Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Seyyed Abbas Noorian Najafabadi | -- | 3445 | 2023-01-09 09:50:57 | | | |

| 2 | Conner Chen | + 14 word(s) | 3459 | 2023-01-10 07:05:13 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Najafabadi, S.A.N.; Sugano, S.; Bluyssen, P.M. Effects of Carpets on Indoor Air Quality. Encyclopedia. Available online: https://encyclopedia.pub/entry/39896 (accessed on 07 February 2026).

Najafabadi SAN, Sugano S, Bluyssen PM. Effects of Carpets on Indoor Air Quality. Encyclopedia. Available at: https://encyclopedia.pub/entry/39896. Accessed February 07, 2026.

Najafabadi, Seyyed Abbas Noorian, Soma Sugano, Philomena M. Bluyssen. "Effects of Carpets on Indoor Air Quality" Encyclopedia, https://encyclopedia.pub/entry/39896 (accessed February 07, 2026).

Najafabadi, S.A.N., Sugano, S., & Bluyssen, P.M. (2023, January 09). Effects of Carpets on Indoor Air Quality. In Encyclopedia. https://encyclopedia.pub/entry/39896

Najafabadi, Seyyed Abbas Noorian, et al. "Effects of Carpets on Indoor Air Quality." Encyclopedia. Web. 09 January, 2023.

Copy Citation

Interest in having a healthy and well-being environment has increased the awareness to improve indoor air quality (IAQ). Building materials influence the contribution of indoor air pollution, so understanding their behaviour on IAQ is essential. Among building materials, carpets cover surfaces of indoor environments and significantly impact IAQ due to their large surface area and multi-layers of materials components.

carpets

indoor air quality

emission

sorption

1. VOCs

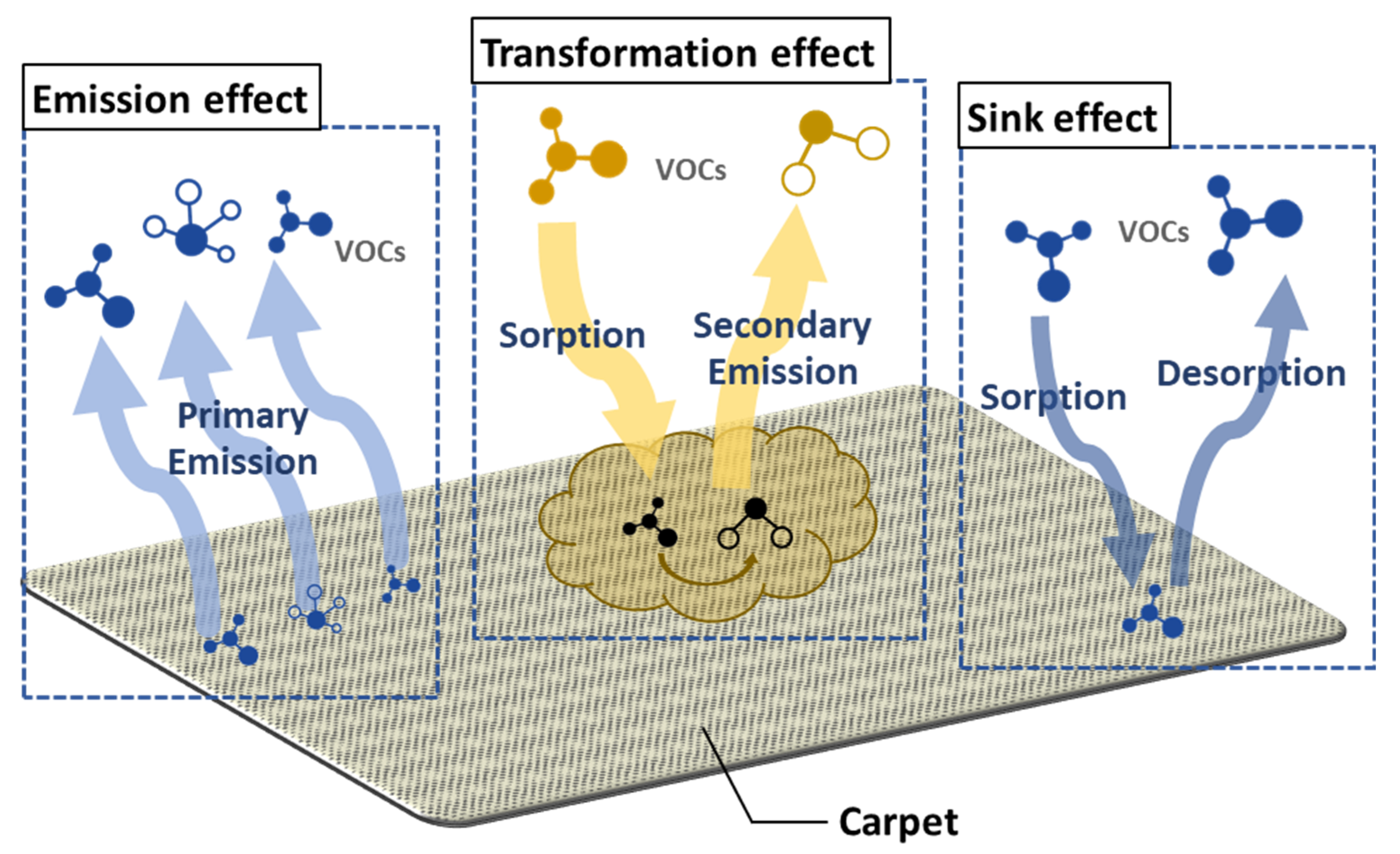

In general, carpets can impact the concentration of volatile organic compounds (VOCs) in the indoor environment through emission, sink effect (sorption and re-emission), and transformation (Figure 1). These processes are discussed in the following sections.

Figure 1. Impact of the carpets on the VOCs concentration in indoor air.

1.1. Emission of VOCs with Carpets

This section discusses the source, kind of VOCs, and emission mechanism, as well as relevant parameters affecting the emission rate from carpets. Carpets can emit VOCs, SVOCs, and microbial VOCs (MVOCs). The most emitted pollutants by carpets are VOCs such as 4-phenylcyclohexene (4-PCH, the source of new carpet odour), aromatic compounds (benzene, styrene, toluene, xylenes), and carbonyl compounds. This emission can range from 10 to 10,000 μg m−2 h−1 [1][2]. Additionally, some SVOCs emitted by carpets are treated by finishing agents, such as per- and polyfluoroalkyl substances (PFAS) from soil retardants [3], organohalogen and organophosphorus from flame retardants [4], triclosan from antimicrobials [5], phthalate esters (PAEs) in plasticizer polyvinyl chloride (PVC) backing [6][7], p-dichlorobenzene from moth repellent, tetrachloroethene from dry-cleaning agents [8], and silicon composition from water repellent [9].

Moreover, microorganisms can emit MVOCs (especially 1-octen-3-ol and 2-ethyl-1-hexanol) as part of the metabolic processes of microbes. The emission of MVOCs depends on the water content of the carpet, the availability of nutrients, and the presence of oxygen [10]. However, more research is required to better understand when microbial growth occurs and MVOCs are emitted from humid carpets.

There are various measurement methodologies for studying the impact of carpets on indoor air quality (IAQ). Practically, the ISO 16,000 series and EN 16,516 are used for sampling, preparation, and measuring the emission of VOCs [11][12]. Nowadays, some voluntary standards are involved in measuring the VOCs emitted by carpets to label carpets with low emission rates. The most applied ones are green labels supported by the Carpet and Rug Institute, the trade association for the North American carpet industry, and Gemeinschaft umweltfreundlicher Teppichboden (GUT), supported by the European textile floor-covering industry. To receive GUT Certification, the emission rates for several VOCs must be less than certain defined rates: the VOCs and SVOCs emissions must be less than 250 μg m−3 and 30 μg m−3, respectively, after three days [13]. Most of these labelling systems use chemical analyses for the measurement of TVOCs, and some specific VOCs and a few, like GUT, use odour tests with trained panels [14][15].

Two mechanisms reflect the emission rate of VOCs from building materials with no internal chemical reactions: (1) the diffusion of VOCs within the building materials and (2) the evaporation from the building materials’ surface to the ambient air. The emission rate may be limited by one or both mechanisms based on the type of building material. In the case of the second mechanism (evaporation), the emission rate of VOCs may be affected by the concentration in the indoor air (equilibrium concentration) [16]. Additionally, the molecular weight of VOCs affects the emission rate as the diffusion coefficient mostly decreases as the molecular weight of the VOCs increases [17].

There are several models available for predicting VOC and SVOC emissions from carpets, such as the first-order decay and dilution models with or without considering the sink effect [17][18][19]. If the sink effect is considered in the model, a better fit between the predictor variable and the response was found, resulting in higher regression values [19]. However, a more rigorous validation of models is desirable because of the principal assumptions of the model effect on the predicted result of the model. For example, the result of separated fibres and polymer backings of the carpet confirmed that the backing was the most predominant source of emission due to serving as a slow diffusive source of the VOCs. Therefore, the model of these results assumed that the VOCs initiate emission predominantly from a uniform slab of polymer backing material; hence, the researchers claim that this model can predict VOC emissions from new carpets based solely on a knowledge of the physical properties of the relevant compounds and the carpet backing material [17].

Effect of ventilation: Both emission and evaporation mechanisms control the emission rates when the ventilation rate changes. Indeed, a significant impact of the ventilation rate on emission rates was achieved when the ventilation rate was low, but the emission rates become independent of ventilation rates when the ventilation rate is high in both sensory and chemical assessments [20]. For example, Gunnarsen [20] studied the emission from construction products and found that when the low ventilation rate was increased (less than one week), the emission concentration of VOCs from the sources with large surfaces increased. This increase may be caused by an increase in the air velocity above the surface, increasing the mass transfer coefficient and consequently increasing the evaporation of VOCs from the surface [16][20][21][22].

Effect of temperature: Generally, indoor air temperatures are limited between 17 °C and 28 °C. However, the temperature of the floor covering materials may increase to a higher degree by solar irradiation or floor heating. The VOC emission increases with higher indoor temperatures due to increased diffusion and evaporation of VOC from the surface. For example, the 4-PCH emission from carpets increased when the temperature increased from 23 °C to 50 °C [18][23]. However, increasing the temperature decreases the amount of chemical compounds in carpets as well as the emission rate over time [22][23][24].

The emission of four finishing materials (carpet, oil-based paint, plywood board, and water-based paint) showed that different air temperatures (23 °C and 30 °C) significantly impacted the chemical emissions, but mainly for the initial emission. For example, after ventilation for two weeks, both the chemical (TVOC) and the sensory emission rate for each material showed no changes in emission between the two temperature levels [25].

Effect of dimensions of a space: Small chambers are typically used to study the influence of different parameters (e.g., temperature, humidity, air exchange rate, air velocity) on emission/sink properties of building materials [26], because in large chambers, the environmental conditions are difficult to control. Additionally, large chambers are cost-intensive, time-consuming, and require complicated test equipment [27]. However, large chambers are more practical in estimating real-life situations for simulating inhabitants’ behaviour and sink effects of building materials [26].

Emission of the same carpets in various sizes of chambers with the same air temperature and humidity is ideally expected to demonstrate similar results. However, in some studies, significant differences in the emission isotherm of the carpets in a large chamber (30 m3) compared to small chambers (0.02, 0.28, and 0.45 m3) were found [1].

Effect of carpet materials: The material components of carpet layers affect the emission behaviour of carpets. Several studies have been performed on VOC emission of carpets with different material compositions, various fibre piles and backing, the same fibre pile and different backing, and even the same fibre pile and backing. In a study on VOCs emission of 14 carpets with separated layers, emissions from the complete structures were found to be lower than the sum of emissions from the single component layers [28].

1.2. Sink Properties of Carpets for VOCs

Research has shown that the sorption potential of carpets may have an impact on IAQ; sorption and desorption of VOCs on materials, are therefore, relevant to consider [29]. However, to test whether 100% of the adsorbed VOCs are re-emitted, long-term desorption data are required to monitor [30].

Carpet materials have been shown to have the largest sorption capacity among different indoor surface materials. Due to their ab/adsorption properties, carpets can reduce indoor air VOC concentrations, but has shown to be followed by re-emission of those VOCs over prolonged periods [31].

Effect of environmental parameters: It has been observed that RH significantly impacts the sorption amount of 2-propanol, a highly soluble VOC. However, no noticeable impact on sorption with increasing the RH was seen for nonpolar VOCs on polyamide and poly olefin carpets [31]. Therefore, it was concluded that RH affects the sorption capacity of VOCs based on the hydrophilicity or hydrophobicity of those VOCs.

In a study, it was found that an increase in temperature and air velocity affected the amount of VOCs adsorbed by ceiling tiles and carpets [32]. In another study, the results of adsorption and desorption of some VOCs in the temperature range of 25–45 °C showed that the adsorption rate decreased more rapidly with increasing temperature than the desorption rate [33]. Additionally, some studies showed that the air velocity and size of chambers did not influence the sorption of VOCs on wool and nylon carpets [29][34].

Moreover, the sink effect of the chamber test can influence the sorption study. To minimise this sink effect, the use of inert materials such as Teflon or glass for chamber walls has been recommended. In addition, results of wool and nylon carpets’ sorption studies showed that an experiment conducted with a relatively high loading of VOCs liquid reduced the sink effects of the test chamber and is therefore recommended as well [35].

Effect of type of VOCs: A study on the sorption of toluene and a-pinene by wool and nylon carpets revealed that the sorption was enhanced when both compounds were present in the chamber. The outcome of the experiment was successfully used in the Langmuir model in order to provide a chemical explanation of the adsorption process [36].

Effect of carpet materials: In a study with two nylon carpets from different suppliers, similar sorption capacities were found while the emissions differed. Moreover, another carpet with mainly olefin-based fibres revealed a greater sorption capacity for all VOCs than these two nylon carpets [31].

A study on the sorption effect of carpets comprising of different materials resulted in the following ranking of the sorption capacity for toluene and α-pinene: wool carpet > nylon carpet > PVC coverings > cotton curtain > empty chamber. Additionally, for the wool carpet, it was found that different air velocities (0, 10, and 20 cm/s) did not influence the sorption capacity because of the large surface area of the carpet [29].

1.3. VOC Transformation Reactions with Carpets

There are primary emissions from various sources of indoor building materials present in the indoor air. Besides, a building material can release secondary emissions resulting from transformation reactions (like physical, biological, or chemical reactions) [37]. Materials with a large amount of organic compounds, such as carpets, wood, fabrics, and paint, can emit VOCs as secondary emissions [38]. In addition, newer carpets can have higher secondary emissions than older carpets [39]. One study showed that increasing ventilation might result in higher secondary emissions, especially for the material surface with high reactivity to oxidative degradation. Consequently, the secondary emissions, instead of the primary emissions, are expected to impact the perceived IAQ in the long run. It was observed that after a limited decay during the first one or two weeks, the odour intensity remained almost constant during the rest of the experiment period (50 days) [16].

One crucial transformation reaction in the carpet is the chemical reaction between oxidants and materials [37]. Ozone, as an oxidant agent, can react with gas-phase VOC emitted from building materials as well as the organic interface of building materials [40]. The ventilation rate and removal effects of surface interactions with building materials, such as wallpaper, latex paint, carpet, plywood, and plaster, can affect indoor ozone concentrations [41]. Among the building materials studied, carpets reacted significantly with ozone, owing to their high surface area and covering a large fraction of surfaces in the indoor area [42][43]. Ozone reactions with carpet can lead to elevated concentrations of oxidized products (such as aliphatic aldehydes, i.e., formaldehyde, acetaldehyde, and aldehydes with 5–10 carbons), resulting in secondary emissions [41][44].

Reactions among VOCs in an actual indoor environment are the source of short-lived, highly reactive compounds indoors, which makes the investigation of them by physical/chemical analyses difficult. The new reactive products may be readily sensed by occupants but are challenging to identify using standard analytical methods. While, it is possible to study the net effect of a complex VOCs mixture on human perception by sensory evaluation [45]. Therefore, sensory assessments are suitable for identifying variations derived from indoor chemistry, especially for variations missed by the routine analytical methods evaluating indoor air [46]. In this regard, sensory evaluations of ozone removal with building materials (plasterboard, carpet, linoleum, pinewood, and melamine) were conducted to reveal the perceptual effects. Results showed the greatest effect with significantly high odour intensity for carpet when exposed to ozone. Indeed, the compounds emissions from the carpet were transformed to oxidant compounds with negative odour notes caused by the ozone exposure [47].

Nylon carpets with styrene butadiene-rubber (SBR) backing were exposed to an ozone environment to investigate the primary and secondary emissions [44]. The carpet backing primarily emitted styrene, 4-ethenylcyclohexene, and 4-PCH, while the nylon fibre emitted C5-C10 aldehydes ~4 times more concentrated than the backing in the presence of ozone. Moreover, in the presence of ozone, benzaldehyde, benzoic acid, and acetophenone reached much higher concentrations in the chamber with the backing material than in the chamber containing the nylon fibres [44].

2. Particulate Matter

Since people spend most of their time indoors, indoor PMs can significantly affect human health. Indoor particles are either generated from indoor activities, such as the combustion of gas and petroleum-based fuels, smoking, and cooking, or introduced from outdoors via ventilation and infiltration. Resuspension of particulate matter (PM) from floorings is an important cause of human exposure, and carpets are a significant reservoir of PM due to their complex structure and high surface area. The following section introduces the behaviour of carpets with regards to deposition and resuspension of PMs.

2.1. Particulate Matter Deposition on Carpets

It is known that carpets deposit more particles, dust, and allergens than non-carpet floors and possibly cause worsening of asthma and allergies [48][49][50]. A study using an isolated room (volume = 14.2 m3) showed that a carpet contributed to a higher deposition loss rate of particles (<10 µm) under airflow conditions (mean air speed = 5 to 19 cm/s) compared to a bare room [48].

Moreover, the surface of carpets has the potential to support chemical and biological transformations, including particle-bound SVOCs or fungal growth [15]. For example, one study showed that dust presence is an important factor in fungal growth in carpets, and the elevated RH (≥85%) is also an essential variable of increased fungi in carpets [51]. It is also suggested that the material of carpet fibre relates to the potential fungal growth and allergen production, and Olefin fibre showed less fungal and A. alternata growth compared to nylon and wool fibres [51].

In addition, a recent study reported the persistence of viruses (MS2 and Phi6 bacteriophages) on carpets for several hours to days, and vacuum cleaning and hot water extraction did not show significant effects in reducing the concentration of viruses [52]. Therefore, understanding the environmental conditions or cleaning methods that reduce the resuspension of deposited particles from carpets is needed to improve IAQ and human health.

2.2. Particulate Matter Resuspension from Carpets

Previous experimental studies on particle resuspension from carpets mainly focused on the effects of human activities and indoor RH. Some studies compared the resuspension rate (fraction of a surface species removed per unit time) of particles from carpets to other flooring materials. Various scales of chambers were used in previous studies, and some experiments were conducted using human subjects to simulate resuspending particles by walking. The types of test particles were also different between the experiments, and dust samples from actual building carpets and ISO 12103–1 test dust (Arizona test dust [53]) were mainly used in the previous studies.

Human activities and PM resuspension. The key reason for the resuspension of PM from carpets is human activities such as vacuum cleaning and walking [54][55]. Previous studies showed that the size of PM affects the resuspension mass, and bigger PMs consistently resuspend from carpets more than smaller PMs through human activities. For example, one study showed that PM10 (sizes below 10 μm) has more resuspended than PM2.5 (sizes below 2.5 μm) during vacuum cleaning [56]. Additionally, the resuspension rate was higher for larger particles (size range of 0.8–10 μm) during walking on loop fibre carpets [57]. Another full-scale chamber study using a walking subject also found a higher resuspension rate for bigger particles [58].

The dominant adhesion and removal forces of particles to carpets vary depending on their sizes. While adhesion forces increase with particle size, the removal forces, such as drag forces of vibration and convection, are proportional to the third and second power of the particle size, respectively [59][60]. Therefore, larger particles more easily resuspend than smaller particles.

Some recent studies focused on particle resuspension and exposure induced by infants’ crawling and children’s walking. A study that used a robotic infant showed that an infant would receive a nearly four times greater respiratory tract deposited dose of resuspended biological aerosol particles than an adult in terms of per kg body mass [61]. Additionally, the resuspension fractions for infants’ crawling (10−6–10−1 [-]) are similar to those for adults’ walking [62]. Another study used a bipedal robot simulating children’s walking and showed that different shoe materials (cotton socks, polyvinyl chloride, and ethylene-vinyl acetate copolymer) produced different sizes and concentrations of particles from carpets [63].

Flooring materials and PM resuspension. In several studies, the resuspension rate of PM between carpets and other hard flooring materials was compared. Generally, carpets resuspend more particles than hard floorings. A new level-loop carpet had a higher resuspension rate than vinyl tile flooring for particle sizes of 1.0–10 μm via walking activity under a ceiling air supply system [57]. Another study that used air jet tubes to simulate vortices induced at the edges of the foot during human walking also reported a higher resuspension rate from nylon carpets than the linoleum surfaces at the same RH levels (10% and 80%) [64]. In addition, the linoleum surface showed significant increases in the resuspension rate of hydrophilic particles as RH decreased from 80% to 10% compared to nylon carpets [64]. Another study that used a mechanical resuspension device to simulate human walking also showed higher resuspension fractions of nylon cut pile carpets than hard floorings (hardwood and vinyl) for particles 3.0–10 µm [65].

In previous studies, it was found that the carpets’ surface roughness, fibre resiliency, and electrostatic force may cause a higher resuspension rate of carpets [65]. In addition, low-density carpets resuspend dust more than high-density carpets because of the lower bending resiliency of fibre piles [65]. In contrast, one study reported that a laminate floor resuspended more particles (5 µm and 10 µm) than carpets through vacuum cleaning after several times of simulated walking activities. This result may be related to the surface condition of the test carpets and the positions of embedded particles inside the carpets [55].

One experimental study showed that the resuspension rate of PM could be increased and decreased by higher RH depending on the surface condition of the medium-pile carpets (old and new) [66]. Another study showed that increased RH levels (40% and 70%) enhanced dust resuspension from nylon high-density pile carpets, while hard floorings showed decreased resuspension [65]. It is also reported that shaggy carpets did not show an obvious influence of different RH (40, 60, and 80%) on the mass concentration of particles with diameters between 0 and 5.0 µm but showed an influence on the mass concentration of particles with diameters between 5.0 and 10.0 µm [67]. This result may be affected by condensing of fine particles due to humidity.

The RH levels affect the electrostatic and capillary forces of particles. In high humidity conditions, the capillary force will be increased by forming meniscuses between particles and surface asperities, and the adhesion force will be increased. Additionally, higher RH increases cohesive forces between the particles and helps to form an agglomerate, resulting in the reducing resuspension due to the presence and strength of the particle clusters [65]. Moreover, the adhesion force by electrostatics was thought to decrease with higher RH because the extra water increases the leak-off rates of charges on particles, resulting in a reduction of adhesion forces and prevention of charge accumulation [65]. However, the results of Tian et al. [65] showed that the difference in surface materials caused differences in the impacts of the capillary and electrostatic forces on particles’ adhesion forces in the different RH conditions. Thus, the effect of RH on PM resuspension can differ depending on the material type and surface condition of carpets.

The previous studies also showed that the effect of indoor RH on the resuspension of PM from carpets is related to the type of particles. A recent study examined the effect of humidity on the resuspension of biological particles from nylon carpets and linoleum [64]. While hydrophilic particles (quartz and dust mite) showed an increased resuspension rate as RH decreased from 80% to 10%, the resuspension rate of hydrophobic particles (cat and dog fur) did not show a significant effect of RH. The hydrophilic particles may make water films under high humidity conditions by absorbing moisture. The water film may reduce particles’ resuspension by increasing the particles’ adhesion force and decreasing the potential for electrostatic repulsion.

References

- Katsoyiannis, A.; Leva, P.; Kotzias, D. VOC and Carbonyl Emissions from Carpets: A Comparative Study Using Four Types of Environmental Chambers. J. Hazard. Mater. 2008, 152, 669–676.

- Guo, H.; Murray, F.; Lee, S.C.; Wilkinson, S. Evaluation of Emissions of Total Volatile Organic Compounds from Carpets in an Environmental Chamber. Build. Environ. 2004, 39, 179–187.

- Prevedouros, K.; Cousins, I.T.; Buck, R.C.; Korzeniowski, S.H. Sources, Fate and Transport of Perfluorocarboxylates. Environ. Sci. Technol. 2006, 40, 32–44.

- Liu, X.; Allen, M.R.; Roache, N.F. Characterization of Organophosphorus Flame Retardants’ Sorption on Building Materials and Consumer Products. Atmos. Environ. 2016, 140, 333–341.

- Petersen, R.C. Triclosan Antimicrobial Polymers. AIMS Mol. Sci. 2016, 3, 88–103.

- Sukiene, V.; von Goetz, N.; Gerecke, A.C.; Bakker, M.I.; Delmaar, C.J.E.; Hungerbühler, K. Direct and Air-Mediated Transfer of Labeled SVOCs from Indoor Sources to Dust. Environ. Sci. Technol. 2017, 51, 3269–3277.

- Lin, W.; Chen, C.-Y.; Lee, C.; Chen, C.; Lo, S. Air Phthalate Emitted from Flooring Building Material by the Micro-Chamber Method: Two-Stage Emission Evaluation and Comparison. Toxics 2021, 9, 216.

- Won, D.; Corsi, R.L.; Rynes, M. Sorptive Interactions between VOCs and Indoor Materials. Indoor Air 2001, 11, 246–256.

- Hendy, A.M.; Bakr, D.; Kamal Bakr, D. Indoor Air Quality Between Textiles’ Treatment And Human Health Article In. Int. J. Sci. Technol. Res. 2020, 9, 200–206.

- Haines, S.R.; Hall, E.C.; Marciniak, K.; Misztal, P.K.; Goldstein, A.H.; Adams, R.I.; Dannemiller, K.C. Correction to: Microbial Growth and Volatile Organic Compound (VOC) Emissions from Carpet and Drywall under Elevated Relative Humidity Conditions. Microbiome 2021, 9, 219.

- ISO Standard No. 16000; Series 1–11, Indoor Air. International Organization for Standardization: Geneva, Switzerland, 2004.

- European Standard. EN 16516:2017; Construction Products: Assessment of Release of Dangerous Substances—Determination of Emissions into Indoor Air. European Parliament and of the Council: Washington, DC, USA, 2017.

- Emission Test for Volatile Organic Compounds (VOC’s) in Textile Floor Coverings. Available online: https://Gut-Prodis.Eu/En/Product-Testing-Gut/Emission-Test (accessed on 1 December 2022).

- Kephalopoulos, S.; Crump, D.; Daumling, C.; Funch, L.; Horn, W.; Keirsbulck, M.; Maupetit, F.; Sateri, J.; Saarela, K.; Scutaru, A.; et al. Harmonisation Framework for Indoor Products Labelling Schemes in the EU; ECA Report No. 27; Publications Office of the European Union: Luxembourg, 2012.

- Haines, S.R.; Adams, R.I.; Boor, B.E.; Bruton, T.A.; Downey, J.; Ferro, A.R.; Gall, E.; Green, B.J.; Hegarty, B.; Horner, E.; et al. Ten Questions Concerning the Implications of Carpet on Indoor Chemistry and Microbiology. Build. Environ. 2020, 170, 106589.

- Knudsen, H.N.; Kjaer, U.D.; Nielsen, P.A.; Wolkoff, P. Sensory and Chemical Characterization of VOC Emissions from Building Products: Impact of Concentration and Air Velocity. Atmos. Environ. 1999, 33, 1217–1230.

- Little, J.C.; Hodgson, A.T.; Gadgil, A.J.; Hotxson, A.T.; Gadgil, A.J. Modeling Emissions Of Volatile Organic Compounds From New Carpets. Atmos. Environ. 1994, 28, 227–234.

- Wal, J.F.; Hoogeveen, A.W.; Wouda, P. The Influence of Temperature on the Emission of Volatile Organic Compounds from PVC Flooring, Carpet, and Paint. Indoor Air 1997, 7, 215–221.

- Hodgson, A.T.; Wooley, J.D.; Daisey, J.M. Emissions of Volatile Organic Compounds from New Carpets Measured in a Large-Scale Environmental Chamber. Air Waste 1993, 43, 316–324.

- Gunnarsen, L. The Influence of Area-Specific Ventilation Rate on the Emissions from Construction Products. Indoor Air 1997, 7, 116–120.

- Sollinger, S.; Levsen, K.; Wünsch, G. Indoor Air Pollution by Organic Emissions from Textile Floor Coverings. Climate Chamber Studies under Dynamic Conditions. Atmos. Environ. Part B. Urban Atmos. 1993, 27, 183–192.

- Wolkoff, P. Impact of Air Velocity, Temperature, Humidity, and Air on Long-Term Voc Emissions from Building Products. Atmos. Environ. 1998, 32, 2659–2668.

- Igielska, B.; Wiglusz, R.; Sitko, E.; Nikel, G. The Release of Volatile Organic Compounds from Textile Floor Coverings at Higher Temperature. Rocz. Panstw. Zakl. Hig. 2003, 54, 329–335.

- Yang, S.; Chen, Q.; Bluyssen, P.M. Prediction of Short-Term and Long-Term VOC Emissions from SBR Bitumen-Backed Carpet under Different Temperatures. In Proceedings of the ASHRAE Transactions, ASHRAE Annual Meeting, Toronto, ON, Canada, 20–24 June 1998; part 2. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 1998; Volume 104.

- Bluyssen, P.M.; Cornelissen, H.J.M.; Hoogeveen, A.W.; Wouda, P.; Van der Wal, J.F. The effect of temperature on the chemical and sensory emission of indoor materials. In Proceedings of the Indoor Air ’96, Nagoya, Japan, 21–26 July 1996.

- Rothweiler, H.; Wager, P.A.; Schlatter, C. Long Term Emissions from Two Glued Carpets with Different Backings Measured in Indoor Air. Environ. Technol. 1992, 13, 891–896.

- Kowalska, J.; Gierczak, T. Qualitative and Quantitative Analyses of the Halogenated Volatile Organic Compounds Emitted from the Office Equipment Items. Indoor Built Environ. 2013, 22, 920–931.

- Wilke, O.; Jann, O.; Brodner, D. VOC- and SVOC-Emissions from Adhesives, Floor Coverings and Complete Floor Structures. Indoor Air 2004, 14, 98–107.

- Jorgensen, R.B.; Bjorseth, O.; Malvik, B. Chamber Testing of Adsorption of Volatile Organic Compounds (VOCs) on Material Surfaces. Indoor Air 1999, 9, 2–9.

- Chang, J.C.S.; Sparks, L.E.; Guo, Z.; Fortmann, R. Evaluation of Sink Effects on Vocs from a Latex Paint. J. Air Waste Manag. Assoc. 1998, 48, 953–958.

- Won, D.; Corsi, R.L.; Rynes, M. New Indoor Carpet as an Adsorptive Reservoir for Volatile Organic Compounds. Environ. Sci. Technol. 2000, 34, 4193–4198.

- Zhang, J.; Zhang, J.; Chen, Q. Effects of Environmental Conditions on the VOC Sorption by Building Materials-Part I: Experimental Results. ASHRAE Trans. 2002, 108, 273–282.

- Elkilani, A.; Baker, C.G.; Al-Shammari, Q.; Bouhamra, W. Sorption of Volatile Organic Compounds on Typical Carpet Fibers. Environ. Int. 2003, 29, 575–585.

- Deng, Q.; Zhang, J.S.; Yang, X. The Validation of a VOC Diffusion Sink Model Based on Full-Scale Chamber Test. ASHRAE Trans. 2009, 115, 943–963.

- Senitkova, I. Impact of Indoor Surface Material on Perceived Air Quality. Mater. Sci. Eng. C 2014, 36, 1–6.

- Jorgensen, R.B.; Bjorseth, O. Sorption Behaviour of Volatile Organic Compounds on Material Surfaces—The Influence of Combinations of Compounds and Materials Compared to Sorption of Single Compounds on Single Materials. Environ. Int. 1999, 25, 17–27.

- Gall, E.; Darling, E.; Siegel, J.A.; Morrison, G.C.; Corsi, R.L. Evaluation of Three Common Green Building Materials for Ozone Removal, and Primary and Secondary Emissions of Aldehydes. Atmos. Environ. 2013, 77, 910–918.

- Abbass, O.A.; Sailor, D.J.; Gall, E.T. Effect of Fiber Material on Ozone Removal and Carbonyl Production from Carpets. Atmos. Environ. 2017, 148, 42–48.

- Wang, H.; Morrison, G.C. Ozone-Initiated Secondary Emission Rates of Aldehydes from Indoor Surfaces in Four Homes. Environ. Sci. Technol. 2006, 40, 5263–5268.

- Lee, C.S.; Haghighat, F.; Ghaly, W.S. A Study on VOC Source and Sink Behavior in Porous Building Materials—Analytical Model Development and Assessment. Indoor Air 2005, 15, 183–196.

- Palmisani, J.; Nørgaard, A.W.; Kofoed-Sørensen, V.; Clausen, P.A.; de Gennaro, G.; Wolkoff, P. Formation of Ozone-Initiated VOCs and Secondary Organic Aerosol Following Application of a Carpet Deodorizer. Atmos. Environ. 2020, 222, 117149.

- Morrison, G.C.; Nazaroff, W.W. The Rate of Ozone Uptake on Carpets: Experimental Studies. Environ. Sci. Technol. 2000, 34, 4963–4968.

- Nicolas, M.; Ramalho, O.; Maupetit, F. Reactions between Ozone and Building Products: Impact on Primary and Secondary Emissions. Atmos. Environ. 2007, 41, 3129–3138.

- Weschler, C.J.; Hodgson, A.T.; Wooley, J.D. Indoor Chemistry: Ozone, Volatile Organic Compounds, and Carpets. Environ. Sci. Technol. 1992, 26, 2371–2377.

- Sakr, W.; Weschler, C.J.; Fanger, P.O. The Impact of Sorption on Perceived Indoor Air Quality. Indoor Air 2006, 16, 98–110.

- Weschler, C.J. Chemical Reactions among Indoor Pollutants: What We’ve Learned in the New Millennium. Indoor Air 2004, 14, 184–194.

- Knudsen, H.N.; Nielsen, P.A.; Clausen, P.A.; Wilkins, C.K.; Wolkoff, P. Sensory Evaluation of Emissions from Selected Building Products Exposed to Ozone. Indoor Air 2003, 13, 223–231.

- Thatcher, T.L.; Lai, A.C.K.; Moreno-Jackson, R.; Sextro, R.G.; Nazaroff, W.W. Effects of Room Furnishings and Air Speed on Particle Deposition Rates Indoors. Atmos. Environ. 2002, 36, 1811–1819.

- Bramwell, L.; Qian, J.; Howard-Reed, C.; Mondal, S.; Ferro, A.R. An Evaluation of the Impact of Flooring Types on Exposures to Fine and Coarse Particles within the Residential Micro-Environment Using CONTAM. J. Expo. Sci. Environ. Epidemiol. 2016, 26, 86–94.

- Becher, R.; Øvrevik, J.; Schwarze, P.E.; Nilsen, S.; Hongslo, J.K.; Bakke, J.V. Do Carpets Impair Indoor Air Quality and Cause Adverse Health Outcomes: A Review. Int. J. Environ. Res. Public Health 2018, 15, 184.

- Nastasi, N.; Haines, S.R.; Xu, L.; da Silva, H.; Divjan, A.; Barnes, M.A.; Rappleye, C.A.; Perzanowski, M.S.; Green, B.J.; Dannemiller, K.C. Morphology and Quantification of Fungal Growth in Residential Dust and Carpets. Build. Environ. 2020, 174, 106774.

- Nastasi, N.; Renninger, N.; Bope, A.; Cochran, S.J.; Greaves, J.; Haines, S.R.; Balasubrahmaniam, N.; Stuart, K.; Panescu, J.; Bibby, K.; et al. Persistence of Viable MS2 and Phi6 Bacteriophages on Carpet and Dust. Indoor Air 2022, 32, e12969.

- ISO 12103-1:2016; Road Vehicles—Test Contaminants for Filter Evaluation—Part 1: Arizona Test Dust. International Organization for Standardization: Geneva, Switzerland, 2016.

- Ferro, A.R.; Kopperud, R.J.; Hildemann, L.M. Source Strengths for Indoor Human Activities That Resuspend Particulate Matter. Environ. Sci. Technol. 2004, 38, 1759–1764.

- Lewis, R.D.; Ong, K.H.; Emo, B.; Kennedy, J.; Kesavan, J.; Elliot, M. Resuspension of House Dust and Allergens during Walking and Vacuum Cleaning. J. Occup. Environ. Hyg. 2018, 15, 235–245.

- Corsi, R.L.; Siegel, J.A.; Chiang, C. Particle Resuspension During the Use of Vacuum Cleaners on Residential Carpet. J. Occup. Environ. Hyg. 2008, 5, 232–238.

- Qian, J.; Ferro, A.R. Resuspension of Dust Particles in a Chamber and Associated Environmental Factors. Aerosol Sci. Technol. 2008, 42, 566–578.

- Benabed, A.; Boulbair, A. PM10, PM2.5, PM1, and PM0.1 Resuspension Due to Human Walking. Air Qual. Atmos. Health 2022, 15, 1547–1556.

- Corn, M. The Adhesion of Solid Particles to Solid Surfaces Ii. J. Air Pollut. Control Assoc. 1961, 11, 566–584.

- Corn, M. The Adhesion of Solid Particles to Solid Surfaces, i. a Review. J. Air Pollut. Control Assoc. 1961, 11, 523–528.

- Wu, T.; Täubel, M.; Holopainen, R.; Viitanen, A.K.; Vainiotalo, S.; Tuomi, T.; Keskinen, J.; Hyvärinen, A.; Hämeri, K.; Saari, S.E.; et al. Infant and Adult Inhalation Exposure to Resuspended Biological Particulate Matter. Environ. Sci. Technol. 2018, 52, 237–247.

- Wu, T.; Fu, M.; Valkonen, M.; Taübel, M.; Xu, Y.; Boor, B.E. Particle Resuspension Dynamics in the Infant Near-Floor Microenvironment. Environ. Sci. Technol. 2021, 55, 1864–1875.

- Zhang, L.; Yao, M. Walking-Induced Exposure of Biological Particles Simulated by a Children Robot with Different Shoes on Public Floors. Environ. Int. 2022, 158, 106935.

- Salimifard, P.; Rim, D.; Gomes, C.; Kremer, P.; Freihaut, J.D. Resuspension of Biological Particles from Indoor Surfaces: Effects of Humidity and Air Swirl. Sci. Total Environ. 2017, 583, 241–247.

- Tian, Y.; Sul, K.; Qian, J.; Mondal, S.; Ferro, A.R. A Comparative Study of Walking-Induced Dust Resuspension Using a Consistent Test Mechanism. Indoor Air 2014, 24, 592–603.

- Rosati, J.A.; Thornburg, J.; Rodes, C. Resuspension of Particulate Matter from Carpet Due to Human Activity. Aerosol Sci. Technol. 2008, 42, 472–482.

- Zheng, S.; Zhang, J.; Mou, J.; Du, W.; Yu, Y.; Wang, L. The Influence of Relative Humidity and Ground Material on Indoor Walking-Induced Particle Resuspension. J. Environ. Sci. Health Part A Toxic Hazard. Subst. Environ. Eng. 2019, 54, 1044–1053.

More

Information

Subjects:

Engineering, Environmental

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.0K

Revisions:

2 times

(View History)

Update Date:

10 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No