Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Vittoria Laghi | -- | 1862 | 2022-12-01 14:16:39 | | | |

| 2 | Camila Xu | -6 word(s) | 1856 | 2022-12-02 02:44:07 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Puzatova, A.; Shakor, P.; Laghi, V.; Dmitrieva, M. 3D Printing in Construction. Encyclopedia. Available online: https://encyclopedia.pub/entry/37672 (accessed on 07 March 2026).

Puzatova A, Shakor P, Laghi V, Dmitrieva M. 3D Printing in Construction. Encyclopedia. Available at: https://encyclopedia.pub/entry/37672. Accessed March 07, 2026.

Puzatova, Anastasia, Pshtiwan Shakor, Vittoria Laghi, Maria Dmitrieva. "3D Printing in Construction" Encyclopedia, https://encyclopedia.pub/entry/37672 (accessed March 07, 2026).

Puzatova, A., Shakor, P., Laghi, V., & Dmitrieva, M. (2022, December 01). 3D Printing in Construction. In Encyclopedia. https://encyclopedia.pub/entry/37672

Puzatova, Anastasia, et al. "3D Printing in Construction." Encyclopedia. Web. 01 December, 2022.

Copy Citation

Using 3D printing in the construction industry is gaining attention as a high-potential means of digitalization and automation of the construction process. Digital fabrication in construction would help reduce the environmental and economic impact of the building industry, allowing to realize efficient and sustainable structures for the future. Various types of large-scale 3D printing techniques and construction materials can be used.

large-scale 3D printing

structural application

concrete 3D printing

metal 3D printing

additive construction

additive manufacturing

1. Introduction

Using 3D printing in the construction industry is gaining attention as a high-potential means of digitalization and automation of the construction process. This new level of technology is often referred to as Construction Industry 4.0. In many industries, additive manufacturing technologies has already gone beyond laboratory research and is used in real-life applications, such as industrial use [1][2][3] in the pharmaceutical industry [4][5][6], food industry [7][8] and even in the textile industry and the fashion world [9]. Additive manufacturing technologies are used, for example, in medicine of printing implants [10][11], in the mechanical industry to create parts [12][13] and moulds for casting metal products [14][15].

The growth of automation since the beginning of the 21st century has prevailed in most production domains with the exception of the building and construction sector, in which the use of automatic tools is still challenging and requires further development to implement in real-life applications. The main challenge is due to some particular aspects in the construction sector: (i) building and construction produces extremely large-scale products requiring customization of conventional automated fabrication technologies; (ii) conventional design approaches are not tailored for automation; (iii) there is a significantly smaller ratio of production quantity to type of final product as compared with other industries; (iv) limitations in the materials that can be employed by an automated system [16]; (v) each instance of automotive manufacturing has a specific manufacturing process [17]. Only in the last few years, the fast development in digital fabrication techniques is leading to applications, as seen, for example, in the structural and civil engineering field, Additive Manufacturing (AM)-based technologies are commonly used in other sectors, such as aerospace, automotive and biomedical engineering [18][19][20]. Meanwhile, a large number of tests was carried out on the use of concrete 3D printing technologies in construction to create non-formwork structures [21][22]. Many tests on building materials for 3D printed structures were also carried out. The requirements for freshly mixed and hardened compositions for structures [23][24][25][26] were conducted, including eco-friendly materials [27].

Despite the fact that 3D printing in construction has already been studied sufficiently in the laboratory, there are still no regulatory documents in this area of application for additive manufacturing technologies. Currently, all known research has been carried out using existing test methods to adapt concrete for 3D printing [28]. Therefore, while the amount of research conducted on large-scale printing is not great at this stage [29], the introduction of regulatory documents would be the first step towards the transition from experimental construction to its use in the mass construction of buildings and structures. Moving from lab to large-scale printing comes with inevitable challenges, as printing large scale can dramatically change even a well-studied technology [30].

The most widely used 3D printing technology for construction is the layer-by-layer extrusion technique [22][23][31][32][33][34][35]. This technology is suitable for large-scale mass construction [36] and can be functional for concrete and metal; these two are the most widely adopted in the construction materials market. Additionally, these two materials can be combined to provide reinforced concrete 3D printed structures [37][38][39][40][41][42] or alternatively, as composite concrete 3DP structures.

2. Overview of 3DP in Construction

2.1. Methodology

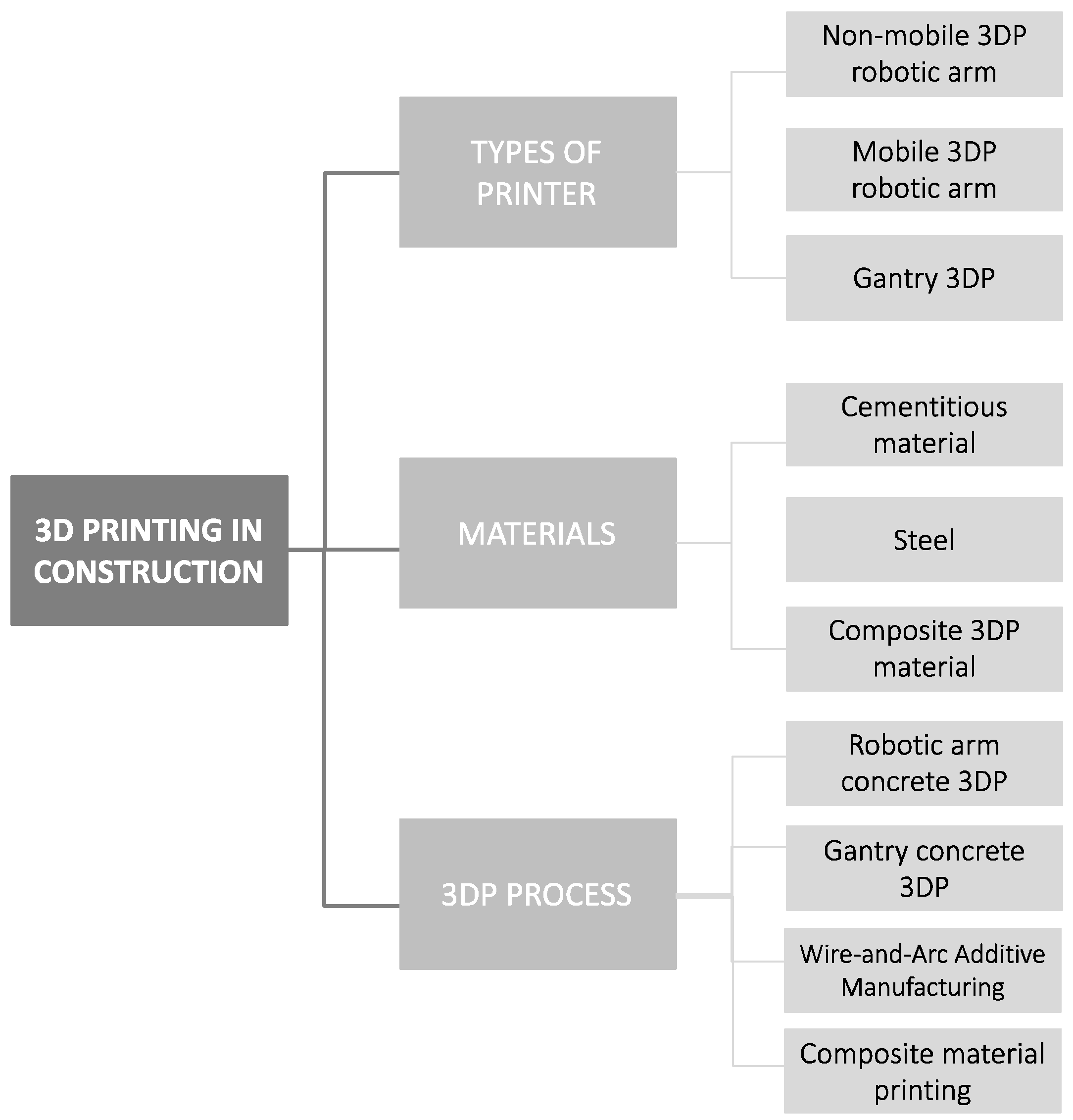

A systematic methodology for the research is adopted in this research which includes three main stages: types of printer, materials and the printing process. The compilation of these stages involves identifying and shortlisting the best research papers in this field. Figure 1 showed the detail of the methodology in this research. The search involved using keywords in the Scopus database which is publishes papers in this field.

Figure 1. Concrete 3DP methodology categorization.

Figure 1 displays the main categories of this overview research; under types of printer, both non-mobile and mobile robotic arm 3DP were discussed in one section. Materials and 3DP process are the other two sections.

The methodology for writing this research was to search, systematize and analyze relevant information on the topic of large-scale 3DP. The scientific research of leading scientists on construction additive technologies, as well as technological developments of universities and private manufacturing companies, were taken as the basis. The scientific studies analyzed in this research are published in high-ranking scientific journals and have a large percentage of citations, which confirms the relevance of the chosen review topic and the reliability of the information sources. Particular attention was paid to the review of projects in the field of concrete 3D printing and steel 3D printing (and in particular Wire-and-Arc Additive Manufacturing, which is the most promising for large-scale metal 3D printing applications), implemented around the world. Both classical prototypes of the first building 3D printers and the latest developments in this area, the number of which is increasing every month, are presented. The main purpose of this research was to systematize current developments, that is, to present the most popular methods of large-scale construction 3DP, to determine their advantages and disadvantages, to state the problems that must be solved for the successful implementation of large-scale construction 3D printing, and to describe the materials used and their characteristics. The research includes only successfully realized projects that give an idea of the rapid development of concrete 3D printing technology and WAAM.

The method of studying a large number of sources of information and comparing various technologies used in this research allowed to combine data from numerous studies and come to a single conclusion that is statistically stronger than that of individual studies.

2.2. Significance of 3DP in Construction

The development of additive manufacturing technologies in construction is associated with many advantages for the construction industry. Firstly, there is the progress of digitalization and the general automation of the production process, which also affects construction. There is a reduction in working labour required due to the introduction of automation, and programming equipment to perform certain types of work. Thus, for the construction of a small building using 3D printing technologies, a group of workers is not necessary; a few qualified specialists are enough to run a printed project, develop the project itself and select the types of materials that are crucial. Secondly, there is a reduction in construction time. There is a well-known example of the Apis Cor company who created a small building in only 24 h [40]. Another example is building with a CONPrint3D printer. The 3DP method was compared with the traditional construction method, and it is 25% cheaper to build one floor of a building with a printer. The printing of one floor with an area of about 130 m2 can be made in one day. The current printing speed is 150 mm/s with a layer height of 50 mm. The printing process requires only two people: a specially trained machine operator and a professional skilled worker [36]. Thus, by using construction 3D printing, it is possible to build houses in a very short time, particularly where it is urgently needed. For example, to build hospitals after devastating earthquakes, fires, and other natural disasters such as spreading viruses, or for the urgent resettlement of a large number of people such as refugees.

According to many researchers, 3D printing technology in construction is accompanied by a reduction in material consumption and less generated construction waste [29][43][44]. Accordingly, it would be logical to assume that this also reduces the cost of construction. However, this issue still remains controversial, since the ingredients of construction 3D printing contain an increased amount of cement, which leads to an increase in the cost of the material. In addition, a large amount of cement has a negative impact on the environment, since the production of cement is harmful due to the release of huge amounts of carbon dioxide, and the high amount of energy required to produce it. The solution for this issue could be use of industrial waste to reduce the amount of cement, or using alternative materials such as geopolymer or earth-based materials such as calcined clay. Large-scale construction usually uses large amounts of coarse aggregate in concrete. The ingredients of concrete contains less cement, which is more environmentally friendly and less expensive [45][46], in comparison with concretes and mortars for additive manufacturing technologies in construction. Despite the fact that a lot of research has been carried out in the field of construction 3D printing, the use of such a technique in large-scale construction is still under development, due to reasons including the high cost of the technology itself [47][48]. In addition, it is necessary to study this technology from the point of view to its impact on the environment, that is, to assess its life cycle. The Life Cycle Assessment method is a method to assess the impact of producing products and their processes on the environment, this method has been used in the construction sector over the past 20 years [49]. This method includes two approaches—firstly, a comprehensive assessment of the environmental impact of a building throughout its entire life cycle, including all associated processes and materials. The second approach evaluates and compares only the environmental impact of construction materials and/or construction methods. When it comes to 3D printing, researchers mainly focus on the environmental impact of printing small objects. For example, it is estimated that 3D printing with geopolymer has less impact on the environment when building elements with a complex structure, while printing with ordinary concrete is more environmentally friendly when creating structures with ordinary walls. Recently, scientists have been interested in materials for 3D printing which are earth-based such as cob, which is obviously more environmentally friendly than concrete, since it consists mainly of natural materials (water, earth, straw, additionally clay and sand) [49].

The most attractive feature of building with a 3D printer is the ability to create complex geometric shapes, as opposed to the process of conventional concrete casting. In a study by [50], the authors give two examples of using 3D printing to create large-scale structural elements. Both printed elements have a hollow structure to be filled with high performance concrete with fiber reinforcement or an insulating material, such as foam used as a thermal insulation. Some parts may be left unfilled for communication cables or electrical wires. In such printed walls with internal voids, the thermal insulation properties can be increased by up to 56% compared to classic walls. Also, printed walls with different configurations of voids inside can provide improved acoustic insulation properties of the element by damping acoustic waves passing through it, depending on the geometry of the wall cells and material properties. This is also beneficial to reduce the effect of fire in complicated geometric structures. Based on the results presented in [43][50], it can be concluded that the main interest in the use of additive manufacturing technologies in large-scale construction is not just in the speed of construction or cost reduction; it also improves the characteristics of building elements (for example, thermal insulation or sound insulation), mainly due to the smart use of the geometry in printing structural elements.

References

- Sandeep, B.; Kannan, T.; Chandradass, J.; Ganesan, M.; Rajan, A.J. Scope of 3D printing in manufacturing industries-A review. Mater. Today Proc. 2021, 45, 6941–6945.

- Fox, B.; Subic, A. An Industry 4.0 Approach to the 3D Printing of Composite Materials. Engineering 2019, 5, 621–623.

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D printing: From innovation to evolution. Adv. Colloid Interface Sci. 2021, 294, 102482.

- Sen, K.; Mehta, T.; Sansare, S.; Sharifi, L.; Ma, A.W.; Chaudhuri, B. Pharmaceutical applications of powder-based binder jet 3D printing process—A review. Adv. Drug Deliv. Rev. 2021, 177, 113943.

- Parulski, C.; Jennotte, O.; Lechanteur, A.; Evrard, B. Challenges of fused deposition modeling 3D printing in pharmaceutical applications: Where are we now? Adv. Drug Deliv. Rev. 2021, 175, 113810.

- Awad, A.; Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D printing: Principles and pharmaceutical applications of selective laser sintering. Int. J. Pharm. 2020, 586, 119594.

- Mantihal, S.; Kobun, R.; Lee, B.-B. 3D food printing of as the new way of preparing food: A review. Int. J. Gastron. Food Sci. 2020, 22, 100260.

- Tomašević, I.; Putnik, P.; Valjak, F.; Pavlić, B.; Šojić, B.; Markovinović, A.B.; Kovačević, D.B. 3D printing as novel tool for fruit-based functional food production. Curr. Opin. Food Sci. 2021, 41, 138–145.

- Chakraborty, S.; Biswas, M.C. 3D printing technology of polymer-fiber composites in textile and fashion industry: A potential roadmap of concept to consumer. Compos. Struct. 2020, 248, 112562.

- Bozkurt, Y.; Karayel, E. 3D printing technology; methods, biomedical applications, future opportunities and trends. J. Mater. Res. Technol. 2021, 14, 1430–1450.

- Liu, C.; Xu, N.; Zong, Q.; Yu, J.; Zhang, P. Hydrogel prepared by 3D printing technology and its applications in the medical field. Colloid Interface Sci. Commun. 2021, 44, 100498.

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707.

- Gadagi, B.; Lekurwale, R. A review on advances in 3D metal printing. Mater. Today Proc. 2020, 45, 277–283.

- Sivarupan, T.; Balasubramani, N.; Saxena, P.; Nagarajan, D.; El Mansori, M.; Salonitis, K.; Jolly, M.; Dargusch, M.S. A review on the progress and challenges of binder jet 3D printing of sand moulds for advanced casting. Addit. Manuf. 2021, 40, 101889.

- Sama, S.R.; Wang, J.; Manogharan, G. Non-conventional mold design for metal casting using 3D sand-printing. J. Manuf. Process. 2018, 34, 765–775.

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19.

- Shakor, P.; Nejadi, S.; Paul, G.; Malek, S. Review of Emerging Additive Manufacturing Technologies in 3D Printing of Cementitious Materials in the Construction Industry. Front. Built Environ. 2019, 4, 85.

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688.

- Giannatsis, J.; Dedoussis, V. Additive fabrication technologies applied to medicine and health care: A review. Int. J. Adv. Manuf. Technol. 2007, 40, 116–127.

- Shakor, P.; Chu, S.H.; Puzatova, A.; Dini, E. Review of binder jetting 3D printing in the construction industry. Prog. Addit. Manuf. 2022, 7, 643–669.

- Duarte, G.; Brown, N.; Memari, A.; Duarte, J.P. Learning from historical structures under compression for concrete 3D printing construction. J. Build. Eng. 2021, 43, 103009.

- Perrot, A.; Pierre, A.; Nerella, V.; Wolfs, R.; Keita, E.; Nair, S.; Neithalath, N.; Roussel, N.; Mechtcherine, V. From analytical methods to numerical simulations: A process engineering toolbox for 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104164.

- Bhattacherjee, S.; Basavaraj, A.S.; Rahul, A.; Santhanam, M.; Gettu, R.; Panda, B.; Schlangen, E.; Chen, Y.; Copuroglu, O.; Ma, G.; et al. Sustainable materials for 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104156.

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and harden properties of the high-thixotropy 3D printing concrete. Constr. Build. Mater. 2019, 201, 278–285.

- Bai, G.; Wang, L.; Wang, F.; Ma, G. In-process reinforcing method: Dual 3D printing procedure for ultra-high performance concrete reinforced cementitious composites. Mater. Lett. 2021, 304, 130594.

- Markin, V.; Krause, M.; Otto, J.; Schröfl, C.; Mechtcherine, V. 3D-printing with foam concrete: From material design and testing to application and sustainability. J. Build. Eng. 2021, 43, 102870.

- Bai, G.; Wang, L.; Ma, G.; Sanjayan, J.; Bai, M. 3D printing eco-friendly concrete containing under-utilised and waste solids as aggregates. Cem. Concr. Compos. 2021, 120, 104037.

- Izadgoshasb, H.; Kandiri, A.; Shakor, P.; Laghi, V.; Gasparini, G. Predicting Compressive Strength of 3D Printed Mortar in Structural Members Using Machine Learning. Appl. Sci. 2021, 11, 10826.

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642.

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital Concrete: Opportunities and Challenges. RILEM Tech. Lett. 2016, 1, 67–75.

- Yu, S.; Du, H.; Sanjayan, J. Aggregate-bed 3D concrete printing with cement paste binder. Cem. Concr. Res. 2020, 136, 106169.

- Ramakrishnan, S.; Muthukrishnan, S.; Sanjayan, J.; Pasupathy, K. Concrete 3D printing of lightweight elements using hollow-core extrusion of filaments. Cem. Concr. Compos. 2021, 123, 104220.

- Mohan, M.K.; Rahul, A.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2020, 115, 103855.

- Geng, Z.; She, W.; Zuo, W.; Lyu, K.; Pan, H.; Zhang, Y.; Miao, C. Layer-interface properties in 3D printed concrete: Dual hierarchical structure and micromechanical characterization. Cem. Concr. Res. 2020, 138, 106220.

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601.

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction–CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933.

- Wang, L.; Ma, G.; Liu, T.; Buswell, R.; Li, Z. Interlayer reinforcement of 3D printed concrete by the in-process deposition of U-nails. Cem. Concr. Res. 2021, 148, 106535.

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D Concrete Printing. Autom. Constr. 2019, 109, 102992.

- Baduge, S.K.; Navaratnam, S.; Abu-Zidan, Y.; McCormack, T.; Nguyen, K.; Mendis, P.; Zhang, G.; Aye, L. Improving performance of additive manufactured (3D printed) concrete: A review on material mix design, processing, interlayer bonding, and reinforcing methods. Structures 2021, 29, 1597–1609.

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231.

- Bester, F.; van den Heever, M.; Kruger, J.; van Zijl, G. Reinforcing digitally fabricated concrete: A systems approach review. Addit. Manuf. 2020, 37, 101737.

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41.

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D printing in the construction industry—A systematic review of the thermal performance in buildings. Renew. Sustain. Energy Rev. 2021, 141, 110794.

- Apis-Cor.com. Apis-Cor 3D Concrete Printing. 2021. Available online: https://www.apis-cor.com/ (accessed on 1 September 2021).

- Chen, Y.; Zhang, Y.; Pang, B.; Liu, Z.; Liu, G. Extrusion-based 3D printing concrete with coarse aggregate: Printability and direction-dependent mechanical performance. Constr. Build. Mater. 2021, 296, 123624.

- Shakor, P.; Nejadi, S.; Paul, G. Investigation into the effect of delays between printed layers on the mechanical strength of inkjet 3DP mortar. Manuf. Lett. 2020, 23, 19–22.

- Xiao, J.; Ji, G.; Zhang, Y.; Ma, G.; Mechtcherine, V.; Pan, J.; Wang, L.; Ding, T.; Duan, Z.; Du, S. Large-scale 3D printing concrete technology: Current status and future opportunities. Cem. Concr. Compos. 2021, 122, 104115.

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.-S.; Jiang, H.B. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. Scanning 2021, 2021, 9950131.

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental assessment of large-scale 3D printing in construction: A comparative study between cob and concrete. J. Clean. Prod. 2020, 270, 122463.

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

02 Dec 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No