Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Luis Jesús Villarreal-Gómez | -- | 1889 | 2023-01-20 17:58:11 | | | |

| 2 | Sirius Huang | Meta information modification | 1889 | 2023-01-28 03:04:59 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Vargas-Molinero, H.Y.; Serrano-Medina, A.; Palomino-Vizcaino, K.; López-Maldonado, E.A.; Villarreal-Gómez, L.J.; Pérez-González, G.L.; Cornejo-Bravo, J.M. The Electrohydrodynamic Method for Nanomaterial Production. Encyclopedia. Available online: https://encyclopedia.pub/entry/40462 (accessed on 07 March 2026).

Vargas-Molinero HY, Serrano-Medina A, Palomino-Vizcaino K, López-Maldonado EA, Villarreal-Gómez LJ, Pérez-González GL, et al. The Electrohydrodynamic Method for Nanomaterial Production. Encyclopedia. Available at: https://encyclopedia.pub/entry/40462. Accessed March 07, 2026.

Vargas-Molinero, Hever Yuritzy, Aracely Serrano-Medina, Kenia Palomino-Vizcaino, Eduardo Alberto López-Maldonado, Luis Jesús Villarreal-Gómez, Graciela Lizeth Pérez-González, José Manuel Cornejo-Bravo. "The Electrohydrodynamic Method for Nanomaterial Production" Encyclopedia, https://encyclopedia.pub/entry/40462 (accessed March 07, 2026).

Vargas-Molinero, H.Y., Serrano-Medina, A., Palomino-Vizcaino, K., López-Maldonado, E.A., Villarreal-Gómez, L.J., Pérez-González, G.L., & Cornejo-Bravo, J.M. (2023, January 20). The Electrohydrodynamic Method for Nanomaterial Production. In Encyclopedia. https://encyclopedia.pub/entry/40462

Vargas-Molinero, Hever Yuritzy, et al. "The Electrohydrodynamic Method for Nanomaterial Production." Encyclopedia. Web. 20 January, 2023.

Copy Citation

Electrospinning is a versatile technique used to produce fibrous mats. The high surface area of the electrospun mats makes them suitable for applications in fields using nanoparticles. Electrospun mats are used for tissue engineering, wound dressing, water-treatment filters, biosensors, nanocomposites, medical implants, protective clothing materials, cosmetics, and drug delivery systems.

drug delivery

nanoparticles

nanofibers

hybrid system

nanomedicine

electrospinning

1. Introduction

Nanoparticles have been essential as an innovative technology in drug delivery systems. With chemotherapeutic drugs, for example, greater specificity is needed to reduce adverse reactions during cancer treatments. These nanometric systems are able to deliver more concentrated doses in close proximity to tumor tissue due to the effects of improved permeability and retention. This, in turn, reduces the exposure of the drug to healthy tissues, and limits the distribution of chemotherapeutics to the targeted tumor tissue. This results in a more precise and less toxic dosage during treatment. Nanoparticles can also be used as carriers to penetrate the blood-brain barrier (BBB) and deliver antineoplastic drugs to treat brain tumors [1]. Another property offered by nanoparticles is to improve the bioavailability of bioactive molecules prone to enzymatic and hydrolytic degradation. Nanoparticles can be used in this capacity as oral administration vehicles for the encapsulation of peptides and proteins, which protects them from gastrointestinal barriers. They can also be used for gene delivery, improving absorption by increasing the cellular permeability of macromolecules. Nanoparticles can be targeted with specific ligands to provide better strategies for therapeutics [2][3].

Electrospun mats, on the other hand, are being studied for different purposes, such as tissue engineering, wound dressing, water treatment filters, biosensors, nanocomposites, medical implants, protective clothing materials, cosmetics, and drug delivery systems [4]. The nanofiber mats formed by electrospinning have different qualities, such as improving the dissolution of hydrophobic drugs and presenting greater release than other systems (e.g., hydrogels, films). The high surface area to volume ratio and many inter-/intra fibrous pores contribute to drug deposition and accumulation [5].

Independently, nanoparticles and polymeric nanofibers present some limitations and disadvantages. They are prone to degradation when used as implantable devices, affecting the device’s sensitivity and useful life expectancy [6]. Nanoparticles can present difficulties during their physical handling, either in liquid or dry forms, due to their small size and large surface area, which make them prone to aggregation. These properties also limit the drug load to a very small amount [2]. As for nanofibers, they present morphological characteristics that must be adjusted for the desired application. Nanofibers must meet specific requirements regarding their mechanical properties and wettability for use as biomedical membranes. Hydrophobic nanofiber mats have been shown to cause plugging and decreased flow due to air pockets trapped within the mats. The addition of nanoparticles can assist in developing a system with more suitable characteristics by modifying properties such as the tensile strength of the compound, its roughness, and the wettability of the system [7][8].

2. The Electrohydrodynamic Method

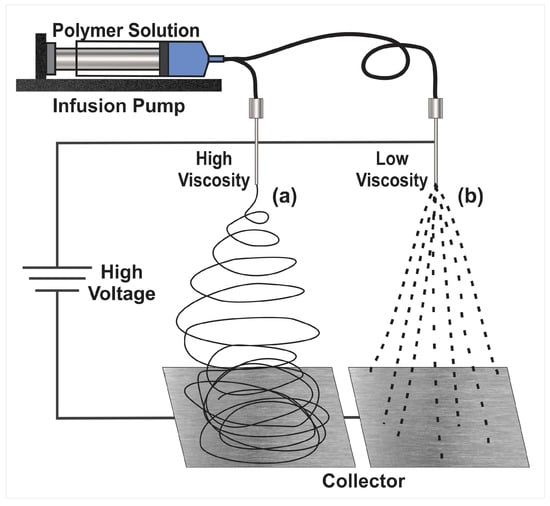

The electrodynamic methods consist of electrospinning for the creation of nanofibers and electrospray for the development of nanoparticles. These are similar techniques that take into account some experimental conditions but with different parameters and produce different material shapes, sizes, and characteristics [9]. The electrohydrodynamic method can make different types, kinds, and sizes of particles, mats, and a blend of both structure types [10][11]. The general setup for the electrodynamic method, either to form fibers (Figure 1a) or particles (Figure 1b), consists of applying high voltage to the tip of a needle of a syringe containing a polymer or biopolymer solution to a conductive metallic collector. First, the plunger is pushed by a syringe-pump, which produces the output of the solution at controlled parameters. Through the tip of the syringe, a cone is formed, called “Taylor’s cone”. The collector must be made of a conductive material that serves as a support for the material that is deposited in it, and the collector must be connected to the electric ground of the high-voltage system.

Figure 1. Basic setup for the electrodynamic method to produce either nanoparticles or nanofibers. (a) Electrospinning and (b) electrospray.

These particles and fibers have qualities that put them at an advantage against other types of materials. One of the most commonly mentioned are the small sizes, which range from micrometers to nanometers and qualifies them as nanotechnology; they also have very desirable characteristics, such as high porosity and small pore size. In addition, they have a high surface area to volume ratio, which means greater exposure to the environment [12]. The products of electrodynamic processes have a huge variety of applications in different areas, such as the food industry and the biomedical industry. Its applications include the encapsulation of substances, filtration, packaging development, and enzyme fixation, among others [13].

Electrospray follows the same principles as electrospinning. A charged solution passes through a needle, leading to the ionization and atomization of the solution, and produces microscopic, charged droplets. The solvent evaporates when nano- and micro-sized droplets are produced and collected on a grounded plate. Electrospray has great encapsulation capacity, especially for hydrophilic particles in hydrophobic carriers [14][15]. Nanoparticles formed by electrospray are suitable for drug-carrying applications. Different morphologies can be obtained in the nanoparticles, such as solid spheres, ellipses, or hollow spheres. In addition to morphology, size can also be controlled [16]. Another use for electrospray is the formation of membranes in conjunction with nanofibers, a useful configuration for filtering technologies [17][18].

2.1. Electrospinning

One of the products of the electrodynamic process is nanofibers. The electrospun nanofibers made from polymeric materials can be biocompatible, biodegradable, have a high load capacity, and encapsulation efficiency. Another advantage is that they can be produced cost-effectively. Additional features can be added to these electrospinning mats by using copolymers or functionalizing the solution with bioactive molecules. Coating the nanofiber’s surface with layers of polymeric materials, for example, which have desired physicochemical properties such as pH sensitivity. This can help to control the degradation of the nanofibers at different pH levels and provide stability in the cellular environment [9]. The electrospinning technique is easy to use, simple, unique, and versatile. With it, nanofibers of different polymeric materials can be created; about 100 different electrospun systems have already been reported, including organic and inorganic polymers. With the electrospinning technique, different strategies can be used to form nanostructures with the necessary qualities to be used as targeted delivery systems. These delivery systems can provide advantages such as increasing the therapeutic efficacy and reducing the toxicity of a drug [19]. Electrospinning nanofibers are networks capable of guiding and promoting cell migration. The properties of the nanofibers allow for cell proliferation in cellular microenvironments, which promotes angiogenesis, aids in healing, and reduces the inflammation response [20].

Nanofibers from the electrodynamic method can be used in cancer treatments, especially in solid tumors, where the implantation of these devices aids in the elimination of remaining cancer cells after the removal of a tumor as well as the regeneration of tissue in the cavity resulting from the tumor removal process. Since they have a nanostructure similar to the cellular matrix, the surface morphology can be modified for the desired properties to solve these needs [21].

Through the electrospinning method, hydrophobic and hydrophilic polymers can be mixed to modulate the rate of drug release according to the pharmacotherapeutic requirements. It is well known that prolonged release of hydrophilic drugs is difficult to maintain since they tend to dissolve very quickly in aqueous media. Through electrospinning, a hydrophilic drug can be loaded onto the nanofibers, and release can be controlled with the help of polymers with hydrophobic characteristics. Combined with the nanofibers, they minimize the drug delivery in the initial stage and keep it continuous, avoiding the typical explosive release of hydrophilic drugs (“burst release”). Another electrodynamic method that can be used when this approach does not work is coaxial electrospinning. In this method, a coaxial syringe is used for the mixture of two concentric fluids, which results in coaxial mats, obtaining nanofibers with a core-shell structure [22]. This method is applied to obtain encapsulated drugs within the nanofiber. These nanofibers, called core-sheath types, can be developed precisely. The interior of the nanofiber (core) is composed of the drug and a hydrophilic polymer, while the exterior (shell) consists of a hydrophobic polymer and controls the rate of release [22][23][24].

Electrospinning can also be used to prepare multilayer systems inspired by the treatment of skin wounds. The systems consist of layers with different physicochemical characteristics (Janus systems). The exterior layer is superhydrophobic to avoid bacterial proliferation, while the internal layer is superhydrophilic to release antibiotics and wound healing drugs, with a middle layer that delays exudate loss [25].

Reactive electrospinning is one of the varieties of electrospinning used to obtain nanofiber mats that resemble and share structural characteristics with biological tissue. Modified electrospinning techniques are used to copy or approximate biological qualities, obtaining anisotropy of the fibers, rigidity, mechanical properties, and porosity similar to living tissue. Functionalized joints are created for the interconnection of the fibers by combining electrospinning with a crosslinking process, either during electrospinning or after the formation of the nanofibers [26][27].

Electrospinning can be photoreactive if the fluid jet of the polymer solution is exposed to radiation, UV light, or laser, giving rise to photocrosslinking. When the use of chemical crosslinkers is necessary in the process, it is referred to as chemical reactive electrospinning [26].

Li-Li Wu et al., developed a nanocomposite of polyaniline and polyacrylonitrile that was electrospun with polymeric materials based on L-lysine due to their large number of amino groups and is used as an ammonium sensor. The nanocomposite is prepared by electrospinning a homogeneous solution of poly(L-Lysine) with base polymers to form uniform nanofibers as compared to fibers prepared with nanogels based on L-lysine. The nanocomposite with nanogels showed a better response to ammonia because the nanostructure of the nanogels resulted in a rougher surface that increases the surface area of the membrane [28].

2.2. Limitations in the Electrohydrodynamic Processes

The synthetic polymers used in electrospinning meet the necessary specifications to be electrospun, such as forming stable solutions in different solvents or having an adequate molecular weight. In contrast, natural polymers that are more focused on meeting needs in the field of biomedicine have more complications to meet qualities that facilitate the electrospinning process. Natural polymers show difficulties in being electrospun. Among these polymers are chitosan, collagen, gelatin, silk fibroins, and fibrinogen. They present instability in their mechanical qualities, low solubility, and high viscosity. This limits their ability to be electrospun [29][30][31]. The mechanical structure of electrospun fibers is of great importance as it influences the expected performance of devices and systems made from these nanofibers. Since these mechanical properties have an effect, for example, on cell growth and migration [32].

Systems and devices are developed for different purposes as required by different needs and individual characteristics. When the design of the nanofibers is projected to be a drug delivery system, another limitation that arises is the incompatibility of drugs and hydrophilic polymers, where the drug can concentrate on the surface of the nanofibers. The uneven distribution can cause an undesired quick release.

Regarding the mechanical properties, they must not only comply with a series of fixed qualities because they are generally developed in dry atmospheres. It is necessary to adjust and test their mechanical changes in environments similar to where they will be used, (generally humid environments). If they are exposed to fluids, for instance, the mechanical properties must be flexible, soft, and resistant at their working conditions [33][34][35].

References

- Li, J.; Zhao, J.; Tan, T.; Liu, M.; Zeng, Z.; Zeng, Y.; Zhang, L.; Fu, C.; Chen, D.; Xie, T. Nanoparticle drug delivery system for glioma and its efficacy improvement strategies: A comprehensive review. Int. J. Nanomedicine 2020, 15, 2563–2582.

- Nikam, A.P.; Ratnaparkhiand, M.P.; Chaudhari, S.P. Nanoparticles—An overview. Int. J. Res. Dev. Pharm. Life Sci. 2017, 3, 1121–1127.

- Vlachopoulos, A.; Karlioti, G.; Balla, E.; Daniilidis, V.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Christodoulou, E.; Koumentakou, I.; Karavas, E.; et al. Poly(Lactic Acid)-Based Microparticles for Drug Delivery Applications: An Overview of Recent Advances. Pharmaceutics 2022, 14, 359.

- Villarreal-Gómez, L.J.; Cornejo-Bravo, J.M.; Vera-Graziano, R.; Grande, D. Electrospinning as a powerful technique for biomedical applications: A critically selected survey. J. Biomater. Sci. Polym. Ed. 2016, 27, 157–176.

- Cornejo-Bravo, J.M.; Villarreal-Gomez, L.J.; Serrano-Medina, A. Electrospinning for Drug Delivery Systems: Drug Incorporation Techniques. In Electrospinning: Material, Techniques, and Biomedical Applications; InTech: Rijeka, Croatia, 2016.

- Puttananjegowda, K.; Takshi, A.; Thomas, S. Silicon carbide nanoparticles electrospun nanofibrous enzymatic glucose sensor. Biosens. Bioelectron. 2021, 186, 113285.

- Goyal, R.; Macri, L.K.; Kaplan, H.M.; Kohn, J. Nanoparticles and nano fi bers for topical drug delivery. J. Control. Release 2016, 240, 77–92.

- Jafarpour, M.; Aghdam, A.S.; Koşar, A.; Cebeci, F.Ç.; Ghorbani, M. Electrospinning of ternary composite of PMMA-PEG-SiO2 nanoparticles: Comprehensive process optimization and electrospun properties. Mater. Today Commun. 2021, 29, 102865.

- Sayin, S.; Tufani, A.; Emanet, M.; Genchi, G.G.; Sen, O.; Shemshad, S.; Ozdemir, E.; Ciofani, G.; Ozaydin Ince, G. Electrospun Nanofibers With pH-Responsive Coatings for Control of Release Kinetics. Front. Bioeng. Biotechnol. 2019, 7, 309.

- Rojas-Aguirre, Y.; Aguado-Castrejón, K.; González-Méndez, I. La nanomedicina y los sistemas de liberación de fármacos: ¿la (r)evolución de la terapia contra el cáncer? Educ. Quim. 2016, 27, 286–291.

- Drosou, C.; Krokida, M.; Biliaderis, C.G. Encapsulation of β-carotene into food-grade nanofibers via coaxial electrospinning of hydrocolloids: Enhancement of oxidative stability and photoprotection. Food Hydrocoll. 2022, 133, 107949.

- Sharif, N.; Golmakani, M.T.; Niakousari, M.; Ghorani, B.; Lopez-Rubio, A. Food-grade gliadin microstructures obtained by electrohydrodynamic processing. Food Res. Int. 2019, 116, 1366–1373.

- Khoshnoudi-Nia, S.; Sharif, N.; Jafari, S.M. Loading of phenolic compounds into electrospun nanofibers and electrosprayed nanoparticles. Trends Food Sci. Technol. 2020, 95, 59–74.

- Batty, C.J.; Gallovic, M.D.; Williams, J.; Ross, T.M.; Bachelder, E.M.; Ainslie, K.M. Multiplexed electrospray enables high throughput production of cGAMP microparticles to serve as an adjuvant for a broadly acting influenza vaccine. Int. J. Pharm. 2022, 622, 121839.

- Chen, N.; Gan, Y.; Luo, Y.; Jiang, Z. A review on the technology development and fundamental research of electrospray combustion of liquid fuel at small-scale. Fuel Process. Technol. 2022, 234, 107342.

- Zhou, H.; Modi, S.; Biswas, P. Controlled synthesis of charged lignin nanocarriers by electrospray. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 648, 129314.

- Ma, Z.; Ren, L.; Ying, D.; Jia, J.; Shao, J. Sustainable electrospray polymerization fabrication of thin-film composite polyamide nanofiltration membranes for heavy metal removal. Desalination 2022, 539, 115952.

- Zou, P.; Lee, W.H.; Gao, Z.; Qin, D.; Wang, Y.; Liu, J.; Sun, T.; Gao, Y. Wound dressing from polyvinyl alcohol/chitosan electrospun fiber membrane loaded with OH-CATH30 nanoparticles. Carbohydr. Polym. 2020, 232, 115786.

- Haider, A.; Haider, S.; Kang, I.K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188.

- ur Rehman Khan, A.; Huang, K.; Khalaji, M.S.; Yu, F.; Xie, X.; Zhu, T.; Morsi, Y.; Jinzhong, Z.; Mo, X. Multifunctional bioactive core-shell electrospun membrane capable to terminate inflammatory cycle and promote angiogenesis in diabetic wound. Bioact. Mater. 2021, 6, 2783–2800.

- Khodadadi, M.; Alijani, S.; Montazeri, M.; Esmaeilizadeh, N.; Sadeghi-Soureh, S.; Pilehvar-Soltanahmadi, Y. Recent advances in electrospun nanofiber-mediated drug delivery strategies for localized cancer chemotherapy. J. Biomed. Mater. Res. Part A 2020, 108, 1444–1458.

- Christy, P.N.; Basha, S.K.; Kumari, V.S.; Bashir, A.K.H.; Maaza, M.; Kaviyarasu, K.; Arasu, M.V.; Al-Dhabi, N.A.; Ignacimuthu, S. Biopolymeric nanocomposite scaffolds for bone tissue engineering applications—A review. J. Drug Deliv. Sci. Technol. 2020, 55, 101452.

- Pant, B.; Park, M.; Park, S.J. Drug delivery applications of core-sheath nanofibers prepared by coaxial electrospinning: A review. Pharmaceutics 2019, 11, 305.

- Villarreal-Gómez, L.J.; Serrano-Medina, A.; Torres-Martínez, E.J.; Perez-González, G.L.; Cornejo-Bravo, J.M. Polymeric advanced delivery systems for antineoplasic drugs: Doxorubicin and 5-fluorouracil. e-Polymers 2018, 18, 359–372.

- Zhang, W.; Guan, X.; Qiu, X.; Gao, T.; Yu, W.; Zhang, M.; Song, L.; Liu, D.; Dong, J.; Jiang, Z.; et al. Bioactive composite Janus nanofibrous membranes loading Ciprofloxacin and Astaxanthin for enhanced healing of full-thickness skin defect wounds. Appl. Surf. Sci. 2023, 610, 155290.

- Ismail, H.M.; Ali-Adib, S.; Younes, H.M. Reactive and functionalized electrospun polymeric nanofibers for drug delivery and tissue engineering applications. Ther. Deliv. 2019, 10, 397–399.

- Xu, Q.; Ensign, L.M.; Boylan, N.J.; Schön, A.; Gong, X.; Yang, J.C.; Lamb, N.W.; Cai, S.; Yu, T.; Freire, E.; et al. Impact of Surface Polyethylene Glycol (PEG) Density on Biodegradable Nanoparticle Transport in Mucus ex Vivo and Distribution in Vivo. ACS Nano 2015, 9, 9217–9227.

- Wu, D.Q.; Wu, L.L.; Cui, H.C.; Zhang, H.N.; Yu, J.Y. A rapid ammonia sensor based on lysine nanogel-sensitized PANI/PAN nanofibers. J. Mater. Chem. B 2016, 4, 1520–1527.

- Juncos Bombin, A.D.; Dunne, N.J.; McCarthy, H.O. Electrospinning of natural polymers for the production of nanofibres for wound healing applications. Mater. Sci. Eng. C 2020, 114, 110994.

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and electrospun nanofibers: Methods, materials, and applications. Chem. Rev. 2019, 119, 5298–5415.

- Mele, E. Electrospinning of natural polymers for advanced wound care: Towards responsive and adaptive dressings. J. Mater. Chem. B 2016, 4, 4801–4812.

- Rao, S.S.; Nelson, M.T.; Xue, R.; DeJesus, J.K.; Viapiano, M.S.; Lannutti, J.J.; Sarkar, A.; Winter, J.O. Mimicking white matter tract topography using core-shell electrospun nanofibers to examine migration of malignant brain tumors. Biomaterials 2013, 34, 5181–5190.

- Carlisle, C.R.; Coulais, C.; Namboothiry, M.; Carroll, D.L.; Hantgan, R.R.; Guthold, M. The mechanical properties of individual, electrospun fibrinogen fibers. Biomaterials 2009, 30, 1205–1213.

- Ren, X.; Han, Y.; Wang, J.; Jiang, Y.; Yi, Z.; Xu, H.; Ke, Q. An aligned porous electrospun fibrous membrane with controlled drug delivery—An efficient strategy to accelerate diabetic wound healing with improved angiogenesis. Acta Biomater. 2018, 70, 140–153.

- Sharpe, J.M.; Lee, H.; Hall, A.R.; Bonin, K.; Guthold, M. Mechanical properties of electrospun, blended fibrinogen: PCL nanofibers. Nanomaterials 2020, 10, 1843.

More

Information

Subjects:

Materials Science, Biomaterials

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

862

Entry Collection:

Biopharmaceuticals Technology

Revisions:

2 times

(View History)

Update Date:

28 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No