Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Malin Liu | -- | 4402 | 2023-01-31 15:08:25 | | | |

| 2 | Sirius Huang | + 3 word(s) | 4405 | 2023-02-01 02:27:39 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Yan, Z.; Liu, R.; Liu, B.; Shao, Y.; Liu, M. Molecular Dynamics Simulation Studies of Silicon Carbide Materials. Encyclopedia. Available online: https://encyclopedia.pub/entry/40673 (accessed on 07 March 2026).

Yan Z, Liu R, Liu B, Shao Y, Liu M. Molecular Dynamics Simulation Studies of Silicon Carbide Materials. Encyclopedia. Available at: https://encyclopedia.pub/entry/40673. Accessed March 07, 2026.

Yan, Zefan, Rongzheng Liu, Bing Liu, Youlin Shao, Malin Liu. "Molecular Dynamics Simulation Studies of Silicon Carbide Materials" Encyclopedia, https://encyclopedia.pub/entry/40673 (accessed March 07, 2026).

Yan, Z., Liu, R., Liu, B., Shao, Y., & Liu, M. (2023, January 31). Molecular Dynamics Simulation Studies of Silicon Carbide Materials. In Encyclopedia. https://encyclopedia.pub/entry/40673

Yan, Zefan, et al. "Molecular Dynamics Simulation Studies of Silicon Carbide Materials." Encyclopedia. Web. 31 January, 2023.

Copy Citation

Silicon carbide (SiC) materials are widely applied in the field of nuclear materials and semiconductor materials due to their excellent radiation resistance, thermal conductivity, oxidation resistance, and mechanical strength. The molecular dynamics (MD) simulation is an important method to study the properties, preparation, and performance of SiC materials. It has significant advantages at the atomic scale.

silicon carbide

molecular dynamics simulation

property

preparation

performance

1. Molecular Dynamics Simulation Studies of Silicon Carbide Properties

1.1. MD Simulation Studies of SiC Thermal Properties

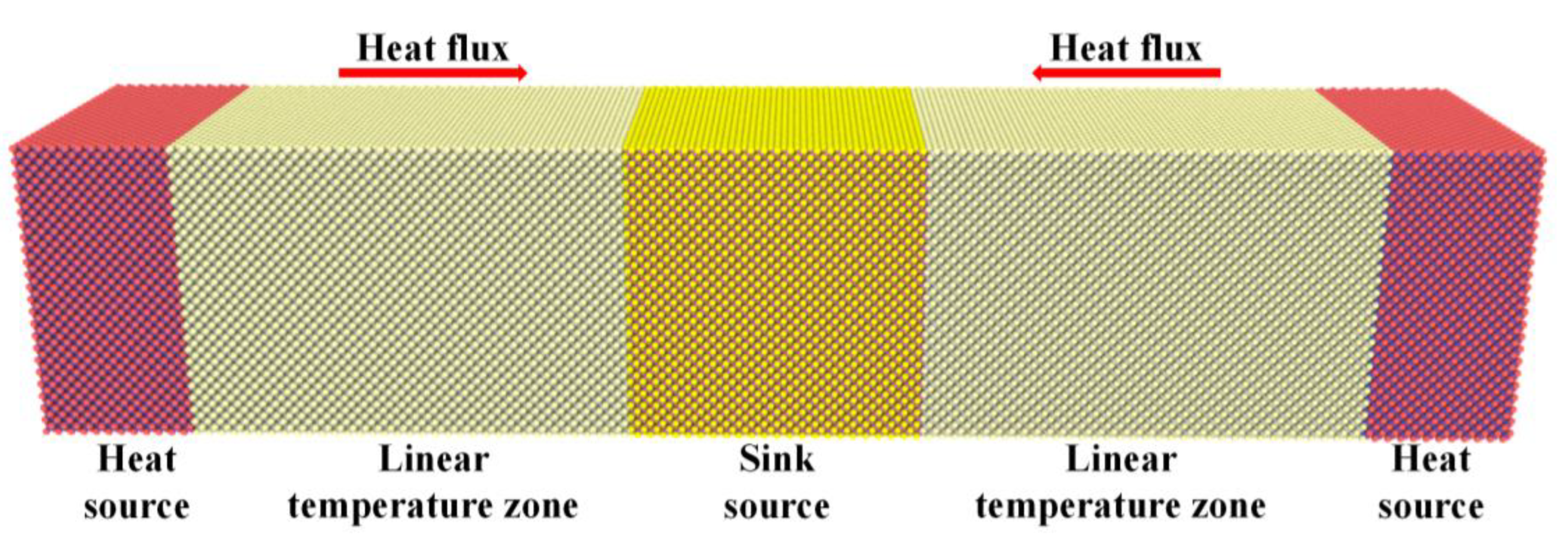

The molecular dynamics (MD) simulation study of silicon carbide (SiC) thermal properties mainly focuses on the calculation of thermal conductivity. The typical thermal conductivity calculation model of SiC was given, as shown in Figure 1. There are three kinds of methods to calculate thermal conductivity, called the EMD (the equilibrium molecular dynamics), the NEMD (the nonequilibrium molecular dynamics), and the RNEMD (the reverse nonequilibrium molecular dynamics).

Figure 1. The typical thermal conductivity calculation model of SiC [1].

The EMD method is based on the Green-Kubo theory, and the NEMD method and the RNEMD method are based on the Fourier theory. The difference between the NEMD method and the RNEMD method is the way the temperature gradient is generated. A constant temperature difference at both ends of the material are applied directly by the NEMD method, while different perturbations in the hot and sink sources is applied by the RNEMD method.

There are two kinds of methods in the RNEMD method, called the Müller-Plathe method [2] and the Jund method. The velocity of atoms in the hot and sink sources is exchanged by the Müller-Plathe method [3]. The energy in the hot and sink sources is exchanged by the Jund method.

In the application of the RNEMD method, the effects of material morphology, temperature, and irradiation on the thermal conductivity of SiC have been paid much attention. Qin et al. [2] used the Müller-Plathe method to calculate the thermal conductivity of SiC nanotubes. The coupling effects of the length, diameter, and temperature on the thermal conductivity of SiC nanotubes were revealed. Mao et al. [4] used the quantum corrected Müller-Plathe method to calculate the thermal conductivity of 3C-SiC. The effects of the point defect type and the concentration on thermal conductivity were revealed. Dong et al. [3] used the Jund method to calculate the thermal conductivity of SiC/SiC composites. The effects of the irradiation dose and temperature on the change of thermal conductivity were revealed.

In the application of the NEMD method, the effects of material structure, temperature, and irradiation on the thermal conductivity of SiC have been paid much attention. Liu et al. [5] successfully studied the effect of different SiC crystal/amorphous layered nanostructures on the interfacial thermal conductivity. Wang et al. [1] revealed the effects of temperature and irradiation on the thermal conductivity of 3C-SiC.

In the application of the EMD method, the effects of irradiation and defects on the thermal conductivity of SiC have been paid much attention. Samolyuk et al. [6] revealed the effect of single vacancy and small vacancy clusters/micropores generated by irradiation on the thermal conductivity of 3C-SiC. Wang et al. [7] successfully studied the effects of types of point defects on the thermal conductivity of 3C-SiC.

1.2. MD Simulation Studies of SiC Mechanical Properties

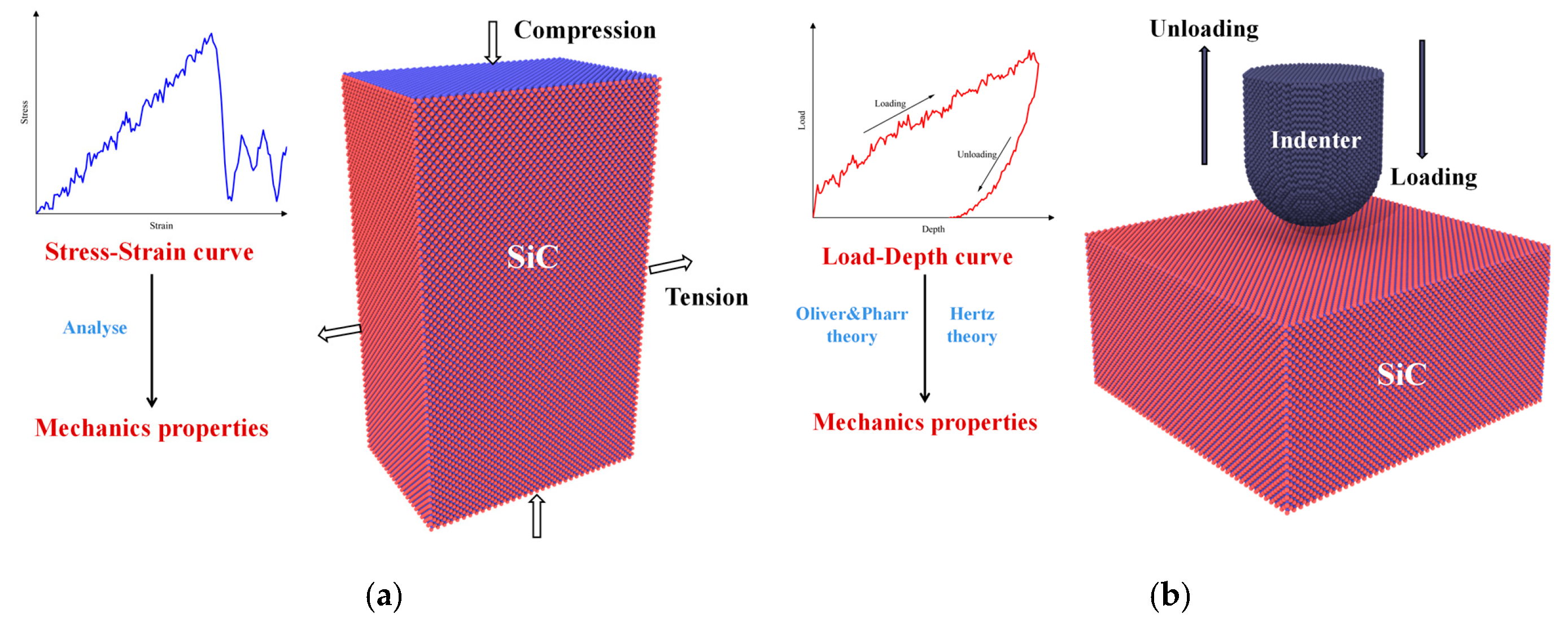

Mechanical properties are important parameters affecting the processing performance and performance of SiC materials, and are one of the hotspots in the MD simulation studies of SiC properties. Various mechanical properties of SiC, such as hardness, elastic modulus, strength, etc., can be well calculated and analyzed at the nanoscale by MD simulation. Uniaxial tensile/compression and nanoindentation are two common methods used in MD studies of the mechanical properties of SiC materials.

The typical mechanical properties calculation model of SiC was given, as shown in Figure 2. The tension/pressure to both ends of the sample in a certain direction at the same time is applied by uniaxial tensile/compression, while the loading-unloading process of the indenter on the sample surface is controlled by nanoindentation.

In the application of the uniaxial tensile/compressive, the tensile/compressive strength is usually calculated by analyzing the stress-strain curve. Yang et al. [10] calculated the tensile/compressive strength by calculating the stress-strain curve. The temperature dependence of the tensile/compressive strength of polycrystalline SiC was studied. Li et al. [11] calculated the tensile strength by the same method. The effects of irradiation and grain boundary on the tensile strength of 3C-SiC were studied. Molaei et al. [12] calculated the tensile strength and elastic modulus by analyzing the stress-strain behavior in the uniaxial tension, based on the virial stress criterion. The effects of the temperature and the crack on the mechanical properties of polycrystalline SiC nanosheets were studied.

In the application of the nanoindentation, the hardness and elastic modulus are usually calculated by analyzing the load-depth curve, based on the Oliver and Pharr theory or Hertz theory. Wu et al. [13] calculated the hardness and elastic modulus using the Oliver and Pharr theory. The effects of Si ion implantation on the mechanical properties of 3C-SiC were studied successfully. Kang et al. [14] studied the effects of H ion implantation and temperature on the hardness and elastic modulus of 4H-SiC by the same method. Xue et al. [15][16] calculated the hardness and elastic modulus based on the Oliver and Pharr theory and Hertz theory. The effects of the temperature and indentation plane on the mechanical properties of 4H-SiC were studied.

1.3. MD Simulation Studies of SiC Electrical Properties

The electrical properties of SiC can be calculated by the MD method. For example, Domingues et al. [17] calculated the frequency-dependent dielectric constant based on the linear response theory and the Lorentz model. The effects of the temperature on the dielectric constant of SiC were revealed. Chen et al. [18] calculated the frequency-dependent dielectric constant of SiCm based on the linear response theory. The feasibility of combining deep neural networks with the MD method was demonstrated.

In general, there are few reports on the MD simulation of the electrical properties of SiC. Because there are few universal models for the correlation between microscopic information and macroscopic electrical characteristic parameters of MD simulation, it is worthy of further study.

2. MD Simulation Studies of Silicon Carbide Preparation

2.1. MD Simulation Studies of SiC Ion Implantation

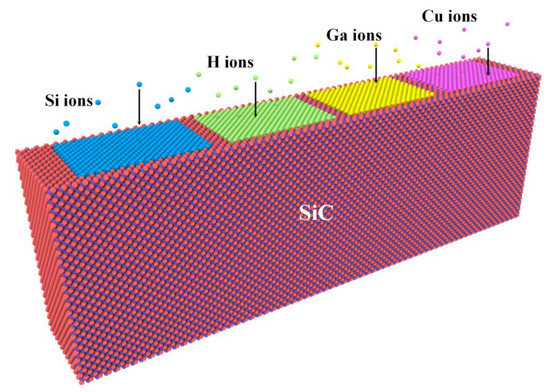

Ion implantation is a method of surface modification by irradiating an ion beam into the surface of a solid material. It is widely applied in the element doping processing of semiconductor materials, such as SiC. A certain dose of the incident ion is injected into the material surface with a certain energy at a certain height from the surface of SiC materials to simulate the ion implantation process in the MD simulation. The typical ion implantation simulation model of SiC was given, as shown in Figure 3. There are three kinds of ion implantation in MD simulation studies of SiC according to the type of the implanted ion, called Si ion implantation, H ion implantation, and metal ion (Ga+, Cu2+, etc.) implantation. The effects of ion implantation on the defect evolution, mechanical properties, and processing properties of SiC materials can be studied by MD simulation.

In the studies of Si ion implantation, Wu et al. [13] studied the effects of Si ion implantation dose and energy on the defect evolution and mechanical properties of 3C-SiC. Dai et al. [21] studied the effects of Si ion implantation energy on the 3C-SiC polishing effect. Liu et al. [22] studied the effects of Si ion implantation on the polishing removal mechanism of 6H-SiC. The studies showed that the hardness and elastic modulus of SiC could be reduced, the formation of dislocations in SiC could be inhibited, and the polishing performance and processing efficiency of SiC could be improved by Si ion implantation.

In the studies of H ion implantation, Fan et al. [23] studied the evolution mechanism of Si vacancy defects and damages during H ion implantation and the subsequent annealing of 4H-SiC. Kang et al. [14] studied the effects of H ion implantation on the mechanical properties of 4H-SiC. The studies showed that the integrity of Si vacancy defects in SiC could be improved, the crack propagation in SiC could be prevented, and the fracture toughness of SiC could be improved by H ion implantation.

In the studies of metal ion implantation, Fan et al. [19] studied the effects of the Ga ion implantation dose on the polishing effects of 4H-SiC. There are also studies on the synergistic implantation of metal ions and H ions. Kang et al. [24] studied the effects of the Cu ion assisted H ion on the modification of 4H-SiC. The studies showed that the ductility and surface toughness of SiC could be improved by metal ion implantation, and the synergistic ion implantation was more effective.

2.2. MD Simulation Studies of SiC Polishing

Polishing is an important process in the manufacturing process of SiC materials. There are three kinds of polishing in MD simulation studies of SiC according to the processing method, called abrasive polishing, tool polishing, and assisted polishing. The typical polishing simulation model of SiC was given, as shown in Figure 4. The removal and deformation mechanism of SiC material surface could be studied by MD simulation.

Figure 4. The typical polishing simulation model of SiC [25].

The surface of SiC materials is polished by spherical diamond abrasives in the abrasive polishing. In the studies of abrasive polishing, the removal mechanism has been paid much attention. Zhou et al. [26] studied the effects of multi-abrasive polishing on the removal mechanism of the 3C-SiC substrate. Wu et al. [27] studied the effects of abrasive size on the removal mechanism of 6H-SiC polishing. Zhou et al. [28] studied the effect of abrasive contact type on the removal mechanism of 3C-SiC polishing. The studies showed that the processing quality could be deteriorated by the random distribution of the abrasive. The type of removal mechanism could be affected by the size of the abrasive, and the damages of the abrasive could be reduced by the rotation.

The surface of SiC materials is polished by sharp diamond tools in tool polishing. In the studies of tool polishing, the removal and deformation mechanism have been paid much attention. Meng et al. [29] studied the effects of polishing speed and thermal effect on the removal mechanism of 3C-SiC. Luo et al. [30] studied the effects of polishing depth and uniformity on the removal mechanism of 6H-SiC. Zhang et al. [31] studied the effects of the tool inclination angle on the deformation mechanism of 6H-SiC. Meng et al. [32] studied the effects of polishing direction on the deformation mechanism of 3C-SiC. Chavoshi et al. [33] studied the deformation mechanism of 3C-SiC polishing on different crystal orientations. The studies showed that the tool wear could be reduced by the thermal effect caused by high-speed polishing, the removal mechanism of SiC could be controlled by changing the cutting depth and uniformity, and the deformation mechanism of SiC could be controlled by changing the cutting direction and tool inclination angle.

The abrasive or tool polishing performance of SiC is improved by the supplementary method in assisted polishing. In the studies of assisted polishing, the removal and deformation mechanism have been paid much attention. Zhou [34] studied the effects of water-assisted polishing on the removal mechanism of 3C-SiC. Nguyen et al. [35] studied the effects of abrasive motion on the removal mechanism of 4H-SiC polishing. Hu et al. [36] studied the effect of vibration-assisted polishing on the removal mechanism of the single crystal SiC. Zhao et al. [37] studied the effect of ultrasonic vibration-assisted polishing on the deformation mechanism of 3C-SiC. Meng et al. [38] studied the effect of femtosecond laser-assisted polishing on the removal mechanism of 3C-SiC. The studies showed that the removal efficiency, surface finish, and integrity of SiC could be improved by assisted polishing.

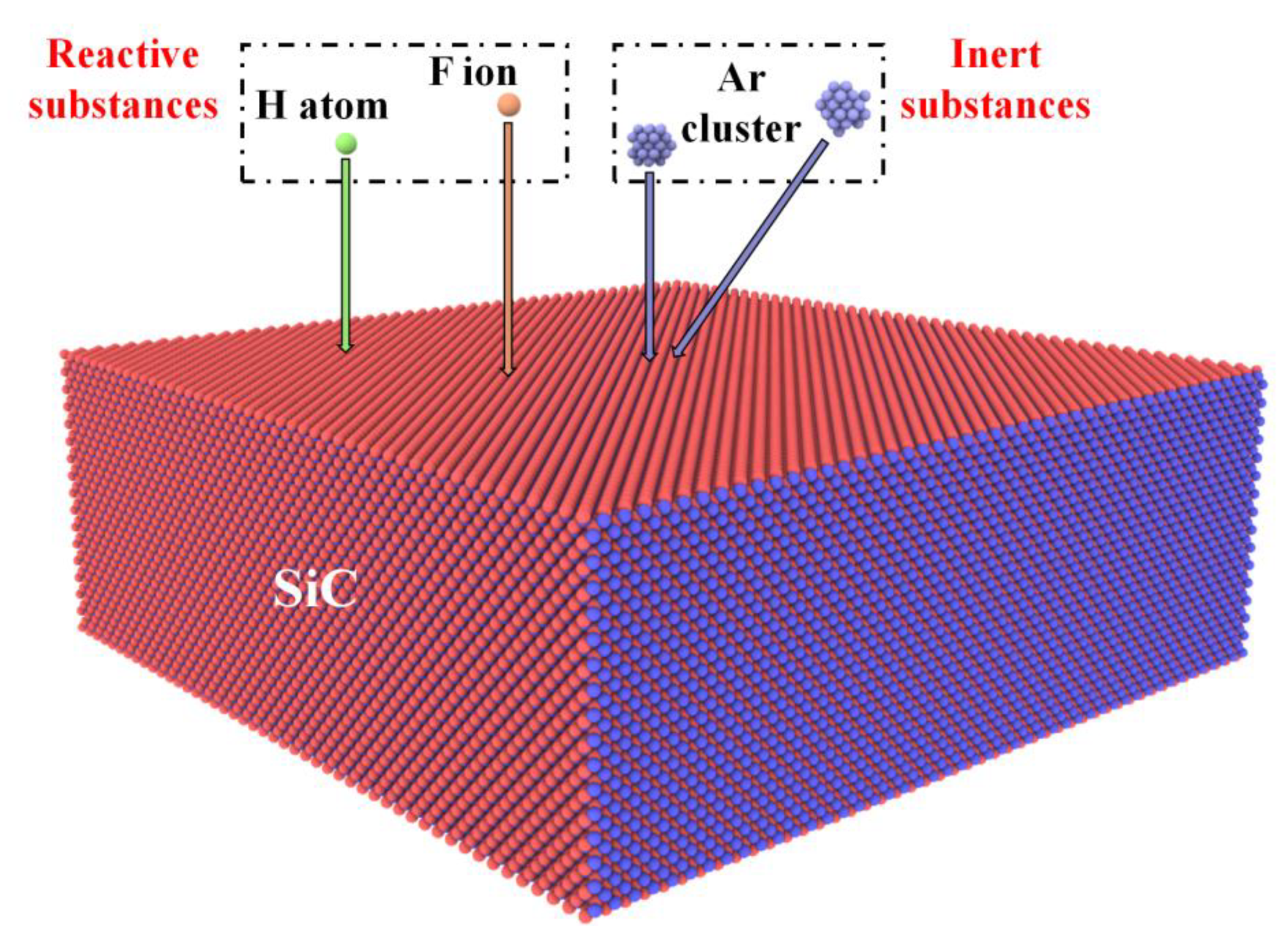

2.3. MD Simulation Studies of SiC Sputtering

Sputtering is an important process in the manufacturing of semiconductor materials, such as SiC. It is applied to fabricate the required micro-nano structures on the surface of materials. There are two kinds of sputtering in MD simulation studies of SiC according to the incident substances, called inert substances sputtering and reactive substance sputtering. The typical sputtering simulation model of SiC was given, as shown in Figure 5. The sputtering mechanism, sputtering yield, and sputtering products on surface can be studied by MD simulation.

In the studies of inert substances sputtering, Satake [39] studied the transverse sputtering mechanism caused by the collision of two Ar clusters on the surface of 4H-SiC. Prskalo et al. [41] studied the sputtering yield of the Ar atom sputtering the 3C-SiC surface. The studies showed that the surface modification effect of Ar atoms on SiC is obvious. The sputtering yield of SiC is a function of the incident energy of Ar atoms.

In the studies of reactive substances sputtering, Sun et al. [42] studied the effects of the incident energy of the H atom on the sputtering products of the continuous bombardment of the SiC surface by the H atom. Gou et al. [43] studied the effects of incident energy of CF3 on the sputtering products of continuous bombardment of the SiC surface by CF3. Lu et al. [44] studied the effect of the substrate temperature on the sputtering products of continuous bombardment of the SiC surface by the F ion. The studies showed that the thickness of the reaction layer, the composition, and yield of the sputtering product could be affected by the incident energy and substrate temperature.

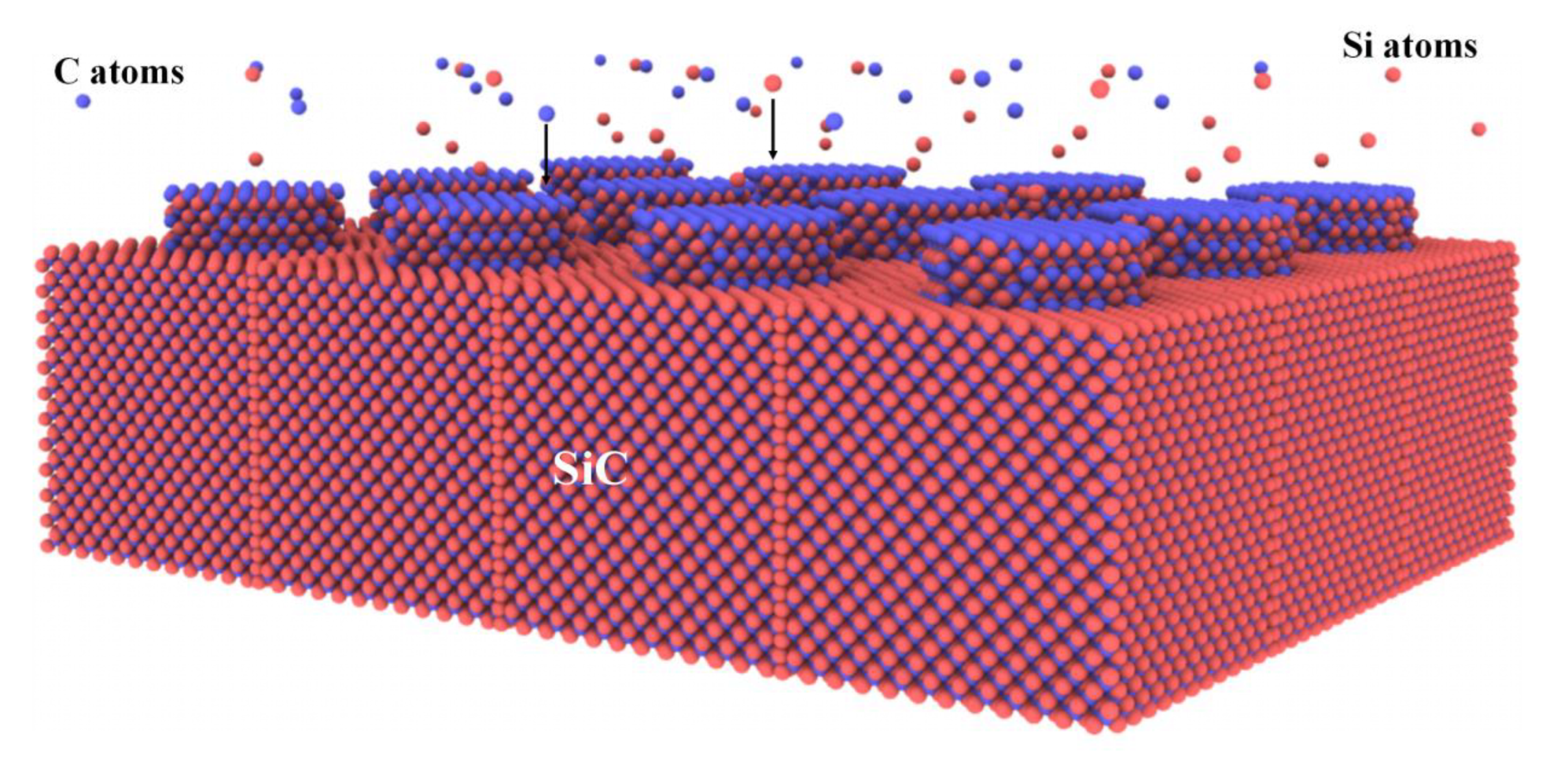

2.4. MD Simulation Studies of SiC Deposition

The thin film deposition is one of the necessary steps in the manufacture of semiconductor materials, such as SiC. The typical deposition simulation model of SiC was given, as shown in Figure 6. The region deposited in the model is called the substrate. A number of Si atoms and C atoms are randomly generated in a region above the substrate. They fall and cover the substrate to form a SiC deposited layer. The effects of the atomic incident energy, substrate morphology, and substrate temperature on the quality of the SiC deposited films can be studied by MD simulation.

Xue et al. [45] studied the effects of the substrate pattern on SiC films deposited on 4H-SiC substrates. Kim et al. [47][48] studied the effects of the substrate temperature and atomic incident energy on the deposition of amorphous SiC films on crystalline silicon substrates. The studies showed that the chemical order of the deposited films can be controlled by adjusting the atomic incident energy, substrate morphology, and substrate temperature to obtain high-quality SiC films with dense and defect-free content.

2.5. MD Simulation Studies of SiC Crystal Growth

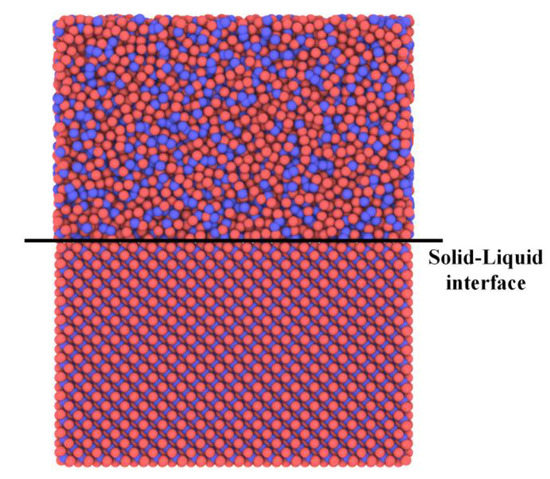

The high-quality growth of SiC crystals is the basis for manufacturing high-performance devices as an important semiconductor material. Fewer defects and higher density are usually required in SiC crystals. The typical crystal growth simulation model of SiC was given, as shown in Figure 7. Solid crystal SiC and liquid amorphous SiC are set in the model, and then the crystal growth process on the solid-liquid interface can be observed. The crystallization behavior and mechanism of SiC can be studied by MD simulation.

Figure 7. The typical crystal growth simulation model of SiC [49].

Narumi et al. [50] studied the effects of the growth interface on the growth behavior of 4H-SiC in the Si-C solution. Gao et al. [49] studied the crystallization behavior induced by SiC crystals at the solid-liquid interface. Kang [51] studied the effect mechanism of process variables on the formation of polymorphs in SiC single crystal growth. Gao et al. [52] studied the mechanism of the amorphous to the crystalline transition of 3C-SiC. The studies showed that the crystal growth rate and growth mechanism of SiC are different at different growth interfaces. The atoms near the growth interface tend to induce further crystallization by forming a stable intermediate-phase crystal structure.

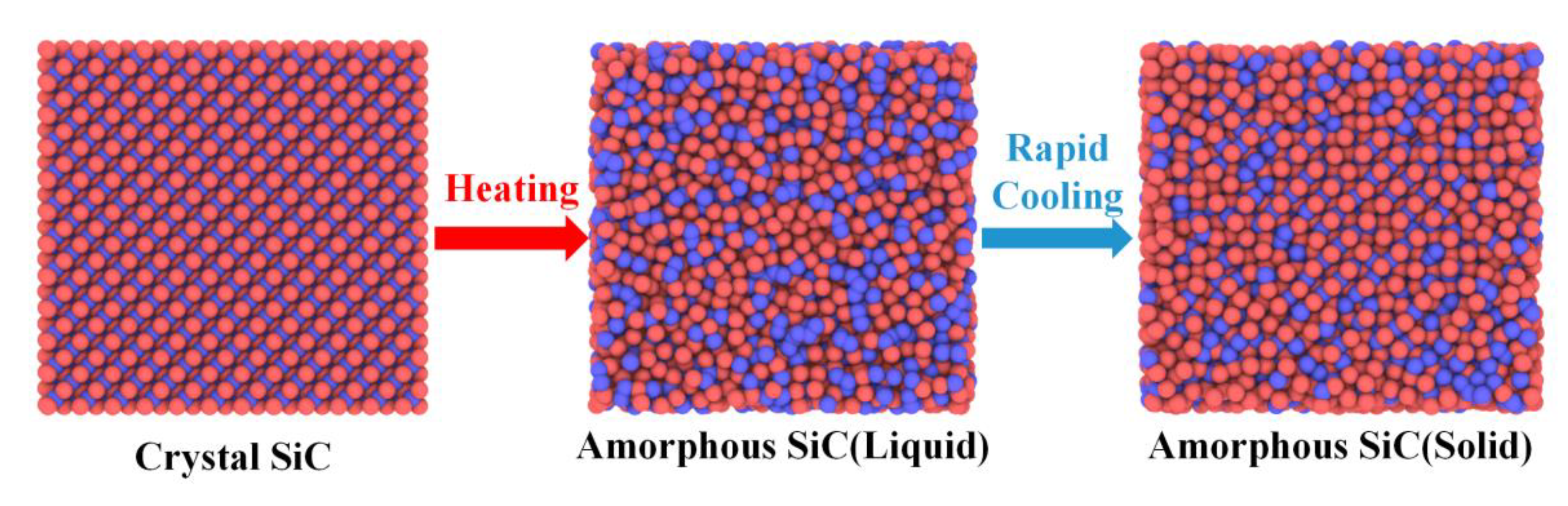

2.6. MD Simulation Studies of SiC Amorphization

The preparation of SiC amorphous materials is also studied widely in the MD simulation of SiC preparation. There are two kinds of amorphization in MD simulation studies of SiC, called heating amorphization and cooling amorphization. The SiC material is heated from a low temperature above its melting point and melts into an amorphous material in the heating amorphization. The high-temperature molten SiC is rapidly cooled to low temperatures to form amorphous materials in the cooling amorphization. The typical amorphization simulation model of SiC was given, as shown in Figure 8. The structural evolution and mechanism of SiC amorphization can be studied by MD simulation.

In the studies of heating amorphization, Nguyen et al. [53] studied the structural evolution of SiC nanosheets during melting. Hoang et al. [55] studied the melting mechanism of two-dimensional (2D) hexagonal SiC nanoribbons. The studies showed that the liquid atoms in SiC first appear in the edge region of the material far below the melting point and then gradually expand to other regions.

In the studies of cooling amorphization, Tranh et al. [54] studied the effect of the potential function on the formation of glassy SiC nanoribbons by rapid cooling of molten SiC. Hoang et al. [56] studied the formation mechanism of the atomic structure of amorphous 2D SiC nanobelts obtained by cooling from melts. The studies showed that the Tersoff potential is more suitable for the simulation of cooling amorphization. The disordered atomic structure of amorphous 2D SiC nanoribbons is caused by various structural defects and the non-alternating distribution of Si and C atoms.

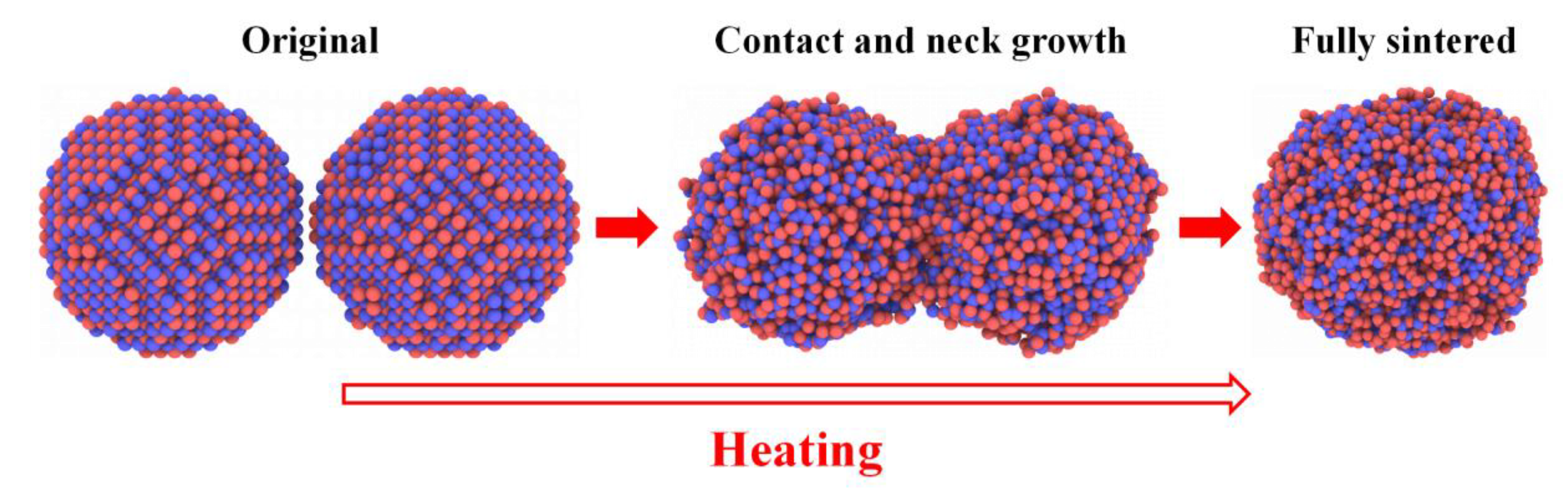

2.7. MD Simulation Studies of SiC Sintering

Sintering is an important preparation method of SiC materials and plays an important role in nuclear fuel study. For example, the matrix material of the fully ceramic microencapsulated accident-tolerant fuel (FCM-ATF) is made of SiC powder or nanoparticles. The typical sintering simulation model of SiC was given, as shown in Figure 9. Two SiC nanoparticles were placed in the cutoff distance of the potential function, then the system was heated to make the two particles contact each other and form a sintering neck, and finally completely sintered. The sintering process and mechanism of SiC nanoparticles from the microscopic view can be studied by MD simulation.

Figure 9. The typical sintering simulation model of SiC [57].

There are few related studies. A research group conducted a preliminary study on MD simulation of SiC nanoparticle sintering recently. The sintering evolution and mechanism of three typical SiC nanoparticles: pure SiC, SiC@Si, and SiC@C were studied. The studies showed that the overall sintering behavior of SiC particles was promoted by the atomic diffusion of the coating layer. The lower heating rate is beneficial to sintering to some extent but did not affect the atomic diffusion mode of the coating particles.

2.8. MD Simulation Studies of New-Type SiC Materials Preparation

In addition to conventional SiC films, SiC bulks, and SiC crystals/amorphous materials, there are also some newly discovered SiC materials emerging in the MD simulation of SiC preparation. The preparation method of new-type SiC materials, such as nanowires and nanotubes can also be studied by MD simulation. SiC nanocage is expected to be an ideal material for drug delivery as a kind of new material. However, it is still in the conceptual stage. Its properties and the feasibility of preparation can be studied by the MD method.

Xin et al. [58] studied the existence, stability, and structure of SimCn nanocages (Figure 10). A series of self-assembled, stable SiC nanocage structural materials were predicted successfully, and the key factors for the preparation of these new materials were studied.

Figure 10. The formation process of a SiC nanocage in MD simulation, modified picture of [58].

3. MD Simulation Studies of Silicon Carbide Performance

3.1. MD Simulation Studies of SiC Irradiation Damage

The defects in materials will be produced by the impact of ray particles (neutrons, protons, heavy ions, electrons, X-rays, γ-rays), and the transmutation elements will be produced by the nuclear reactions. The change of macroscopic properties of materials caused by lattice defects and transmutation elements is called the irradiation effect. SiC is a kind of common nuclear material in advanced nuclear energy systems, and its irradiation process and effect are the key to the studies of performance. Therefore, the studies of irradiation damage have become the most concerned in the MD simulation of SiC performance.

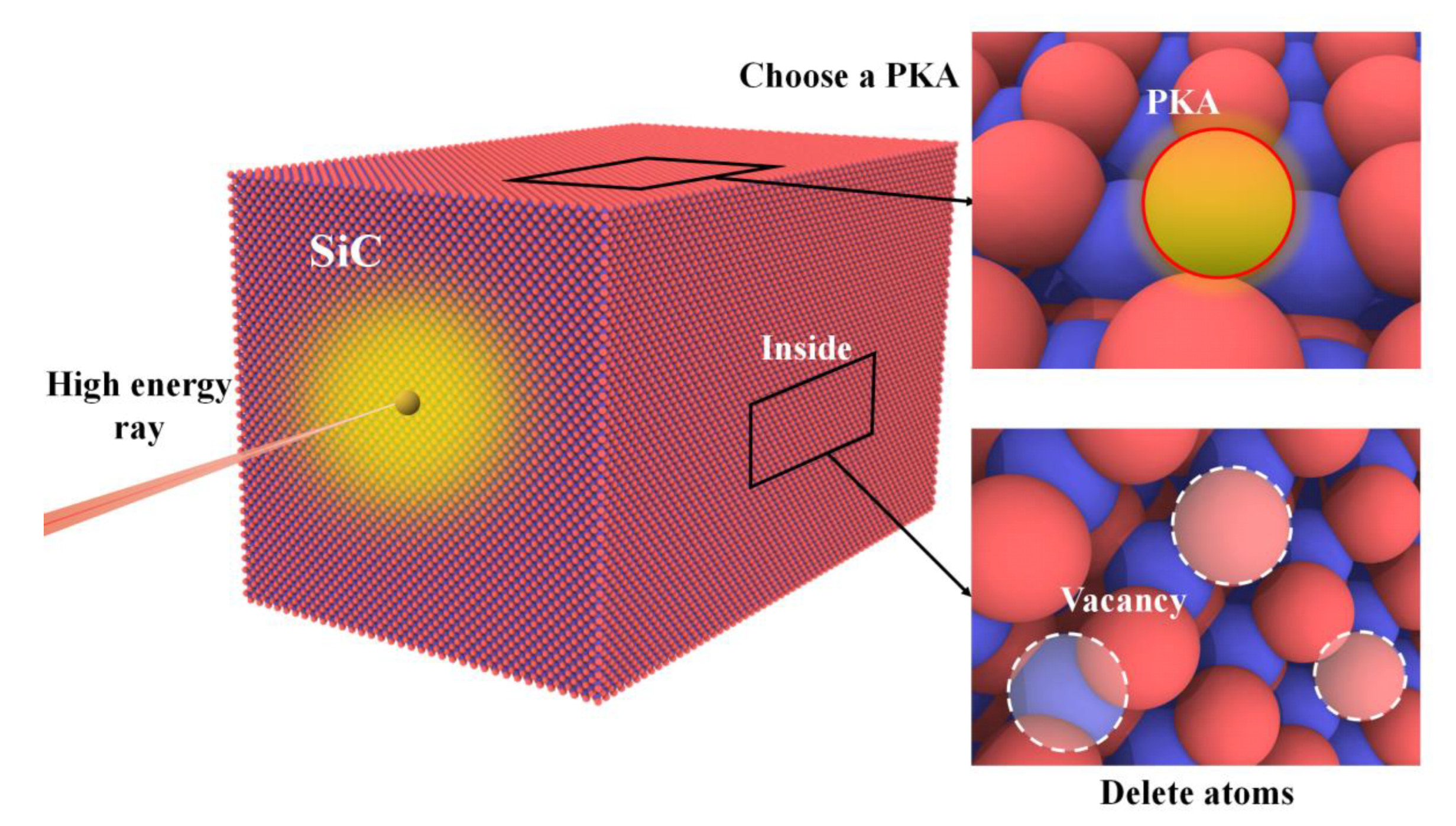

There are three methods to simulate SiC irradiation damage in MD simulation. The first is to artificially remove some atoms in the material to form defects and simulate the damage effect after irradiation. The second is to use high-energy ray particles to impact materials to cause a cascade effect. The third is to choose an atom in the material and give it high energy to become a primary knock-on atom (PKA) to cause a cascade effect. The typical irradiation damage simulation model of SiC was given, as shown in Figure 11.

Figure 11. Three typical irradiation damage simulation models of SiC [59].

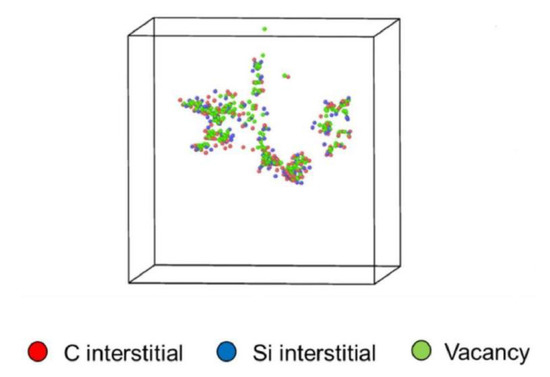

There are two main concerns in the content of MD simulation studies of SiC irradiation damage. The first is the effects of irradiation on properties. The second is the mechanism of irradiation damage, as shown in Figure 12.

Figure 12. The typical irradiation damage mechanism simulation model of SiC, modified picture of [1].

To sum up, there are two aspects in MD simulation studies of the effects of irradiation on SiC properties. The first is the effects of irradiation on the thermal properties of SiC (mainly the thermal conductivity). Wang et al. [1] studied the effects of irradiation on the thermal conductivity of 3C-SiC by simulating the irradiation effect with high-energy Si atoms and subsequent cascade collisions. Nguyen et al. [60] studied the relationship between defect thermal conductivity and vacancy concentration and irradiation dose by calculating the thermal conductivity of SiC/SiC composites under neutron irradiation. Samolyuk et al. [6] studied the effects of irradiation-induced single vacancy and small vacancy clusters/micropores on the thermal conductivity of 3C-SiC. Dong et al. [3] studied the effects of the irradiation-induced point defects at the interface of SiC/SiC composites and the irradiation dose on the thermal conductivity. The studies showed that the thermal conductivity of SiC could be decreased by irradiation damage. The thermal conductivity of SiC could be decreased more by a single vacancy than a micropore with the same total number of vacancies.

The second is the effects of irradiation on the mechanical properties of SiC. Li et al. [11] studied the effects of irradiation on the tensile strength and elastic modulus of 3C-SiC. The studies showed that the tensile strength and elastic modulus of 3C-SiC could be decreased by irradiation damage.

To sum up, there are three aspects in MD simulation studies of the mechanism of SiC irradiation damage. The first is the formation process and mechanism of irradiation defects. Zarkadoula et al. [61] studied the effects of the electron blocking power on defects in 3C-SiC caused by ion irradiation. Samolyuk et al. [62] studied the effects of potential functions on defects in 3C-SiC collision cascade simulation. He et al. [63] studied the formation of defects and the effects of electron energy loss during the irradiation damage of SiC materials. Wu et al. [59] studied the fast, ion-induced effects in 3C-SiC and the effects of the complex correlation between the electronic response and atomic response on the defect formation. Li et al. [64] studied the irradiation damage mechanism of 6H-SiC under ultra-high flux He ions. Ran et al. [65] studied the effects of temperature and PKA energy on collision cascade in 3C-SiC. The studies showed that the formation of irradiation defects was affected importantly by the ratio of electron energy loss to nuclear energy loss. The number and size of defects increased with the increase in PKA energy.

The second Is the recovery mechanism of irradiation defects. Backman et al. [66] studied the defect recovery of irradiated SiC under fast, heavy ion irradiation. Peterson et al. [67] studied the effects of high field bias on the irradiation-induced defect recovery in 3C-SiC. The studies showed that the defects could be recovered by the heavy ion rapid annealing. The defect recovery effect could be enhanced by the field strength lower than the critical breakdown of the wide band gap device.

The third is the formation mechanism of irradiation swelling. Li et al. [68] studied the effect of the C/Si atomic ratio on the irradiation swelling of 3C-SiC. Tian et al. [69] studied the swelling of SiC crystals caused by continuous collision cascades at room temperature. The studies showed that the degree of irradiation swelling decreased with the increase in the C/Si ratio in SiC. The amorphization of SiC could be caused by the irradiation swelling. There are four stages of amorphization, called slow increase, rapid increase, slow increase, and completely amorphous.

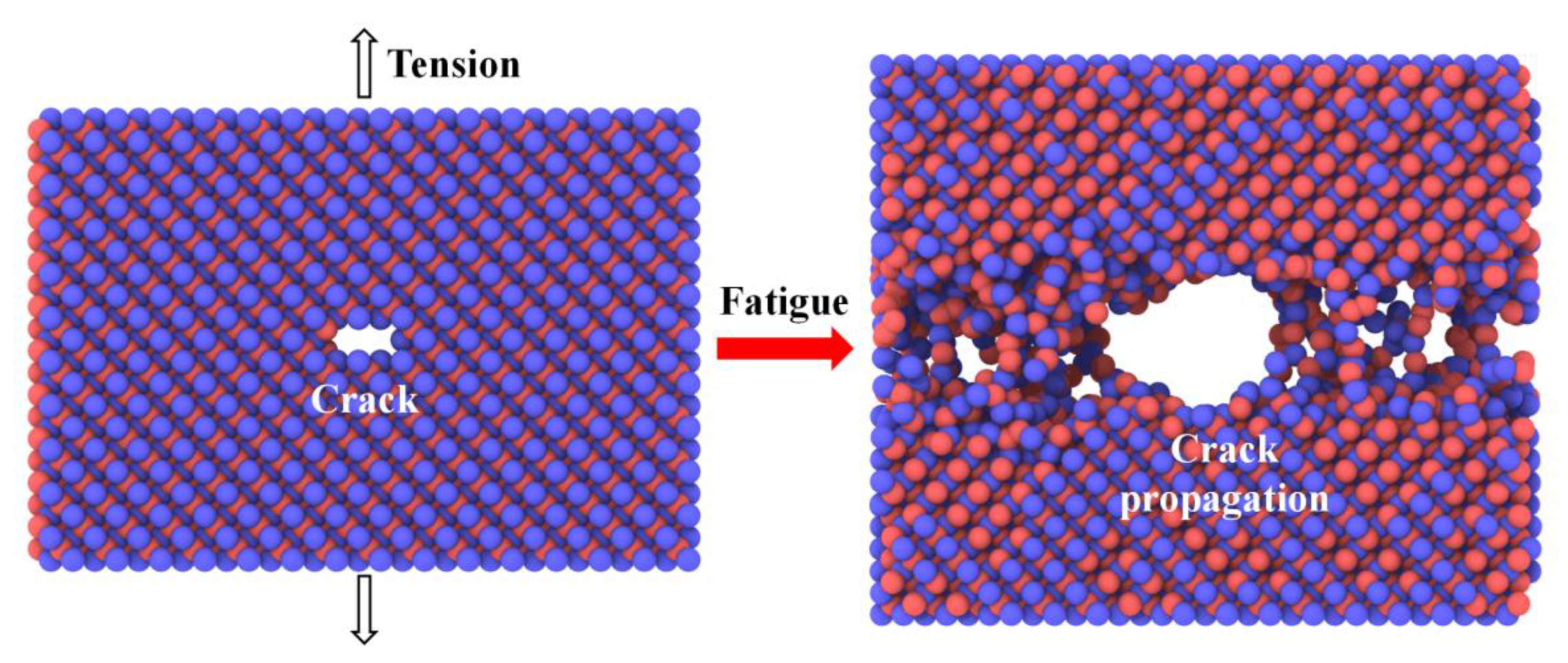

3.2. MD Simulation Studies of SiC Fatigue Damage

A crack is a kind of fatigue damage caused by local fracture of the weak part of material under force. SiC maybe cracks when applied as a structural material if the tension exceeds a certain value. The typical fatigue damage simulation model of SiC was given, as shown in Figure 13. The atoms in certain fields are removed artificially during the material modeling to form initial cracks, then an external force is applied to the material. The evolution of cracks in SiC under external force and its effect on SiC mechanical properties can be studied by MD simulation.

Figure 13. The typical fatigue damage simulation model of SiC [70].

Molaei et al. [12] studied the fracture fingerprint of polycrystalline SiC nanosheets with single crystalline SiC nanosheets as reference. The study showed that the properties of SiC nanosheets with cracks could be degraded with the increase in temperature. The strength of SiC nanosheets was reduced seriously by the large cracks.

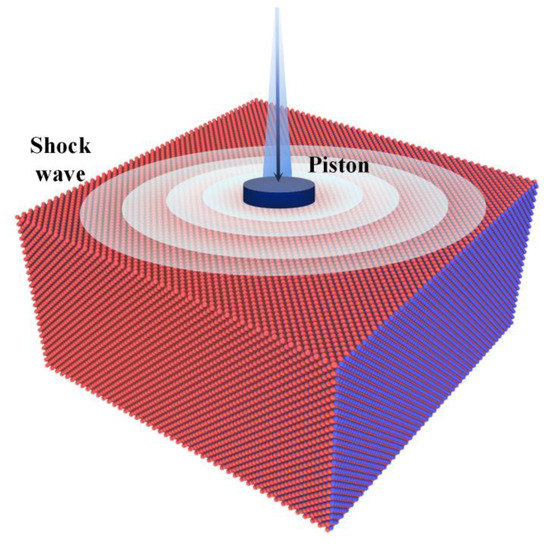

3.3. MD Simulation Studies of SiC Shock Damage

SiC will be subjected to sudden mechanical action when applied as a protective material. For example, SiC is shocked by high-speed moving objects when it is applied as bulletproof materials. The typical shock damage simulation model of SiC was given, as shown in Figure 14. The shock waves are created by hitting SiC samples with a high-velocity virtual piston to result in damage effects. The effects of shock velocity on the shock response to SiC can be studied by MD simulation.

Figure 14. The typical shock damage simulation model of SiC [71].

Feng et al. [71] studied the inelastic response to 6H-SiC and 4H-SiC under strong dynamic shock loading. Lee et al. [72] studied the high-velocity shock compression of 3C-SiC. Zhang et al. [73] studied the shock profile and atomic structure evolution of 3C-SiC under plane shock loading. These studies showed that different response states in SiC could be produced with the change of shock velocity, such as the single elastic wave, structural phase transition wave, etc.

References

- Wang, Q.; Gui, N.; Huang, X.L.; Yang, X.T.; Tu, J.Y.; Jiang, S.Y. The effect of temperature and cascade collision on thermal conductivity of 3C-SiC: A molecular dynamics study. Int. J. Heat Mass Transf. 2021, 180, 121822.

- Qin, C.L.; Luo, X.Y.; Xie, Q.; Wu, Q.D. Molecular dynamics study of thermal conductivity of carbon nanotubes and silicon carbide nanotubes. Acta Phys. Sin. 2022, 71, 030202.

- Dong, X.Y.; Shin, Y.C. Predictions of thermal conductivity and degradation of irradiated SiC/SiC composites by materials-genome-based multiscale modeling. J. Nucl. Mater. 2018, 512, 268–275.

- Mao, Y.C.; Li, Y.Y.; Xiong, Y.H.; Xiao, W. Point defect effects on the thermal conductivity of β-SiC by molecular dynamics simulations. Comput. Mater. Sci. 2018, 152, 300–307.

- Liu, Q.F.; Yu, W.S.; Luo, H.; Ren, X.; Shen, S.P. Tuning thermal resistance of SiC crystal/amorphous layered nanostructures via changing layer thickness. Comput. Mater. Sci. 2020, 184, 109868.

- Samolyuk, G.D.; Golubov, S.I.; Osetsky, Y.N.; Stoller, R.E. Molecular dynamics study of influence of vacancy types defects on thermal conductivity of β-SiC. J. Nucl. Mater. 2011, 418, 174–181.

- Wang, F.; Zhou, Y.; Gao, S.X.; Duan, Z.G.; Sun, Z.P.; Wang, J.; Zou, Y.; Fu, B.Q. Molecular dynamics study of effects of point defects on thermal conductivity in cubic silicon carbide. Acta Phys. Sin. 2022, 71, 036501.

- Zhang, B.Y.; Qiu, H.P.; Tian, Y.; Chen, M.W.; Chen, S.H. Tension-Tension Fatigue of 2.5D-SiC/SiC Ceramic Matrix Composites at Elevated Temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2019, 678, 012057.

- Zhang, Z.Z.; Yao, P.; Wang, J.; Huang, C.Z.; Zhu, H.T.; Liu, H.L.; Zou, B. Nanomechanical characterization of RB-SiC ceramics based on nanoindentation and modelling of the ground surface roughness. Ceram. Int. 2020, 46, 6243–6253.

- Yang, B.; Deng, Q.B.; Su, Y.; Peng, X.H.; Huang, C.; Lee, A.; Hu, N. The effects of atomic arrangements on mechanical properties of 2H, 3C, 4H and 6H-SiC. Comput. Mater. Sci. 2022, 203, 111114.

- Li, Y.Y.; Li, Y.; Xiao, W. Point defects and grain boundary effects on tensile strength of 3C-SiC studied by molecular dynamics simulations. Nucl. Eng. Technol. 2019, 51, 769–775.

- Molaei, F.; Dehaghani, M.Z.; Salmankhani, A.; Fooladpanjeh, S.; Sajadi, S.M.; Safa, M.E.; Abida, O.; Habibzadeh, S.; Mashhadzadeh, A.H.; Saeb, M.R. Applying molecular dynamics simulation to take the fracture fingerprint of polycrystalline SiC nanosheets. Comput. Mater. Sci. 2021, 200, 110770.

- Wu, W.L.; Hu, Y.; Meng, X.S.; Dai, J.B.; Dai, H.F. Molecular dynamics simulation of ion-implanted single-crystal 3C-SiC nano-indentation. J. Manuf. Process. 2022, 79, 356–368.

- Kang, Q.; Fang, X.; Wu, C.; Verma, P.; Sun, H.; Tian, B.; Zhao, L.; Wang, S.; Zhu, N.; Maeda, R.; et al. Mechanical properties and indentation-induced phase transformation in 4H–SiC implanted by hydrogen ions. Ceram. Int. 2022, 48, 15334–15347.

- Xue, L.H.; Feng, G.; Liu, S. Molecular dynamics study of temperature effect on deformation behavior of m-plane 4H-SiC film by nanoindentation. Vacuum 2022, 202, 111192.

- Xue, L.H.; Feng, G.; Wu, G.; Dong, F.; Liang, K.; Li, R.; Wang, S.Z.; Liu, S. Study of deformation mechanism of structural anisotropy in 4H-SiC film by nanoindentation. Mater. Sci. Semicond. Process. 2022, 146, 106671.

- Domingues, G.; Monthe, A.M.; Guevelou, S.; Rousseau, B. Study by molecular dynamics of the influence of temperature and pressure on the optical properties of undoped 3C-SiC structures. J. Quant. Spectrosc. Radiat. Transf. 2018, 205, 220–229.

- Chen, W.; Li, L.S. The study of the optical phonon frequency of 3C-SiC by molecular dynamics simulations with deep neural network potential. J. Appl. Phys. 2021, 129, 244104.

- Fan, Y.X.; Xu, Z.W.; Song, Y.; Dong, B.; Xue, Z.F.; Liu, B.; Liu, L.; Tian, D.Y. Nano material removal mechanism of 4H-SiC in ion implantation-assisted machining. Comput. Mater. Sci. 2021, 200, 110837.

- Zhang, X.D.; Li, Q.; Wang, M.; Zhang, Z.T.; Akhmadaliev, S.; Zhou, S.Q.; Wu, Y.Y.; Guo, B. Defects in hydrogen implanted SiC. Nucl. Instrum. Meth. B 2018, 436, 107–111.

- Dai, H.F.; Hu, Y.; Wu, W.L.; Yue, H.X.; Meng, X.S.; Li, P.; Duan, H.G. Molecular dynamics simulation of ultra-precision machining 3C-SiC assisted by ion implantation. J. Manuf. Process. 2021, 69, 398–411.

- Liu, B.; Xu, Z.W.; Wang, Y.; Gao, X.; Kong, R.J. Effect of ion implantation on material removal mechanism of 6H-SiC in nano-cutting: A molecular dynamics study. Comput. Mater. Sci. 2020, 174, 109476.

- Fan, Y.X.; Xu, Z.W.; Song, Y.; Sun, T.Z. Molecular dynamics simulation of silicon vacancy defects in silicon carbide by hydrogen ion implantation and subsequent annealing. Diam. Relat. Mater. 2021, 119, 108595.

- Kang, Q.; Fang, X.D.; Wu, C.; Sun, H.; Tian, B.; Zhao, L.B.; Wang, S.L.; Jiang, Z.D.; Zhu, N.; Maeda, R.; et al. Modification mechanism of collaborative ions implanted into 4H-SiC by atomic simulation and experiment. Int. J. Mech. Sci. 2021, 212, 106832.

- Ma, G.L.; Li, S.J.; Liu, F.L.; Zhang, C.; Jia, Z.; Yin, X.C. A Review on Precision Polishing Technology of Single-Crystal SiC. Crystals 2022, 12, 101.

- Zhou, P.; Zhu, N.N.; Xu, C.Y.; Niu, F.L.; Li, J.; Zhu, Y.W. Mechanical removal of SiC by multi-abrasive particles in fixed abrasive polishing using molecular dynamics simulation. Comput. Mater. Sci. 2021, 191, 110311.

- Wu, Z.H.; Zhang, L.C.; Yang, S.Y.; Wu, C.H. Effects of grain size and protrusion height on the surface integrity generation in the nanogrinding of 6H-SiC. Tribol. Int. 2022, 171, 107563.

- Zhou, Y.Q.; Huang, Y.H.; Li, J.M.; Zhu, F.L. The effect of contact types on SiC polishing process. Mater. Sci. Semicond. Process. 2022, 147, 106709.

- Meng, B.B.; Yuan, D.D.; Xu, S.L. Study on strain rate and heat effect on the removal mechanism of SiC during nano-scratching process by molecular dynamics simulation. Int. J. Mech. Sci. 2019, 151, 724–732.

- Luo, Q.F.; Lu, J.; Tian, Z.; Jiang, F. Controllable material removal behavior of 6H-SiC wafer in nanoscale polishing. Appl. Surf. Sci. 2021, 562, 150219.

- Zhang, S.; Cheng, X.; Chen, J.Y. Surface deformation, phase transition and dislocation mechanisms of single crystalline 6H-SiC in oblique nano-cutting. Appl. Surf. Sci. 2022, 588, 152944.

- Meng, B.B.; Yuan, D.D.; Zheng, J.; Qiu, P.; Xu, S.L. Tip-based nanomanufacturing process of single crystal SiC: Ductile deformation mechanism and process optimization. Appl. Surf. Sci. 2020, 500, 144039.

- Chavoshi, S.Z.; Luo, X.C. Molecular dynamics simulation study of deformation mechanisms in 3C-SiC during nanometric cutting at elevated temperatures. Mater. Sci. Eng. A-Struct. 2016, 654, 400–417.

- Zhou, P.; Li, J.; Wang, Z.K.; Chen, J.P.; Li, X.; Zhu, Y.W. Molecular dynamics study of the removal mechanism of SiC in a fixed abrasive polishing in water lubrication. Ceram. Int. 2020, 46, 24961–24974.

- Nguyen, V.T.; Fang, T.H. Material removal and interactions between an abrasive and a SiC substrate: A molecular dynamics simulation study. Ceram. Int. 2020, 46, 5623–5633.

- Hu, Z.W.; Chen, Y.; Lai, Z.Y.; Yu, Y.Q.; Xu, X.P.; Peng, Q.; Zhang, L. Coupling of double grains enforces the grinding process in vibration-assisted scratch: Insights from molecular dynamics. J. Mater. Process. Technol. 2022, 304, 117551.

- Zhao, L.; Zhang, J.J.; Zhang, J.G.; Hartmaier, A. Atomistic investigation of machinability of monocrystalline 3C-SiC in elliptical vibration-assisted diamond cutting. Ceram. Int. 2021, 47, 2358–2366.

- Meng, B.B.; Yuan, D.D.; Zheng, J.; Xu, S.L. Molecular dynamics study on femtosecond laser aided machining of monocrystalline silicon carbide. Mater. Sci. Semicond. Process. 2019, 101, 1–9.

- Satake, S.; Yamashina, S.; Inoue, N.; Kunugi, T.; Shibahara, M. Large-scale molecular dynamics simulation of sputtering process with glancing-angle Ar cluster impact on 4H-SiC. Nucl. Instrum. Meth. B 2009, 267, 3258–3262.

- Triendl, F.; Pfusterschmied, G.; Schwarz, S.; Pobegen, G.; Konrath, J.P.; Schmid, U. Barrier height tuning by inverse sputter etching at poly-Si/4H-SiC heterojunction diodes. Semicond. Sci. Technol. 2021, 36, 055021.

- Prskalo, A.P.; Schmauder, S.; Ziebert, C.; Ye, J.; Ulrich, S. Molecular dynamics simulations of the sputtering of SiC and Si3N4. Surf. Coat. Technol. 2010, 204, 2081–2084.

- Sun, W.; Liu, H.; Lin, L.; Zhao, C.; Lu, X.; He, P.; Gou, F. Molecular Dynamics Simulations of Atomic H Etching SiC Surface. Phys. Procedia 2012, 32, 539–544.

- Gou, F.; Zen, L.T.; Meng, C.L. Molecular dynamics simulations of CF3 etching of SiC. Thin Solid Films 2008, 516, 1832–1837.

- Lu, X.; Ning, J.; Qin, Y.; Qiu, Q.; Chuanwu, Z.; Ying, Y.; Ming, J.; Gou, F. Substrate temperature effect on F+ etching of SiC: Molecular dynamics simulation. Nucl. Instrum. Meth. B 2009, 267, 3235–3237.

- Xue, L.H.; Feng, G.; Wu, G.; Wang, S.Z.; Li, R.; Han, X.; Sun, Y.M.; Liu, S. Study of the deposition of nanopillar-patterned 4H-SiC by molecular dynamics simulation. Appl. Surf. Sci. 2022, 579, 152209.

- Teng, M.; He, X.D.; Sun, Y. Composition and nanohardness of SiC films deposited by electron beam physical vapor deposition. Int. J. Mod. Phys. B 2009, 23, 1910–1915.

- Kim, J.Y.; Lee, B.W.; Nam, H.S.; Kwon, D. Effect of substrate temperature on structure and intrinsic stress in vapor-deposited amorphous silicon carbide film. Thin Solid Films 2004, 467, 294–299.

- Kim, J.Y.; Lee, B.W.; Nam, H.S.; Kwon, D. Molecular dynamics analysis of structure and intrinsic stress in amorphous silicon carbide film with deposition process parameters. Mater. Sci. Forum 2004, 449–452, 97–100.

- Gao, Y.; Yan, W.J.; Gao, T.H.; Chen, Q.; Yang, W.S.; Xie, Q.; Tian, Z.A.; Liang, Y.C.; Luo, J.; Li, L.X. Properties of the structural defects during SiC-crystal-induced crystallization on the solid-liquid interface. Mater. Sci. Semicond. Process. 2020, 116, 105155.

- Narumi, T.; Shibuta, Y.; Yoshikawa, T. Molecular dynamics simulation of interfacial growth of SiC from Si-C solution on different growth planes. J. Cryst. Growth 2018, 494, 36–43.

- Kang, K.H.; Eun, T.; Jun, M.C.; Lee, B.J. Governing factors for the formation of 4H or 6H-SiC polytype during SiC crystal growth: An atomistic computational approach. J. Cryst. Growth. 2014, 389, 120–133.

- Gao, F.; Devanathan, R.; Zhang, Y.; Weber, W.J. Annealing simulations of nano-sized amorphous structures in SiC. Nucl. Instrum. Meth. B 2005, 228, 282–287.

- Nguyen, H.T.T. Structural evolution of SiC sheet in a graphene-based in-plane hybrid system upon heating using molecular dynamics simulation. Thin Solid Films 2021, 739, 138992.

- Tranh, D.T.N.; Hoang, V.V.; Hanh, T.T.T. Modeling glassy SiC nanoribbon by rapidly cooling from the liquid: An affirmation of appropriate potentials. Phys. B 2021, 608, 412746.

- Hoang, V.V. Melting and pre-melting of two-dimensional crystalline SiC nanoribbons. Phys. E 2022, 137, 115012.

- Hoang, V.V.; Giang, N.H.; Dong, T.Q.; Bubanja, V. Atomic structure and rippling of amorphous two-dimensional SiC nanoribbons—MD simulations. Comput. Mater. Sci. 2022, 203, 111123.

- Liu, Y.T.; Liu, R.Z.; Liu, M.L.; Chang, J.X. Synthesis of core-shell nanoparticles for dense SiC sintering. Particuology 2019, 44, 80–89.

- Xin, Z.H.; Zhang, C.Y.; Yu, M.; Jayanthi, C.S.; Wu, S.Y. Shedding light on the self-assembly of stable SiC based cage nanostructures: A comprehensive molecular dynamics study. Comput. Mater. Sci. 2014, 84, 49–62.

- Wu, J.T.; Xu, Z.W.; Zhao, J.L.; Rommel, M.; Nordlund, K.; Ren, F.; Fang, F.Z. MD simulation of two-temperature model in ion irradiation of 3C-SiC: Effects of electronic and nuclear stopping coupling, ion energy and crystal orientation. J. Nucl. Mater. 2021, 557, 153313.

- Nguyen, B.N.; Gao, F.; Henager, C.H.; Kurtz, R.J. Prediction of thermal conductivity for irradiated SiC/SiC composites by informing continuum models with molecular dynamics data. J. Nucl. Mater. 2014, 448, 364–372.

- Zarkadoula, E.; Samolyuk, G.; Zhang, Y.W.; Weber, W.J. Electronic stopping in molecular dynamics simulations of cascades in 3C-SiC. J. Nucl. Mater. 2020, 540, 152371.

- Samolyuk, G.D.; Osetsky, Y.N.; Stoller, R.E. Molecular dynamics modeling of atomic displacement cascades in 3C-SiC: Comparison of interatomic potentials. J. Nucl. Mater. 2015, 465, 83–88.

- He, B.; Xue, J.M.; Zou, X.Q.; Wang, Y.G. Molecular Dynamics Study on the Irradiation-Induced Damage in SiC. Acta Sci. Nat. Univ. Pekin. 2009, 45, 385–389.

- Li, B.S.; Zhang, C.; Liu, H.P.; Xu, L.J.; Wang, X.; Yang, Z.; Ge, F.F.; Gao, W.; Shen, T.L. Microstructural and elemental evolution of polycrystalline α-SiC irradiated with ultra-high-fluence helium ions before and after annealing. Fusion. Eng. Des. 2020, 154, 111511.

- Ran, Q.; Zhou, Y.; Zou, Y.; Wang, J.; Duan, Z.A.; Sun, Z.P.; Fu, B.Q.; Gao, S.X. Molecular dynamics simulation of displacement cascades in cubic silicon carbide. Nucl. Mater. Energy 2021, 27, 100957.

- Backman, M.; Toulemonde, M.; Pakarinen, O.H.; Juslin, N.; Djurabekova, F.; Nordlund, K.; Debelle, A.; Weber, W.J. Molecular dynamics simulations of swift heavy ion induced defect recovery in SiC. Comput. Mater. Sci. 2013, 67, 261–265.

- Peterson, R.; Senesky, D. Modeling of radiation-induced defect recovery in 3C-SiC under high field bias conditions. Comput. Mater. Sci. 2019, 161, 10–15.

- Li, Y.Y.; Xiao, W.; Li, H.L. Molecular dynamics simulation of C/Si ratio effect on the irradiation swelling of β-SiC. J. Nucl. Mater. 2016, 480, 75–79.

- Tian, J.T.; Feng, Q.J.; Zheng, J.; Zhou, W.; Li, X.; Liang, X.B.; Liu, D.F. Molecular Dynamics Simulations of Radiation-induced Swelling and Amorphization in a Single Crystal of 3C-SiC. Mater. Rep. 2022, 36, 20100248-5.

- Zhu, S.; Mizuno, M.; Kagawa, Y.; Mutoh, Y. Monotonic tension, fatigue and creep behavior of SiC-fiber-reinforced SiC-matrix composites: A review. Compos. Sci. Technol. 1999, 59, 833–851.

- Feng, L.X.; Li, W.H.; Hahn, E.N.; Branicio, P.S.; Zhang, X.Q.; Yao, X.H. Structural phase transition and amorphization in hexagonal SiC subjected to dynamic loading. Mech. Mater. 2022, 164, 104139.

- Lee, W.H.; Yao, X.H.; Jian, W.R.; Han, Q. High-velocity shock compression of SiC via molecular dynamics simulation. Comput. Mater. Sci. 2015, 98, 297–303.

- Zhang, J.Y.; Branicio, P.S. Molecular Dynamics Simulations of Plane Shock Loading in SiC. Procedia Eng. 2014, 75, 150–153.

More

Information

Subjects:

Materials Science, Ceramics

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.6K

Revisions:

2 times

(View History)

Update Date:

01 Feb 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No