| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Gabriela Vázquez Rodríguez | -- | 2838 | 2022-12-14 00:57:48 | | | |

| 2 | Lindsay Dong | Meta information modification | 2838 | 2022-12-19 07:01:16 | | |

Video Upload Options

Society is highly dependent on natural resources such as rocks (aggregates) and minerals. Although they are an abundant resource on the planet, their recovery is slow in terms of human lifespan, and from this fact, they are considered non-renewable resources. The construction industry currently consumes around 3000 million tons of natural resources annually and is responsible for 34% of greenhouse gas emissions into the atmosphere. An alternative to reduce this over-extraction is the substitution of aggregates and cement for municipal solid waste (MSW), which represents the application of the circular economy principles. This approach and the waste management hierarchy are described, with a focus on the Latin America and the Caribbean situation. MSW is composed of several fractions, such as organic waste, paper, cardboard, metals, plastic, and glass, among other valuable materials. Areas of opportunity for their reuse in the construction industry have been demonstrated worldwide: a) plastics as substitutes for aggregates or reinforcing fibers, or replaced construction elements such as bricks; b) glass in the production of concrete, mortar, and asphalt pavement; c) paper as a hygrothermal and lighting regulator in buildings, among others.

1. Introduction

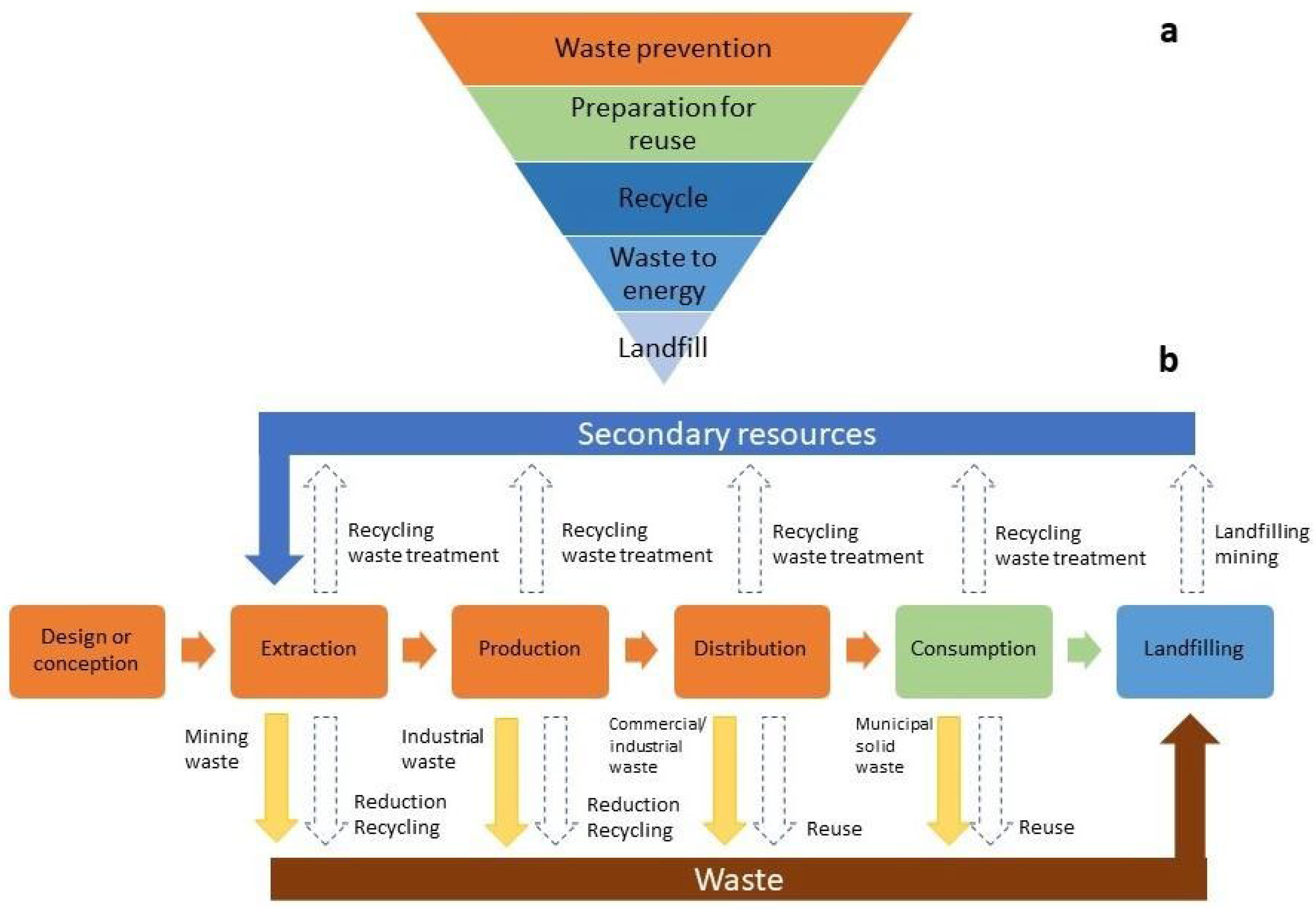

1.1. The Waste Management Hierarchy and the Circular Economy

1.2. Circular Economy Initiatives in Latin America and the Caribbean (LAC)

2. Municipal Solid Waste and Its Use in Construction

2.1. Plastics

Recycling and reuse of plastic waste (PW) in construction allow for reducing the environmental problems that it causes and improving certain properties of conventional materials. The applications of plastics to construction materials can be classified into three categories: (i) addition to concrete, as substitutes for aggregates or reinforcing fibers; (ii) incorporation into asphalt; and (iii) emerging applications, whether to build the base and sub-base of highways and roads, manufacture new composites that replace conventional materials (such as wood), or replace construction elements (such as bricks).

2.2. Glass

Glass is a very versatile and inert material. However, it is not biodegradable, so once it is disposed of, it can remain in nature as waste for at least a million years before it decomposes naturally [34]. If one ton of glass is reused in the cement industry, 560 kg of sand, 190 kg of soda ash, 176 kg of limestone, and 64 kg of feldspar can be preserved [35]. Its reuse as a ground powder in the clinker production process helps reduce air pollution [36]. This makes it an attractive reusable material because concrete is the most used construction input worldwide.

When glass is crushed and sieved, it acquires engineering properties similar to sand and other fine materials [37]. For example, substituting natural aggregates with glass improved the workability of concrete thanks to its non-absorbent properties. This improvement may depend on the particle size of the replaced aggregates, so it is important to determine their ideal granulometry [37]. It has been found that adequate glass amounts for the replacement of fine aggregates vary between 20–30% and between 10–20% for replacing coarse aggregates [36].

2.3. Paper and Cardboard

2.4. Ashes from the MSW Incineration

References

- Chang, N.B.; Pires, A. . Sustainable Solid Waste Management: A Systems Engineering Approach; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 20.

- Kaza, S.; Yao, L.; Bhada-Tata, P.; VanWoerden, F.. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018; pp. 3.

- Bukhkalo, S.I.; Klemeš, J.J.; Tovazhnyanskyy, L.L.; Arsenyeva, O.P.; Kapustenko, P.O.; Perevertaylenko, O.Y.; Eco-Friendly Synergetic Processes of Municipal Solid Waste Polymer Utilization. Chem. Eng. Trans. 2018, 70, 1-6.

- European Environment Agency . Overview of National Waste Prevention Programmes in Europe - European Environment Agency: Sweden; European Environment Agency. : Stockholm, 2021; pp. 14.

- López-Ruiz, L.A.; Roca-Ramón, X.; Gassó-Domingo, S.; The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238, https://doi.org/10.1016/j.jclepro.2019.119238.

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X.; Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906-1916, https://doi.org/10.1016/j.rser.2017.06.001.

- Intergovernmental Panel on Climate Change. Summary for Policymakers - Climate Change 2022: Impacts, Adaptation, and Vulnerability. Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Pörtner, H.-O.; Roberts, D.C.; Tignor, M.; Poloczanska, E.S.; Mintenbeck, K.; Alegría, A.; Craig, M.; Langsdorf, S.; Löschke, S.; Möller, V.; Okem, A.; Rama, B., Eds.; Cambridge University Press: Cambridge, U.K., and New York, U.S.A. , 2022; pp. 3-33.

- Pomponi, F.; Stephan, A.; Water, energy, and carbon dioxide footprints of the construction sector: A case study on developed and developing economies. Water Res. 2021, 194, 116935, https://doi.org/10.1016/j.watres.2021.116935.

- Elhacham, E.; Ben-Uri, L.; Grozovski, J.; Bar-On, Y.M.; Milo, R.; Global human-made mass exceeds all living biomass. Nature 2020, 588, 442-444, https://doi.org/10.1038/s41586-020-3010-5.

- Organisation for Economic Co-operation and Development . Global Material Resources Outlook to 2060: Economic Drivers and Environmental Consequences; OECD Publishing: Paris, France, 2019; pp. 15.

- Akhtar, A.; Sarmah, A.K.; Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262-281, https://doi.org/10.1016/j.jclepro.2018.03.085.

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A.; An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892, https://doi.org/10.1016/j.scitotenv.2021.149892.

- United Nations Environment Programme. Waste and Climate Change. Global Trends and Strategy Framework; International Environmental Technology Centre – UNEP: Osaka, Japan, 2010; pp. 5.

- Reike, D.; Vermeulen, W.J.; Witjes, S.; The circular economy: new or refurbished as CE 3.0? — exploring controversies in the conceptualization of the circular economy through a focus on history and resource value retention options.. Resour. Conserv. Recycl. 2018, 135, 246-264, https://doi.org/10.1016/j.resconrec.2017.08.027.

- Schröder, P.; Albaladejo, M.; Ribas, P.A.; MacEwen, M.; Tilkanen, J.. The Circular Economy in Latin America and the Caribbean; The Royal Institute of International Affairs, Eds.; Chatham House: London, UK, 2020; pp. 2.

- ONU Medio Ambiente. Perspectiva de la gestión de residuos en América Latina y el Caribe. Programa de las Naciones Unidas para el Medio Ambiente, Oficina para América Latina y el Caribe: Ciudad de Panamá, Panamá, 2018.

- Overview . Circular Economy Coalition for Latin America and the Caribbean. Retrieved 2022-12-15

- Red de Economía Circular . Gobierno de la Ciudad de Buenos Aires. Retrieved 2022-12-15

- Muñoz-Meléndez, G.; Delgado-Ramos, G.C.; Díaz-Chávez, R. Circular Economy in Mexico. In Circular Economy: Recent Trends in Global Perspective; Ghosh, S.K., Ghosh, S.K., Eds.; Springer: Singapore, 2021; pp. 497–523.

- Ayora-Sánchez, J.I.; Zárate-Carabajo, A.E.; Jimbo-Días, J.S.; La verdadera inclusión: Controversia entre el reciclaje inclusivo y el reciclaje justo, en el marco del desarrollo sostenible. Let. Verdes – Rev. Latinoam. Estud. Socioamb. 2020, 27, 71–89, https://doi.org/10.17141/letrasverdes.27.2020.4316.

- Soliz-Torres, M.F.; Yépez-Fuentes, M.A.; Valencia-Velasco, M.D.; Solíz-Carrión, R.F. Reciclaje sin RecicladorAs es Basura: El Retorno de las Brujas; Universidad Andina Simón Bolívar-Ediciones La Tierra: Quito, Ecuador, 2019.

- Calderón-Márquez, A.J.; Rutkowski, E.W.; Waste management drivers towards a circular economy in the global south–The Colombian case. Waste Manag. 2020, 110, 53-65, https://doi.org/10.1016/j.wasman.2020.05.016.

- Babafemi, A. J.; Šavija, B.; Paul, S. C.; Anggraini, V.; Engineering properties of concrete with waste recycled plastic: A review. Sustainability 2018, 10, 3875, https://doi.org/10.3390/su10113875.

- Awoyera, P. O.; Adesina, A.; Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330, https://doi.org/10.1016/j.cscm.2020.e00330.

- Islam, M.J.; Meherier, M.S.; Islam, A.R.; Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr. Build. Mater. 2016, 125, 946-951, https://doi.org/10.1016/j.conbuildmat.2016.08.128.

- Dhanani, M.G.; Bhimani, M.P.; Effect of use plastic aggregates as partial replacement of natural aggregates in concrete with plastic fibres. Int. Res. J. Eng. Technol. 2016, 3, 2569-2573.

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N.; Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180-188, https://doi.org/10.1016/j.conbuildmat.2015.05.105.

- Ahmadi, M.; Farzin, S., Hassani, A.; Motamedi, M.; Mechanical properties of the concrete containing recycled fibers and aggregates. Constr. Build. Mater. 2017, 144, 392-398, https://doi.org/10.1016/j.conbuildmat.2017.03.215.

- Foti, D.; Use of recycled waste PET bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396-404, https://doi.org/10.1016/j.compstruct.2012.09.019.

- Berkowski, P.; Kosior-Kazberuk, M.; Effect of fiber on the concrete resistance to surface scaling due to cyclic freezing and thawing. Procedia Eng. 2015, 111, 121-127, https://doi.org/10.1016/j.proeng.2015.07.065.

- Gupta, T.; Sharma, R. K.; Chaudhary, S.; Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76-87, https://doi.org/10.1016/j.ijimpeng.2015.05.002.

- Ochi, T.; Okubo, S.; Fukui, K.; Development of recycled PET fiber and its application as concrete-reinforcing fiber. Cem. Concr. Compos. 2007, 29, 448-455, https://doi.org/10.1016/j.cemconcomp.2007.02.002.

- Choudhary, A.K.; Jha, J.N.; Gill, K.S.; Utilization of plastic wastes for improving the sub-grades in flexible pavements. Paving Mater. Pavement Anal. 2010, 203, 320-326.

- Gedik, A.; An exploration into the utilization of recycled waste glass as a surrogate powder to crushed stone dust in asphalt pavement construction. Constr. Build. Mater. 2021, 300, 123980, https://doi.org/10.1016/j.conbuildmat.2021.123980.

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S.; Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443-467, https://doi.org/10.1016/j.conbuildmat.2017.09.005.

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Thomas, B.; Effect of recycled waste glass on the properties of high-performance concrete: A critical review. Case Stud. Constr. Mater. 2022, 9, e0114, https://doi.org/10.1016/j.cscm.2022.e01149.

- Lu, J.X.; Poon, C.S. Recycling of waste glass in construction materials. In New trends in eco-efficient and recycled concrete; Elsevier: Woodhead Publishing, 2018; pp. 153-167. https://doi.org/10.1016/B978-0-08-102480-5.00006-3.

- Yaghoubi, E.; Yaghoubi, M.; Guerrieri, M.; Sudarsanan, N.; Improving expansive clay subgrades using recycled glass: Resilient modulus characteristics and pavement performance. Constr. Build. Mater. 2021, 302, 124384, https://doi.org/10.1016/j.conbuildmat.2021.124384.

- Khan, Q.S.; Sheikh, M.N.; McCarthy, T.J.; Robati, M.; Allen, M.; Experimental investigation on foam concrete without and with recycled glass powder: A sustainable solution for future construction. Constr. Build. Mater. 2019, 201, 369-379, https://doi.org/10.1016/j.conbuildmat.2018.12.178.

- Ahmad, A.; Adil, M., Khalil, A.; Rahman, M.; Mechanical properties and durability of boardcrete blocks prepared from recycled cardboard. J. Build. Eng. 2021, 33, 101644, https://doi.org/10.1016/j.jobe.2020.101644.

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z.; A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759, https://doi.org/10.1016/j.conbuildmat.2021.123759.

- Haigh, R.; Bouras, Y.; Sandanayake, M.; Vrcelj, Z.; The mechanical performance of recycled cardboard kraft fibres within cement and concrete composites. Constr. Build. Mater. 2022, 317, 125920, https://doi.org/10.1016/j.conbuildmat.2021.125920.

- Tang, Z.; Li, W.; Tam, V.W.; Xue, C.; Advanced progress in recycling municipal and construction solid wastes for manufacturing sustainable construction materials. Resour. Conserv. Recycl. 2020, 6, 100036, https://doi.org/10.1016/j.rcrx.2020.100036.

- Parkes, B.; Hansell, A.L.; Ghosh, R.E.; Douglas, P.; Fecht, D.; Wellesley, D.; Kurinczukh, J.J.; Rankini, J.; de Hoogh, K., Fuller, G.W.; Elliott, P.; et al.Toledano, M.B. Risk of congenital anomalies near municipal waste incinerators in England and Scotland: Retrospective population-based cohort study. Environ. Int. 2020, 134, 104845, https://doi.org/10.1016/j.envint.2019.05.039.

- Tait, P.W.; Brew, J.; Che, A.; Costanzo, A.; Danyluk, A.; Davis, M.; Khalaf, A.; McMahon, K.; Watson, A.; Rowcliff, K.; et al.Bowles, D. The health impacts of waste incineration: a systematic review. Australian New Zealand J. Public Health 2020, 44, 40-48, https://doi.org/10.1111/1753-6405.12939.

- Ghosh, R.E.; Freni-Sterrantino, A.; Douglas, P.; Parkes, B.; Fecht, D.; de Hoogh, K.; Fuller, G.; Gulliver, J.; Font, A.; Smith, R.B.; et al.Blangiardo, M. Fetal growth, stillbirth, infant mortality and other birth outcomes near UK municipal waste incinerators; retrospective population based cohort and case-control study. Environ. Int. 2019, 122, 151-158, https://doi.org/10.1016/j.envint.2018.10.060.

- Bernardin, A. M. Recycling and reuse of bottom ashes from municipal solid-waste incineration plants in building materials. In Advances in the Toxicity of Construction and Building Materials; Duxford: Woodhead Publishing, United Kingdom, 2022; pp. 285-298.

- Al-Ghouti, M.A.; Khan, M.; Nasser, M.S.; Al-Saad, K.; Heng, O.E.; Recent advances and applications of municipal solid wastes bottom and fly ashes: Insights into sustainable management and conservation of resources. Environ. Technol. Innov. 2021, 21, 101267, https://doi.org/10.1016/j.eti.2020.101267.

- Joseph, A.M.; Snellings, R.; Nielsen, P.; Matthys, S.; De Belie, N.; Pre-treatment and utilisation of municipal solid waste incineration bottom ashes towards a circular economy. Constr. Build. Mater. 2020, 260, 120485, https://doi.org/10.1016/j.conbuildmat.2020.120485.