Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ramalingam Senthil | -- | 1374 | 2023-01-03 04:32:03 | | | |

| 2 | Conner Chen | -106 word(s) | 1268 | 2023-01-03 07:43:15 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Vedulla, G.; Geetha, A.; Senthil, R. Features of Solar Photovoltaic Modules and Systems. Encyclopedia. Available online: https://encyclopedia.pub/entry/39672 (accessed on 07 February 2026).

Vedulla G, Geetha A, Senthil R. Features of Solar Photovoltaic Modules and Systems. Encyclopedia. Available at: https://encyclopedia.pub/entry/39672. Accessed February 07, 2026.

Vedulla, Gowtham, Anbazhagan Geetha, Ramalingam Senthil. "Features of Solar Photovoltaic Modules and Systems" Encyclopedia, https://encyclopedia.pub/entry/39672 (accessed February 07, 2026).

Vedulla, G., Geetha, A., & Senthil, R. (2023, January 03). Features of Solar Photovoltaic Modules and Systems. In Encyclopedia. https://encyclopedia.pub/entry/39672

Vedulla, Gowtham, et al. "Features of Solar Photovoltaic Modules and Systems." Encyclopedia. Web. 03 January, 2023.

Copy Citation

Solar systems are designed to maximize energy generation with abundantly available solar energy. As a result, the properties of photovoltaic (PV) systems are permanent, and some of these qualities may lead to soiling loss, especially if regular cleaning regimes are not meticulously followed.

solar energy

photovoltaics (PV)

dust

soiling

performance degradation

1. Tilt Angle and Orientation

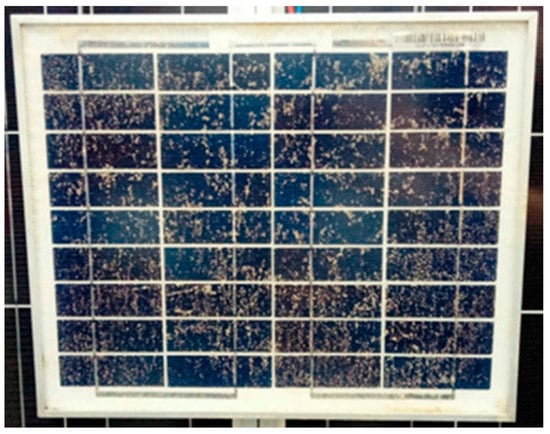

Salim et al. [1] constructed a photovoltaic (PV) testing system in Saudi Arabia to examine the effects of dust particle accumulation over time on PV power generation. The system’s monthly output power reduction was calculated by comparing its performance in the clean range to a tilt angle with a fixed value of 24.6°. After eight months, the reduction in energy production reached 32%. However, this inquiry did not reveal the physical characteristics of the PV system at the test site. The energy obtained from dirty solar panels diminishes over a period leading to a fall in efficiency because dust and dirt block solar radiation affecting output power. The experiment conducted by Hassan et al. [2] demonstrated that power output decreased within the first 30 days of exposure to dust. Without proper PV panel cleaning, the output capacity decreased by 33.5% after one month and by 65.8% after six months. Sayigh et al. [3] found that after 38 days of exposure to the atmosphere with 0°, 15°, 30°, and 45° tilt angles, dust-covered glass panels’ transmission had decreased by 64%, 48%, 30%, and 17%, respectively. Figure 1 shows the actual views of dust accumulated solar PV panels [4].

Figure 1. Actual photographic view of dust accumulation density of 13.2 g/m2 [4].

El-Shobokshy and Hussein [5] examined the PV exteriors that had been tarnished with various sorts of dirt and gauged the power of the PV cells under various conditions. The most important factor to be considered is that all PV surfaces are contaminated at low air velocities [6][7]. Hottel and Woertz [8] performed a three-month performance examination of collectors with tilt angles of 30° exposed to dust from four-track railroads as they were in an industrial area close to the PV power plant. On examining the dust accumulation on the collector, it was noted that the net capacity was significantly lower (4.7%) than expected, while forecasts reported a maximum reduction in glass transmission of 2.7%. They referred to these lower values as indicating a degradation in performance, which was attributed to soiling by snow and rain in Boston, USA, while recommending the use of self-cleaning of solar collectors. Similarly, dust build-up on the surfaces of solar PV panels raises maintenance costs and cleaning expenses [9]. According to Michalsky et al. [10], enough data must be available to develop efficient solar PV systems that consider dust collection and removal measures.

All PV modules should face south for optimal power production in the northern hemisphere. PV modules in the southern hemisphere must be oriented north of the equator. This placement ensures that the PV modules are exposed to intense sunlight for a prolonged duration to maximize solar energy collection. Elminir et al. [11] investigated the relationship between dust accumulation and the orientation and tilt angle of the PV module. They concluded that glass samples in the northeast collected more dust than samples in other directions. This was due to the wind blowing in the study area, bringing in emissions from the nearby manufacturing manufacturers. The analysis showed that dust density and surface orientation significantly impacted the typical solar transmission efficiency of the PV glass and reduced power generation efficiency. The transmission was estimated to be reduced by 52.54 to 12.38 percent when the dust density ranged from 15.84 to 4.48 g/m2. A decrease in inclination angle and an increase in dust deposition led to a large reduction in solar PV transmittance. A significant decrease in transmittance was seen with an inclination angle of 150 degrees and a 450-degree north orientation. The northeast winds blew in small particles from different sources, primarily from the emissions of cement manufacturing industries, and this particulate matter accumulated on the glass plates.

2. Glazing Surface Characteristics

Airborne dust on external surfaces of solar system modules lowers solar cell glazing transmittance and significantly reduces PV module output efficiency. Mustafa et al. [12] experimentally tested the output reduction of several solar modules with component surface impacted by dust deposition from air pollution. The experiments were conducted on a continuous basis under controlled settings. The results of the study revealed that dust contamination had a considerable effect on the output generation of the solar system. As dust density increased from 0 to 22 g−2, PV productivity decreased by up to 26%. The relation between energy capacity reduction and variation in deposition due to PV cell types was unclear.

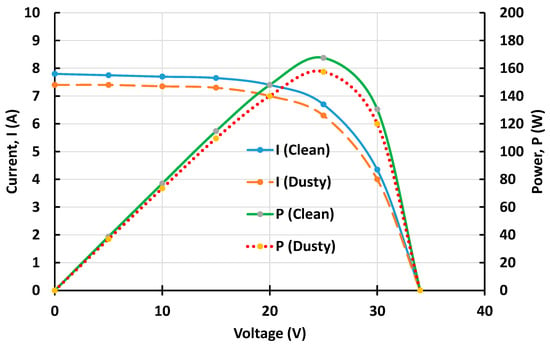

Semaoui et al. [13] considered the energy production obtained from PV modules connected in series in the desert areas of Algeria. A 32% decrease in PV output was observed due to the deposition of dust over 8 months. The reduced reduction in solar PV performance was noted to be 10% in the sunny season and 6% in the cold season. Dusty panels blocked the solar radiation by 60–70% of its initial value if there was no cleaning of solar PV modules for a year [14]. A one-year experiment was conducted by Hegazy [15] in central Egypt at a desert temperature. The solar panel tilt angle was found to be the most influential factor for dust deposition among the other factors, such as the time of exposure and site climatic conditions. After 10 days of exposure, researchers in Roorkee observed that dust and other pollutants deposited over a glass plate tilted at 45 degrees reduced solar transmittance by 8% [16]. The tilt angles of solar panels and solar coverage rate results were studied by Elminir et al. [11]. With an inclination angle of 0 to 60°, and varied concentrations of dust deposition on PV panels, the equivalent transfer power output was reduced from 52.54% to 12.38%. Figure 2 shows the outdoor dust deposition testing research infrastructure [4]. Figure 3 shows the power output variation of solar PV surfaces with and without dust [4].

Figure 2. Outdoor PV panel testing facility with clean and dusty panels [4].

Figure 3. The variation of PV output power for clean and dusty solar panels [4].

The grouping of common outdoor atmospheric dust that accumulates on components of PV systems is shown in detail in Figure 4, based on particle size. The influence of dust on the transmission of different polished materials was investigated in the arid climatic condition of the Thar desert (India) [17]. The glass transmission decrease was noted to be 19.17%, 13.81%, and 5.67% for the respective 0°, 45°, and 90° tilt angles. The decrease in the acrylic light transfer was 23%, 13.98%, and 8.29% for the 0°, 45°, and 90° tilt angles, respectively. According to Mastekbayeva [18], the solar system performance was affected by the glazing’s ability to transmit solar radiation. The effect of dust deposition on the solar radiation transmittance of low-density polyethylene glazing with a thickness of 0.2 mm was assessed.

Figure 4. Most normal open-air dust molecule sources and their trademark components.

3. Height of Solar Panel

The height at which a solar power plant is installed determines the quantity of soiling on its surface. As the panel’s installation height is raised, dust deposition may be reduced. Quang et al. [19] investigated the profiles of dust particle density close to the metro lines. Researchers found that the dust concentration was lower for panels located 5 m above the ground because of automobile exhaust pollution. Ambient particulate matter (PM10) dust concentration and dust deposition were reported by McGowan et al. [20]. For panels located under a height of 5 m, PM10 concentrations peaked at around 125 µg/m3; at about 100 m, they dropped to 95 µg/m3. The air traveling over deployed PV modules diminishes the dust deposition since wind velocity increases with height [21]. Beattie et al. [22] tested PV modules indoors under controlled conditions. The height of the panel arrangement was altered due to nonlinearity, and it was discovered that as the height increased, the dust deposition on panel surfaces reduced.

References

- Salim, A.; Huraib, F.S.; Eugenio, N.N. PV power-study of system options and optimization. In EC Photovoltaic Solar Conference; Kluwer Academic Publishers: Dordrecht, The Netherlands; Boston, MA, USA; London, UK, 1988; Volume 8, pp. 688–692.

- Hassan, A.H.; Rahoma, U.A.; Elminir, H.K.; Fathy, A.M. Effect of airborne dust concentration on the performance of PV modules. J. Astron. Soc. Egypt 2005, 13, 24–38.

- Sayigh, A.A.M.; Al-Jandal, S.; Ahmed, H. Dust Effect on Solar Flat Surfaces Devices in Kuwait. In Proceedings of the Workshop on the Physics of Non-Conventional Energy Sources and Materials Science for Energy, Triest, Italy, 2–20 September 1985; pp. 353–367.

- Alonso-Montesinos, J.; Martínez, F.R.; Polo, J.; Martín-Chivelet, N.; Batlles, F.J. Economic effect of dust particles on photovoltaic plant production. Energies 2020, 13, 6376.

- El-Shobokshy, M.S.; Hussein, F.M. Effect of dust with different physical properties on the performance of photovoltaic cells. Sol. Energy 1993, 51, 505–511.

- Rudnicka, M.; Klugmann-radziemska, E. Soiling effect mitigation obtained by applying transparent thin-films on solar panels: Comparison of different types of coatings. Materials 2021, 14, 964.

- Goossens, D.; Van Kerschaever, E. Aeolian dust deposition on photovoltaic solar cells: The effects of wind velocity and airborne dust concentration on cell performance. Sol. Energy 1999, 66, 277–289.

- Hottel, H.; Woertz, B. Performance of flat-plate solar-heat collectors. ASME (Am. Soc. Mech. Eng.) 1942, 64, 91–104.

- Wang, P.; Yan, X.; Zeng, J.; Luo, C.; Wang, C. Antireflective superhydrophobic coatings with excellent durable and Self-cleaning properties for solar cells. Appl. Surf. Sci. 2022, 602, 154408.

- Michalsky, J.J.; Perez, R.; Stewart, R.; LeBaron, B.A.; Harrison, L. Design and development of a rotating shadow band radiometer solar radiation/daylight network. Sol. Energy 1988, 41, 577–581.

- Elminir, H.K.; Ghitas, A.E.; Hamid, R.H.; El-Hussainy, F.; Beheary, M.M.; Abdel-Moneim, K.M. Effect of dust on the transparent cover of solar collectors. Energy Convers. Manag. 2006, 47, 3192–3203.

- Mustafa, R.J.; Gomaa, M.R.; Al-Dhaifallah, M.; Rezk, H. Environmental impacts on the performance of solar photovoltaic systems. Sustainability 2020, 12, 608.

- Semaoui, S.; Arab, A.H.; Boudjelthia, E.K.; Bacha, S.; Zeraia, H. Dust Effect on Optical Transmittance of Photovoltaic Module Glazing in a Desert Region. Energy Proc. 2015, 74, 1347–1357.

- El-Nashar, A.M. The effect of dust accumulation on the performance of evacuated tube collectors. Sol. Energy 1994, 53, 105–115.

- Hegazy, A.A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 2001, 22, 525–540.

- Garg, H.P. Effect of dirt on transparent covers in flat-plate solar energy collectors. Sol. Energy 1974, 15, 299–302.

- Nahar, N.M.; Gupta, J.P. Effect of dust on transmittance of glazing materials for solar collectors under arid zone conditions of India. Solar Wind Technol. 1990, 7, 237–243.

- Mastekbayeva, G.A.; Kumar, S. Effect of dust on the transmittance of low density polyethylene glazing in a tropical climate. Sol. Energy 2000, 68, 135–141.

- Quang, T.N.; He, C.; Morawska, L.; Knibbs, L.D.; Falk, M. Vertical particle concentration profiles around urban office buildings. Atmos. Chem. Phys. 2012, 12, 5017–5030.

- McGowan, H.A.; Clark, A. A vertical profile of PM10 dust concentrations measured during a regional dust event identified by MODIS Terra, western Queensland, Australia. J. Geophys. Res. 2008, 113, 1–10.

- Cano, J.; John, J.J.; Tatapudi, S.; TamizhMani, G. Effect of tilt angle on soiling of photovoltaic modules. In Proceedings of the IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 3174–3176.

- Beattie, N.S.; Moir, R.S.; Chacko, C.; Buffoni, G.; Roberts, S.H.; Pearsall, N.M. Understanding the effects of sand and dust accumulation on photovoltaic modules. Renew. Energy 2012, 48, 448–452.

More

Information

Subjects:

Energy & Fuels

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

03 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No