compos. 2013, 38, 1–11.

- Yalçınkaya, Ç.; Çopuroğlu, O. Hydration heat, strength and microstructure characteristics of UHPC containing blast furnace slag. J. Build. Eng. 2021, 34, 101915.

- Adam, F.; Walia, D.; Hartmann, H.; Schünemann, P.; Großmann, J. A novel modular tlp-design for offshore wind turbines using ultra high performance concrete. In ACMSM25; Springer: Berlin/Heidelberg, Germany, 2020; pp. 257–268.

- Voo, Y.; Foster, S.; Pek, L. Ultra-high performance concrete—Technology for present and future. In Proceedings of the High Tech Concrete: Where Technology and Engineering Meet, Maastricht, The Netherlands, 12–14 June 2017; pp. 12–14.

- Guingot, L.; Dekhil, D.; Soulier, P. Strengthening of hydraulic structures with UHPC. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fibre-Reinforced Concrete, Marseille, France, 1–3 October 2013; pp. 137–146.

- Habert, G.; Arribe, D.; Dehove, T.; Espinasse, L.; Le Roy, R. Reducing environmental impact by increasing the strength of concrete: Quantification of the improvement to concrete bridges. J. Clean. Prod. 2012, 35, 250–262.

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournier, B.; Foo, S. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cem. Concr. Compos. 2009, 31, 555–563.

- Ibrahim, A.M.; Abd, S.M.; Hussein, O.H.; Tayeh, B.A.; Najm, H.M.; Qaidi, S. Influence of adding short carbon fibers on the flexural behavior of textile-reinforced concrete one-way slab. Case Stud. Constr. Mater. 2022, 17, e01601.

- He, X.; Yuhua, Z.; Qaidi, S.; Isleem, H.F.; Zaid, O.; Althoey, F.; Ahmad, J. Mine tailings-based geopolymers: A comprehensive review. Ceram. Int. 2022, 48, 24192–24212.

- Faraj, R.H.; Ahmed, H.U.; Rafiq, S.; Sor, N.H.; Ibrahim, D.F.; Qaidi, S.M.A. Performance of Self-Compacting mortars modified with Nanoparticles: A systematic review and modeling. Clean. Mater. 2022, 4, 100086.

- Emad, W.; Mohammed, A.S.; Bras, A.; Asteris, P.G.; Kurda, R.; Muhammed, Z.; Hassan, A.M.T.; Qaidi, S.M.A.; Sihag, P. Metamodel techniques to estimate the compressive strength of UHPFRC using various mix proportions and a high range of curing temperatures. Constr. Build. Mater. 2022, 349, 128737.

- Yu, R.; Spiesz, P.; Brouwers, H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39.

- Salaimanimagudam, M.P.; Suribabu, C.R.; Murali, G.; Abid, S.R. Impact response of hammerhead pier fibrous concrete beams designed with topology optimization. Period. Polytech. Civ. Eng. 2020, 64, 1244–1258.

- El-Hacha, R.; Abdelazeem, H.; Cariaga, I. Performance of UHPC Crossarms for High-Voltage Transmission Lines. Des. Build. UHPFRC 2011, 447–466.

- Delplace, G.; Hajar, Z.; Simon, A.; Chanut, S.; Weizmann, L. Precast thin UHPFRC curved shells in a waste water treatment plant. In Proceedings of the International Symposium on Ultra-High Performance Fiber-Reinforced Concrete, Marseille, France, 1–3 October 2013; Toutlemonde, F., Resplendino, J., Eds.; pp. 49–58.

- Kodur, V.; Wang, T.; Cheng, F. Predicting the fire resistance behaviour of high strength concrete columns. Cem. Concr. Compos. 2004, 26, 141–153.

- Vande Voort, T.L.; Suleiman, M.T.; Sritharan, S. Design and Performance Verification of UHPC Piles for Deep Foundations; Iowa State University. Center for Transportation Research and Education: Ames, IA, USA, 2008.

- Russell, H.G.; Graybeal, B.A.; Russell, H.G. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community; United States, Federal Highway Administration, Office of Infrastructure: Washington, DC, USA, 2013.

- Ngo, T.; Mendis, P.; Krauthammer, T. Behavior of ultrahigh-strength prestressed concrete panels subjected to blast loading. J. Struct. Eng. 2007, 133, 1582.

- Menétrey, P. UHPFRC cladding for the Qatar National Museum. In Proceedings of the International Symposium on Ultra-High Performance Fiber-Reinforced Concrete, Marseille, France, 1–3 October 2013; pp. 1–3.

- Aaleti, S.; Sritharan, S. Design of ultrahigh-performance concrete waffle deck for accelerated bridge construction. Transp. Res. Rec. 2014, 2406, 12–22.

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, e00197.

- Jaishankar, P.; Murali, G.; Salaimanimagudam, M.P.; Amran, Y.H.M.; Fediuk, R.; Karthikeyan, K. Study of topology optimized hammerhead pier beam made with novel preplaced aggregate fibrous concrete. Period. Polytech. Civ. Eng. 2021, 65, 287–298.

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093.

- Althoey, F.; Hakeem, I.Y.; Hosen, M.A.; Qaidi, S.; Isleem, H.F.; Hadidi, H.; Shahapurkar, K.; Ahmad, J.; Ali, E. Behavior of Concrete Reinforced with Date Palm Fibers. Materials 2022, 15, 7923.

- Almeshal, I.; Al-Tayeb, M.M.; Qaidi, S.M.A.; Abu Bakar, B.H.; Tayeh, B.A. Mechanical properties of eco-friendly cements-based glass powder in aggressive medium. Mater. Today Proc. 2022, 58, 1582–1587.

- Salaimanimagudam, M.P.; Murali, G.; Vardhan, C.V.; Amran, M.; Vatin, N.; Fediuk, R.; Vasilev, Y. Impact response of preplaced aggregate fibrous concrete hammerhead pier beam designed with topology optimization. Crystals 2021, 11, 147.

- Qaidi, S.M.A.; Tayeh, B.A.; Ahmed, H.U.; Emad, W. A review of the sustainable utilisation of red mud and fly ash for the production of geopolymer composites. Constr. Build. Mater. 2022, 350, 128892.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part IV: Durability properties, cost assessment, applications, and challenges. Case Stud. Constr. Mater. 2022, 17, e01271.

- Qaidi, S.M.A.; Sulaiman Atrushi, D.; Mohammed, A.S.; Unis Ahmed, H.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Mohammed Najm, H. Ultra-high-performance geopolymer concrete: A review. Constr. Build. Mater. 2022, 346, 128495.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part I: Developments, principles, raw materials. Case Stud. Constr. Mater. 2022, 17, e01290.

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.İ.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513.

- Unis Ahmed, H.; Mahmood, L.J.; Muhammad, M.A.; Faraj, R.H.; Qaidi, S.M.A.; Hamah Sor, N.; Mohammed, A.S.; Mohammed, A.A. Geopolymer concrete as a cleaner construction material: An overview on materials and structural performances. Clean. Mater. 2022, 5, 100111.

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Influence of the proportion of materials on the rheology and mechanical strength of ultrahigh-performance concrete. Case Stud. Constr. Mater. 2022, 17, e01433.

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Ultra-high-performance concrete: Impacts of steel fibre shape and content on flowability, compressive strength and modulus of rupture. Case Stud. Constr. Mater. 2022, 17, e01615.

- Qaidi, S.M.A.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Althoey, F.; Zaid, O.; Sor, N.H. Rubberized geopolymer composites: A comprehensive review. Ceram. Int. 2022, 48, 24234–24259.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part II: Hydration and microstructure. Case Stud. Constr. Mater. 2022, 17, e01289.

- Bache, H.H. Densified cement ultra-fine particle-based materials. In Proceedings of the International Conference on Superplasticizers in Concrete, Ottawa, ON, Canada, 10–12 January 1981.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Majeed, S.S.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part V: Mixture design, preparation, mixing, casting, and curing. Case Stud. Constr. Mater. 2022, 17, e01363.

- Aisheh, Y.I.A.; Atrushi, D.S.; Akeed, M.H.; Qaidi, S.; Tayeh, B.A. Influence of steel fibers and microsilica on the mechanical properties of ultra-high-performance geopolymer concrete (UHP-GPC). Case Stud. Constr. Mater. 2022, 17, e01245.

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Influence of microsilica and polypropylene fibers on the fresh and mechanical properties of ultra-high performance geopolymer concrete (UHP-GPC). Case Stud. Constr. Mater. 2022, 17, e01367.

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Influence of sand grain size distribution and supplementary cementitious materials on the compressive strength of ultrahigh-performance concrete. Case Stud. Constr. Mater. 2022, 17, e01495.

- Saeed, A.; Najm, H.M.; Hassan, A.; Sabri, M.M.S.; Qaidi, S.; Mashaan, N.S.; Ansari, K. Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials 2022, 15, 8250.

- Saeed, A.; Najm, H.M.; Hassan, A.; Qaidi, S.; Sabri, M.M.S.; Mashaan, N.S. A Comprehensive Study on the Effect of Regular and Staggered Openings on the Seismic Performance of Shear Walls. Buildings 2022, 12, 1293.

- Rossi, P.; Arca, A.; Parant, E.; Fakhri, P. Bending and compressive behaviours of a new cement composite. Cem. Concr. Res. 2005, 35, 27–33.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Emad, W.; Faraj, R.H.; Mohammed, A.S.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part III: Fresh and hardened properties. Case Stud. Constr. Mater. 2022, 17, e01265.

- Aisheh, Y.I.A.; Atrushi, D.S.; Akeed, M.H.; Qaidi, S.; Tayeh, B.A. Influence of polypropylene and steel fibers on the mechanical properties of ultra-high-performance fiber-reinforced geopolymer concrete. Case Stud. Constr. Mater. 2022, 17, e01234.

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511.

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441.

- Acker, P.; Behloul, M. Ductal® technology: A large spectrum of properties, a wide range of applications. In Proc. of the Int. Symp. on UHPC; University of Kassel: Kassel, Germany, 2004; pp. 11–23.

- Hassan, A.; Jones, S.; Mahmud, G. Experimental test methods to determine the uniaxial tensile and compressive behaviour of ultra high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2012, 37, 874–882.

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502.

- Resplendino, J.; Toutlemonde, F. The UHPFRC revolution in structural design and construction. In Proceedings of the RILEM-Fib-AFGC int. Symposium on Ultra-High Performance Fibre-Reinforced Concrete, UHPFRC, Marseille, France, 1–3 October 2013; pp. 791–804.

- Cavill, B.; Chirgwin, G. The world’s first RPC road bridge at Shepherds Gully Creek, NSW. In Proceedings of the 5th Austroads Bridge Conference 2004, Hobart, Australia, 19–21 May 2004.

- Brühwiler, E.; Denarié, E. Rehabilitation and strengthening of concrete structures using ultra-high performance fibre reinforced concrete. Struct. Eng. Int. 2013, 23, 450–457.

- Naaman, A.E.; Wille, K. The path to ultra-high performance fiber reinforced concrete (UHP-FRC): Five decades of progress. Proc. Hipermat. 2012, pp. 3–15. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=%D9%84%D8%A5he+path+to+ultra-high+performance+fiber+reinforced+concrete+%28UHP-FRC%29%3A+Five+decades+of+progress.&btnG= (accessed on 5 December 2022).

- Tadros, M.K.; Voo, Y. Taking ultra-high-performance concrete to new heights. ASPIRE 2016, 10, 36–38.

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029.

More

Information

Subjects:

Engineering, Civil

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.5K

Revisions:

2 times

(View History)

Update Date:

08 Feb 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No