Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Santosh Kumar Sahu | -- | 2607 | 2022-12-06 08:22:20 | | | |

| 2 | Vivi Li | Meta information modification | 2607 | 2022-12-07 04:48:13 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Paladugu, S.R.M.; Sreekanth, P.S.R.; Sahu, S.K.; Naresh, K.; Karthick, S.A.; Venkateshwaran, N.; Ramoni, M.; Mensah, R.A.; Das, O.; Shanmugam, R. Self-Healing Polymer, Metal, and Ceramic Matrix Composites. Encyclopedia. Available online: https://encyclopedia.pub/entry/38105 (accessed on 13 January 2026).

Paladugu SRM, Sreekanth PSR, Sahu SK, Naresh K, Karthick SA, Venkateshwaran N, et al. Self-Healing Polymer, Metal, and Ceramic Matrix Composites. Encyclopedia. Available at: https://encyclopedia.pub/entry/38105. Accessed January 13, 2026.

Paladugu, Sri Ram Murthy, P. S. Rama Sreekanth, Santosh Kumar Sahu, K. Naresh, S. Arun Karthick, N. Venkateshwaran, Monsuru Ramoni, Rhoda Afriyie Mensah, Oisik Das, Ragavanantham Shanmugam. "Self-Healing Polymer, Metal, and Ceramic Matrix Composites" Encyclopedia, https://encyclopedia.pub/entry/38105 (accessed January 13, 2026).

Paladugu, S.R.M., Sreekanth, P.S.R., Sahu, S.K., Naresh, K., Karthick, S.A., Venkateshwaran, N., Ramoni, M., Mensah, R.A., Das, O., & Shanmugam, R. (2022, December 06). Self-Healing Polymer, Metal, and Ceramic Matrix Composites. In Encyclopedia. https://encyclopedia.pub/entry/38105

Paladugu, Sri Ram Murthy, et al. "Self-Healing Polymer, Metal, and Ceramic Matrix Composites." Encyclopedia. Web. 06 December, 2022.

Copy Citation

Composites can be divided into three groups based on their matrix materials, namely polymer, metal and ceramic. Composite materials fail due to micro cracks. Repairing is complex and almost impossible if cracks appear on the surface and interior, which minimizes reliability and material life. In order to save the material from failure and prolong its lifetime without compromising mechanical properties, self-healing is one of the emerging and best techniques.

microcapsules

hollow fibers

vascular network

healing mechanisms

1. Introduction

Materials with self-healing capability have gained much attention recently. For example, scratches on a car can be patched or repaired on their own, restoring its original shiny appearance. This is somewhat similar to wound healing in mammals [1]. Structural materials deteriorate and degrade over time leading to micro-cracks that cause failure. Accordingly, to improve the reliability and lifetime of products, repair is necessary [2]. However, it is quite challenging to integrate the healing process of extreme conditions such as fractured bones into manufacturing products due to changing trends in the healing mechanisms of human bodies and other living beings [3].

Self-healing composites are capable of auto-repairing upon crack initiation and regaining their mechanical properties without disturbing the mode of application. Self-healing mechanisms can be divided into two types, extrinsic and intrinsic healing. In extrinsic healing, the healing agent is used as an additive to fill up the cracks in the matrix and in intrinsic healing, a reversible crosslinking bond (supramolecular chemistry) is used to bind the monomers and fill the cracks [4]. Furthermore, classification can also be made on autonomic healing or non-autonomic healing (i.e., with or without external stimuli). A few well-known methods for developing self-healing composites are the inclusion of microcapsules, hollow fibers, and a vascular network containing healing agents. Self-healing can also be achieved by thermal activation of reversible interactions or dissolved thermoplastic polymers [5].

The self-healing concept is an emerging technique in the engineering field and it can be applied to composite materials such as polymer matrix composites (PMCs), ceramic matrix composites (CMCs), metal matrix composites (MMCs), and cementitious composites. Apart from the specified areas, the self-healing concept can also be applied to coatings for corrosion protection for commercial applications [6][7]. Many potential applications of self-healing composites are implemented in resistant fabrics, resealing tires, long-life batteries, aerospace sectors, and automobile fields. In the aerospace sector, the damage due to impact load is severe [8]. However, self-healing materials can repair damage caused due to outside environment and increase the lifetime of the components. One key application of self-healing materials is to repair dynamic damage and maintain impact resistance [9].

2. Self-Healing of Metals and Metal Matrix Composites

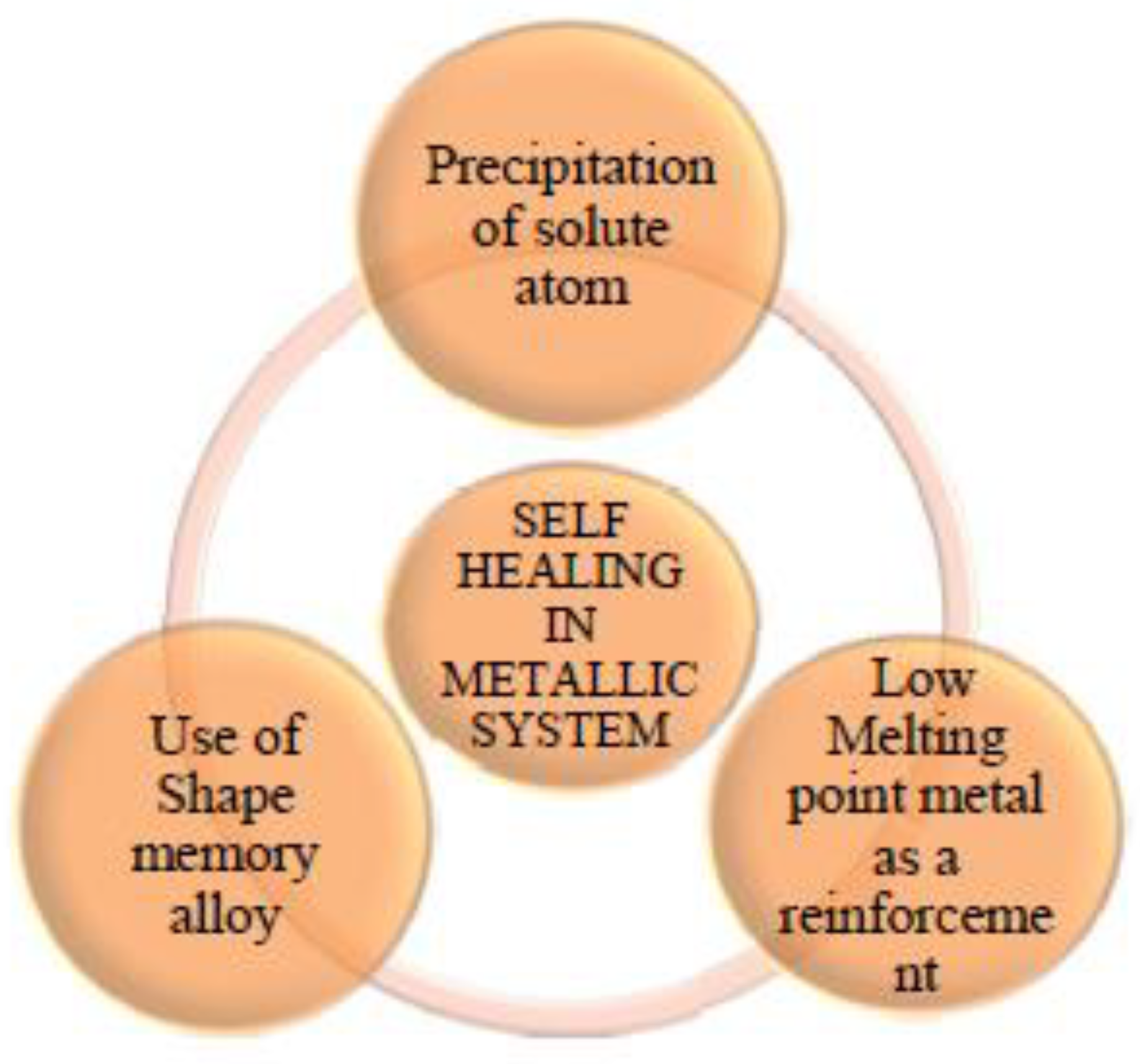

2.1. Classification of Metallic Structures in Self-Healing

The self-healing procedures of revolutionary metallic materials are classified according to their product composition or autonomy (Figure 1). Additional actuation, such as applying heat or electricity, is essential for non-autonomous self-healing systems. Even though autonomous self-healing materials do not require outside actuation, autonomous metallic self-healing systems continue to be mostly theoretical currently, due to a lack of noticeable experimental results. Self-healing metal matrix composites (MMCs) are homogeneous macroscopic materials, formed from memory alloy (SMA) fibers and encapsulated healing chemicals commonly spread in a matrix. Irrespective of size, SMA wires are already placed in metal matrices (Al, Zn, Sn, or alloy that is Sn-Bi) as reinforcements to produce self-healing materials centered on SMA. Self-healing, depending on encapsulated recovery agents, is established by injecting capsules or pipes carrying a representation that is curing as solder [10][11][12][13]. Recovery through coatings, electro-heating, eutectic-based, and precipitation-based recovery are typical examples of self-healing [14][15][16][17]. Theoretical research focuses on nano-scale processes, including nano-SMA and ground boundary migration self-healing metals.

Figure 1. Methods of self-healing metals [18].

2.2. Mechanisms of Self-Healing Metal and MMCs

2.2.1. Precipitation-Dependent Healing

In precipitation-based recovery, micro-cracks/voids in the substance behave as nucleation areas for supersaturated or under-aged alloy precipitation. Solute atoms happen to be defects and voids in underaged alloys, in essence, “healing” them. This procedure shows the void as the outcome of being filled by migrant atoms in self-recovery and being examined. This healing, nonetheless, happens on a nanometer scale level comparable to the standard age-hardening process; however, it cannot fix heavy cracks. Precipitation occurs at microcracks that generate precipitates within the localized, highly stressed location, and recovery can be expedited by warming an alloy to an aging temperature that is particular. [19]. If the alloy cools, it becomes supersaturated meta-stable from high heat, and then returns to equilibrium, which happens during aging by precipitating supersaturated solutes over voids and cracks. An under-aged alloy such as Al-Cu-Ag-Mg increases its creep resistance by heat treating at high temperature but at a constraint rather than fully hardened, e.g., to T6 temper, dynamic precipitation of the following alloy even at 500 h creep at 300 MPa and 150 °C, even associated with dislocations and healing of the cracks, is obtained by further aging of heat treatment.

The curing of the break triggered additional heat that is aged. Precipitation heat treatment impacts the crack action in Al-Cu AA 2001 alloy in under-aged boundary situations, which has been investigated [20]. It indicates the microstructures of the under-aged alloy were crack healed after the aging treatment for 10 h. The work [21] studied the precipitation of boron nitride (BN), which leads to a self-healing mechanism in 304 stainless steel improvised with boron (B), cerium (Ce), and titanium (Ti). The alteration of B, Ce, and Ti of the alloy contributed towards the preferential BN accumulation in the locations associated with the creep cavity, and it is stable at high temperatures at creep cavity surfaces and leads to an increase in the creep resistance of 304 stainless steel. This procedure, as conducted over voids, holes, and other free surfaces, is heterogeneous to attain self-healing, which will behave as nucleation in odd cracks. Researchers examined how precipitation heals in two different areas. Precipitation recovery at high temperatures (575–750 °C) was mostly examined on stainless steel and Cr-Mo-V alloys, although it was mostly studied on Al alloys at low conditions (120–185 °C). Diffusion, which is the rate-constrained site that can manage the motion of atoms to the matrix and into gaps and fissures in the matrix, requires some time to accelerate. Precipitation-based recovery has thus far been limited to small-scale injury by studies. This can remove fatigue fracture start sites over extended periods, although restricted to early harm stages. Precipitation-based mending could have a small effect if a break widens.

2.2.2. Healing Based on Nano-SMA-Dispersoids

Nanosize shape memory alloy (nano-SMA) dispersoids were suggested for self-healing metallic materials. Period change of SMA nanoparticles, which belongs to the grouped community of nanoscale recovery processes, fills nano-voids. Few authors stated that the essential idea is currently in its very early phases of development. Additionally, the capability to self-heal has yet to be proved. The microstructure is first made up of a host matrix with embedded coherent SMA nanoparticles stabilized by the host matrix in its austenite phase which is a high-temperature zone [22][23][24][25][26]. Whenever damage is generated by dislocation localization and nanovoids are formed, activation of nanoparticles occurs, and the nanovoid strain is expected to change the phase transition of the SMA nanoparticle from austenite to martensite [27]. The change of phases is followed closely by a sharp change in the shape of the particle that produces regional stress areas on the host matrix and plays a part in the closing of cracks.

Theoretically, when small-size nano-dispersions fill voids, it can cause residual stresses and alter the fatigue characteristics of the material. The unit’s absence of bonding capabilities could be a performance impediment on the other side.

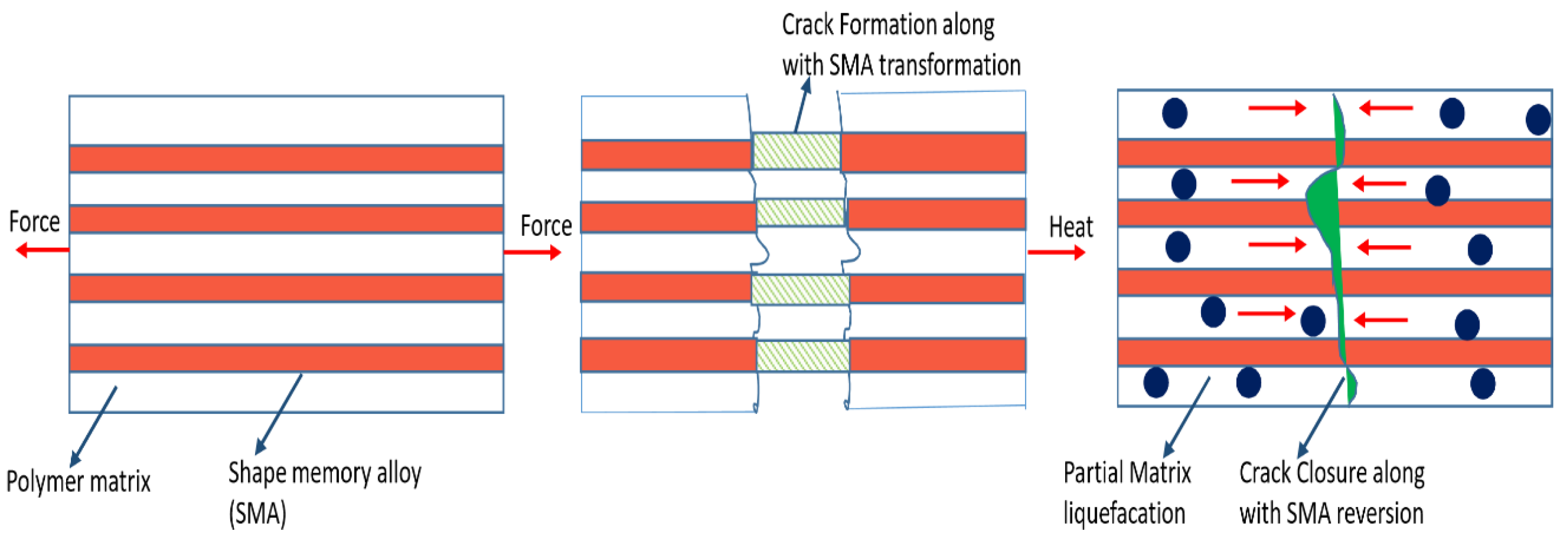

2.2.3. SMA-Based Healing

Self-healing materials with memory components aid in regenerating bulk geometry after having a fracture which is a feature not found in other self-healing modes. This is crucial regarding restoring a building’s previous functionality after significant damage. SMA reinforcements are utilized in selected steel matrices for self-healing in this technique. Shape pseudoelasticity and memory are two characteristics that distinguish SMAs. Whenever heated above its austenite transformation temperature, an SMA’s ability to deform into the martensitic state and then return to its original shape is known as pseudoelasticity [28]. The latter is connected with an SMA that can recover the strain which is highly applied upon unloading the material when it is in its austenite phase. In self-healing materials, heating at a high temperature helps to achieve substantial recovery by constraining shape recovery, which can lead to geometric reconstruction and crack closure. SMA has been enhanced to aid the healing process; nevertheless, the services and products remain essentially non-autonomous and need external actuation (typically heating).

The primary challenges encountered by self-healing SMA-reinforced materials, are (I) maintaining the bond between the SMA and matrix. (II) Synthesis affinity between SMA and the steel matrix; (III) The characteristics and recovery kinetics of SMA-reinforced matrix. (IV) SMA-metal matrix compatibility during synthesis; (V) An intensive knowledge of the dynamics and recovery kinetics of SMA-reinforced matrix; (VI) A clear understanding of the damaged area and how to speed the recovery process up. A self-healing material that is tin (Sn)-based was created using a strengthened Sn-21 Bi (wt. %) matrix alloy with 1% equiatomic NiTi SMA wires [29]. The composite, which contained a matrix that is complete in a tensile test, cooled to atmospheric temperature, and tested again, was fixed within an oven at 169 °C for 24 hours. The break, along with the restored specimens, was indeed found to be closed. It was unearthed that 95% of the original tensile strength was recoverable. The design was preserved by warming the SMA and softening the matrix solders. During heating, NiTi cables started to stress the matrix to recover to their original form (shorter lengths) The usage of other alloys as matrix materials for self-healing components has additionally been investigated. In experiments on healing, in a matrix that is magnesium-dependent partial recovery can happen at a given temperature. Qiao et al. [30] investigated the utilization of NiTi SMA wires within an Al-A380 matrix. Due to a lack of adhesion between the cable and the matrix, SMA cables alone were not able to repair the damaged faces. Wrapping SMA wire along the threaded stainless steel and casting Al-A380 around the rod/wire addressed the challenge. This rod acted as a technical anchor, allowing the SMA to pull, although the whole cable had disintegrated. It was discovered that the strengthened component was approximately twice as strong and ductile due to the unreinforced sample. Since the re-bonding was inadequate, there was no significant power, although a significant decrease in fracture width and residual compressive stresses was observed. Because SMA is now a part of self-healing, limited rehabilitation may now be used to produce recurring compressive stress fracture repair. This residual load by post-tensioned tangible systems enables the structure to withstand externally induced stress without bonding. Continuous initiatives are fond of describing this possibility in terms of how healing systems may be constructed to withstand axial or external bending stresses. Since applied stress rises, adhesive bond energy grows; this capacity is thought to aid bonding in self-healing.

2.2.4. Encapsulated Healing

In this section, the healing performance of capsule-based self-healing materials is discussed. Table 1 shows the healing performance of capsule-based self-healing materials. Microcapsules containing dicyclopentadiene (DCDP), a monomer curing representative, were embedded inside a polymeric epoxy matrix, including a catalyst to achieve the self-healing of autonomous polymers. Self-healing happens when capsules that discharge the agent (a monomer) are propagated and broken by a break in polymeric materials. Encapsulated agents treatments, such as polymer healing agents, have been utilized to create self-healing MMCs. Ferguson et al. [31] proposed the growth of the latest MMCs being self-healing encapsulated solders in 2008. Materials with low melting temperatures were encased in ceramic shells to identify the breach and then scattered within a host matrix with a greater melting temperature [32][33][34]. After heating, the solders had low temperatures and flooded into the fracture, charging the space by capillary action and starting bonding at particular conditions. The energy data recovery with this curing procedure depends on this host steel structure; therefore, the properties of alloys having a low melting temperature exhibited an energy restoration of 60% associated with the initial pre-damaged energy [35][36][37][38].

Table 1. Healing performance of capsule-based self-healing materials [39].

| Mechanism | Healing Percentage (%) | Time for Healing (hrs) | Conditions for Healing | Matrix | Reference |

|---|---|---|---|---|---|

| DCPD + Grubbs | 75–100 | 10–48 | Room temperature | Epoxy | [40] |

| DCPD + Grubbs | 30 | 24 | Room temperature | Epoxy vinyl ester | [40] |

| DCPD + Grubbs | 70–100 | 48 | Room temperature | Epoxy + CFRC | [40] |

| DCPD + WCl6 | 20–64 | 24 | 25–50 °C | Epoxy | [41] |

| ENB + Grubbs | 45–80 | 48 | Room temperature- 80 °C | Epoxy | [42] |

| ENB/DCPD+ Grubbs | 85 | 48 | Room Temperature | Epoxy | [42] |

| ENB + Hoveyda Grubbs | 95 | 2 | 170 °C | Epoxy | [42] |

| HOPDMS and PDES | 20–24 | 24 | 50 °C | Epoxy vinyl ester | [43] |

| HOPDMS and PDES | 100 | 48 | 150 °C | Epoxy +FRC | [43] |

| Epoxy and Solvent | 85–100 | 24 | Room Temperature | Epoxy | [44] |

| Epoxy and Solvent + Scandium triflate | More than 80 | 48 | 80 °C | Epoxy | [30] |

| Epoxy + CuBr (2) (2-Melm)4 | 111 | 1.5 | 130 °C-180 °C | Epoxy | [45] |

| Epoxy + Mercaptan | 104 | 24 | 20 °C | Epoxy | [45] |

| Epoxy + MBM tetrathol | 120 | 5 days | 25 °C | Epoxy | [46] |

| Epoxy + antimony pentafluoride | 70 | 20 sec | Room temperature at 0.2 MPa | Epoxy | [46] |

2.2.5. Coating-Based Healing

The authors created the facet of the titanium alloy with a thickness of 2.03 mm, a 60 percent indium–40 percent tin (wt. percent) self-healing coating with a melting temperature of 124 °C and a thickness range of 0.005–0.0015 mm. If a surface break appears, these devices may be heated through the In–Sn alloy’s melting point. As soon as the specimen is heated, the break in the titanium alloy is covered by molten area alloys [47][48][49][50]. Crack healing evaluation revealed that after the procedure, which is a self-healing process, crack development is avoided by employing a low crack-tip driving force. An increased crack-tip driving force can result in a 50% reduction in the break development rate. The self-healing coating could be activated repeatedly, indicating the chance of multicycle heating in inert conditions.

2.2.6. Electro Healing

Steel ions are electrodeposited onto a fracture in a bath with electrolytic-regulated electric currents in pure nickel sheets, resulting in break recovery. The authors examined electro-healing. The cracks with sizes up to 100 µm within the micrometer range had been effectively healed utilizing the procedure of electro-healing. This action has regained almost 96 percent of tensile power. While this option would be effective, there could be a limitation to the need to place a framework combined with a small scale of heating.

2.2.7. Eutectic-Based Recovery

Numerous researchers [51][52][53][54] examined eutectic-based healing using eutectic liquid formed in its solid phase and acting as a healing region, while the solid dendrites are composed of structural integrity. The best path to accomplish this is to use a matrix that is distant from eutectic composition to form eutectic dendrites at higher temperatures. When the melt is cooled, dendrites of this main period are created because of their high melting temperature. These dendrites deform the structure of the remaining inter-dendritic fluid, repelling the dissolved substances, so the composition of the inter-dendritic fluid changes. To achieve this for self-healing, the temperature has to be increased until the interdendritic eutectic melts and flows into the specimen through the mechanism of cracks and then closes the crack, while the hard dendrites keep the structural coherence of the system. The fluid is a eutectic movement involving the dendrites and enters any holes or gaps within the unit; the eutectic liquid solidifies in the cracks and heals the specimen, as shown in Figure 2.

Figure 2. Liquid-aided healing of MMCs reinforced with SMA [55].

2.3. Applications and Future Scope

The attractive advantages of the usage of self-recovery in metal substances include low renovation costs, lengthy carrier life, and avoidance of catastrophic remarks. However, self-recovery in metal substances has not been extensively utilized in real-international applications, particularly for load-bearing applications. MMCs with self-recovery traits are being evaluated properly now. Self-recovery metals and substances are not blanketed in any purchaser products. Self-recovery polymers crafted from MMCs, which include self-recovery slicing pads, are currently commercially viable. Nonetheless, self-recovery metals and self-recovery MMCs have several uses. In the renewable strength and biomedical sectors, self-recovery metallic substances with sturdy mechanical properties can be created for wing parts, structural components, spinning components, blades of turbines, and steel implants.

References

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 163, 165–174.

- Wang, X.; Liang, D.; Cheng, B. Preparation and research of intrinsic self-healing elastomers based on hydrogen and ionic bond. Compos. Sci. Technol. 2020, 193, 108127.

- Rahmani, H.; Eslami-Farsani, R.; Ebrahimnezhad-Khaljiri, H. High velocity impact response of aluminum- carbon fibres-epoxy laminated composites toughened by nano silica and zirconia. Fibres Polym. 2020, 21, 170–178.

- Han, J.; Ding, Q.; Mei, C.; Wu, Q.; Yue, Y.; Xu, X. An intrinsically self-healing and biocompatible electroconductive hydrogel based on nanostructured nanocellulose-polyaniline complexes embedded in a viscoelastic polymer network towards flexible conductors and electrodes. Electrochim. Acta. 2019, 318, 660–672.

- Ding, Q.; Xu, X.; Yue, Y.; Mei, C.; Huang, C.; Jiang, S.; Wu, Q.; Han, J. Nanocellulose-mediated electroconductive self-healing hydrogels with high strength, plasticity, viscoelasticity, stretchability, and biocompatibility toward multifunctional applications. ACS Appl. Mater. Interfaces 2018, 10, 27987–28002.

- Ghosh, S.K. (Ed.) Self-Healing Materials: Fundamentals, Design Strategies, and Applications; Wiley-vch: Weinheim, Germany, 2009.

- Feiz, A.; Khosravi, H. Multiscale composites based on a nanoclay-enhanced matrix and E-glass chopped strand mat. J. Reinforc. Plast. Compos. 2019, 38, 591–600.

- Naresh, K.; Cantwell, W.J.; Khan, K.A.; Umer, R. Single and multi-layer core designs for Pseudo-Ductile failure in honeycomb sandwich structures. Compos. Struct. 2021, 256, 113059.

- Khan, T.; Irfan, M.S.; Cantwell, W.J.; Umer, R. Crack healing in infusible thermoplastic composite laminates. Compos. Part A: Appl. Sci. Manuf. 2022, 156, 106896.

- Li, F.; Yu, H.Y.; Wang, Y.Y.; Zhou, Y.; Zhang, H.; Yao, J.M.; Ahdalkarim, S.Y.H.; Tam, K.C. Natural biodegradable poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nano composites with multifunctional cellulose aanocrystals/graphene oxide hybrids for high-performance food packaging. J. Agr. Food. Chem. 2019, 67, 10954–10967.

- Azizi, A.; Gadinski, M.R.; Li, Q.; Al Saud, M.A.; Wang, J.; Wang, Y.; Wang, B.; Liu, F.; Chen, L.Q.; Alem, N.; et al. High-performance polymers sandwiched with chemical vapor deposited hexagonal boron nitrides as scalable high-temperature dielectric materials. Adv. Mater. 2017, 29, 1701864.

- An, F.; Li, X.; Min, P.; Li, H.; Dai, Z.; Yu, Z.Z. Highly anisotropic graphene/boron nitride hybrid aerogels with long-range ordered architecture and moderate density for highly thermally conductive composites. Carbon 2018, 126, 119–127.

- Misra, S.K. Shape Memory Alloy Reinforced Self-Healing Metal Matrix Composites. Ph.D. Thesis, The University of Wisconsin-Milwaukee, Milwaukee, WI, USA, 2013.

- Han, L.; Cui, S.; Yu, H.Y.; Song, M.; Zhang, H.; Grishkewich, N.; Huang, C.; Kim, D.; Tam, K.M.C. Self-healable conductive nanocellulose nanocomposites for biocompatible electronic skin sensor systems. ACS Appl. Mater. Interfaces. 2019, 11, 44642–44651.

- Karaiskos, G.; Tsangouri, E.; Aggelis, D.G.; Van Tittelboom, K.; De Belie, N.; Van Hemelrijck, D. Performance monitoring of large-scale autonomously healed concrete beams under four-point bending through multiple non-destructive testing methods. Smart Mater. Struct. 2016, 25, 055003.

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Rana, S. Self-healing epoxy nanocomposites via reversible hydrogen bonding. Compos. Part B Eng. 2019, 157, 1–13.

- Mi, X.; Zhong, L.; Wei, F.; Zeng, L.; Zhang, J.; Zhang, D.; Xu, T. Fabrication of halloysite nanotubes/reduced graphene oxide hybrids for epoxy composites with improved thermal and mechanical properties. Polym. Test. 2019, 76, 473–480.

- Srivastava, V.; Manish, G. Approach to self-healing in metal matrix composites: A review. Mater. Today Proc. 2018, 5, 19703–19713.

- Mohammadi, M.A.; Eslami-Farsani, R.; Ebrahimnezhad-Khaljiri, H. Experimental investigation of the healing properties of the microvascular channels-based self-healing glass fibres/epoxy composites containing the three-part healant. Polym. Test. 2020, 91, 106862.

- Djugum, R.; Lumley, R.N.; Viano, D.M.; Davidson, C.J. Davidson, Enhanced fatigue resistance in a commercial Al-Cu-Mg alloy through underageing. In Proceedings of the 2nd international conference on self healing materials, Chicago, IL, USA, 28 June–1 July 2009.

- Guadagno, L.; Longo, P.; Raimondo, M.; Naddeo, C.; Mariconda, A.; Sorrentino, A.; Russo, S. Cure behavior and mechanical properties of structural self-healing epoxy resins. J Polym. Sci. Part B Polym. Phys. 2010, 48, 2413–2423.

- Zhu, M.; Yu, H.; Tang, F.; Li, Y.; Liu, Y.; Yao, J. Robust natural biomaterial based flexible artificial skin sensor with high transparency and multiple signals capture. Chem. Eng. J. 2020, 394, 124855.

- Muhammad, N.Z.; Keyvanfar, A.; Majid, M.Z.A.; Shafaghat, A.; Mirza, J. Waterproof performance of concrete: A critical review on implemented approaches. Constr. Build Mater. 2015, 101, 80–90.

- Shinya, N.; Kyono, J.; Laha, K.; Masuda, C. Paper Presented at the 1st International Conference on Self-Healing Materials; Springer: Noordwijk aan Zee, The Netherlands, 2007.

- Salowitz, N.; Correa, A.; Moghadam, A.D. Mechanics of NiTi Reinforced Self-Healing Materials Producing Crack Closing Loads. In Proceedings of the ASME 2017 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Snowbird, UT, USA, 18–20 September 2017.

- Norris, C.J.; Bond, I.P.; Trask, R.S. Interactions between propagating cracks and bioinspired self-healing vascules embedded in glass fibre reinforced composites. Compos. Sci. Technol. 2011, 71, 847–853.

- Han, J.; Wang, H.; Yue, Y.; Mei, C.; Chen, J.; Huang, C.; Wu, Q.; Xu, X. A self-healable and highly flexible supercapacitor integrated by dynamically cross-linked electro-conductive hydrogels based on nanocellulose-templated carbon nanotubes embedded in a viscoelastic polymer network. Carbon 2019, 149, 1–18.

- Grabowski, B.; Tasan, C.C. Self-Healing Materials; Hager, M.D., van der Zwaag, S., Schubert, U.S., Eds.; Springer: New York, NY, USA, 2016; p. 387.

- Manuel, M.V.; Olson, G.B. Self-Healing Materials. In Proceedings of the 1st International Conference on Self-Healing Materials, Noordwijik aan Zee, The Netherlands, 18–20 April 2007; Springer: Dordrecht, The Netherlands, 2007.

- Qiao, H.; Qi, P.; Zhang, X.; Wang, L.; Tan, Y.; Luan, Z.; Xia, Y.; Li, Y.; Sui, K. Multiple Weak H-Bonds Lead to Highly Sensitive, Stretchable, Self-Adhesive, and Self-Healing Ionic Sensors. ACS Appl. Mater. Interfaces 2019, 11, 7755–7763.

- Ferguson, J.B.; Schultz, B.F.; Rohatgi, P.K. Self-healing metals and metal matrix composites. Jom 2014, 66, 866–871.

- Kwon, O.H.; Ha, T.; Kim, D.G.; Kim, B.G.; Kim, Y.S.; Shin, T.J.; Koh, W.G.; Lim, H.S.; Yoo, Y. Anisotropy-driven high thermal conductivity in stretchable poly(vinyl alcohol)/hexagonal boron nitride nanohybrid films. ACS Appl. Mater. Interfaces 2018, 10, 34625–34633.

- Leser, P.E.; Newman, J.A.; Smith, S.W.; Leser, W.P.; Wincheski, R.A.; Wallace, T.A.; Glaessgen, E.H.; Piascik, R.S. NASA Technical Reports Server-NTRS. 2014. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20140006911.pdf (accessed on 3 October 2022).

- Chen, J.; Sun, D.X.; Gu, T.; Qi, X.D.; Yang, J.H.; Lei, Y.Z.; Wang, Y. Photo-induced shape memory blend composites with remote selective self-healing performance enabled by polypyrrole nanoparticles. Compos. Sci. Technol. 2022, 217, 109123.

- Palanisamy, M.; Kolandasamy, P.; Awoyera, P.; Gobinath, R.; Muthusamy, S.; Krishnasamy, T.R.; Viloria, A. Permeability properties of lightweight self-consolidating concrete made with coconut shell aggregate. J. Mater Res. Technol. 2020, 9, 3547–3557.

- Ubi, P.A.; Asipita, S.A. Effect of Sodium Hydroxide Treatment on the Mechanical Properties of Crushed and Uncrushed Luffa Cylindrica Fibre Reinforced rLDPE Composites. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2015, 9, 203–208.

- Han, J.; Wang, S.; Zhu, S.; Huang, C.; Yue, Y.; Mei, C.; Xu, X.; Xia, C. Electrospun Core-Shell Nanofibrous Membranes with Nanocellulose-Stabilized Carbon Nanotubes for Use as High-Performance Flexible Supercapacitor Electrodes with Enhanced Water Resistance, Thermal Stability, and Mechanical Toughness. ACS Appl. Mater. Interfaces 2019, 11, 44624–44635.

- Alaneme, K.K.; Bodunrin, M.O. Self-healing using metallic material systems—A review. Appl. Mater. Today 2017, 6, 9–15.

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fibre reinforced thermoplastic composites using fused deposition modelling. Compos. B Eng. 2015, 80, 369–378.

- Bolimowski, P.A.; Bond, I.P.; Wass, D.F. Robust synthesis of epoxy resin-filled microcapsules for application to self-healing materials. Phil. Trans. R. Soc. A 2016, 374, 20150083.

- Ahangaran, F.; Hayaty, M.; Navarchian, A.H.; Picchioni, F. Micromechanical assessment of PMMA microcapsules containing epoxy and mercaptan as self-healing agents. Polym. Test. 2017, 64, 330–336.

- Al-Tabbaa, A.; Litina, C.; Giannaros, P.; Kanellopoulos, A.; Souza, L. First UK field application and performance of microcapsule-based self-healing concrete. Constr. Build. Mater. 2019, 208, 669–685.

- Rule, J.D.; Sottos, N.R.; White, S.R. Effect of microcapsule size on the performance of self-healing polymers. Polymer 2007, 48, 3520–3529.

- De Carvalho, A.C.M.; Ferreira, E.P.D.C.; Bomio, M.; Melo, J.D.D.; Cysne Barbosa, A.P.; Costa, M.C.B. Influence of synthesis parameters on properties and characteristics of poly (urea-formaldehyde) microcapsules for self-healing applications. J Microencapsul. 2019, 36, 410–419.

- Han, N.X.; Xing, F. A comprehensive review of the study and development of microcapsule based self-resilience systems for concrete structures at Shenzhen University. Materials 2016, 10, 2.

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R. The tensile properties and interlaminar shear strength of microcapsules-glass fibres/epoxy self-healable composites. Eng. Fract. Mech. 2020, 230, 106937.

- Je, P.C.; Sultan, M.T.; Selvan, C.P.; Irulappasamy, S.; Mustapha, F.; Basri, A.A.; Safri, S.N. Manufacturing challenges in self-healing technology for polymer composites—A review. J. Mater. Res. Technol. 2020, 9, 7370–7379.

- Zheng, K.; Yang, X.; Chen, R.; Xu, L. Application of a capillary crystalline material to enhance cement grout for sealing tunnel leakage. Constr. Build. Mater. 2019, 214, 497–505.

- Krahl, P.A.; Gidrão, G.D.M.S.; Carrazedo, R. Cyclic behavior of UHPFRC under compression. Cem. Concr. Compos. 2019, 104, 103363.

- Van den Heede, P.; Mignon, A.; Habert, G.; De Belie, N. Cradle-to-gate life cycle assessment of self-healing engineered cementitious composite with in-house developed (semi-)synthetic superabsorbent polymers. Cement Concr. Compos. 2018, 94, 166–180.

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, H.U.; Iagodkine, E.; Haque, A.; Chen, L.Q.; Jackson, N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579.

- Weng, Q.; Wang, X.; Wang, X.; Bando, Y.; Golberg, D. Golberg, Functionalized hexagonal boron nitride nanomaterials: Emerging properties and applications. Chem. Soc. Rev. 2016, 45, 3989–4012.

- Anjabin, R.; Khosravi, H. Property improvement of a fibrous composite using functionalized carbon nanofibres. Polym. Compos. 2019, 40, 4281–4288.

- Saeed, M.U.; Chen, Z.F.; Bin Li, B. Manufacturing strategies for microvascular polymeric composites: A review. Compos. Part A Appl. Sci. Manuf. 2015, 78, 327–340.

- Bellah, M.; Nosonovsky, M.; Rohatgi, P. Recent Advances in Self-healing Metal Matrix Composites. In Metal-Matrix Composites; Springer: Cham, Switzerland, 2022; pp. 297–310.

More

Information

Subjects:

Materials Science, Composites

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.9K

Revisions:

2 times

(View History)

Update Date:

07 Dec 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No