Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Tapiwa Reward Sithole | -- | 3409 | 2022-12-22 06:34:42 | | | |

| 2 | Sirius Huang | Meta information modification | 3409 | 2022-12-22 10:34:56 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Sithole, T.R.; Ma, Y.; Qin, Z.; Liu, H.; Wang, X. Influence of Peanut Variety on Peanut Butter Flavor. Encyclopedia. Available online: https://encyclopedia.pub/entry/39069 (accessed on 08 February 2026).

Sithole TR, Ma Y, Qin Z, Liu H, Wang X. Influence of Peanut Variety on Peanut Butter Flavor. Encyclopedia. Available at: https://encyclopedia.pub/entry/39069. Accessed February 08, 2026.

Sithole, Tapiwa Reward, Yu-Xiang Ma, Zhao Qin, Hua-Min Liu, Xue-De Wang. "Influence of Peanut Variety on Peanut Butter Flavor" Encyclopedia, https://encyclopedia.pub/entry/39069 (accessed February 08, 2026).

Sithole, T.R., Ma, Y., Qin, Z., Liu, H., & Wang, X. (2022, December 22). Influence of Peanut Variety on Peanut Butter Flavor. In Encyclopedia. https://encyclopedia.pub/entry/39069

Sithole, Tapiwa Reward, et al. "Influence of Peanut Variety on Peanut Butter Flavor." Encyclopedia. Web. 22 December, 2022.

Copy Citation

For peanut butter, flavor is one of the most important quality attributes, with strong influence on consumer acceptance. There are numerous peanut cultivars on the market, with widely differing chemical compositions and metabolite profiles, which can significantly affect the sensory quality attributes of peanut butter.

peanut varieties

peanut butter

peanut butter flavor

1. Peanut Varieties and Cultivars

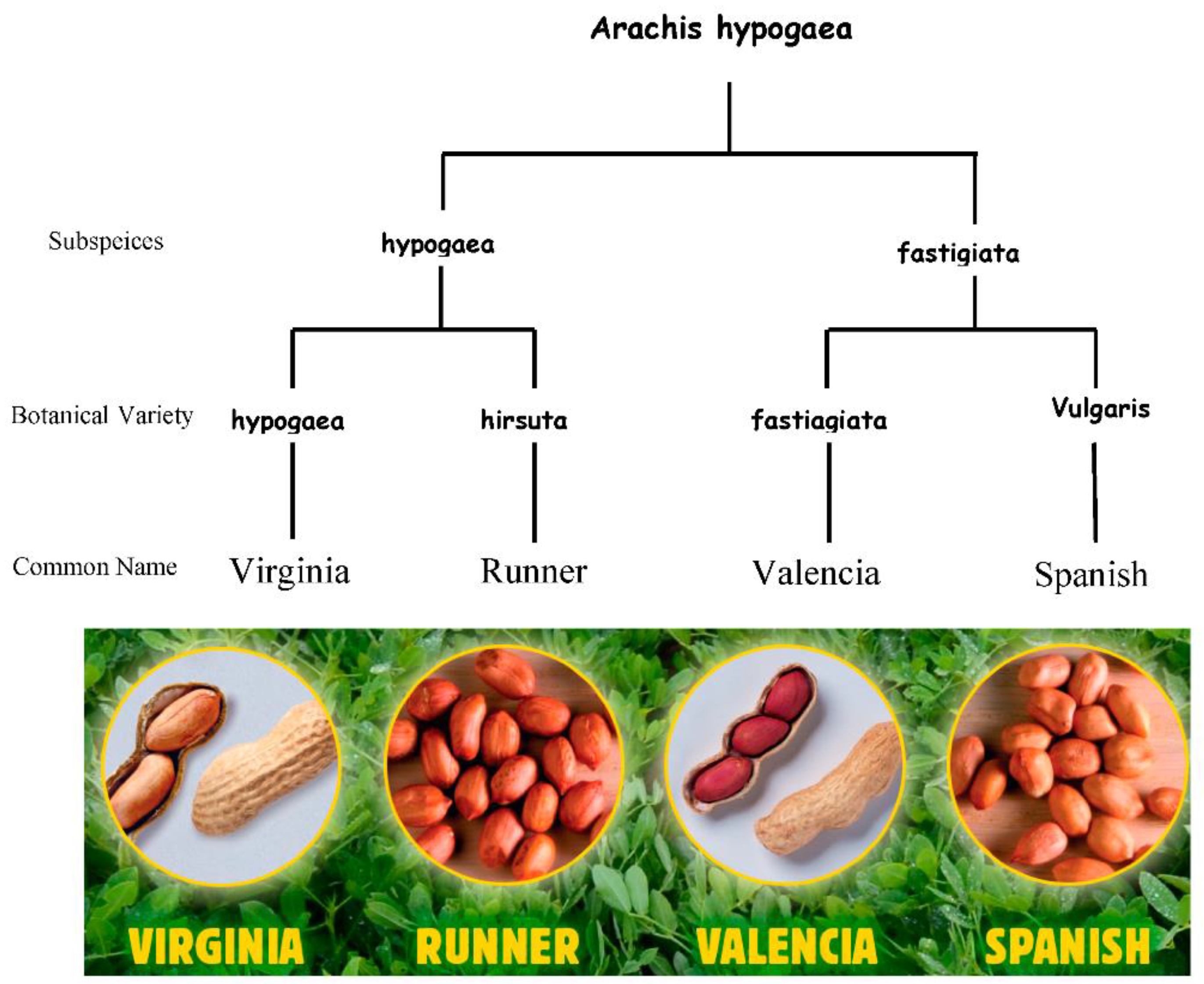

Peanuts (Arachis hypogaea) are the major ingredient used to manufacture peanut butter. The cultivated species of peanuts (Arachis hypogaea L.) is an allotetraploid (genome AABB) and comes from the Arachis segment of the Luguminosae family [1][2][3]. Arachis duranensis and Arachis ipaënsis, having gone through a series of multiple hybridizations and duplication processes, are believed to be the two progenitors of the modern cultivated peanut varieties [2][4]. Further, the cultivated peanuts (Arachis hypogaea L.) can be classified into subspecies: subsp. fastigiata Waldron and subsp. hypogaea Krap [5]. Subsp. fastigiata contains four botanical varieties: var. vulgaris, var. fastigiata, var. peruviana, and var. aequatoriana; subsp. hypogaea contains two varieties: var. hypogaea and var. hirsuta [1][3]. The taxonomic arrangement of the four main subspecies of peanuts in the United States of America [6][7] is shown in Figure 1.

Figure 1. Image showing taxonomic arrangement of the four main subspecies of peanuts in the United States of America.

The characteristics and uses of some of the most popular peanut varieties has been detailed by many authors [6][8][9][10][11][12][13]. Table 1 shows some of the most popular peanut varieties, their general characteristics, and their uses.

Table 1. Characteristics and uses of the most popular peanut varieties.

| Popular Varieties in US | Characteristics | Popular Uses | |

|---|---|---|---|

| Virginia | Bailey, Champs, Florida Fancy, Gregory, Perry, Phillips, Sugg, Sullivan, Titan, and Wynne | Large-sized kernel, generally elongated, and tapered towards the sprout end. Pinkish-tan skins when fresh, which change to reddish-brown color with storage. Skin texture is comparable to the Runner variety. |

Snacking cocktails and partial use in peanut butter. |

| Runner | Florunner, Sunrunner, Southern Runner, Georgia Runner, Georgia Green, and Flavor Runner 458 | Medium-sized, uniformly shaped kernels that are elongated with blunt flattened ends. Rougher skins in comparison to the Spanish type. Color is generally pinkish-brown when fresh and turns to reddish brown with storage. Large yield output and medium-sized and uniformly shaped kennels. Relative uniformity during roasting. |

Peanut butter production. |

| Valencia | Tennessee Reds | Cylindrical and slender pods, containing two to four kernels with blocky, flattened ends. Kernels are small to medium in size with a distinctive bright red color when fresh, turning dark red with storage. A distinctive sweet taste. |

Homemade peanut butter and fresh boiled peanuts. |

| Spanish | Georgia-045, Olin, Pronto, Spanco, and Tamspan 90 | Distinctive rounded shape and relatively small-sized kernels for older varieties and medium-sized kernels for new varieties. Smooth skin and delicate texture; color changes from pinkish buff when fresh to a light brown with an increase in storage time. Their distinctive reddish-brown color and small size make them most suitable for candies and salted-shell nuts. High oil content and a distinctively strong nutty flavor. |

Oil production, candies, and salted shelled nuts. |

2. Influence of Peanut Variety on Peanut Butter Flavor

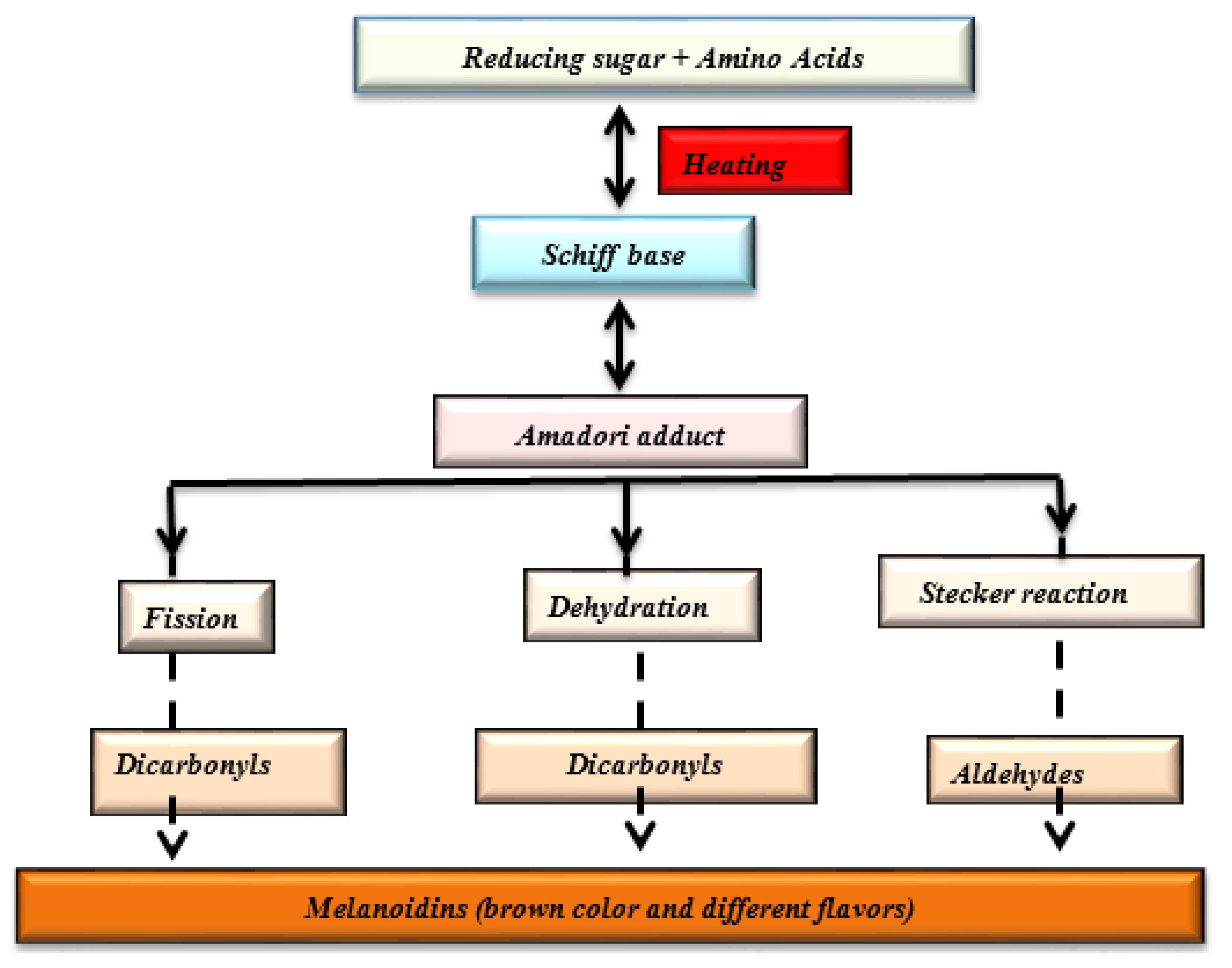

For peanut butter, flavor is one of the most important quality attributes, with strong influence on consumer acceptance [14]. Human interpretation of the notes of peanut butter flavor involves the combined experience of the gustatory, olfactory, and trigeminal systems [15]. The olfactory system processes aroma (smell/odor) which is mostly linked to low-molecular-weight volatile compounds of peanut butter. The gustatory system is involved with the taste (sweet, bitter, salty, sour, and umami) sensation that is stimulated by mastication of the non-volatile high-molecular-weight components. Somatosensory perception (astringency, pungency, and acridness) is interpreted by the trigeminal nerves [15][16]. Peanut butter flavor is generated during roasting, when the high temperatures of the roasting process initiate a series physical changes and chemical reactions involving the peanuts’ chemical constituents and metabolites. The reactions to these high temperatures can significantly alter the peanuts’ flavor profile [17]. While the actual temperature-time profile of the roasting process is very significant in the development of peanut butter flavor, the specific chemical composition and metabolite profile, which provide the precursors to the distinct flavor notes that are generated during roasting, are of equal if not greater importance [18][19]. Proteins, sugars, and lipids are the major precursors of volatile compounds in peanuts, and different kinds of sugars and protein mixtures react differently, resulting in different volatile formations [20]. The principal reaction, believed to be mainly responsible for flavor development during peanut roasting, is Maillard and Strecker degradation [20][21]. This reaction proceeds with the linking of free or bound amino acids, mostly lysine and arginine, to the carbonyl group of simple sugars by nonenzymatic glycosylation to form Amadori products on the proteins [22][23]. The Amadori products then undergo rearrangements, cyclizations, and dehydrations to form structurally diverse compounds that are known as advanced glycation end (AGE) products [22]. The resulting structures, mostly pyrazines, pyrroles, pyridines, carbonyl and sulfur compounds, are responsible for the development of the roasted peanut flavor [20][21]. In general, the pyrazines and carbonyl compounds contribute to the desired peanut butter flavor [24] while, on the other hand, sulfur-containing compounds (specifically methionine and cysteine) are primarily responsible for the burnt notes in peanut flavor [21]. Development of color and flavor during roasting involves a number of stages [25]. The stages in the development of flavor and color in peanuts during roasting are illustrated in Figure 2.

Figure 2. Schematic showing how the Maillard reaction results in color and flavor generation. The reduction of sugars and amino acids in peanuts reacting at high temperatures with low water activity during roasting generates a brown color and various flavors.

While significant efforts have been made to identify and profile the potent odorants in peanuts [26][27][28], the specific compound(s) or groups of compounds that are precursors, and the actual reaction pathways and mechanisms responsible for the typical roasted peanut flavor, remain elusive [15][29]. A clear understanding of the roles of the specific chemical constituents and metabolites of peanuts that are precursors to aroma-active compounds; the biosynthetic pathways for volatile flavor compounds; and the genes that regulate the synthesis of these precursor compounds, is of key importance in improving peanut butter flavor [30].

In 1967, work by Newell et al. [31] demonstrated that off-flavors were highly associated with the presence of threonine, tyrosine, lysine, and an unknown amino acid, while aspartic acid, asparagine- glutamine, glutamic acid, phenylalanine, and histidine were judged to be essential in the development of desirable peanut flavors. In Maillard reaction models, α-amino carbonyl or α-amino hydroxy compounds are believed to be the precursors of pyrazines, and higher concentrations of glutamine, asparagine, diglycine, and triglycine are expected to result in the generation of more pyrazines and, subsequently, a typical roasted/nutty flavor [20]. Significant variations in the amino-acid composition of different peanut varieties have been reported [32]. In 1967, Newell et al. [31] emphasized that the degradation of free amino acids during roasting had a positive correlation to the original concentration. A positive correlation between total sugars and the roasted peanuts’ attributes and a negative correlation between total sugars and bitterness/astringency have also been reported by Pattee et al. in 2000 [33]. It has also been established that the sweetness trait, which is a function of the carbohydrates content of a cultivar, is a heritable trait [33]. Thus, given any two varieties of peanut market-types, the total carbohydrate assays can be used as a basis for the screening and efficient selection of peanut varieties that have higher chances of producing peanut butter with greater sweetness and a superior roasted flavor [33]. With different peanut cultivars having different initial compositions of sugars and free amino acids, appreciable differences in flavor can be observed during roasting, even under the same conditions of roasting [29]. This probably explains why the Runner type peanut, when roasted under the same conditions as the Virginia type, is generally slower in developing a roasted flavor compared with that of the Virginia type; therefore, the Runner type requires a more aggressive time–temperature profile to produce an equivalent roasted flavor [18]. In 2003, Baker et al. [29] emphasized that even if peanuts from different cultivars were to be roasted to the same final color, some appreciable differences in their flavors could still be observed. In 1982, Pattee et al. [34] observed that the larger-sized Virginia peanut seeds (7.14 mm), which had superior flavor in comparison to small-sized peanut seeds (5.14 mm), had a comparatively lower average concentration of free amino acids (32.3%) related to typical roasted flavor (aspartic acid, glutamic acid, histidine, phenylalanine, and histidine) and a lower concentration of amino acids (59.8%) related to atypical roasted flavor (threonine, tyrosine, lysine, and arginine). This further demonstrated the significant effects of varying the chemical composition of peanuts on the development of flavor, even with the same peanut variety.

2.1. Effects of Variation of Lipids Composition on Peanut Butter Flavor

Lipids also have a profound effect on the flavor of peanut butter, contributing to both undesirable and desirable flavors. Discussion on lipids’ contribution to peanut butter flavor usually centers on lipid oxidation and the generation of undesirable flavor notes. However, given that almost half of the weight of peanut butter is lipids, the influence of lipids on taste during mastication, and the possibility generating lipoxygenase-derived lipid-based volatile compounds that are responsible for desirable flavors in peanuts, lipids might require further consideration [16]. Twelve different fatty acids have been reported in peanut oil; of these twelve, only oleic, linoleic, and palmitic fatty acids exist in concentrations above 5%. [35]. These three fatty acids (oleic, linoleic, and palmitic) combined have been reported to constitute about 90% of total peanut oil [36]. Peanuts with oleic content above 80% are generally referred to as high oleic, while standard peanut varieties normally have, on average, 50% oleic fatty acid and approximately 25% linoleic fatty acid [35][36][37][38].

The difference in roasted flavor between the high-oleic and normal standard cultivars has been investigated by several researchers; however, this is another area where there is an apparent lack of general consensus among researchers. In 2009, Grosso et al. [39] reported that they found no significant difference in consumer preference between Granoleico (GO-P), a high-oleic cultivar, and Tegua (T-P), a normal oleic cultivar, both from Argentina. In a uniform peanut performance test (UPPT) performed in 2015 by Isleib et al. [40], the mean of a total of 27 high-oleic cultivars were compared to the mean of a total of 32 normal oleic cultivars; no observable variation in sensory attribute intensity, other than stale/cardboard, was reported. In a 2006 study, Isleib et al. [41] showed that high-oleic cultivars exhibited a slightly greater intensity of astringent over-roast in roasted peanuts, together with nutty attributes. However, a principal component and cluster analysis (PCC) on some Argentinian high-oleic peanut genotypes (4896-11-C and 9399-10) and some normal oleic varieties showed that high-oleic varieties received higher consumer acceptance ratings [42]. In addition, in work by Wang et al. in 2016 [43], the overall liking, liking of flavor, sweetness, and roasted peanut flavor of normal-oleic runner cultivar GA 06G were compared with those of the high-oleic GA 13M variety; the results showed that the high-oleic variety ranked higher in all of these attributes, as well as in general consumer preference.

On the other hand, Hu et al. [20] observed in 2021 that the initial concentration of the characteristic precursors of strong peanut flavor were higher in normal-oleic peanuts than in high-oleic peanuts, resulting in the formation of more typical volatile components and a stronger, specific aroma, even when processed under the same conditions. Further, it is not clear whether the aldehydes formed by lipid oxidation or Maillard reactions (in the form of Strecker aldehydes) act in the same way or otherwise, in tandem, during flavor and color formation [29]. In the assumption that they do, Baker et al. [29] suggested in 2003 that this could mean that high-oleic peanuts have less potential for forming precursors to color and flavor via Maillard browning and subsequent pyrazine formation. Therefore, in comparison to normal-oleic lines, a more intense roasting temperature–time profile will be required for the high-oleic peanuts to achieve comparable flavors and colors [29].

While further research is required to reconcile these apparent contradictions and to understand the peanut butter flavor phenomena as a function of fatty acid chemistry, at this time the lack of agreement between researchers probably serves as proof that, indeed, different varieties of peanuts result in significantly different flavor profiles. Only with extensive and large-scale research that incorporates as many different representative cultivars as possible will bring to rest these apparent contradictions on the effects of high-oleic content on the development of desirable flavors during roasting. In any case, as desirable flavor development depends not only on lipid content, but also on other peanut constituents, it will not be surprising if only cultivar-specific generalizations are meaningful.

2.2. Effects of Lipid Composition of Peanuts on Oxidation Stability

Lipid oxidation reactions make a significant contribution to peanuts butter flavor [17]. Lipid oxidation affects the flavor of peanut butter in two ways. First, during roasting, the lipids in peanuts can undergo degradation, producing some volatile compounds that can directly alter the flavor profile of peanut butter or indirectly influence the flavor of peanut butter by possibly interacting with other constituents developed from the Maillard reaction and Strecker degradation [16]. Second, during storage, lipid oxidation can lead to a fading out of the desirable peanut butter flavor with time. In both cases, lipid degradation in peanut butter could be initiated by autoxidation, photooxidation, or the presence of metallic ions and, in some cases, a combination of all three. Oxidation proceeds with the generation of aliphatic aldehydes, ketones, and alcohols that are highly associated with undesirable flavors, and which can compromises the nutritional quality of fats, possibly leading to the production of toxic compounds [16][26][44]. Both the total lipid content and the actual oil profile have a effects on the propensity and actual rate of peanut butter deterioration by oxidation and, subsequently, on flavor [44][45]. The percentage distribution between the major peanut oil fractions, oleic and linoleic, is one key determinant of the oxidation stability of peanut butter. Linoleic fatty acid is less saturated and suffers more from oxidation, compared with oleic and palmitic fatty acids [36].

Accordingly, in peanuts and their products, the ratio of oleic to linoleic fatty acids (O/L) is used as a quality score; the higher the ratio, the greater the product’s shelf life, due to its higher oxidative stability [46]. The peroxide value (PV) is a widely used indicator of storage stability, due to its superior correlation with peanut butter stability, compared with other measures [47]. In 2018, Gong et al. [47] observed a significant (<0.05) positive correlation between the oleic/linoleic ratio in peanut butter stability, as inferred from the peroxide values, further demonstrating the significance of oleic-acid and linoleic-acid content in peanut butter stability. In 2016, Davis et al. [48] established that the oxidative stability Index (OSI) of peanut butter increased more than sevenfold when the O/L ratio increased from 1.3 to 33.8, and the obtained response fit well in a second-order polynomial relationship.

Wide variability in O/L ratios among peanut cultivars has been reported. In 1987, within some experimental breeding lines in Florida, Norden et al. [49] reported a high variability in the oleic/linoleic ratios, ranging from 0.9 to as high as 35. In Pakistan, peanut cultivars Bard-479 and Local-334, with high oleic/linoleic ratios, were judged to produce better peanut butter in comparison to Bard-92, which has a low oleic/linoleic ratio [50]. Of the three, Bard -479, a Virginia large-seeded cultivar, was recommended for making peanut butter, due to its comparatively high O/L ratio [50]. Among the natural breading lines, the Spanish and the Valencia are generally known to have lower O/L ratios and, subsequently, lower oxidation stabilities, in comparison to the Virginia or Runner types [11][35]. However, in the wake of several breed improvement programs, these generalizations are diminishing. For example, it has been reported that a Runner peanut cultivar, IAC Runner 886, is highly susceptible to oxidation, due to its high percentage of unsaturated fatty acids [46]. In 2021, Huang et al. [51] considered the lipidomic characteristics and free fatty acids of 13 peanut cultivars and compared their lipid compositions. They obtained a significant difference in lipid composition and oxidation stabilities, even among the high-oleic-acid (OA) peanut cultivars [51]. Moreover, they obtained 11 lipid molecules with the potential to be used as indicators for identifying high-OA and non-high-OA peanut cultivars. Thus, these lipid molecules can be used for the screening and determination of the suitability of a given peanut variety for a given function.

Although the total oil content and the lipid profile have profound effects on the stability of peanut oil, the effects of variability in moisture, tocopherols, beta carotene, and chlorophyll should also be considered [44]. The effects of these functional compounds in peanut oil have long been studied and established; thus, they might = be applicable to peanut butter.

2.3. Variations in Mineral Constituent of Peanut Cultivar and Oxidative Stability

The mineral constituencies of peanuts also vary with peanut varieties. In 2019, Shibli et al. [50] observed a significant variation in the P, K, and Na mineral constituents of three indigenous Pakistan peanut varieties. It has long been established that metalloproteins, iron, and copper salts are major catalysts of fatty acid oxidation in peanut butter [52]. Further, it is known that contamination of peanut oil with some metallic elements from an external source can accelerate the oxidation of oils. While, in general, the effect of Cu could be more pronounced than that of Fe, the overall effects of these metals on oxidative stability is less pronounced, compared with that of the oleic/linoleic ratio [48]. In the absence of specific research that focuses on the effects of these metallic elements in peanut butter that is prepared from widely varying peanut cultivars, it remains unclear whether such reported variations in mineral content with cultivars can also result in significant oxidation differences in peanut butter. Perhaps a specific study to ascertain this hypothesis might be worthwhile.

2.4. Varieties of Peanuts on Flavor Loss during Peanut Butter Storage

The most significant effects of lipid oxidation on peanut butter flavor are related to losses in flavor due to storage, which is also influenced by the lipid profile of a given peanut cultivar [17]. Insuring that the desirable peanut butter flavor developed during roasting does not quickly fade with time is one of the challenges of peanut butter producers [17][53][54]. The oxidation of the lipid component of peanut butter is the chief cause of loss of flavor in peanut butter [48][55]. However, the actual mechanism of flavor loss in peanut butter is still a contentious issue. In 1996, Warner et al. [54] determined that the deterioration of the peanut flavor with time is not necessarily driven by the absence or fading of essential volatile compounds (pyrazines) for peanut flavors, but rather that it results from the masking effect of these flavors by the process of oxidation. In contrast, Bett and Boylston [56] noted in 1992 that alkylpyrazines and peanut flavor intensities actually decreased in intensity, while the lipid oxidation flavors, such as the painty and cardboard flavors, increased with hexanal, octanal, and 2-octanone compounds. Another possibility for flavor fading that still remains unclear is whether or not the desirable peanut flavor compounds undergo a chemical reaction with the off-flavor compounds during storage time, resulting in new products with undesirable off-flavors. The current general understanding is that when the lipids in the peanuts are oxidized, they produce hydroperoxides, which then further degrade to alcohols, alkanes, ketones, and aldehydes, contributing to the off-flavors in peanut butter with an increase in storage time [55]. The off-flavor development in peanuts generally proceeds in a successive order, starting with a cardboard-like flavor followed by a fish-like flavor, and then a paint-like flavor [17]. Because the secondary off-flavor compounds, such as octanal and nonanal, are dependent on the relative starting composition of the fatty acids, it can be thus concluded that peanut variety can contribute to the rate of flavor loss in peanut butter [17]. High-oleic cultivars have better oxidation stability and, subsequently, increased shelf life, compared with that of conventional cultivars [47][48][57]. When the sensory and oxidation stability of a high-oleic peanut variety (i.e., Granoleico, GO-P) was compared with that of a normal-oleic peanut variety (i.e., Tegua, T-P), both prepared under the same conditions and stored at 4 °C, 23 °C, and 40 °C, the peanut paste prepared with high-oleic peanuts had four (at 4 °C), two (at 23 °C), and three (at 40 °C) times longer shelf-life than peanut paste prepared with the normal-oleic variety [58]. The advantages of high-oleic varieties in conferring a longer shelf life has prompted some studies to use advanced techniques, such as near-infrared reflectance spectroscopy (NIRS) for the rapid identification of peanut varieties with high-oleic composition for the purposes of screening and selecting peanuts [59][60]. Further development and the uptake of high-oleic varieties in mainstream peanut butter production processes could be very advantageous, especially for natural peanut butter formulations that are more prone to oxidation, due to the absence of stabilizers [47].

References

- Moretzsohn M de, C.; Hopkins, M.S.; Mitchell, S.E.; Kresovich, S.; Valls, J.F.M.; Ferreira, M.E. Genetic diversity of peanut (Arachis hypogaea L.) and its wild relatives based on the analysis of hypervariable regions of the genome. BMC Plant Biol. 2004, 4, 11. Available online: https://pubmed.ncbi.nlm.nih.gov/15253775 (accessed on 17 February 2022).

- Yang, X.; Luo, L.; Yu, W.; Mo, B.; Liu, L. Recent Advances in the Acclimation Mechanisms and Genetic Improvement of Peanut for Drought Tolerance. Agric. Sci. 2019, 10, 1178–1193.

- Janila, P.; Nigam, S.N.; Pandey, M.K.; Nagesh, P.; Varshney, R.K. Groundnut improvement: Use of Genetic and Genomic Tools. Front. Plant Sci. 2013, 4, 23. Available online: https://pubmed.ncbi.nlm.nih.gov/23443056 (accessed on 17 February 2022).

- Jung, S. The Phylogenetic Relationship of Possible Progenitors of the Cultivated Peanut. J. Hered. 2003, 94, 334–340.

- Janila, P.; Variath, M.T.; Pandey, M.K.; Desmae, H.; Motagi, B.N.; Okori, P.; Manohar, S.S. Genomic Tools in Groundnut Breeding Program: Status and Perspectives. Front. Plant Sci. 2016, 7, 289. Available online: https://pubmed.ncbi.nlm.nih.gov/27014312 (accessed on 5 March 2022).

- Chriscoe, S. Characterization of Transgenic Peanuts Expressing Oxalate Oxidase for Governmental Approval of Their Release for Control of Sclerotinia Blight. Virginia Polytechnic Institute and State University. Available online: https://vtechworks.lib.vt.edu/handle/10919/30951 (accessed on 4 January 2022).

- González, T.O.A.; Acevedo, E. Manejo Agronómico De Cultivos Textiles Y Oleaginosos. Available online: https://blogtextilesyoleaginosasfagroucv.files.wordpress.com/2015/10/semana_1_morfologia-cultivos-oleaginosos-20016.pdf (accessed on 4 January 2022).

- Larum, D. Peanuts. Gardening Know How. Available online: https://www.gardeningknowhow.com/edible/vegetables/peanuts/different-varieties-of-peanut.htm (accessed on 5 January 2022).

- United States Department of Agriculture (USDA). Farmers’ Stock Peanut Inspection Instructions; United States Department of Agriculture: Washington, DC, USA, 2019. Available online: https://www.ams.usda.gov/sites/default/files/media/FarmersStockPeanutsInspectionInstructions.pdf (accessed on 10 September 2022).

- Sanders, T.H.; Calhoun, R.S. Effect of Oil and Dry Roasting of Peanuts at Various Temperatures and Times on Survival of Salmonella and Enterococcus faecium. Peanut Sci. 2014, 41, 65–71.

- López, Y.; Smith, O.D.; Senseman, S.A.; Rooney, W.L. Genetic Factors Influencing High Oleic Acid Content in Spanish Market-Type Peanut Cultivars. Crop Sci. 2001, 41, 51–56.

- National Peanut Board. Peanut Types. Available online: https://www.nationalpeanutboard.org/peanut-info/peanut-types.htm (accessed on 5 January 2022).

- Abady, S.; Shimelis, H.; Janila, P.; Yaduru, S.; Shayanowako, A.I.T.; Deshmukh, D.; Chaudhari, S.; Manohar, S.S. Assessment of the genetic diversity and population structure of groundnut germplasm collections using phenotypic traits and SNP markers: Implications for drought tolerance breeding. PLoS ONE 2021, 16, e0259883. Available online: https://pubmed.ncbi.nlm.nih.gov/34788339 (accessed on 22 June 2022).

- Liu, Y.; Hu, H.; Liu, H.; Wang, Q. Recent Advances for the Developing of Instant Flavor Peanut Powder: Generation and Challenges. Foods 2022, 11, 1544. Available online: https://pubmed.ncbi.nlm.nih.gov/35681294 (accessed on 17 July 2022).

- Neta, E.R.; Sanders, T.; Drake, M.A. Understanding Peanut Flavor: A Current Review. In Handbook of Fruit and Vegetable Flavors; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 985–1022.

- Shahidi, F.; Hossain, A. Role of Lipids in Food Flavor Generation. Molecules 2022, 27, 5014. Available online: https://pubmed.ncbi.nlm.nih.gov/35956962 (accessed on 17 July 2022).

- Adhikari, K.; Wang, S. Extensions Publications; Roasted Peanut Flavour. University of Georgia. 2017. Available online: https://extension.uga.edu/publications/detail.html?number=B1478&title=RoastedPeanutFlavor (accessed on 16 February 2022).

- Lykomitros, D.; Fogliano, V.; Capuano, E. Drivers of Preference and Perception of Freshness in Roasted Peanuts (Arachis spp.) for European Consumers. J. Food Sci. 2018, 83, 1103–1115.

- Sanders, T.H.; Pattee, H.E.; Vercellotte, J.R.; Bett, K.L. Advances in peanut flavour quality. In Advances in Peanut Science; Pattee, H.E., Stalker, H., Eds.; Tifton, American Peanut Research and Education Society: Alexandria, VA, USA, 1995; pp. 528–553.

- Hu, H.; Shi, A.; Liu, H.; Liu, L.; Fauconnier, M.L.; Wang, Q. Study on Key Aroma Compounds and Its Precursors of Peanut Oil Prepared with Normal- and High-Oleic Peanuts. Foods 2021, 10, 3036. Available online: https://pubmed.ncbi.nlm.nih.gov/34945587 (accessed on 5 May 2022).

- Zook, D.E.; Macku, C.; Deming, D. Effect of microwave heating on roasted nut flavor. Dev. Food Sci. 1995, 37, 1493–1518.

- Chung, S.-Y.; Champagne, E.T. Allergenicity of Maillard Reaction Products from Peanut Proteins. J. Agric. Food Chem. 1999, 47, 5227–5231.

- Teodorowicz, M.; van Neerven, J.; Savelkoul, H. Food Processing: The Influence of the Maillard Reaction on Immunogenicity and Allergenicity of Food Proteins. Nutrients 2017, 9, 835. Available online: https://pubmed.ncbi.nlm.nih.gov/28777346 (accessed on 13 February 2022).

- Lin, M.; Long, M.; Li, G.; Chen, X.; Zheng, J.; Li, C.; Kan, J. Analysis of Peanut Using Near-Infrared Spectroscopy and Gas Chromatography–Mass Spectrometry: Correlation of Chemical Components and Volatile Compounds. Int. J. Food Prop. 2015, 19, 508–520.

- Arihara, K.; Zhou, L.; Ohata, M. Bioactive Properties of Maillard Reaction Products Generated from Food Protein-derived Peptides. In Advances in Food Research and Nutrition; Elsevier: Amsterdam, The Netherlands, 2017; pp. 161–185.

- Lykomitros, D.; Fogliano, V.; Capuano, E. Flavor of roasted peanuts (Arachis hypogaea)—Part II: Correlation of volatile compounds to sensory characteristics. Food Res. Int. 2016, 89, 870–881.

- Chetschik, I.; Granvogl, M.; Schieberle, P. Quantitation of Key Peanut Aroma Compounds in Raw Peanuts and Pan-Roasted Peanut Meal. Aroma Reconstitution and Comparison with Commercial Peanut Products. J. Agric. Food Chem. 2010, 58, 11018–11026.

- Kaneko, S.; Sakai, R.; Kumazawa, K.; Usuki, M.; Nishimura, O. Key Aroma Compounds in Roasted In-shell Peanuts. Biosci. Biotechnol. Biochem. 2013, 77, 1467–1473.

- Baker, G.L.; Cornell, J.A.; Gorbet, D.W.; O’Keefe, S.F.; Sims, C.A.; Talcott, S.T. Determination of Pyrazine and Flavor Variations in Peanut Genotypes During Roasting. J. Food Sci. 2003, 68, 394–400.

- Shen, J.; Tieman, D.; Jones, J.B.; Taylor, M.G.; Schmelz, E.; Huffaker, A.; Bies, D.; Chen, K.; Klee, H.J. A 13-lipoxygenase, TomloxC, is essential for synthesis of C5 flavour volatiles in tomato. J. Exp. Bot. 2014, 65, 419–428. Available online: https://pubmed.ncbi.nlm.nih.gov/24453226 (accessed on 5 May 2022).

- Newell, J.A.; Mason, M.E.; Matlock, R.S. Precursors of typical and atypical roasted peanut flavor. J. Agric. Food Chem. 1967, 15, 767–772.

- Young, C.T. Amino Acid Composition of Three Commercial Peanut Varieties. J. Food Sci. 1980, 45, 1086–1087.

- Pattee, H.E.; Isleib, T.G.; Giesbrecht, F.G.; McFeeters, R.F. Relationships of Sweet, Bitter, and Roasted Peanut Sensory Attributes with Carbohydrate Components in Peanuts. J. Agric. Food Chem. 2000, 48, 757–763.

- Pattee, H.E.; Pearson, J.L.; Young, C.T.; Giesbrecht, F.G. Changes in roasted peanut flavor and other quality factors with seed size and storage time. J. Food Sci. 1982, 47, 455–456.

- Hajisaheb, L.N.; Ramesh, S.B.; Kavera, B.; M.angesh, P.J.; Malagoud, D. Innovative breeding methods to enhance the oleic acid content in peanut for better oil quality and human health. Nov. Tech. Nutr. Food Sci. 2020, 4, 382–385.

- Holbrook, C.C.; Stalker, H. Peanut breeding and genetic resources. In Pant Breeding Reviews; Janick, J., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2002; pp. 297–356.

- Patel, N.C. Standardizing peanut roasting process of peanut butter production. Int. J. Eng. Res. Technol. 2013, 2, 713–717.

- Davis, J.P.; Dean, L.O.; Faircloth, W.H.; Sanders, T.H. Physical and Chemical Characterizations of Normal and High-Oleic Oils from Nine Commercial Cultivars of Peanut. J. Am. Oil. Chem. Soc. 2008, 85, 235–243.

- Grosso, N.R.; Riveros, C.G.; Mestrallet, M.G.; Nepote, V. Chemical composition and sensory analysis of peanut pastes elaborated with high-oleic and regular peanuts from Argent. Grasas Y Aceites 2009, 60, 388–395.

- Isleib, T.G.; Pattee, H.E.; Tubbs, R.S.; Sanders, T.H.; Dean, L.O.; Hendrix, K.W. Intensities of Sensory Attributes in High- and Normal-Oleic Cultivars in the Uniform Peanut Performance Test. Peanut Sci. 2015, 42, 83–91.

- Isleib, T.G.; Pattee, H.E.; Sanders, T.H.; Hendrix, K.W.; Dean, L.O. Compositional and Sensory Comparisons between Normal- and High-Oleic Peanuts. J. Agric. Food Chem. 2006, 54, 1759–1763.

- Nepote, V.; Olmedo, R.H.; Mestrallet, M.G.; Grosso, N.R. A study of the relationships among consumer acceptance, oxidation chemical indicators, and sensory attributes in high-oleic and normal peanuts. J. Food Sci. 2009, 74, S1–S8.

- Wang, S.; Adhikari, K.; Hung, Y.-C. Acceptability and Preference Drivers of Freshly Roasted Peanuts. J. Food Sci. 2016, 82, 174–184.

- Shakerardekani, A.; Karim, R.; Ghazali, H.M.; Chin, N.L. Textural, rheological and sensory properties and oxidative stability of nut spreads—A review. Int. J. Mol. Sci. 2013, 14, 4223–4241. Available online: https://pubmed.ncbi.nlm.nih.gov/23429239 (accessed on 16 February 2022).

- Chamberlin, K.D.; Grey, T.L.; Puppala, N.; Holbrook, C.C.; Isleib, T.G.; Dunne, J.; Dean, L.; Hurdle, N.; Payton, M. Comparison of Field Emergence and Thermal Gradient Table Germination Rates of Seed from High Oleic and Low Oleic Near Isogenic Peanut Lines. Peanut Sci. 2021, 48, 131–143.

- de Camargo, A.C.; de Souza Vieira, T.M.F.; Regitano-D’Arce, M.A.B.; de Alencar, S.M.; Calori-Domingues, M.A.; Canniatti-Brazaca, S.G. Gamma radiation induced oxidation and tocopherols decrease in in-shell, peeled and blanched peanuts. Int. J. Mol. Sci. 2012, 13, 2827–2845. Available online: https://pubmed.ncbi.nlm.nih.gov/22489128 (accessed on 13 February 2022).

- Gong, A.; Shi, A.; Liu, H.; Yu, H.; Liu, L.; Lin, W.; Wang, Q. Relationship of chemical properties of different peanut varieties to peanut butter storage stability. J. Integr. Agric. 2018, 17, 1003–1010.

- Davis, J.P.; Price, K.M.; Dean, L.L.; Sweigart, D.S.; Cottonaro, J.M.; Sanders, T.H. Peanut Oil Stability and Physical Properties Across a Range of Industrially Relevant Oleic Acid/Linoleic Acid Ratios. Peanut Sci. 2016, 43, 1–11.

- Norden, A.J.; Gorbet, D.W.; Knauft, D.A.; Young, C.T. Variability in Oil Quality Among Peanut Genotypes in the Florida Breeding Program. Peanut Sci. 1987, 14, 7–11.

- Shibli, S.; Siddique, F.; Raza, S.; Ahsan, Z.; Raza, I. Chemical Composition and Sensory Analysis of Peanut Butter from Indigenous Peanut Cultivars of Pakistan. Pakistan J. Agric. Res. 2019, 32, 159.

- Huang, Y.; Ma, R.; Xu, Y.; Zhong, K.; Bu, Q.; Gao, H. A Comparison of Lipid Contents in Different Types of Peanut Cultivars Using UPLC-Q-TOF-MS-Based Lipidomic Study. Foods 2021, 11, 4. Available online: https://pubmed.ncbi.nlm.nih.gov/35010129 (accessed on 16 February 2022).

- Felland, S.L.; Koehler, P.E. Sensory, Chemical, and Physical Changes in Increased Water Activity Peanut Butter Products. J. Food Qual. 1997, 20, 145–156.

- Mohd Rozalli, N.H.; Chin, N.L.; Yusof, Y.A.; Mahyudin, N. Quality changes of stabilizer-free natural peanut butter during storage. J. Food Sci. Technol. 2016, 53, 694–702. Available online: https://pubmed.ncbi.nlm.nih.gov/26787989 (accessed on 13 February 2022).

- Warner, K.J.H.; Dimick, P.S.; Ziegler, G.R.; Mumma, R.O.; Hollender, R. “Flavor-fade” and Off-Flavors in Ground Roasted Peanuts As Related to Selected Pyrazines and Aldehydes. J. Food Sci. 1996, 61, 469–472.

- Schirack, A.V.; Drake, M.A.; Sanders, T.H.; Sandeep, K.P. Characterization of Aroma-Active Compounds in Microwave Blanched Peanuts. J. Food Sci. 2006, 71, C513–C520.

- Bett, K.L.; Boylston, T.D. Effect of Storage on Roasted Peanut Quality. In ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1992; pp. 322–343.

- Mugendi, J.B.; Sims, C.A.; Gorbet, D.W.; O’Keefe, S.F. Flavor stability of high-oleic peanuts stored at low humidity. J. Am. Oil. Chem. Soc. 1998, 75, 21–25.

- Riveros, C.G.; Mestrallet, M.G.; Gayol, M.F.; Quiroga, P.R.; Nepote, V.; Grosso, N.R. Effect of storage on chemical and sensory profiles of peanut pastes prepared with high-oleic and normal peanuts. J. Sci. Food Agric. 2010, 90, 2694–2699.

- Sundaram, J.; Kandala, C.V.; Butts, C.L.; Chen, C.Y.; Sobolev, V. Nondestructive NIR Reflectance Spectroscopic Method for Rapid Fatty Acid Analysis of Peanut Seeds. Peanut Sci. 2011, 38, 85–92.

- Bansod, B.; Thakur, R.; Holser, R. Analysis of Peanut Seed Oil by NIR. Am. J. Anal. Chem. 2015, 6, 917–922.

More

Information

Subjects:

Food Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

2 times

(View History)

Update Date:

22 Dec 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No