Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | zhao qi | -- | 1715 | 2022-12-09 12:09:00 | | | |

| 2 | Catherine Yang | Meta information modification | 1715 | 2022-12-12 04:18:20 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zhao, Q.; Qiang, M.; Hou, Y.; Chen, S.; Lai, T. Aerostatic Thrust Bearings. Encyclopedia. Available online: https://encyclopedia.pub/entry/38463 (accessed on 28 February 2026).

Zhao Q, Qiang M, Hou Y, Chen S, Lai T. Aerostatic Thrust Bearings. Encyclopedia. Available at: https://encyclopedia.pub/entry/38463. Accessed February 28, 2026.

Zhao, Qi, Mingchen Qiang, Yu Hou, Shuangtao Chen, Tianwei Lai. "Aerostatic Thrust Bearings" Encyclopedia, https://encyclopedia.pub/entry/38463 (accessed February 28, 2026).

Zhao, Q., Qiang, M., Hou, Y., Chen, S., & Lai, T. (2022, December 09). Aerostatic Thrust Bearings. In Encyclopedia. https://encyclopedia.pub/entry/38463

Zhao, Qi, et al. "Aerostatic Thrust Bearings." Encyclopedia. Web. 09 December, 2022.

Copy Citation

In aerostatic thrust bearings (ATBs), a high-pressure gas film with a certain bearing capacity and stiffness is formed by passing high-pressure gas between the moving surface and the static surface. Aerostatic bearings have outstanding advantages in the following aspects: high precision, high speed, and long service life, etc. They are widely used in many fields, such as high-speed air spindles, precision machine tools, air-bearing guideways, turbine machinery, and high-speed drills.

aerostatic thrust bearings

static performance

dynamic performance

applications

1. The Applications of ATBs

1.1. High Precision Applications

High-precision applications using ATBs mainly include precision machine tools and precision flotation equipment. A large number of mature products have been developed and produced. Moore and Precitch in the United States, Fanuc in Japan, the Loxham Precision Company, Cranfield University in the United Kingdom, the Harbin Institute of Technology in China, and other institutions have developed a variety of high-precision machine tools and mature commercial products.

The Nanotech 250 UPL and Nanotech 450 UPL ultra-precision machine tools were developed by the Moore company, adopting impact-resistant air bearing spindles, as shown in Figure 1 [1][2]. The motion accuracy of machine tools is no more than 12.5 nm at 10 krpm. Precitch ‘s Nanoform X small-frame diamond lathe adopts HS150 and HS75 spindles [3], as shown in Figure 1. The surface roughness of the workpiece is less than 1 nm. The axial stiffness of the HS75 spindle is 105 N/μm. The maximum speed of this working spindle is 18 krpm. Axial/radial motion accuracy is less than 20 nm. The axial stiffness of the HS150 spindle is 230 N/μm. The maximum working speed is 10 krpm. Axial/radial motion accuracy is less than 15 nm. Fanuc has successfully developed a ROBONANO α-0iB five-axis ultra-precision nanomachine [4]. This machine tool is supported by the aerostatic bearing, and the rotation accuracy can reach 0.05 μm. Both the B-axis and C-axis can achieve 360-degree continuous rotation. Loxham [5] has developed an Ultra precision six-axis ultra-precision machine, named μ6. The guideway system is supported by ATBs. The surface roughness is less than 5 nm during turning cutting and less than 10 nm during micro washing.

In addition, study on precision machine tools has been carried out by many research institutions. A three-axis ultra-precision machine tool has been successfully developed by the Tokyo Institute of Technology [6][7], named ANGEL. A new air bearing platform is applied in this machine, and the Z axis is supported by the ATB. The max machined workpiece size is 230 mm × 230 mm × 70 mm. Groove machining with a precision of 20 nm can be realized. National Cheng-Kung university [8] has developed a pneumatic servo table. The sliding guideway is supported by the ATB. The positioning accuracy of the platform can reach 0.04 μm. A small ultra-precision milling machine for micro parts has been developed by Brunel University of the UK [9][10], named Ultramill. Both the spindle and the linear guideway are supported by aerostatic bearings. The motion accuracy of the linear axis of the machine tool is less than 1 μm. The rotation accuracy of the turntable is less than 1′′ (1/3600 degree), and the motion accuracy of the other rotation axis is less than 10′′. For microgroove machining based on the diamond tool, surface roughness can reach 10 nm and straightness error can reach 0.28 μm/40 mm. The Beijing Institute of Aeronautical Precision Machinery [11] has successfully developed an ultra-precision lathe, named Nanosys-300. The aspheric machining accuracy is between 0.3 and 0.5 μm, and surface roughness is less than 0.01 μm. The Institute of Mechanical Manufacturing Technology, Chinese Academy of Sciences [11] has developed an aerostatic lathe spindle. Two aerostatic journal bearings and a thrust bearing are integrated to support the spindle. The roundness of the cutting brass (H62) parts is less than 0.1 μm, and the surface roughness can reach 0.03 μm. Cranfield University [12] has developed a six-axis ultra-precision machine tool, named Integ-μ4. A self-developed porous ATB is adopted in this machine. It has a linear motion resolution of 1 nm and a rotational motion resolution of less than 1 × 10−8 rad. The dynamic stiffness of this machine is extremely high. A variety of complex shapes of hard and soft materials can be processed. The maximum machined workpiece size is 50 mm × 50 mm × 50 mm, and the machining accuracy can reach the sub-micron level. The Harbin Institute of Technology [13] has developed an ultra-precision machine tool, named HCM-1. Ultra-precision ATBs of jade materials are used to support this machine tool. The maximum circumferential machining diameter can reach 1200 mm. The surface shape accuracy is 2 μm, and the surface roughness can reach 4 nm.

1.2. High-Speed Applications

A typical machine of high-speed applications using ATBs is the turboexpander. In the development of high-speed turboexpanders, the Air Liquid Company, Xi’an Jiaotong University, the Technology Institute of Physics and Chemistry, the Chinese Academy of Science, and other institutions have accumulated profound technical expertise. A lot of research has been conducted on air turboexpanders, hydrogen turboexpanders, and helium turboexpanders using ATBs.

Helium turboexpanders produced by Air Liquid Company have been used in many large scientific devices, such as the tokamak device KSTAR of the Korean National Fusion Research Center (NFRC), and the International Thermonuclear Experimental Reactor (ITER). The 9 kW @ 4.5 K helium refrigerator of KSTAR was equipped with six TC4-500 and TC5-500 helium turboexpanders supported by ATBs [14]. Each of ITER’s 65 kW @ 4.5 K helium refrigerators was equipped with three TC-4 and one TC-5 turboexpander supported by ATBs [15]. The power of three TC-4 turboexpanders is 15, 13, and 11 kW, respectively. The power of the TC-5 turboexpander is 11 kW. The efficiency of all the turboexpanders is greater than 74%. The Creare company in the United States has been working on research for a two-phase helium turbine expander [16]. A helium expander has been designed with a length of 365 mm, a diameter of 150 mm, and a weight of approximately 17 kg. The rotor is supported by two aerostatic journal bearings and one ATB. This turboexpander has been successfully applied in a small helium liquefaction device. The expander works safely in the two-phase region for more than 7500 h. The rotation speed is 354 krpm, with a flow rate of 43 g/s. The isentropic efficiency is about 63%, and the liquefaction is 84 L/h. The Technology Institute of Physics and Chemistry of The Chinese Academy of Science has successfully developed a helium turbine expander. The wheel diameter of the turboexpander is 35 mm, and the brake wheel diameter is 60 mm. Aerostatic thrust bearings have been applied to support the shaft. During testing, the outlet temperature of the helium turboexpander has reached 15.4 K. The maximum cooling capacity is 2.2 kW, and the adiabatic efficiency exceeds 72% [17].

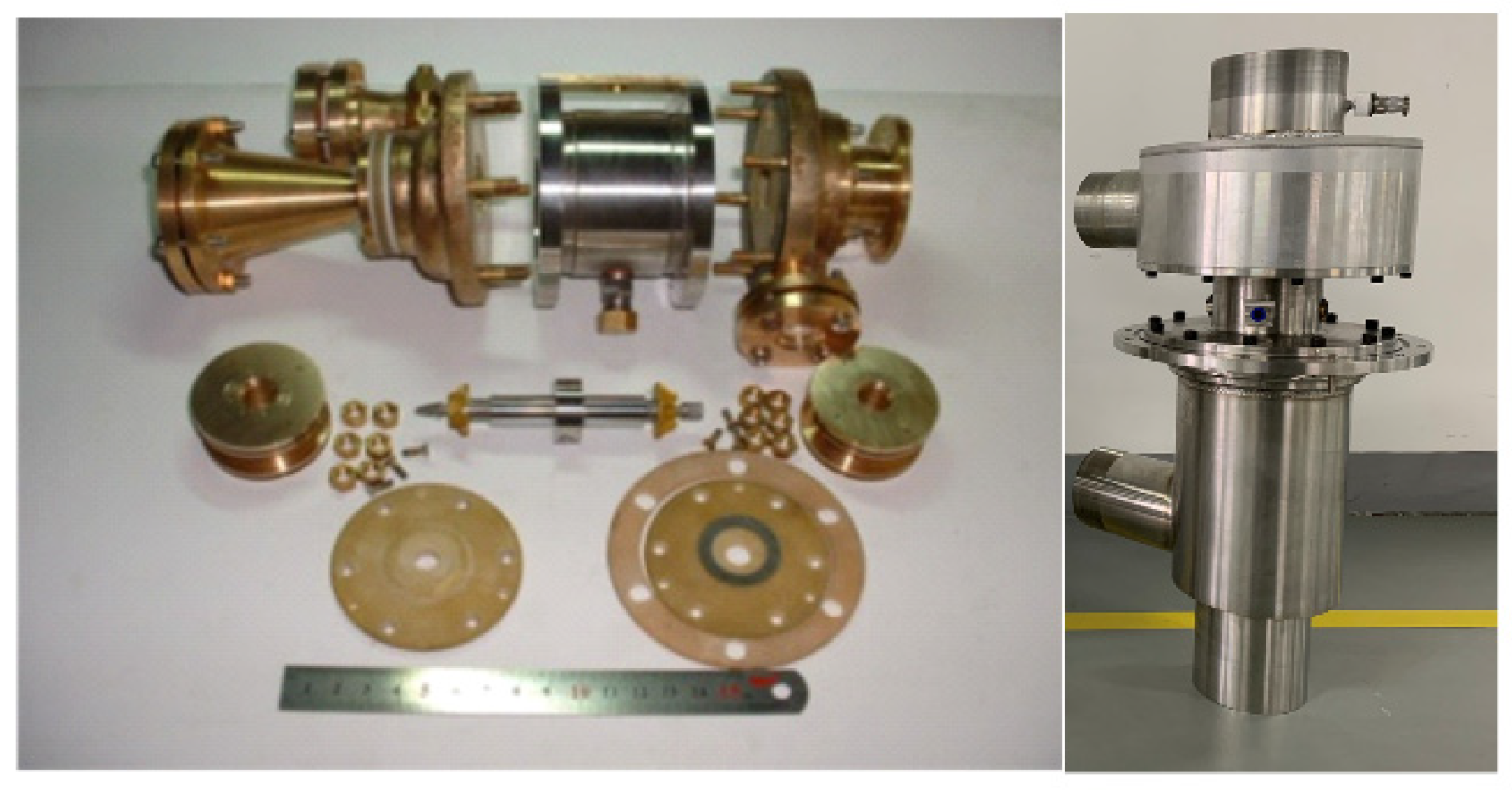

Xi’an Jiaotong University has also conducted a lot of research on turboexpanders. A helium turboexpander supported by ATBs was developed for the space environment simulator KM6 in the late 1990s [18]. The working wheel diameter was 35 mm, and the brake fan wheel diameter was 60 mm. In the low-temperature air environment test, the highest speed reached 127 krpm, and adiabatic efficiency was 68%. While the outlet temperature was 12.8 K, the efficiency of the turboexpander could reach 75%. The maximum cooling capacity was close to 2 kW. In addition, a series of hydrogen and helium turboexpanders have been developed recently [19]. To meet the requirements of axial load, ATBs have been applied as thrust bearings in these hydrogen and helium turboexpanders, as shown in Figure 2. The power of the hydrogen turboexpanders is 20~40 kW. The helium turboexpander is 39.7 kW with a rotation speed of 74.5 krpm. In the air environment test, the rotation speed of the helium turboexpander can reach 60 krpm, and the amplitude is less than 0.023 μm.

Figure 2. The air turboexpander and hydrogen turboexpander using ATBs by Xi’an Jiaotong University.

2. The Development Trends of ATBs

Aerostatic thrust bearings are widely used in many high-tech fields. The research on ATBs is deepening, and many advances have been achieved. However, there are still some challenges with ATBs. More effort should be put into the study of ATBs.

1. Due to the low viscosity of the gas, the bearing capacity and stiffness of ATBs are much lower than oil bearings. These shortcomings limit the further application of ATBs. It is necessary to produce ATBs with greater stiffness and greater load capacity. In the theoretical analysis of ATBs, some traditional assumptions and neglected factors must be considered. For example, in the case of low gas film thickness, the influence of factors such as surface roughness and the mean free path of gas molecules must be considered. In the case of high-speed flow, the assumption of isothermal gas flow, the influence of gas inertial effects, shock waves, and turbulent flow effects, etc., must be carefully analyzed. In addition, under the guidance of theoretical analysis, the design level of the bearing should be continuously improved. The manufacturing process and the machining accuracy of ATBs should be enhanced. The use of modern and more precise experimental methods is also critical. It is necessary to combine theoretical analysis with experimental analysis to design ATBs with higher load capacity and higher stiffness.

2. In addition to air, nitrogen, hydrogen, and helium, other gases are also used in ATBs to meet different working conditions and needs. With the development of hydrogen and helium liquefaction equipment, the application of ATBs using special gas becomes more extensive. There is much research on aerostatic bearings, while the research on aerostatic bearings using special gas is still limited. Due to the flammability and leakage of hydrogen and the scarcity of helium, it is relatively difficult to carry out related experimental research. The relevant experimental data are even more scarce. Due to the unique physical properties of special gases, their flow characteristics, load-carrying characteristics, and the stability performance of ATBs are completely different from traditional air ATBs. Therefore, more effort should be put into the research of ATBs using special gases. In addition, the corresponding protective measures should be taken during experimentation to ensure experiment safety.

3. When gas is used as a lubricating medium, problems such as solidification at low temperature and volatilization at high temperature of oil are completely overcome. Aerostatic bearings are suitable for high- and low-temperature environments. There are many studies of ATBs in normal temperature and low-temperature environments, while the research in high-temperature environments is relatively less. In a high-temperature environment, the effects of high temperature on gas properties should be considered. In addition, the influence of high temperature on the thermal deformation of the bearings should be considered. The gas film thickness changes due to the thermal deformation of the bearing, which will affect the bearing performance.

References

- The Nanotech 250UPL Ultra-Precision Machine Tools. . Available online: https://nanotechsys.com/250-upl/ (accessed on 3 October 2022).

- The Nanotech 450UPL Ultra-Precision Machine Tools. . Available online: https://nanotechsys.com/450-upl/ (accessed on 3 October 2022).

- Nanoform X Diamond Lathe. . Available online: https://www.precitech.cn/product/smallframelathesoverview/nanoform-x (accessed on 3 October 2022).

- Wu, Y.K. Research on Self-Excited Vibration of Air Hammer of Disk Hydrostatic Gas Thrust Bearing Based on Weak Coupling Method; Harbin Institute of Technology: Harbin, China, 2021. (In Chinese)

- Ultra Precision 6-Axis Ultra-Precision Machine. . Available online: https://www.loxhamprecision.com/products/μ6-diamond-turning-machine/ (accessed on 3 October 2022).

- Shinno, H.; Yoshioka, H.; Taniguchi, K. A newly developed linear motor-driven aerostatic x-y planar motion table system for nano-machining. CIRP Ann. Manuf. Technol. 2007, 56, 369–372.

- Hidenori, S.; Hayato, Y. Design concept and structural configuration of advanced nano-pattern generator with large work area ‘ANGEL’. Int. J. Autom. Technol. 2011, 5, 38–44.

- Tsai, M.H.; Hsu, T.Y.; Pai, K.R.; Shih, M.C. Precision position control of pneumatic servo table embedded with aerostatic bearing. J. Syst. Des. Dyn. 2008, 2, 940–949.

- Huo, D.; Cheng, K.; Wardle, F. Design of a five-axis ultra-precision micro-milling machine—UltraMill. Part 2: Integrated dynamic modeling, design optimization and analysis. Int. J. Adv. Manuf. Technol. 2010, 47, 879–890.

- Huo, D.; Cheng, K.; Wardle, F. Design of a five-axis ultra-precision micro-milling machine—UltraMill. Part 1: Holistic design approach, design considerations and specifications. Int. J. Adv. Manuf. Technol. 2010, 47, 867–877.

- Zhao, W.Y.; Tao, J.Z. Design of the ultra-precision aerostatic lathe spindle. Chin. Hydraul. Pneum. 2012, 1, 25–27. (In Chinese)

- Shore, P.; Morantz, P.; Castelli, M.; Read, R.; Carlisle, K.; Comley, P. Design overview of the μ4 Compact 6 axes ultra precision diamond machining centre. In Laser Metrology and Machine Performance X 10th International Conference and Exhibition on Laser Metrology, Machine Tool, CMM and Robotic Performance; European Society for Precision Engineering & Nanotechnology: Buckinghamshire, UK, 2013; pp. 9–18.

- Linag, Y.C.; Chen, G.D.; Sun, Y.Z.; Sun, Y.Z.; Chen, J.X.; Chen, W.Q.; Yu, N. Research status and outlook of ultra-precision machine tool. J. Harbin Inst. Technol. 2014, 46, 28–39. (In Chinese)

- Choi, C.; Chang, H.-S.; Park, D.; Kim, Y.; Bak, J.; Lee, G.; Kwon, I.; Kim, H.; Cho, M.; Kim, H.-S.; et al. Helium refrigeration system for the KSTAR. Fusion Eng. Des. 2006, 81, 2623–2631.

- Fauve, E.; Bonneton, M.; Chalifour, M.; Chang, H.-S.; Chodimella, C.; Monneret, E.; Vincent, G.; Flavien, G.; Fabre, Y.; Grillot, D. ITER LHe plants parallel operation. Phys. Procedia 2015, 67, 42–47.

- Fu, B. Design and Test of Helium Turbine Expander for EAST Cryogenic System. Master’s Thesis, Hefei Institute of Material Science, Chinese Academy of Sciences, Beijing, China, 2007. (In Chinese).

- Sun, L.J.; Sun, W.; Ren, X.K.; Zhang, W.; Zhang, L.L. Design of turbo-expander in helium refrigeration system. Cryogenics 2013, 3, 7–10. (In Chinese)

- Hou, Y.; Chen, C.Z.; Xiong, L.Y.; Liu, L.Q.; Wang, J. Design of cryogenic helium expansion turbine. Cryogenics 2003, 3, 7–11. (In Chinese)

- Hou, Y.; Zhao, Q.; Guo, Y.; Ren, X.H.; Lai, T.W.; Chen, S.T. Application of gas foil bearings in china. Appl. Sci. 2021, 11, 6210.

More

Information

Subjects:

Engineering, Industrial

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

12 Dec 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No