Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Beata Piotrowska | -- | 1775 | 2023-01-04 11:16:31 | | | |

| 2 | Beatrix Zheng | Meta information modification | 1775 | 2023-01-05 01:50:54 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Piotrowska, B.; Słyś, D. Drain Water Heat Recovery Applications in Domestic Conditions. Encyclopedia. Available online: https://encyclopedia.pub/entry/39725 (accessed on 07 February 2026).

Piotrowska B, Słyś D. Drain Water Heat Recovery Applications in Domestic Conditions. Encyclopedia. Available at: https://encyclopedia.pub/entry/39725. Accessed February 07, 2026.

Piotrowska, Beata, Daniel Słyś. "Drain Water Heat Recovery Applications in Domestic Conditions" Encyclopedia, https://encyclopedia.pub/entry/39725 (accessed February 07, 2026).

Piotrowska, B., & Słyś, D. (2023, January 04). Drain Water Heat Recovery Applications in Domestic Conditions. In Encyclopedia. https://encyclopedia.pub/entry/39725

Piotrowska, Beata and Daniel Słyś. "Drain Water Heat Recovery Applications in Domestic Conditions." Encyclopedia. Web. 04 January, 2023.

Copy Citation

The use of energy from waste can be a key means of reducing the consumption of fossil fuels and thus reduction of greenhouse gas emissions. Waste energy can be a worthy alternative to conventional energy sources in construction.

waste heat

grey water

heat exchangers

technologies

1. General Classification of DWHR Units

Based on the amount of waste and the temperature, waste water from residential buildings can be divided into grey water and black water. Black water is characterized by a large amount of sullage and a relatively low temperature, usually ranging from 10 to 25 °C [1][2][3][4], which makes it less valuable as a source of heat waste. On the other hand, grey water is characterized by a much smaller amount of sullage and a higher temperature of about 18–50 °C [1][5]. Grey water is discharged from showers, bathtubs, washbasins, washing machines and dishwashers, while black water comes from toilet bowls and urinals. The definition and division of domestic waste water is included in the DIN-EN 12056-2 [6].

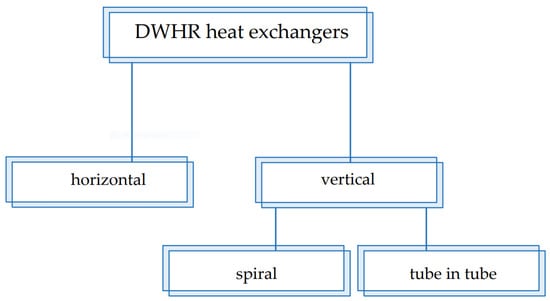

In the case of the sanitary installation, the design solution that does not include the separation of the system into drainage pipes for grey water and black water, drain water heat recovery (DWHR) exchangers can be used to preheat water at sanitary facilities. DWHR heat exchangers are the most commonly used in residential construction [7][8][9][10]. The division of this type of device is shown in Figure 1.

Waste heat exchangers are most often made of materials with good thermal conductivity, such as copper or aluminum, but there are also devices made of stainless steel or plastic, which are characterized by a much lower thermal conductivity [7][11].

2. Variants of Heat Exchanger Installation

Waste heat recovery at the residential building is possible: (i) individually, i.e., through the use of individual DWHR units located directly at the sanitary utensils, (ii) collectively, i.e., through the use of heat exchangers to which wastewater flows from several sanitary utensils [11].

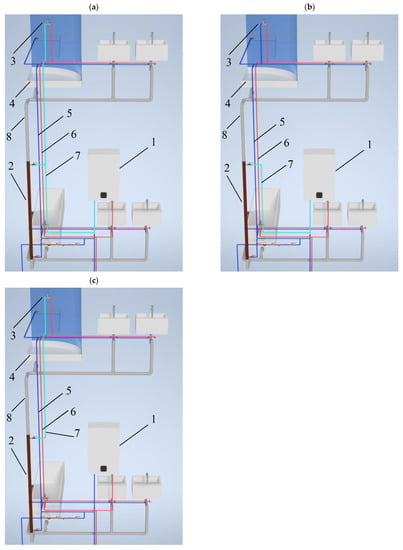

Heat exchangers intended for installation directly next to sanitary fittings can be installed according to various design variants that differ in their arrangement of planned cold water and heated water pipes (Figure 2) [9][12][13]. The following variants are distinguished: (i) Variant I, in which heated water flows to the water heater and the mixing valve (Figure 2a), (ii) Variant II, in which heated water flows only to the water heater (Figure 2b), (iii) Variant III, in which the pre-heated water is directed only to the mixing valve (Figure 2c). The adoption of a specific design variant of the heat recovery system determines the energy efficiency of the system [13][14][15][16]. Manouchehri and Collins [12] estimate that the energy efficiency of DWHR systems largely depends on the ratio of wastewater flow to water flow in the heat exchanger. It was determined [17] that Variant I of the system allows for maximizing the efficiency of energy recovery. In addition, Wehbi [18] emphasizes that part of the heat deposited in wastewater is lost already at the stage of its flow in the installation, which is important from the point of view of the efficiency of waste energy recovery. With this in mind, the water heater should be installed near the domestic hot water preparation system.

Figure 2. Examples of installation of a vertical heat exchanger: (a) Variant I—installation with DWHR heat exchanger and preheated water flowing to the water heater and shower mixing valve, (b) Variant II—installation with DWHR heat exchanger and preheated water flowing to the water heater, (c) Variant III—installation with DWHR heat exchanger and preheated water flowing to the shower mixing valve; 1—water heater, 2—DWHR heat exchanger, 3—shower mixing valve, 4—shower stall, 5—cold water pipe, 6—hot water pipe, 7—preheated water pipe, 8—waste stack.

3. DWHR Standards

In Poland and other EU countries, in accordance with Directive (EU) 2018/2001 [19], wastewater is considered a renewable energy source, but the use of wastewater as an alternative source of heat in the residential sector is not covered by specific legal regulations [20][21].

According to the California Statewide Codes and Standards Enhancement (CASE) report [22], there are currently no federal regulations related to the standardization of DWHR applications in residential buildings. However, it is worth noting that in Canada, DWHR technology is promoted by the US Department of Energy (DOE) [22] and is also recommended by the US Environmental Protection Agency (EPA) (ENERGY STAR program) as an optional energy saving tool [22]. However, there are documents standardizing the efficiency analysis of vertical heat exchangers. These are the standards CSA B55.1:20 [23] and IAPMO IGC 346-2017 [24], which define the requirements for tests of the efficiency of heat recovery and safety standards for horizontal and vertical DWHR units. These documents also standardize test conditions for experimental analyses of heat exchangers.

DWHR units should be designed to provide protection against possible contamination of tap water by wastewater; therefore, vertical tube-in-tube heat exchangers often have an additional center tube to provide protection in the event that the internal pipe is damaged and leaks. The use of twin wall construction in DWHR units should be in accordance with BS EN 1717:2000 [25].

The ability to reduce CO2 emissions as a result of using grey water heat recovery technology to preheat utility water has been recognized in the Standard Assessment Procedure (SAP) system of methods for the energy assessment of residential buildings, recommended by the UK government [26].

As emphasized by Pomianowski et al. [1], it is common experience that if a given technology is included in the calculations of the Standard Assessment Procedure, its market share becomes more and more significant.

Heat recovery from wastewater is not a common technology used [1]; however, it is possible to specify the countries in which DWHR waste energy collection systems operate, i.e., Canada, USA, Switzerland, Norway, Denmark and the Netherlands [1][18][27].

4. A Short Review of Published Studies

In developed and developing countries, domestic hot water consumption has increased over the last 20 years. In Denmark, the demand for hot water increased from 10 m3/year to about 15 m3/year per person [28]. In view of observed changes, it becomes obvious that improving the energy efficiency of domestic hot water production is a key topic for the development of modern, low-energy buildings [1].

On the example of a multi-family building located in Brazil, it was found that the use of a shower, where hot water is prepared in an electric heater, can consume as much as 32% of the total monthly electricity consumption [29].

Researches [30] carried out for exchangers placed separately, in series and in combination with a vertical and horizontal arrangement, allowed the estimation of energy recovery savings at the level of 30 to 35%. The authors observed that the turbulence of the flow has quite a large impact on the efficiency of heat recovery. The influence of the layer of slime accumulated in the exchanger (thickness 0.01 mm) after about 6 months of using the device was also analyzed. It was estimated that after this period, the efficiency of heat recovery decreased by 0.8%. The authors found an approximate payback period of about 3 years for a family of four, emphasizing that the return on investment depends on a number of individual operating conditions.

A study by De Paepe et al. [31] presented a system of heat recovery from dishwasher wastewater, in which the heated water was to be used to power the dishwasher. This system was based on the idea of retaining sewage in a tank with a spiral pipe through which cold water flowed. Research has shown that the proposed solution is technically, ecologically and economically justified.

Tomlinson [17] determined that the installation of a vertical heat exchanger in a residential building, depending on the average daily number of showers, saves electricity in the range of 800 kWh/year to 2300 kWh/year.

Bartkowiak [32] conducted research on a prototype of a plate heat exchanger installed at the shower outlet. The analyses carried out for various grey water volume flows and at variable temperatures of the flowing fluids showed the financial justification for the installation of the device, but also showed the environmental legitimacy of using heat exchangers resulting from the reduction of energy demand and CO2 emissions.

McNabola and Shields [33] presented a new design for a horizontal heat exchanger. The device consists of a grey water pipe made of plastic, inside which there is a cold water pipe made of copper or other material with good thermal conductivity. The plastic pipe for grey water is an insulator that retains the waste heat. The design of the new exchanger is characterized by a certain number of loops, thanks to which it is possible to maintain the appropriate length of the device for a satisfactory level of heat exchange. Research has shown that for the proposed structure, efficiency of up to 50% can be achieved.

Torras et al. [34] studied an exchanger in the form of a tank with a coil and grey water retention. The proposed system was able to recover between 34% and 60% of the available heat energy in grey water.

Research [35] on the justification of using a common DWHR unit for two separate showers in a residential building and the analysis of savings resulting from the use of different types of water heaters showed that the legitimacy of installing a DWHR unit for two separate showers depends on the unit prices of energy consumption. As energy prices increase, so does the benefit of using separate DWHR units. Single heat exchangers may be more cost-effective in facilities with a long cumulative lifetime of the heat recovery system.

Analysis of the financial efficiency [36] of the heat exchanger installation depending on the method of hot water preparation showed that the type of hot water heater has a decisive influence on the profitability of the investment. Analyses conducted in Poland in 2017 proved that the use of heat recovery technology is particularly profitable when using electric heaters.

Research conducted by Manouchehri and Collins [37] showed that changes in the efficiency of waste heat collection from grey water depend mainly on the temperature of the flowing fluids and occur independently of the physical parameters characterizing the device.

Using the investment risk assessment method [38], it was found that the increase in financial results is achieved with the increase in the time of use of the shower installation and water consumption.

Analyses conducted at the Canadian Center for Housing Technology [39] confirmed that energy savings for the preparation of hot domestic water increase with the increase in the amount of outflowing sewage, but also depend on the temperature of the incoming cold utility water.

The results of the financial analysis carried out by Stec [40] show that the installation of a heat exchanger in an installation in which pre-heated water is supplied to the shower mixing valve can reduce the energy consumption needed to prepare domestic hot water by about 30% compared to a system that does not uses a heat exchanger unit.

References

- Pomianowski, M.Z.; Johra, H.; Marszal-Pomianowska, A.; Zhang, C. Sustainable and energy-efficient domestic hot water systems: A review. Renew. Sustain. Energy Rev. 2020, 128, 109900.

- Cipolla, S.S.; Maglionico, M. Heat recovery from urban wastewater: Analysis of the variability of flow rate and temperature in the sewer of Bologna, Italy. Energy Procedia 2014, 45, 288–297.

- Chudzicki, J.; Sosnowski, S. Instalacje Kanalizacyjne. Projektowanie, Wykonanie, Eksploatacja. Wydanie Trzecie; Wydawnictwo Seidel-Przywecki: Warszawa, Poland, 2011.

- Juan, Y.K.; Chen, Y.; Lin, J.M. Greywater reuse system design and economic analysis for residential buildings in Taiwan. Water 2016, 8, 546.

- Oteng-Peprah, M.; Acheampong, M.A.; de Vries, N.K. Greywater Characteristics, Treatment Systems, Reuse Strategies and User Perception—A Review. Water Air Soil Pollut. 2018, 229, 255.

- DIN-EN 12056-2; Gravity Drainage Systems Inside Buildings—Part 2: Sanitary Pipework, Layout and Calculation. British Standards Institution: London, UK, 2001.

- Vavricka, R.; Bohac, J.; Matuska, T. Experimental development of the plate shower heat exchanger to reduce the domestic hot water energy demand. Energy Build. 2022, 254, 111536.

- Kordana, S. SWOT analysis of wastewater heat recovery systems application. In Proceedings of the 9th Conference on Interdisciplinary Problems in Environmental Protection and Engineering EKO-DOK, Boguszow-Gorce, Poland, 23–25 April 2017.

- Kimmels, A. Shower Heat Recovery Systems. Meander Heat Recovery. Available online: http://www.meanderhr.com/report/meanderhr_com_shower_dwhr_overview.pdf (accessed on 1 September 2022).

- Marszal-Pomianowska, A.; Jensen, R.L.; Pomianowski, M.; Larsen, O.K.; Jørgensen, J.S.; Knudsen, S.S. Comfort of Domestic Water in Residential Buildings: Flow, Temperature and Energy in Draw-Off Points: Field Study in Two Danish Detached Houses. Energies 2021, 14, 3314.

- Nagpal, H.; Spriet, J.; Murali, M.; McNabola, A. Heat Recovery from Wastewater—A Review of Available Resource. Water 2021, 13, 1274.

- Manouchehri, R.; Collins, M.R. Investigating the Impact of Plumbing Configuration on Energy Savings for Falling-Film Drain Water Heat Recovery Systems. Energies 2022, 15, 1141.

- Kordana-Obuch, S.; Starzec, M.; Słyś, D. Assessment of the Feasibility of Implementing Shower Heat Exchangers in Residential Buildings Based on Users’ Energy Saving Preferences. Energies 2021, 14, 5547.

- Mazhar, A.; Liu, S.; Shukla, A. A key review of non-industrial greywater heat harnessing. Energies 2018, 11, 386.

- Piotrowska, B.; Słyś, D.; Kordana-Obuch, S.; Pochwat, K. Critical Analysis of the Current State of Knowledge in the Field of Waste Heat Recovery in Sewage Systems. Resources 2020, 9, 72.

- Collins, M.R.; van Decker, G.W.E.; Murray, J. Characteristic effectiveness curves for falling-film drain water heat recovery systems. HVACR Res. 2013, 19, 649–662.

- Tomlinson, J. Heat Recovery from Wastewater Using a Gravity-Film Heat Exchanger. Federal Energy Management Program, Department of Energy, Washington, DC, USA, 2005. Available online: http://gfxtechnology.com/Femp-ORNL.pdf (accessed on 29 November 2022).

- Wehbi, Z.; Taher, R.; Faraj, J.; Ramadan, M.; Castelain, C.; Khaled, M. A short review of recent studies on wastewater heat recovery systems: Types and applications. Energy Rep. 2022, 8, 896–907.

- Directive (EU) 2018/2001 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=LEGISSUM:4372645 (accessed on 25 November 2022).

- Ratajczak, K.; Michalak, K.; Narojczyk, M.; Amanowicz, Ł. Real Domestic Hot Water Consumption in Residential Buildings and Its Impact on Buildings’ Energy Performance—Case Study in Poland. Energies 2021, 14, 5010.

- Niewitecka, K. Possibilities of heat energy recovery from greywater systems. The First Conference of the International Water Association IWA for Young Scientist in Poland “Water, Wastewater and Energy in Smart Cities”. ES3 Web Conf. 2018, 30, 03003.

- 2019-RES-DHW2-F; Codes and Standards Enhancement (CASE) Initiative, California Building Energy Efficiency Standards Drain Water Heat Recovery—Final Report; Residential Plumbing. 2017. Available online: https://title24stakeholders.com/wp-content/uploads/2017/09/2019-T24-CASE-Report_DWHR_Final_September-2017.pdf (accessed on 15 December 2022).

- CSA. B55.1-15; Test Method for Measuring Efficiency and Pressure Loss of Drain Water Heat Recovery Units. Canadian Standards Association: Mississauga, ON, Canada, 2015.

- IAPMO IGC 346-2017; Test Method for Measuring the Performance of Drain Water Heat Recovery Units. IAPMO: Ontario, CA, USA, 2017.

- BS EN 1717:2000; Protection Against Pollution of Potable Water in Water Installations and General Requirements of Devices to Prevent Pollution by Backflow. BSI Standards Publication: London, UK, 2000.

- Ip, K.; She, K. Waste heat recovery from showers: Case study of a university sport facility in the UK. Water Effic. Conf. 2016, 114–121. Available online: http://www.watefnetwork.co.uk/files/default/resources/Conference2016/WatefCon2016_Proceedings.pdf (accessed on 4 December 2022).

- Danish Energy Agency. Regulation and Planning of District Heating in Denmark; Danish Energy Agency: København, Denmark, 2016; p. 27.

- Bøhm, B.; Schrøder, F.; Bergsøe, N.C. Varmt Brugsvand—Måling af Forbrug og Varmetab fra Cirkulationsledninger; SBI Forlag: Hoersholm, Denmark, 2009.

- Prado, R.T.A.; Gonçalves, M. Water heating through electric shower and energy demand. Energy Build. 1998, 29, 77–82.

- Peereboo, P.W.E.; Visser, J.C. Recovering heat from shower water in dwellings. In Proceedings of the CIBW062 Symposium on Water Supply and Drainage for Buildings, Sydney, Australia, 8-10 November 1998.

- de Paepe, M.; Theuns, E.; Lenaers, S.; van Loon, J. Heat recovery system for dishwashers. Appl. Therm. Eng. 2003, 23, 743–756.

- Bartkowiak, S.; Fisk, R.; Funk, A.; Hair, J.; Skerlos, S.J. Residential drain water heat recovery systems: Modeling, analysis, and implementation. J. Green Build. 2010, 5, 85–94.

- McNabola, A.; Shields, K. Efficient drain water heat recovery in horizontal domestic shower drains. Energy Build. 2013, 59, 44–49.

- Torras, S.; Oliet, C.; Rigola, J.; Oliva, A. Drain water heat recovery storage-type unit for residential housing. Appl. Therm. Eng. 2016, 103, 670–683.

- Kordana, S. An assessment of the potential for shower water heat recovery. E3S Web Conf. 2018, 45, 00034.

- Kordana, S.; Słyś, D. Analysis of profitability of using a heat recovery system from grey water discharged from the shower (case study of Poland). E3S Web Conf. 2017, 22, 00085.

- Manouchehri, R.; Collins, M.R. An experimental analysis of the impact of temperature on falling film drain water heat recovery system effectiveness. Energy Build. 2016, 130, 1–7.

- Słyś, D.; Kordana, S. Financial analysis of the implementation of a Drain Water Heat Recovery unit in residential housing. Energy Build. 2014, 71, 1–11.

- Zaloum, C.; Gusdorf, J.; Parekh, A. Drainwater Heat Recovery Performance Testing at Canadian Centre for Housing Technology; Technical Series, CCHT, 07-116; Canada Mortgage and Housing Corporation: Ottawa, ON, Canada, 2007.

- Stec, A.; Kordana, S. Analysis of profitability of rainwater harvesting, gray water recycling and drain water heat recovery systems. Resour. Conserv. Recycl. 2015, 105, 84–94.

More

Information

Subjects:

Engineering, Environmental

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.4K

Revisions:

2 times

(View History)

Update Date:

05 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No