You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Tonni Agustiono Kurniawan | -- | 1890 | 2022-12-22 09:30:32 | | | |

| 2 | Amina Yu | + 1 word(s) | 1891 | 2022-12-23 01:42:34 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kurniawan, T.A.; Othman, M.H.D.; Liang, X.; Ayub, M.; Goh, H.H.; Kusworo, T.D.; Mohyuddin, A.; Chew, K.W. Microbial Fuel Cells. Encyclopedia. Available online: https://encyclopedia.pub/entry/39070 (accessed on 22 December 2025).

Kurniawan TA, Othman MHD, Liang X, Ayub M, Goh HH, Kusworo TD, et al. Microbial Fuel Cells. Encyclopedia. Available at: https://encyclopedia.pub/entry/39070. Accessed December 22, 2025.

Kurniawan, Tonni Agustiono, Mohd Hafiz Dzarfan Othman, Xue Liang, Muhammad Ayub, Hui Hwang Goh, Tutuk Djoko Kusworo, Ayesha Mohyuddin, Kit Wayne Chew. "Microbial Fuel Cells" Encyclopedia, https://encyclopedia.pub/entry/39070 (accessed December 22, 2025).

Kurniawan, T.A., Othman, M.H.D., Liang, X., Ayub, M., Goh, H.H., Kusworo, T.D., Mohyuddin, A., & Chew, K.W. (2022, December 22). Microbial Fuel Cells. In Encyclopedia. https://encyclopedia.pub/entry/39070

Kurniawan, Tonni Agustiono, et al. "Microbial Fuel Cells." Encyclopedia. Web. 22 December, 2022.

Copy Citation

The intensive energy requirement of conventional wastewater treatment for aeration demands an alternative technological option that requires less energy for its operation. Due to its cost-effectiveness, biological processes such as activated sludge have been widely used for wastewater treatment. However, this technique depends on the ability of bacterial population to maintain acceptable effluent quality. If the treatment is interfered with, the bacterial population respond to the varying influents. When this occurs, exceeding effluent limits lead to environmental damage and costly fines. Consequently, treatment facilities have to be overhauled, resulting in a loss of time and financial resources.

carbon neutrality

circular economy

decarbonization

1. Mechanism of Electricity Generation by Microbial Fuel Cell (MFC)

Scientific exploration in MFC results from its ability to operate at varying weather and pressure using Geobacter sulphurreducens that form biofilms onto electrodes. The biofilms promote electron flows to electrodes and release a c-type cytochrome that accumulates at the biofilm–electrode interface to promote electron transfer to electrodes [1]. The bacteria attached with the MFCs remove the need to isolate costly enzymes, as they provide inexpensive substrates for its operations. The process occurs in a small bioreactor, where the microbes are retained in stable conditions for a period of time as biofilms, thus saving operational and maintenance (O&M) costs [2].

An MFC acts a battery-like energy generator that produces electricity through an electrochemical process. As MFCs convert chemical energy directly into electricity, they have the potential to operate at high efficiency. By exploiting their electron transfer abilities, MFCs produce energy directly, without combusting the organic compounds in wastewater, while treating them without requiring traditional energy. This facilitates users to comply with their obligations at a lower cost. However, it has the same ability to eliminate organic matter as efficiently as conventional wastewater treatment plants do [3].

An MFC is dependent on biofilms for electron transfer. When it is used, a large surface area is required to accumulate on the anode’s chamber. It is important to develop bioelectrodes with capability of resisting fouling. A key to the disparity lies in the fact that MFCs must operate at neutral pH in the anode chamber to maximize growth and activity of the micro-organisms that catalyze the reactions. At the cathode, OH− causes an increasing pH due to the limiting rate of their transport. Furthermore, every unit of pH increase at the cathode leads to an energy loss of 59 mV [3]. The cathode’s pH could reach pH > 12, implying a major loss [4]. To ensure that they do not re-mix, the membrane is placed to separate the electrode from the other, while ensuring that there is no leakage from the cell’s assembly [5].

By harnessing bacterial metabolism for energy generation that can be sold to produce income for wastewater treatment operators, the income not only defrays the cost of MFC operations, but also keeps on enhancing its prototype design for operations. The power produced by the MFC’s operation supplies the need for energy, while the value of energy produced by the MFC creates a jobs. Decentralized electricity production also makes cities livable, with low-voltage applications that could be powered using MFCs, supplying a sustainable energy system for water treatment [6]. This provides an affordable and practical way to operate the system for a decentralized process using a wide range of wastewater for water reuse and energy supply [7].

MFCs are eco-friendly because they produce far fewer CO2 emissions. Furthermore, MFCs can continuously generate electricity as long as the fuel and the oxidant are provided to the cell. As the fuel in the cells is stored externally, it is not internally depleted. Hence, the MFC is ideal, as the device does not have moving parts, making it a reliable source of power [8].

With this paradigm in mind, researchers aim at developing an anaerobic MFC with efficient electrodes that can be used to generate electricity from wastewater, while at the same time treating it with a minimum amount of waste generated during its operation. In the short-term, the MFC represents a temporary solution to the unresolved issue of providing energy to undeveloped areas without requiring changes to existing network facilities. By using bioenergy from MFCs, GHG emissions can be reduced substantially. It would be an important breakthrough in the field of energy recovery if energy produced from MFCs could be integrated into electricity networks. Successful operation of MFCs can open the door to their commercialization and deployment. Although the systems are promising in generating clean energy, there are improvements needed to enable their widespread application to attain carbon neutrality [9].

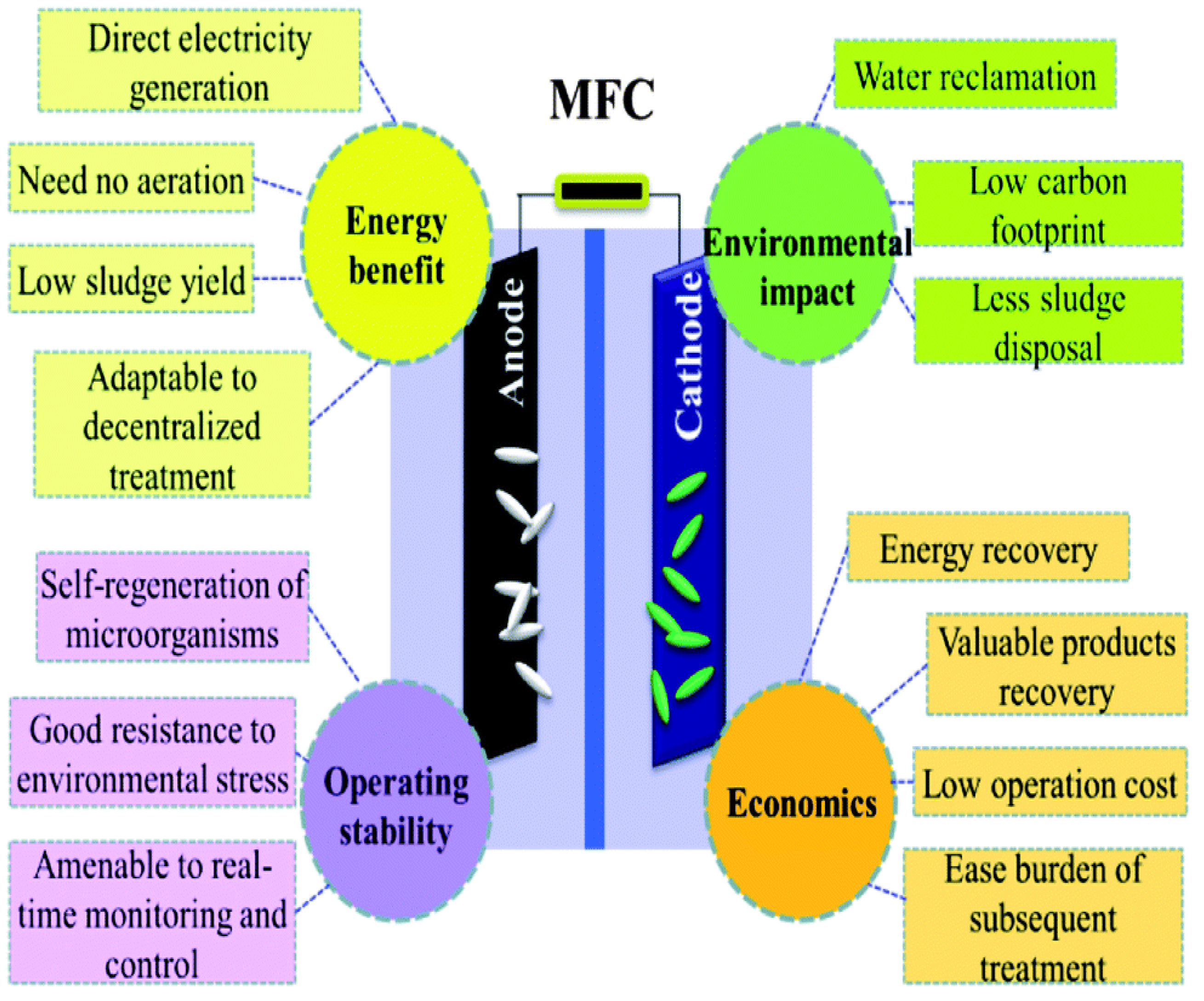

MFC utilization contributes to sustainability such as by GHG emission reduction, energy generation, and reduction of carbon footprints. When applying a certain voltage to bacteria for biodegradation of organic pollutants, this leads to water electrolysis, generating H2 from the wastewater (Figure 1). To contribute to decarbonization, MFC can reverse the process by producing hydrogen (H2). One metric ton of H2 contains 33.3 MW·h of clean energy [10]. Hydrogen may be the safest gas known with high diffusion rate for CO2, and it burns in air to form water. For a sustainable zero-emission energy and carbon-neutral future, hydrogen is considered a next-generation source of energy, which has potential to replace fossil fuels such as oil, gas, and coal. The annual production of clean hydrogen, a low-carbon energy carrier, would need to increase more than sevenfold for the world to hit net-zero emissions in 2050.

Figure 1. Unique selling points of MFC.

Energy production in the recovered H2 would help industries offset the treatment costs of wastewater. This decarbonization strategy is more beneficial than landfill gas (LFG) that not only generates a bad odor, but also contains CH4 that contributes to climate change. As society is benefited from technological revolutions, using H2 gas as a fuel benefits it in the long-term. Unlike fossil fuels, during its production, H2 does not emit CO2 into the atmosphere, reducing environmental impacts and protecting the environment [11].

As compared to natural gas that takes millions of years to develop, hydrogen or electricity can be produced on-site by MFCs for a relatively short time with much less CO2 emission. This provides net GHG savings with respect to carbon neutrality. As compared to MFCs, hydrogen production from the extraction of natural gas contributes 2% to all anthropogenic CO2 emissions into the atmosphere, accelerating climate change. With the hydrogen being produced originating from fossil fuels, there is a growing need for a cleaner and more environmentally friendly option for its production.

For this reason, the world needs to achieve carbon neutrality between 2050 and 2070 by accelerating the energy transition to achieving a low-carbon and sustainable energy system. Measures to address climate change have shifted course toward achieving carbon neutrality by 2050. In 2020, the EU unveiled a long-term strategy with a firm commitment to climate neutrality by 2050. The roadmap toward decarbonization society has begun not only in Japan, China and Korea, but also in Indonesia and Malaysia. This movement will inevitably lead to carbon neutrality in other countries [12].

2. Technological Strengths of MFC

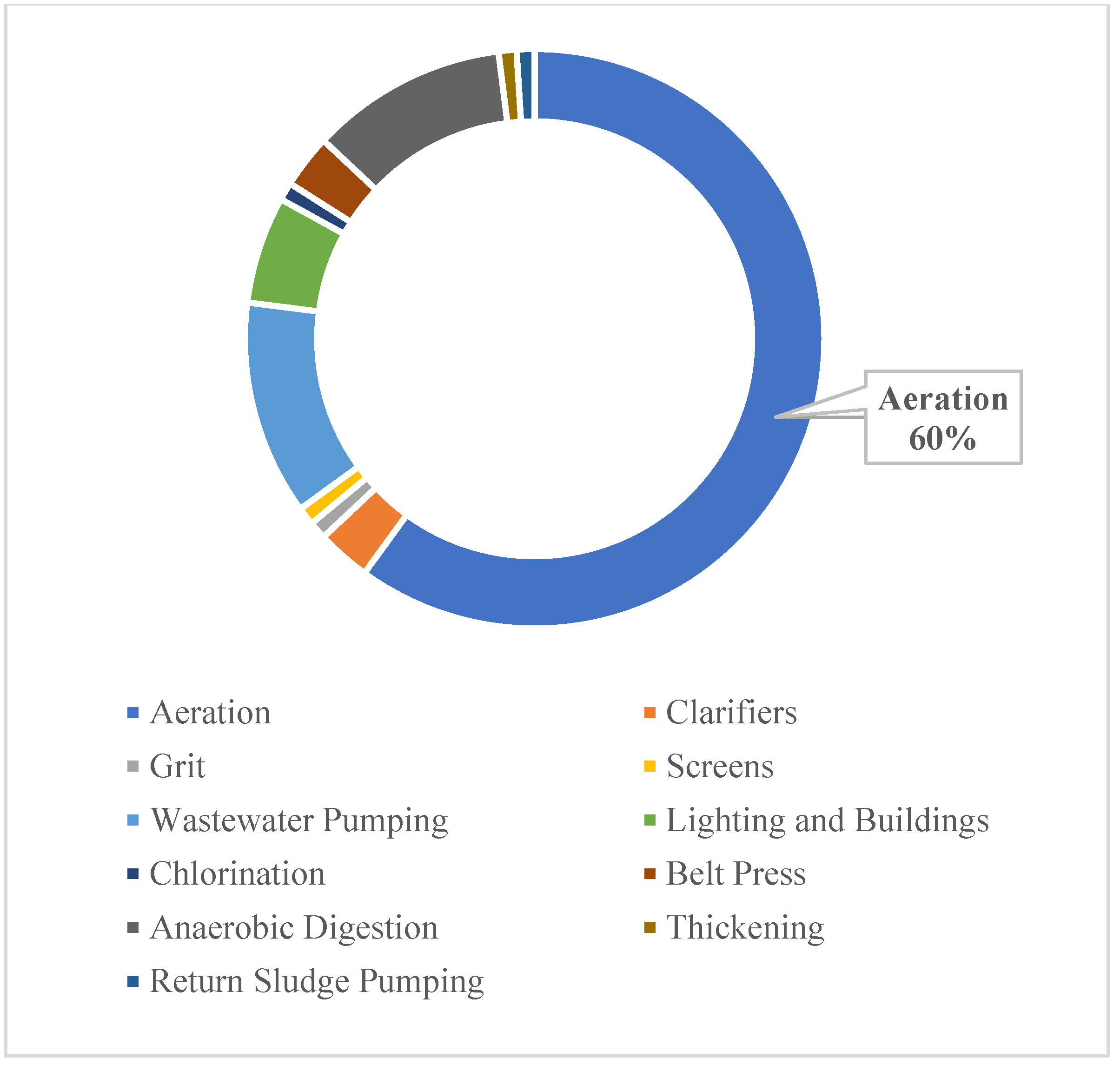

Traditionally, wastewater treatment is costly due to energy consumption. In an aerobic process, existing conventional technology using activated sludge consumes 60% of energy for aeration (Figure 2). The air cathode of an MFC uses oxygen directly from air, lowering energy consumption cost. MFCs also reduce treatment cost by producing electricity on-site to power plant’s operation. MFCs can efficiently operate at ambient temperature with low strength of wastewater, and yields less solids to be disposed of in landfills, making it economically attractive compared to existing water technologies [13].

Figure 2. Energy consumption in activated sludge.

Unlike activated sludge, MFC-based treatment has the potential to treat wastewater without aeration, but through the growth of bacteria while generating bioenergy. Although the idea of generating energy using bacteria may not be new, as a practical technology of energy production, MFC utilization is promising. As a by-product of MFC operations, electricity justifies the cost of operating this system by itself [14]. By assuming that continuous operations of MFCs reach 15 Watts/m3 of wastewater flowing through it, if an MFC system is installed at a wastewater treatment plant for 5000 inhabitants, it produces 0.75 MW, enough to power about 500 homes [15].

When calculating the price/Watt installed, power output/m2 and MFC’s lifespan are important. As MFC’s power outputs range from 0.25 to 3.75 W/m2, the price/Watt installed at its lower limit is over USD 4000 [16]. If the higher limit is applied, the price would decrease to USD 30/m2, less than USD 6/Watt, including operations and maintenance costs [17]. If electrochemical techniques progress and the price of electrodes decrease, this treatment method can convert organic materials of wastewater into electricity.

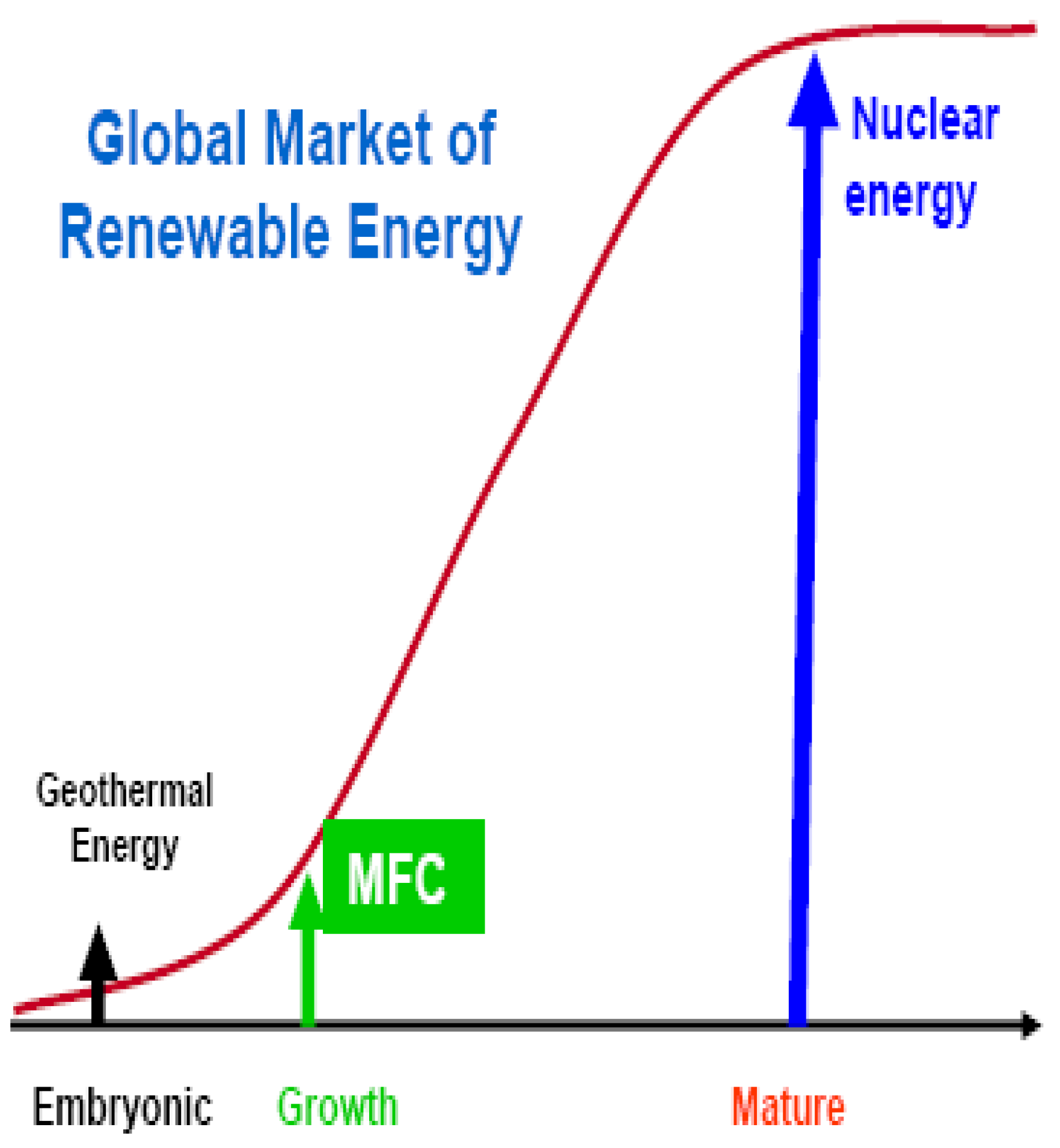

However, the removal of contaminants in wastewater at zero energy cost would warrant the use of MFCs for this goal. MFC technology reflects a frontier science. So far, only a few works have been translated into a practical configuration using an affordable and suitable material. An MFC reactor, designed with low-cost and compatible biomaterials for bioelectricity production, paves the way forward for industrial application in the next stage (Figure 3). This technology is expected to lead to another necessary step toward achieving carbon neutrality.

Figure 3. MFC among renewable energy.

Herein, well-designed and cost-effective MFC technology is essential to accelerating electrification in the developing world. If enacted swiftly, favorable climate technology and energy policy could level the playing field between electricity and other power sources. This will encourage the adoption of sustainable technologies, leading to less consumption of polluting fossil fuels.

Principally, anaerobic MFCs are capable of generating electricity from municipal wastewater and treating wastewater with low oxygen requirements using cost-effective and ecofriendly processes. Wastewater treatment plant operators can be self-sustaining with power generated by MFCs on-site, where they can use the energy generated for operating water treatment plants or for market commercialization. Eventually, the application of anaerobic MFC would enable treatment of wastewater with minimal energy investment and less carbon footprint during water treatment, and recovery of chemical energy laden in the wastewater in the form of bioenergy produced through anaerobic processes.

3. Bottlenecks of MFCs

In spite of their potential, a variety of bottlenecks need to be addressed before MFCs are commercialized on the market. Low electricity production, high internal resistance and high material cost are the major obstacles of MFC technology implementation. This could be explained due to the fact that MFCs depend on biofilms for promoting mediator-less electron transfer. When MFC is utilized for wastewater treatment, a large surface area is vital to biofilm accumulation on the anode chamber [17]. Consequently, this needs electrodes with the capability to resist fouling, thus enhancing the operational cost of water treatment plants.

In addition, as the material cost of an MFC is expensive; scientists need to develop suitable materials that can overcome low energy production [18]. To scale up the reactor, the cost of MFC components such as anodes, cathodes, and membranes will increase to maintain its high performance. Stability, long-term performance, efficiency, and scaling up the process from a lab scale to full scale are future challenges. MFC’s bottlenecks also include low electricity production, current instability, and high internal resistance. This makes them difficult to apply due to the high cost of MFC fabrication (electrode, proton exchange membrane, and mediator), and low power generation. If the bottlenecks can be solved, potential energy outputs and the MFC’s versatility could transform the method of wastewater treatment universally. This could generate electricity on-site to treat water off the grid in remote areas.

References

- Wu, T.; Yang, S.; Zhong, L.; Pang, J.; Zhang, L.; Xia, X.; Yang, F.; Xie, G.; Liu, B.; Ren, N. Simultaneous nitrification, denitrification and phosphorus removal: What have we done so far and how do we need to do in the future? Sci. Total Environ. 2022, 856, 158977.

- De Vela, R.J. A review of the factors affecting the performance of anaerobic membrane bioreactor and strategies to control membrane fouling. Rev. Environ. Sci. Biotechnol. 2021, 20, 607–644.

- Hernández-Fernández, F.J.; de los Ríos, A.P.; Mateo-Ramírez, F.; Juarez, M.D.; Lozano-Blanco, L.J.; Godínez, C. New application of polymer inclusion membrane based on ionic liquids as proton exchange membrane in microbial fuel cell. Separ. Purif. Technol. 2016, 160, 51–58.

- Vijay, A.; Sonawane, J.M.; Chhabra, M. Denitrification process in microbial fuel cell: A comprehensive review. Bioresour. Technol. Rep. 2022, 17, 100991.

- Zhang, S.; Chen, W. China’s energy transition pathway in a carbon neutral vision. Engineering 2022, 14, 64–76.

- Acién, F.G.; Gómez-Serrano, C.; Morales-Amaral, M.M. Wastewater treatment using microalgae: How realistic a contribution might it be to significant urban wastewater treatment? Appl. Microbiol. Biotechnol. 2016, 100, 9013–9022.

- Gajda, I.; Greenman, J.; Melhuish, C.; Ieropoulos, I. Self-sustainable electricity production from algae grown in a microbial fuel cell system. Biomass Bioenergy 2015, 82, 87–93.

- Rajalakshmi, N.; Balaji, R.; Ramakrishnan, S. Recent developments in hydrogen fuel cells: Strengths and weaknesses. In Sustainable Fuel Technologies Handbook; Elsevier: London, UK, 2021; pp. 431–456.

- Kokabian, B.; Gude, V.G. Photosynthetic microbial desalination cells (PMDCs) for clean energy, water and biomass production. Environ. Sci. Process. Impacts 2013, 15, 2178–2185.

- Goh, H.H.; Liao, L.; Zhang, D.; Dai, W.; Lim, C.S.; Kurniawan, T.A.; Goh, K.C.; Cham, C.L. Denoising transient power quality disturbances using an improved adaptive wavelet threshold method based on energy optimization. Energies 2022, 15, 3081.

- Hinkley, J.T.; Heenan, A.R.; Low, A.C.; Watson, M. Hydrogen as an export commodity–Capital expenditure and energy evaluation of hydrogen carriers. Int. J. Hydrogen Energy 2022, 47, 35959–35975.

- Capodaglio, A.G.; Molognoni, D.; Dallago, E.; Liberale, A.; Cella, R.; Longoni, P.; Pantaleoni, L.; Marceta Kaninski, M.P.; Pei, P.; Morosuk, T. Microbial fuel cells for direct electrical energy recovery from urban wastewaters. Sci. World J. 2013, 2013, 634738.

- Santoro, C.; Artyushkova, K.; Babanova, S.; Atanassov, P.; Ieropoulos, I.; Grattieri, M.; Cristiani, P.; Trasatti, S.; Li, B.; Schuler, A.J. Parameters characterization and optimization of activated carbon (AC) cathodes for microbial fuel cell application. Bioresour. Technol. 2014, 163, 54–63.

- Mahmoud, R.H.; Samhan, F.A.; Ali, G.H.; Ibrahim, M.K.; Hassan, R.Y. Assisting the biofilm formation of exoelectrogens using nanostructured microbial fuel cells. J. Electroanal. Chem. 2018, 824, 128–135.

- Munoz-Cupa, C.; Hu, Y.; Xu, C.; Bassi, A. An overview of microbial fuel cell usage in wastewater treatment, resource recovery and energy production. Sci. Total Environ. 2021, 754, 142429.

- Vilve, M.; Vilhunen, S.; Vepsäläinen, M.; Kurniawan, T.A.; Lehtonen, N.; Isomäki, H.; Sillanpää, M. Degradation of 1,2-dichloroethane from contaminated water laden with ion-exchange resin using Fenton’s oxidation. Environ. Sci. Pollut. Res. 2010, 17, 875–884.

- Li, M.; Zhou, M.; Tian, X.; Tan, C.; Gu, T. Enhanced bioenergy recovery and nutrient removal from swine wastewater using an airlift-type photosynthetic microbial fuel cell. Energy 2021, 226, 120422.

- Samrat, M.V.V.N.; Rao, K.K.; Ruggeri, B.; Tommasi, T. Denitrification of water in a microbial fuel cell (MFC) using seawater bacteria. J. Clean. Prod. 2018, 178, 449–456.

More

Information

Subjects:

Engineering, Environmental

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

980

Revisions:

2 times

(View History)

Update Date:

23 Dec 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No