Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Cui, J.; Yu, X.; Shen, Y.; Sun, B.; Guo, W.; Liu, M.; Chen, Y.; Wang, L.; Zhou, X.; Shafiq, M.; et al. Electrospinning Inorganic Nanomaterials. Encyclopedia. Available online: https://encyclopedia.pub/entry/40467 (accessed on 07 February 2026).

Cui J, Yu X, Shen Y, Sun B, Guo W, Liu M, et al. Electrospinning Inorganic Nanomaterials. Encyclopedia. Available at: https://encyclopedia.pub/entry/40467. Accessed February 07, 2026.

Cui, Jie, Xiao Yu, Yihong Shen, Binbin Sun, Wanxin Guo, Mingyue Liu, Yujie Chen, Li Wang, Xingping Zhou, Muhammad Shafiq, et al. "Electrospinning Inorganic Nanomaterials" Encyclopedia, https://encyclopedia.pub/entry/40467 (accessed February 07, 2026).

Cui, J., Yu, X., Shen, Y., Sun, B., Guo, W., Liu, M., Chen, Y., Wang, L., Zhou, X., Shafiq, M., & Mo, X. (2023, January 21). Electrospinning Inorganic Nanomaterials. In Encyclopedia. https://encyclopedia.pub/entry/40467

Cui, Jie, et al. "Electrospinning Inorganic Nanomaterials." Encyclopedia. Web. 21 January, 2023.

Copy Citation

Tissue engineering (TE) has attracted the widespread attention of the research community as a method of producing patient-specific tissue constructs for the repair and replacement of injured tissues. Different types of scaffold materials have been developed for various tissues and organs. The choice of scaffold material should take into consideration whether the mechanical properties, biodegradability, biocompatibility, and bioresorbability meet the physiological properties of the tissues.

tissue engineering

inorganic materials

electrospinning

1. Introduction

Tissue engineering (TE) is an emerging field of bioengineering, which has witnessed continuous development recently. The TE combines techniques and principles from multidisciplinary research disciplines, such as engineering, cell biology, and materials science to create native-like artificial tissues [1]. Moreover, TE is revolutionizing healthcare by providing on-demand, artificially developed tissues and organs for regenerative medicine. Intelligent multifunctional scaffolds provide instructional cues for the precise manipulation of cells in vitro and in vivo as well as to drive their assembly into artificial tissues to either replicate the in vivo microenvironment for disease and development-related studies or to assemble platforms for in vivo implantation [2]. A myriad of scaffolds based on an array of materials has been explored for TE applications. In addition, a series of biomaterials, such as natural and synthetic polymers [3][4][5], ceramics [6][7][8], silk proteins [9][10], alginates [11], chitosan [12][13], cellulose [14][15], and bioactive molecules [16][17] has been explored for different TE disciplines. These scaffold materials have shown promise for the regeneration of different types of tissues, including bone, cartilage, skin, and tendon [18][19][20] through cellular and signaling stimulation.

In addition to natural and synthetic polymers, inorganic materials, such as metal oxides (MOs), metal nanoparticles (NPs), and carbon-based nanomaterials (NMs) are being intensively studied for TE applications [21]. Layered silicate nanoclays have been widely pursued for dermatological and musculoskeletal applications [22][23]. Similarly, carbon-based NMs have been exploited as fillers for TE applications owing to their chemical stability, low coefficient of friction, good mechanical properties, heat and wear resistance, high electrical conductivity, and hardness [24][25][26]. On the other hand, MOs, including bioceramics, bio-glasses (BGs), and magnetic NPs have also been exploited for TE. Of these, bioceramics have been shown to induce biomineralization due to their excellent osteo-conductivity, chemical resistance, and durability. Bioceramics can be further classified as biologically inert, bioactive, or bioresorbable, which are mainly based on their interaction with the host tissues in vivo [27]. While biologically inert ceramics are physically and chemically stable and do not interact with the tissues, bioactive ceramics can repair, replace and regenerate tissues. On the other hand, bioresorbable ceramics gradually degrade in vivo without inducing obvious toxicity risks. Metal NPs are also widely exploited in TE due to their high stability and ease of synthesis. Different types of metal NPs, such as gold (Au), silver (Ag), iron (Fe), aluminum (Al), nickel (Ni), copper (Cu), strontium (Sr), and zirconium (Zr) [28] have been shown to play a pivotal role in regulating cellular behavior as well as promoting tissue regeneration. Since inorganic NMs exhibit unique physico-chemical and mechanical properties, their introduction into TE scaffolds may impart bio-functionality as well as improve elasticity and resistance to mechanical stress. Consequently, bio-scaffolds comprised of inorganic/organic hybrids may help realize customized biomechanical properties as well as sufficient bioresorbability [29].

Although polymeric scaffolds may induce tissue repair, the addition of inorganic NMs may further impart complementary functionalities to the scaffold; thereby, further broadening their application prospects. For instance, the addition of inorganic NPs may improve the osteogenic properties for bone tissue regeneration, antimicrobial activity and angiogenesis for wound healing, and electrical conductivity and anti-oxidative properties for nerve repair [30][31].

2. Electrospun Inorganic Nanofibers for Tissue Engineering Applications

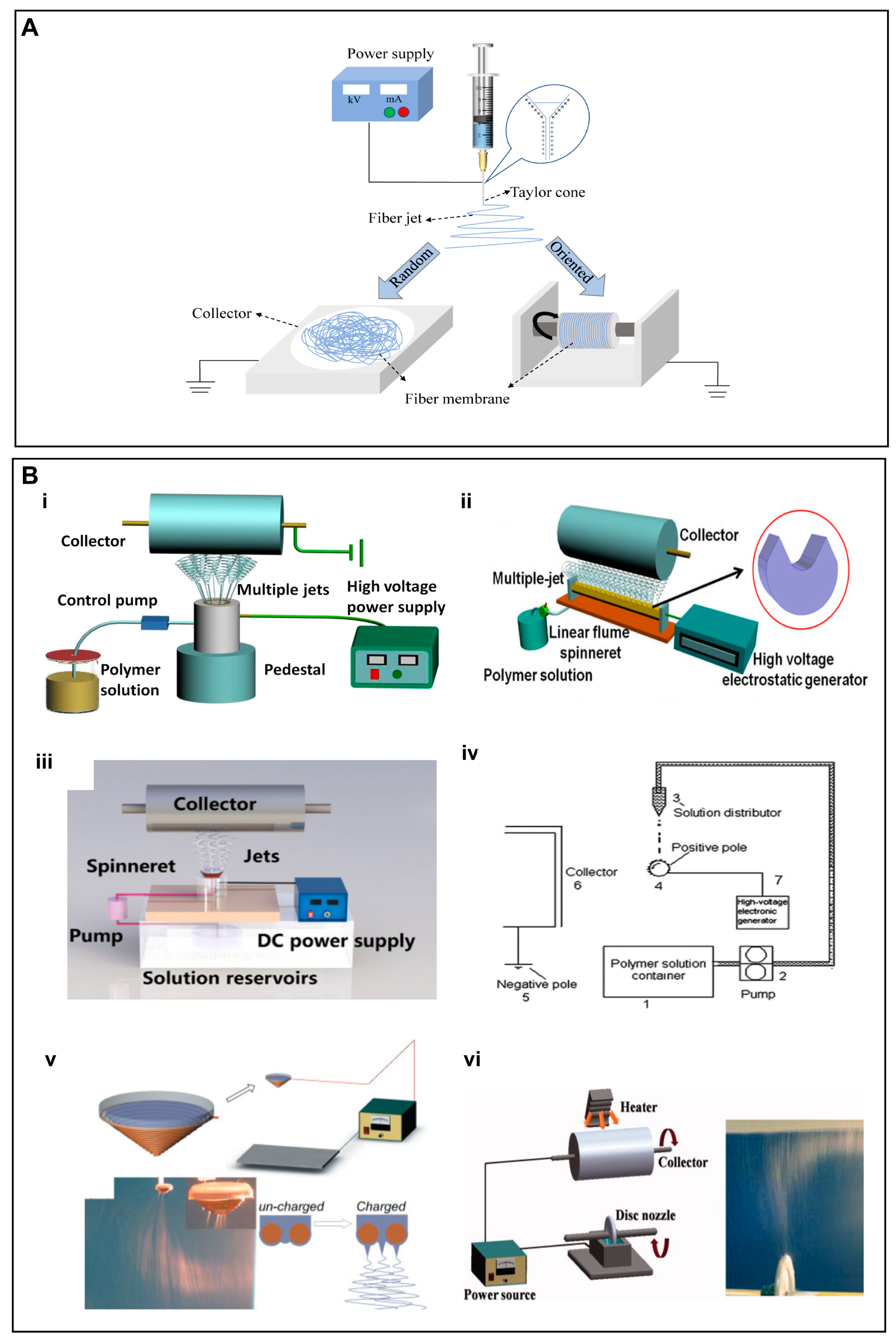

Electrospinning technology uses a high voltage power supply to charge the surface of a polymer solution or solute under the influence of an applied electric field, which then accelerates the flow of the jet towards a collector of the opposite polarity. As the electrostatic gravitational force between the oppositely charged liquid and the collector, while electrostatic repulsion among the similar charges in the liquid becomes stronger, the solution forms a Taylor cone at the tip of the propeller. Once the strength of the electric field exceeds the surface tension of the liquid, the fiber jet is eventually ejected from the Taylor cone, while the solvent evaporates during the jet stroke and the solid polymer fibers are deposited on the collector to afford micro/nanofibers [32] (Figure 1A). The nature of the polymer itself, the magnitude of the applied electric field, spinneret-to-collector distance, temperature, and other environmental factors may influence the morphology and diameter of the nanofibers [33]. Depending upon the collector as well as its rotational speed, randomly-oriented or aligned micro/nanofibers can be fabricated to control the overall mechanical properties as well as the biological response of the scaffold.

Figure 1. (A) Schematic illustration of an electrospinning setup for the fabrication of random and aligned nanofibers. For random nanofibers, a flat collector is used, while for aligned nanofibers, a fast rotating collector is used. (B) (i–vi) Schematic diagram of a few needleless electrostatic spinning devices. (i) The experimental setup of wire loop spinneret, (ii) a multi-jet needleless electrostatic spinning device with the shape of the spinneret in the upper right corner, (iii) mushroom-electrospinning setup, (iv) splashing needleless electrospinning system, (v) wire coil electrospinning setup, (vi) apparatus for disc electrospinning and a photo of the electrospinning process. (B) (i) Reproduced with permission from reference [34]. Copyright 2019. Published by Elsevier Ltd. (ii) Reproduced with permission from reference [35]. Copyright 2019 Polymers. (iii) Reproduced with permission from reference [36]. Copyright 2020, the author(s). Published by Elsevier Ltd. (iv) Reproduced with permission from reference [37]. Copyright 2010, Society of Plastics Engineers. (v) Reproduced with permission from reference [38]. Copyright 2009, Society of Plastics Engineers, and (vi) Reproduced with permission from reference [39], Copyright 2012, Wiley Journals.

Another electrostatic spinning technology of note is needle-free electrostatic spinning, which is characterized by the fact that it does not employ needle nozzles, but rather uses a free liquid surface where Taylor cones are randomly generated to produce several polymer jets [40]. Consequently, a variety of needleless spinnerets have been designed for the fabrication of scaffold materials, such as spiral coils, yarns, cylinders, discs, balls and wires [34][35][36][37][38][39][41][42][43][44] (Figure 1B).

In recent decades, electrospinning technology has attracted the considerable interest of the research community due to its simplicity, versatility, and cost-effectiveness [45][46][47][48]. Different types of electrospun nanofibrous scaffolds are being exploited for various TE disciplines. In addition, an array of materials has been employed for the mass production of continuous nanofibers with appropriate mechanical properties [48][49]. Being one of the most common biofabrication techniques, electrospinning has been widely used to produce micro- and nano-fibers manifesting one-dimensional (1D) to three-dimensional (3D) morphologies [50]. These micro/nanofibers can mimic the characteristics of the natural extracellular matrix (ECM), which may also have implications for regenerative medicine and TE applications.

In addition to its ability to afford micro/nano-fiber scaffolds with tailorable porosity and pore size [51][52][53], the simplicity and cost-effectiveness of electrospinning technique renders it as a potential polymer processing technique for TE applications [54]. Appropriate porosity and pore size of electrospun fibers may leverage essential cues to influence multiple cellular effects, including adhesion, proliferation, differentiation, and migration. Moreover, electrospun nanofibers may afford temporal and spatial release of biological cues, such as growth factors (GFs), peptides, and nucleic acid therapeutics to further facilitate tissue repair [55][56][57][58][59][60].

The physicochemical aspects of scaffolds, such as mechanical properties, biocompatibility, and degradability may be tailored by using appropriate materials during electrospinning, which may further broaden the applicability of electrospun scaffolds. Until now, a series of materials has been electrospun, which include natural and synthetic polymers as well as inorganic NMs. The latter may further be customized to afford the sustained and controlled release of therapeutic ions for tissue repair.

2.1. Electrospinning of Pure Inorganic Nanofibres

Herein, researchers will be discussing the research reports related to the fabrication of nanofibrous scaffolds either based on pure inorganic NMs or the combination of inorganic NMs along with metal ions, natural polymers, or synthetic polymers.

2.1.1. Bioactive Glass-Based Electrospun Scaffolds

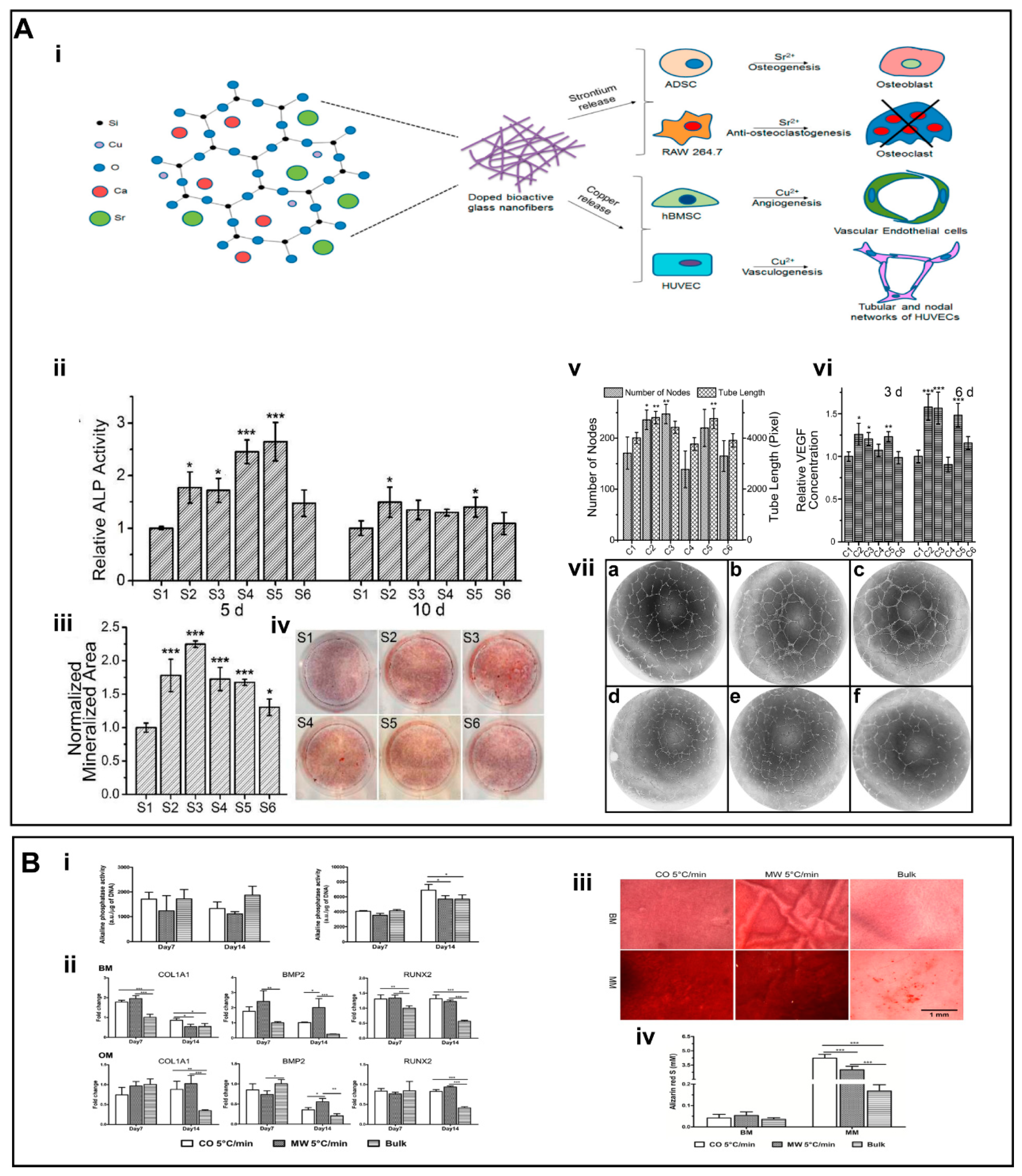

Among the inorganic components, BGs are a group of inorganic NMs that have been widely exploited for the treatment of bone defects, primarily owing to their ability to promote bone repair through therapeutic ions release or the formation of a superficial layer of hydroxyapatite (HAp) upon exposure to the physiological fluids [61][62]. This surface layer resembles the chemical composition and structure of bone minerals and therefore plays a key role for osteo-inductivity and interaction with the surrounding bone tissue. The BGs belong to a well-known class of synthetic bone replacement materials, which have been harnessed to mimic the 3D nanofilament structure of bone ECM. Kim et al. [63] employed sol–gel precursors to realize 1D BG-based electrospun nanofibers, which displayed cytocompatibility and simulated the biomineralization of HAp crystals in simulated body fluids. These BGs-based nanofibers may impart bio-activity as well as afford ECM-like morphological features. Electrospun BGs nanofibers can maintain the bionic nature of the bone ECM as well as leverage bioactive signals for bone tissue repair. The BGs may stimulate/induce the osteogenic differentiation of osteoblasts, inhibit bone resorption and collagen degradation, and promote osteogenic differentiation through relevant signaling pathways. Weng et al. [64] successfully prepared BG nanofibers doped with inorganic metals, such as strontium (Sr) and Cu, by using electrospinning technology (Figure 2A i). The doping of BGs with Sr significantly improved osteogenesis and inhibited osteoclast formation (Figure 2A ii–iv), while doping with the Cu promoted angiogenesis (Figure 2A v–vii). Owing to their ability to mimic the bone microenvironment and release therapeutic ions, these BG nanofibers may hold promise for bone TE. Similarly, Gazquez et al. [65] leveraged electrospinning to fabricate yttria-stabilized zirconia (YSZ) scaffolds by using polyvinylpyrrolidone (PVP) and YSZ precursors. As compared to pure ceramic materials, YSZ ceramic nanofibers exhibited remarkable flexibility as well as promoted the growth of human mesenchymal stromal cells (hMSCs), which may have implications for bone TE owing to the unique combination of the high stiffness and flexibility of resulting scaffolds (Figure 2B).

Figure 2. (A) (i) Schematic representation of the strategy for the action of Cu and Sr ions. (ii) The ALP activities of BG nanofibers. (iii) The mineralized area was stained by alizarin red at day 15. (iv) Alizarin red staining of different groups. (v) Quantification of the number of nodes and tube length of human umbilical vein endothelial cells (HUVECs) cultured on the Matrigel for 16 h. (vi) Quantification of secreted vascular endothelial growth factor (VEGF) from human bone marrow mesenchymal stem cells (hBMSCs) for different groups. (vii) (a–f) Inverse color images of the vascularization of HUVECs cultured in the presence of the extraction media from different glass nanofiber. (B) (i) ALP activity. (ii) Gene expression analysis for COL1A1, BMP2, and RUNX2. (iii) The formation of mineralized ECM was ascertained by staining the scaffolds with alizarin red S. (iv) Quantitative analysis of the mineral deposits per scaffold by alizarin red S staining at day 28. (A) (i–vii) Reproduced with permission from reference [64]. Copyright 2017, American Chemical Society (ACS) publishers. (B) (i–iv) reproduced with permission from reference [65]. Copyright 2016, American Chemical Society (ACS) publishers. Asterisks indicate significant differences (p < 0.05).

Recently, bioactive glass nanofiber film consisting of electrostatically spun flexible MgO2-doped silica (SiO2/MgO) has also been developed [66]. In vitro results revealed good cytocompatibility and bioactivity of these purely inorganic nanofiber membranes, which improved cell proliferation and angiogenesis. The sustained release of silicon and magnesium ions induced antibacterial effects of membranes by modulating the expression of inflammatory factors by stimulating effector cells, thereby promoting healing of infected wounds in a murine allograft model.

2.1.2. Inorganic Oxides-Based Electrospun Nanofibers

A series of inorganic MOs have been spun to afford nanofibrous scaffolds. Silica (SiO2) has been widely exploited as a drug delivery carrier as well as a scaffold for TE [67][68][69][70]. In addition, SiO2 NPs have been incorporated into polymers to afford electrospun scaffolds [71][72][73]. The release of silicon ions plays an important role in enhancing the biological performance of scaffolds. Electrospun nanofibers solely composed of inorganic SiO2 have also been fabricated.

Application of Electrospun Nanofibres of Inorganic Oxides Prepared into Hydrogels

Hydrogels are widely used in a variety of biomedical applications due to their inherent ability to retain high water content as well as their good miscibility with a range of natural and synthetic polymers [74][75]. The overall physical and mechanical behavior of hydrogels depends on the underlying internal structure [76]. However, the low mechanical strength and limited functionality of conventional hydrogels adversely affect their use in tissue engineering [77]. Consequently, the combination of hydrogels with electrospun scaffolds may be an effective way to improve inherent limitations associated with hydrogel.

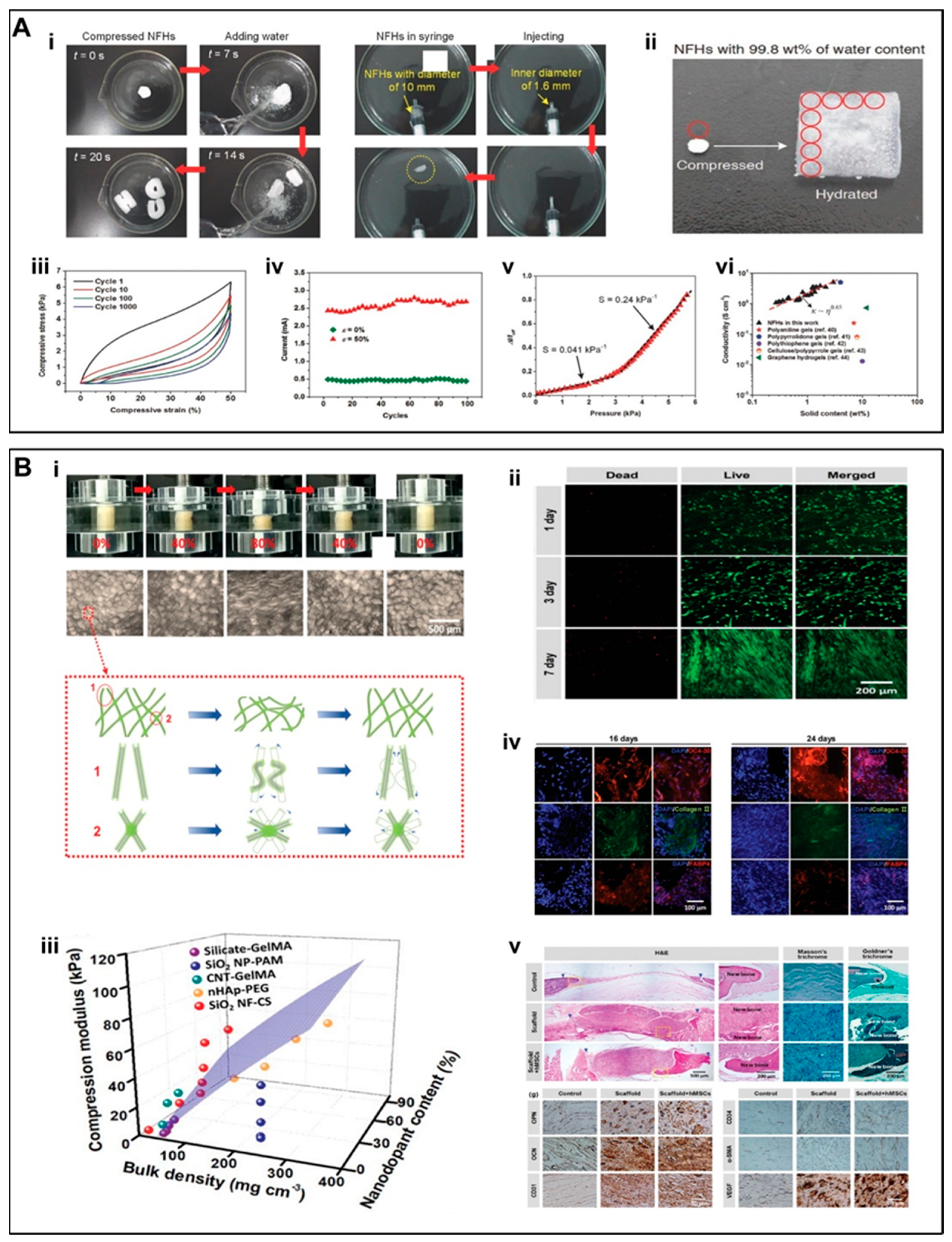

Yang et al. [78] developed nanofibrous hydrogels (NFH) by combining flexible SiO2 nanofibers along with ionically-crosslinked alginate. As compared to the hydrogels composed of pristine alginate, NFH exhibited remarkably higher mechanical properties, which were attributable to flexible SiO2 nanofibers. The NFH showed a plastic deformation value of only 9.5% after 1000 compression cycles at 50% strain (Figure 3A iii). In addition, the Al-alginate was uniformly wrapped around the surface of the SiO2 nanofibers, which further improved the water content of NFH for up to 99.8 wt.% (Figure 3A ii). This highly hydrated and porous nanofibrous structure allowed NFH to maintain a sensitive shape memory recovery function as well as imparted injectability characteristics (Figure 3A i). The combination of highly sensitive responsiveness of NFH with the current and pressure may further open a window of opportunity for research in electrical/pressure-stimulated TE scaffolds (Figure 3A vi. Despite these encouraging results, the biocompatibility of these NFH hydrogels as well as their long-term in vivo implantation yet remains to be explored.

Figure 3. (A) (i) Stent shape recoverability and injectability. (ii) NFH with an ultra-high water content of 99.8 wt.%. (iii) A fatigue compression test with 1000 cycles and at ε = 50%. (iv) 100 cycle current compression-responsive test at ε = 50%. (v) Response of NFHs toward applied current at various pressures. The dotted lines showed two linear regions with different sensitivities. (vi) Electrical conductivities of NFHs and other selected hydrogels with high water content. (B) (i) Macroscopic and microscopic structural changes during compression and shape recovery in aqueous medium. (ii) Live/dead staining of hMSCs. (iii) 3D compression modulus map of SiO2 NF-CS scaffolds as compared to other nanodopants-enhanced hydrogels reported in literatures. (iv) Representative images for the immunostaining of OC4-30 (red), collagen II (green), and FABP4 (red). (v) Histological staining by using H&E, Masson’s trichrome, and Goldner’s trichrome as well as immunostaining by using OPN, OCN, CD31, CD34, α-SMA, and VEGF of rat cranial defects at 10 weeks postoperatively. (A) (i–vi) Reproduced with permission from Ref. [78]. Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (B) (i–v) Reproduced with permission from Ref. [79]. Copyright 2019 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

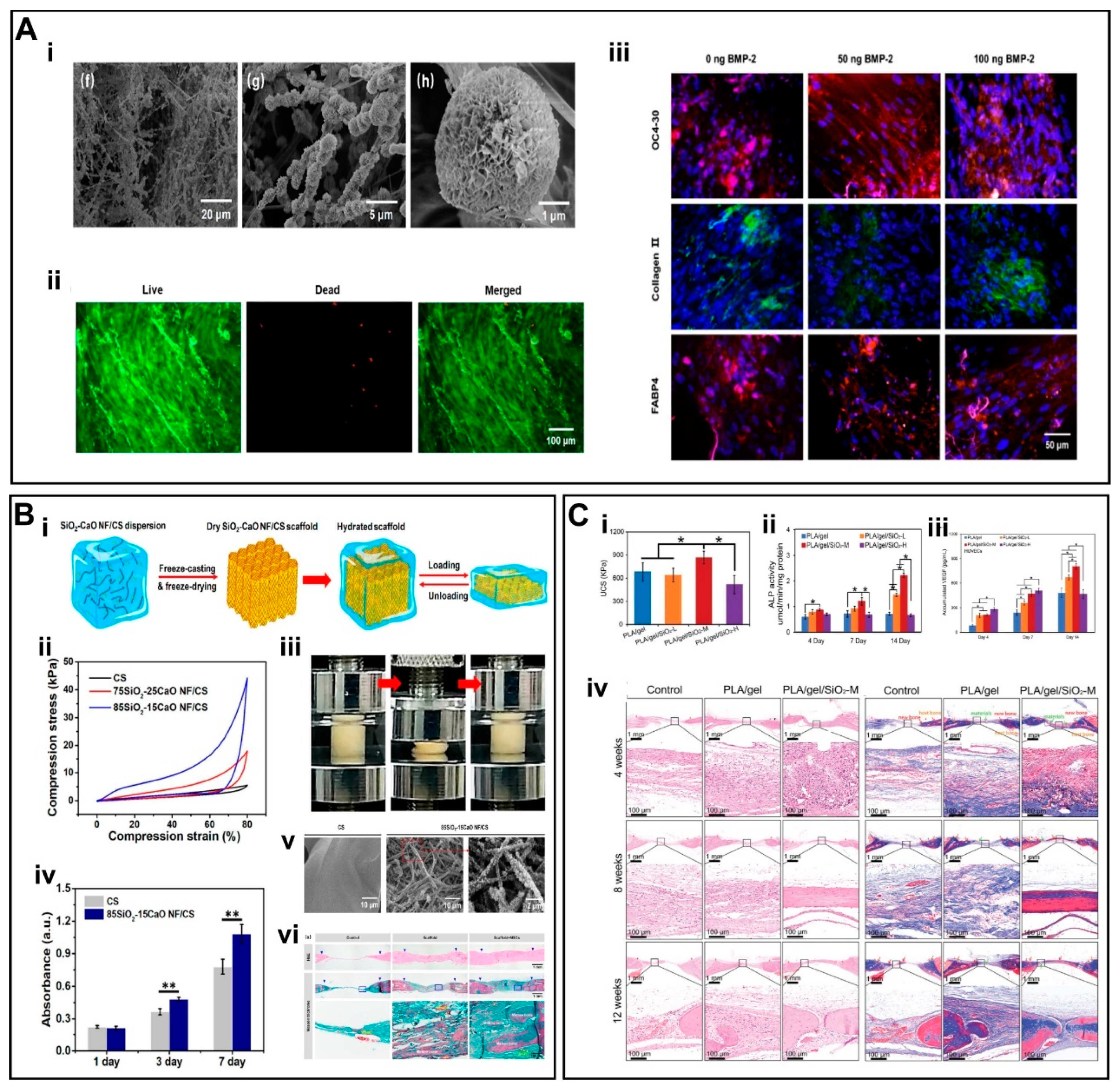

Wang et al. [80] incorporated SiO2 nanofiber membranes into CS hydrogels to afford NF/CS composite hydrogels. The addition of SiO2 remarkably improved the mechanical properties of hydrogels in contrast to that of cellulose acetate (CA) or polyacrylonitrile (PAN) nanofiber membranes. The obvious effects of SiO2 membranes over CA or PAN nanofibers were ascribed to the higher modulus and tetrahedral structure of SiO2. The mechanical properties of NF/CS composite hydrogels were also increased with an increase in the SiO2 content. Owing to their resemblance to the bone ECM, these composite NF/CS hydrogels not only exhibited higher mineralization and biocompatibility but also promoted the osteogenic differentiation of hMSCs (Figure 4A i,ii), which was even comparable to the hydrogels immobilized with bone morphogenetic protein-2 (BMP2, 50 ng per matrix) (Figure 4A iii). Despite these encouraging in vitro results, in vivo evaluation over a long time period yet remains to be accomplished to better discern the effect of these scaffolds on bone repair.

Figure 4. (A)(i) SEM images of mineralized SiO2 NF/CS matrices. (ii) Live/dead staining assay of hMSCs. (iii) IF staining of scaffolds by using OC4-30, collagen II, and FABP4. (B) (i) Schematic illustration of the fabrication of 3D SiO2-CaO NF/CS scaffold. (ii) Compression curves. (iii) Shape recovery of scaffold in aqueous medium. (iv) Cell viability of MSCs. (v) SEM photomicrographs of in situ mineralized scaffolds. (vi) H&E and Masson’s trichrome staining of scaffolds. (C) (i) UCS of scaffolds under dry conditions. (ii) Alkaline phosphatase (ALP) activity of scaffolds. (iii) Cumulative release of VEGF. (iv) H&E staining and Masson’s trichrome staining of scaffolds. (A) (i–iii) Reproduced with permission from Ref. [80]. Copyright 2020 Elsevier Inc. (B) (i–vi) Reproduced with permission from Ref. [81]. Copyright 2019 American Chemical Society. (C) (i–iv) Reproduced with permission from Ref. [82]. Copyright 2022 Wiley-VCH GmbH.

Application of Electrospun Nanofibres of Inorganic Oxides Prepared as Composite Three-Dimensional Scaffolds

Wang et al. [79] developed a 3D fibrous scaffold (SiO2NF-CS) constructed from chitosan (CS) layers wrapped around flexible SiO2 nanofibers [78]. Unlike the inherent structural fragility of inorganic nanofibers, the SiO2NF-CS scaffolds displayed super-resilience in the aqueous environment, showing full recovery to their initial height as well as maintaining an intact porous structure under cyclic compression at strain values for up to 80% (Figure 3B i). These data indicate that the scaffolds can maintain perfect shape recovery properties in the aqueous environment. The inorganic rigid SiO2 nanofibers remarkably improved the mechanical properties of the scaffold (Figure 3B iii), which may also have implications for bone TE. The hMSCs maintained >95% cellular activity and a significant growth trend on the SiO2NF-CS scaffold (Figure 3B ii). In addition to its good cytocompatibility, SiO2NF-CS also induced multi-directional differentiation of hMSCs (Figure 3B iv,v); SiO2 promoted the differentiation of MSCs into osteoblasts through enhanced mineral deposition [83]. The implantation of these scaffolds in a cranial defect model in rats further led to significant bone regeneration.

To accurately replicate the composition and stiffness gradients of subchondral bone, Wang et al. fabricated 3D SiO2 nanofiber-CS scaffolds (SiO2NF-CS), which showed a stiffness gradient attributable to the SiO2 nanofiber content. The incorporation of SiO2 remarkably improved the mechanical properties of scaffolds. With an increase in the SiO2 content into the scaffolds from 0% to 90%, the compressive modulus was increased from 4.5 kPa to 45 kPa, while compressive stress from 4 kPa to 18 kPa, respectively. Intriguingly, the gradient in the SiO2 nanofiber content also influenced the stiffness of scaffolds, which promoted the differentiation of hMSCs to chondrocytes and osteoblasts. As can be seen from these data, SiO2 plays an important role to not only influence the mechanical properties of scaffolds but also promote the cytocompatibility and differentiation to promote osteochondral regeneration.

Similarly, Wang et al. [81] developed flexible binary SiO2-CaO nanofiber membranes to afford 3D SiO2-CaO NF/CS scaffolds (Figure 4B i). The 3D SiO2-CaO NF/CS scaffolds were further optimized to better mimic the ratio of inorganic/organic components of the bone ECM. The weight ratio of the SiO2-CaO to chitosan was 65/35. The addition of flexible SiO2-CaO short nanofibers enhanced the stiffness and elasticity of the scaffolds (Figure 4B ii,iii). The hBMSCs co-cultured along with the scaffold showed good biocompatibility and significant biomineralization behavior (Figure 4B iv–vi). These results indicate the potential of the scaffolds to promote osteogenic differentiation in vitro as well as bone repair in a cranial defect model in rats in vivo.

Liu et al. [82] fabricated flexible superelastic organic/inorganic composite aerogel scaffolds consisting of flexible SiO2 nanofibers and electrospun poly(L-lactide)/gelatin nanofibers. The scaffolds displayed good elasticity and mechanical strength with a silica content of up to 40% (Figure 4C i). Silicon ions (Si4+) were sustainably released from the scaffold for up to 8 weeks, which not only promoted the differentiation of rat bone marrow derived mesenchymal stem cells (rBMSCs) into osteoblasts but also induced angiogenesis by promoting the tube formation of HUVECs in vitro (Figure 4C ii–iii). Implantation of these scaffolds in a cranial defect model in rats simultaneously promoted osteogenesis and angiogenesis (Figure 4C iv). Taken together, these flexible yet sufficiently robust scaffolds may possess good potential for bone TE.

References

- Gomes, M.E.; Rodrigues, M.T.; Domingues, R.M.A.; Reis, R.L. Tissue Engineering and Regenerative Medicine: New Trends and Directions-A Year in Review. Tissue Eng. Part B 2017, 23, 211–224.

- Zheng, X.; Zhang, P.; Fu, Z.; Meng, S.; Dai, L.; Yang, H. Applications of nanomaterials in tissue engineering. RSC Adv. 2021, 11, 19041–19058.

- Jiang, T.; Carbone, E.J.; Lo, K.W.H.; Laurencin, C.T. Electrospinning of polymer nanofibers for tissue regeneration. Prog. Polym. Sci. 2015, 46, 1–24.

- Wu, T.; Ding, M.; Shi, C.; Qiao, Y.; Wang, P.; Qiao, R.; Wang, X.; Zhong, J. Resorbable polymer electrospun nanofibers: History, shapes and application for tissue engineering. Chin. Chem. Lett. 2020, 31, 617–625.

- Chen, W.; Ma, J.; Zhu, L.; Morsi, Y.; Ei-Hamshary, H.; Al-Deyab, S.S.; Mo, X. Superelastic, superabsorbent and 3D nanofiber-assembled scaffold for tissue engineering. Colloids Surf. B 2016, 142, 165–172.

- Ma, H.; Feng, C.; Chang, J.; Wu, C. 3D-printed bioceramic scaffolds: From bone tissue engineering to tumor therapy. Acta Biomater. 2018, 79, 37–59.

- Pina, S.; Rebelo, R.; Correlo, V.M.; Oliveira, J.M.; Reis, R.L. Bioceramics for Osteochondral Tissue Engineering and Regeneration. Adv. Exp. Med. Biol. 2018, 1058, 53–77.

- Zafar, M.J.; Zhu, D.; Zhang, Z. 3D Printing of Bioceramics for Bone Tissue Engineering. Materials 2019, 12, 3361.

- Zhang, K.; Wang, H.; Huang, C.; Su, Y.; Mo, X.; Ikada, Y. Fabrication of silk fibroin blended P(LLA-CL) nanofibrous scaffolds for tissue engineering. J. Biomed. Mater. Res. Part A 2010, 93, 984–993.

- Li, G.; Sun, S. Silk Fibroin-Based Biomaterials for Tissue Engineering Applications. Molecules 2022, 27, 2757.

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126.

- Croisier, F.; Jérôme, C. Chitosan-based biomaterials for tissue engineering. Eur. Polym. J. 2013, 49, 780–792.

- de Sousa Victor, R.; Marcelo da Cunha Santos, A.; Viana de Sousa, B.; de Araujo Neves, G.; Navarro de Lima Santana, L.; Rodrigues Menezes, R. A Review on Chitosan’s Uses as Biomaterial: Tissue Engineering, Drug Delivery Systems and Cancer Treatment. Materials 2020, 13, 4995.

- Hickey, R.J.; Pelling, A.E. Cellulose Biomaterials for Tissue Engineering. Front. Bioeng. Biotechnol. 2019, 7, 45.

- Hong, J.K.; Cooke, S.L.; Whittington, A.R.; Roman, M. Bioactive Cellulose Nanocrystal-Poly(epsilon-Caprolactone) Nanocomposites for Bone Tissue Engineering Applications. Front. Bioeng. Biotechnol. 2021, 9, 605924.

- Zhu, L.; Liu, Y.; Wang, A.; Zhu, Z.; Li, Y.; Zhu, C.; Che, Z.; Liu, T.; Liu, H.; Huang, L. Application of BMP in Bone Tissue Engineering. Front. Bioeng. Biotechnol. 2022, 10, 810880.

- Yang, M.; Zhang, Z.C.; Liu, Y.; Chen, Y.R.; Deng, R.H.; Zhang, Z.N.; Yu, J.K.; Yuan, F.Z. Function and Mechanism of RGD in Bone and Cartilage Tissue Engineering. Front. Bioeng. Biotechnol. 2021, 9, 773636.

- Yilmaz, E.N.; Zeugolis, D.I. Electrospun Polymers in Cartilage Engineering-State of Play. Front. Bioeng. Biotechnol. 2020, 8, 77.

- Han, X.; Chang, S.; Zhang, M.; Bian, X.; Li, C.; Li, D. Advances of hydrogel-based bioprinting for cartilage tissue engineering. Front. Bioeng. Biotechnol. 2021, 9, 746564.

- Xie, X.; Cai, J.; Yao, Y.; Chen, Y.; Khan, A.u.R.; Wu, J.; Mo, X. A woven scaffold with continuous mineral gradients for tendon-to-bone tissue engineering. Compos. Part B 2021, 212, 108679.

- Bianchi, E.; Vigani, B.; Viseras, C.; Ferrari, F.; Rossi, S.; Sandri, G. Inorganic Nanomaterials in Tissue Engineering. Pharmaceutics 2022, 14, 1127.

- Tenci, M.; Rossi, S.; Aguzzi, C.; Carazo, E.; Sandri, G.; Bonferoni, M.C.; Grisoli, P.; Viseras, C.; Caramella, C.M.; Ferrari, F. Carvacrol/clay hybrids loaded into in situ gelling films. Int. J. Pharm. 2017, 531, 676–688.

- Kundu, K.; Afshar, A.; Katti, D.R.; Edirisinghe, M.; Katti, K.S. Composite nanoclay-hydroxyapatite-polymer fiber scaffolds for bone tissue engineering manufactured using pressurized gyration. Compos. Sci. Technol. 2021, 202, 108598.

- Ahlawat, J.; Masoudi Asil, S.; Guillama Barroso, G.; Nurunnabi, M.; Narayan, M. Application of carbon nano onions in the biomedical field: Recent advances and challenges. Biomater. Sci. 2021, 9, 626–644.

- Mamidi, N.; Delgadillo, R.M.V.; Castrejón, J.V. Unconventional and facile production of a stimuli-responsive multifunctional system for simultaneous drug delivery and environmental remediation. Environ. Sci. Nano. 2021, 8, 2081–2097.

- Pan, L.; Pei, X.; He, R.; Wan, Q.; Wang, J. Multiwall carbon nanotubes/polycaprolactone composites for bone tissue engineering application. Colloids Surf. B 2012, 93, 226–234.

- Bavya Devi, K.; Lalzawmliana, V.; Saidivya, M.; Kumar, V.; Roy, M.; Kumar Nandi, S. Magnesium phosphate bioceramics for bone tissue engineering. Chem. Rec. 2022, 22, e202200136.

- Eivazzadeh-Keihan, R.; Bahojb Noruzi, E.; Khanmohammadi Chenab, K.; Jafari, A.; Radinekiyan, F.; Hashemi, S.M.; Ahmadpour, F.; Behboudi, A.; Mosafer, J.; Mokhtarzadeh, A.; et al. Metal-based nanoparticles for bone tissue engineering. J. Tissue Eng. Regener. Med. 2020, 14, 1687–1714.

- Pina, S.; Ribeiro, V.P.; Marques, C.F.; Maia, F.R.; Silva, T.H.; Reis, R.L.; Oliveira, J.M. Scaffolding strategies for tissue engineering and regenerative medicine applications. Materials 2019, 12, 1824.

- Wang, X.; Chang, J.; Wu, C. Bioactive inorganic/organic nanocomposites for wound healing. Appl. Mater. Today 2018, 11, 308–319.

- Bramhill, J.; Ross, S.; Ross, G. Bioactive nanocomposites for Tissue repair and regeneration: A Review. Int. J. Environ. Res. Public Health 2017, 14, 66.

- Rahmati, M.; Mills, D.K.; Urbanska, A.M.; Saeb, M.R.; Venugopal, J.R.; Ramakrishna, S.; Mozafari, M. Electrospinning for tissue engineering applications. Prog. Mater. Sci. 2021, 117, 100721.

- Yang, C.; Shao, Q.; Han, Y.; Liu, Q.; He, L.; Sun, Q.; Ruan, S. Fibers by Electrospinning and Their Emerging Applications in Bone Tissue Engineering. Appl. Sci. 2021, 11, 9082.

- Wei, L.; Sun, R.; Liu, C.; Xiong, J.; Qin, X. Mass production of nanofibers from needleless electrospinning by a novel annular spinneret. Mater. Des. 2019, 179, 107885.

- Wei, L.; Liu, C.; Mao, X.; Dong, J.; Fan, W.; Zhi, C.; Qin, X.; Sun, R. Multiple-Jet Needleless Electrospinning Approach via a Linear Flume Spinneret. Polymers 2019, 11, 2052.

- Xiong, J.; Liu, Y.; Li, A.; Wei, L.; Wang, L.; Qin, X.; Yu, J. Mass production of high-quality nanofibers via constructing pre-Taylor cones with high curvature on needleless electrospinning. Mater. Des. 2021, 197, 109247.

- Tang, S.; Zeng, Y.; Wang, X. Splashing needleless electrospinning of nanofibers. Polym. Eng. Sci. 2010, 50, 2252–2257.

- Wang, X.; Niu, H.; Lin, T.; Wang, X. Needleless electrospinning of nanofibers with a conical wire coil. Polym. Eng. Sci. 2009, 49, 1582–1586.

- Huang, C.; Niu, H.; Wu, C.; Ke, Q.; Mo, X.; Lin, T. Disc-electrospun cellulose acetate butyrate nanofibers show enhanced cellular growth performances. J. Biomed. Mater. Res. Part A 2013, 101, 115–122.

- Jahan, I.; Wang, L.; Wang, X. Needleless Electrospinning from a Tube with an Embedded Wire Loop. Macromol. Mater. Eng. 2018, 304, 1800588.

- He, H.-J.; Liu, C.-K.; Molnar, K. A Novel Needleless Electrospinning System Using a Moving Conventional Yarn as the Spinneret. Fibers Polym. 2018, 19, 1472–1478.

- Ng, J.-J.; Supaphol, P. Rotating-disk electrospinning: Needleless electrospinning of poly(caprolactone), poly(lactic acid) and poly(vinyl alcohol) nanofiber mats with controlled morphology. J. Polym. Res. 2018, 25, 155.

- Yan, G.; Niu, H.; Zhou, H.; Wang, H.; Shao, H.; Zhao, X.; Lin, T. Electro-aerodynamic field aided needleless electrospinning. Nanotechnology 2018, 29, 235302.

- Zhang, J.; Song, M.; Li, D.; Yang, Z.; Cao, J.; Chen, Y.; Xu, Y.; Wei, Q. Preparation of self-clustering highly oriented nanofibers by needleless electrospinning methods. Fibers Polym. 2016, 17, 1414–1420.

- Xu, T.; Ding, Y.; Liang, Z.; Sun, H.; Zheng, F.; Zhu, Z.; Zhao, Y.; Fong, H. Three-dimensional monolithic porous structures assembled from fragmented electrospun nanofiber mats/membranes: Methods, properties, and applications. Prog. Mater. Sci. 2020, 112, 100656.

- Xue, J.; Xie, J.; Liu, W.; Xia, Y. Electrospun nanofibers: New concepts, materials, and applications. Acc. Chem. Res. 2017, 50, 1976–1987.

- Zhang, M.; Zhao, X.; Zhang, G.; Wei, G.; Su, Z. Electrospinning design of functional nanostructures for biosensor applications. J. Mater. Chem. B 2017, 5, 1699–1711.

- Al-Dhahebi, A.M.; Ling, J.; Krishnan, S.G.; Yousefzadeh, M.; Elumalai, N.K.; Saheed, M.S.M.; Ramakrishna, S.; Jose, R. Electrospinning research and products: The road and the way forward. Appl. Phys. Rev. 2017, 27, 021101.

- Chen, Y.; Dong, X.; Shafiq, M.; Myles, G.; Radacsi, N.; Mo, X. Recent advancements on three-dimensional electrospun nanofiber scaffolds for tissue engineering. Adv. Fiber Mater. 2022, 4, 959–986.

- Zhang, Y.; Huang, Z.-M.; Xu, X.; Lim, C.T. Seeram Ramakrishna. Preparation of core-shell structured PCL-r-Gelatin Bi-component nanofibers by coaxial electrospinning. Chem. Mater. 2004, 16, 3406–3409.

- Gao, X.; Han, S.; Zhang, R.; Liu, G.; Wu, J. Progress in electrospun composite nanofibers: Composition, performance and applications for tissue engineering. J. Mater. Chem. B 2019, 7, 7075–7089.

- Lin, W.; Chen, M.; Qu, T.; Li, J.; Man, Y. Three-dimensional electrospun nanofibrous scaffolds for bone tissue engineering. J. Biomed. Mater. Res. Part B 2020, 108, 1311–1321.

- Movahedi, M.; Asefnejad, A.; Rafienia, M.; Khorasani, M.T. Potential of novel electrospun core-shell structured polyurethane/starch (hyaluronic acid) nanofibers for skin tissue engineering: In vitro and in vivo evaluation. Int. J. Biol. Macromol. 2019, 146, 627–637.

- Pham, Q.P.; Sharma, U.; Mikos, A.G. Electrospinning of polymeric nanofibers for tissue engineering applications: A review. Tissue Eng. 2006, 12, 1197–1211.

- Lu, Y.; Huang, J.; Yu, G.; Cardenas, R.; Wei, S.; Wujcik, E.K.; Guo, Z. Coaxial electrospun fibers: Applications in drug delivery and tissue engineering. WIREs Nanomed. Nanobiotechnol. 2016, 8, 654–677.

- Maşlakcı, N.N. Development and characterization of drug-loaded PVP/PAN/Gr electrospun fibers for drug delivery systems. ChemistrySelect 2021, 6, 2548–2560.

- Luraghi, A.; Peri, F.; Moroni, L. Electrospinning for drug delivery applications: A review. J. Control. Release 2021, 334, 463–484.

- Grant, J.J.; Pillai, S.C.; Perova, T.S.; Hehir, S.; Hinder, S.J.; McAfee, M.; Breen, A. Electrospun fibres of chitosan/pvp for the effective chemotherapeutic drug delivery of 5-fluorouracil. Chemosensors 2021, 9, 70.

- Gouda, M.; Khalaf, M.M.; Shaaban, S.; El-Lateef, H.M.A. Fabrication of chitosan nanofibers containing some steroidal compounds as a drug delivery system. Polymers 2022, 14, 2094.

- Ajalloueian, F.; Guerra, P.R.; Bahl, M.I.; Torp, A.M.; Hwu, E.T.; Licht, T.R.; Boisen, A. Multi-layer PLGA-pullulan-PLGA electrospun nanofibers for probiotic delivery. Food Hydrocoll. 2022, 123, 107112.

- Gao, C.; Gao, Q.; Bao, X.; Li, Y.; Teramoto, A.; Abe, K. Preparation and in Vitro bioactivity of novel mesoporous borosilicate bioactive glass nanofibers. J. Am. Ceram. Soc. 2011, 94, 2841–2845.

- Santocildes-Romero, M.E.; Crawford, A.; Hatton, P.V.; Goodchild, R.L.; Reaney, I.M.; Miller, C.A. The osteogenic response of mesenchymal stromal cells to strontium-substituted bioactive glasses. J. Tissue Eng. Regener. Med. 2015, 9, 619–631.

- Kim, H.W.; Kim, H.E.; Knowles, J.C. Production and potential of bioactive glass nanofibers as a next-generation biomaterial. Adv. Funct. Mater. 2006, 16, 1529–1535.

- Weng, L.; Boda, S.K.; Teusink, M.J.; Shuler, F.D.; Li, X.; Xie, J. Binary doping of strontium and copper enhancing osteogenesis and angiogenesis of bioactive glass nanofibers while suppressing osteoclast activity. ACS Appl. Mater. Interfaces 2017, 9, 24484–24496.

- Cadafalch Gazquez, G.; Chen, H.; Veldhuis, S.A.; Solmaz, A.; Mota, C.; Boukamp, B.A.; van Blitterswijk, C.A.; Ten Elshof, J.E.; Moroni, L. Flexible yttrium-stabilized zirconia nanofibers offer bioactive cues for osteogenic differentiation of human mesenchymal stromal cells. ACS Nano 2016, 10, 5789–5799.

- Liu, M.; Wang, X.; Cui, J.; Wang, H.; Sun, B.; Zhang, J.; Rolauffs, B.; Shafiq, M.; Mo, X.-M.; Zhu, Z.; et al. Electrospun flexible magnesium-doped silica bioactive glass nanofiber membranes with anti-inflammatory and pro-angiogenic effects for infected wounds. J. Mater. Chem. B 2023.

- Ahmadipour, M.; Mohammadi, H.; Pang, A.L.; Arjmand, M.; Ayode Otitoju, T.; Okoye, P.U.; Rajitha, B. A review: Silicate ceramic-polymer composite scaffold for bone tissue engineering. Int. J. Polym. Mater. Polym. Biomater. 2020, 71, 180–195.

- Khan, A.F.; Saleem, M.; Afzal, A.; Ali, A.; Khan, A.; Khan, A.R. Bioactive behavior of silicon substituted calcium phosphate based bioceramics for bone regeneration. Mater. Sci. Eng. 2014, 35, 245–252.

- Batista, H.; Freitas, J.P.; Abrunheiro, A.; Gonçalves, T.; Gil, M.H.; Figueiredo, M.; Coimbra, P. Electrospun composite fibers of PLA/PLGA blends and mesoporous silica nanoparticles for the controlled release of gentamicin sulfate. Int. J. Polym. Mater. Polym. Biomater. 2021, 71, 635–646.

- Venkatraman, S.K.; Swamiappan, S. Review on calcium- and magnesium-based silicates for bone tissue engineering applications. J. Biomed. Mater. Res. A 2020, 108, 1546–1562.

- Mehrasa, M.; Asadollahi, M.A.; Ghaedi, K.; Salehi, H.; Arpanaei, A. Electrospun aligned PLGA and PLGA/gelatin nanofibers embedded with silica nanoparticles for tissue engineering. Int. J. Biol. Macromol. 2015, 79, 687–695.

- Ganesh, N.; Jayakumar, R.; Koyakutty, M.; Mony, U.; Nair, S.V. Embedded silica nanoparticles in poly(caprolactone) nanofibrous scaffolds enhanced osteogenic potential for bone tissue engineering. Tissue Eng. Part A 2012, 18, 1867–1881.

- Yang, X.; Li, Y.; Liu, X.; Huang, Q.; Zhang, R.; Feng, Q. Incorporation of silica nanoparticles to PLGA electrospun fibers for osteogenic differentiation of human osteoblast-like cells. Regener. Biomater. 2018, 5, 229–238.

- Shafiq, M.; Ali, O.; Han, S.B.; Kim, D.H. Mechanobiological strategies to enhance stem cell functionality for regenerative medicine and tissue engineering. Front. Cell Dev. Biol. 2021, 9, 747398.

- Shafiq, M.; Jung, Y.; Kim, S.H. Insight on stem cell preconditioning and instructive biomaterials to enhance cell adhesion, retention, and engraftment for tissue repair. Biomaterials 2016, 90, 85–115.

- Martin, N.; Youssef, G. Dynamic properties of hydrogels and fiber-reinforced hydrogels. J. Mech. Behav. Biomed. Mater. 2018, 85, 194–200.

- Zhao, H.; Liu, M.; Zhang, Y.; Yin, J.; Pei, R. Nanocomposite hydrogels for tissue engineering applications. Nanoscale 2020, 12, 14976–14995.

- Si, Y.; Wang, L.; Wang, X.; Tang, N.; Yu, J.; Ding, B. Ultrahigh-water-content, superelastic, and shape-memory nanofiber-assembled hydrogels exhibiting pressure-responsive conductivity. Adv. Mater. 2017, 29, 1700339.

- Wang, L.; Qiu, Y.; Lv, H.; Si, Y.; Liu, L.; Zhang, Q.; Cao, J.; Yu, J.; Li, X.; Ding, B. 3D Superelastic Scaffolds Constructed from Flexible Inorganic Nanofibers with Self-Fitting Capability and Tailorable Gradient for Bone Regeneration. Adv. Fiber Mater. 2019, 29, 1901407.

- Wang, L.; Lv, H.; Liu, L.; Zhang, Q.; Nakielski, P.; Si, Y.; Cao, J.; Li, X.; Pierini, F.; Yu, J.; et al. Electrospun nanofiber-reinforced three-dimensional chitosan matrices: Architectural, mechanical and biological properties. J. Colloid Interface Sci. 2020, 565, 416–425.

- Wang, L.; Qiu, Y.; Guo, Y.; Si, Y.; Liu, L.; Cao, J.; Yu, J.; Li, X.; Zhang, Q.; Ding, B. Smart, elastic, and nanofiber-based 3D scaffolds with self-deploying capability for osteoporotic bone regeneration. Nano Lett. 2019, 19, 9112–9120.

- Liu, M.; Shafiq, M.; Sun, B.; Wu, J.; Wang, W.; El-Newehy, M.; El-Hamshary, H.; Morsi, Y.; Ali, O.; Khan, A.U.R.; et al. Composite superelastic aerogel scaffolds containing flexible SiO2 nanofibers promote bone regeneration. Adv. Healthcare Mater. 2022, 11, 2200499.

- Wu, C.; Fan, W.; Chang, J.; Xiao, Y. Mussel-inspired porous SiO2 scaffolds with improved mineralization and cytocompatibility for drug delivery and bone tissue engineering. J. Mater. Chem. 2011, 21, 18300.

More

Information

Subjects:

Materials Science, Biomaterials

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

456

Revisions:

2 times

(View History)

Update Date:

28 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No