| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mohammad Nur E Alam | + 637 word(s) | 637 | 2020-03-11 07:50:34 | | | |

| 2 | Mikhail Vasiliev | + 638 word(s) | 638 | 2020-03-11 09:06:29 | | | | |

| 3 | Mohammad Nur E Alam | -11 word(s) | 627 | 2020-11-02 08:02:06 | | |

Video Upload Options

In Dielectric/Metal/Dielectric (DMD) type multilayer coating applications, it is very important to achieve simultaneously highly stable and durable optical properties together with accurate control over the apparent color properties of coated glass, in both reflection and transmission. In this encyclopedia entry, we report on the properties of RF magnetron co-sputtered metal-dielectric composite (MDC) material systems of interest for forward-looking applications in the areas of thin-film nanomaterials and optical coatings.

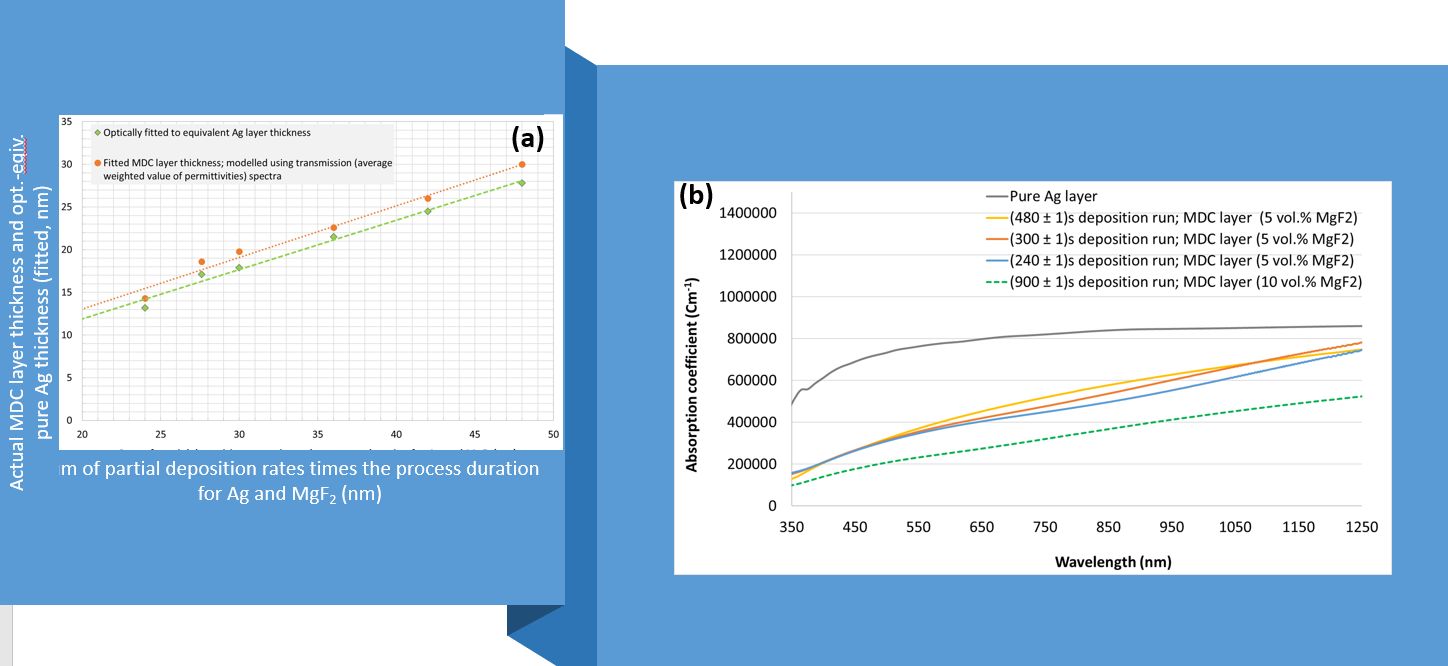

ure 1 (reproduced from Ref. [1]) illustrates (a) the relationships between the actual (best fitted from optical transmission properties) MDC layer thickness, the “apparent sum-thickness derived from measured partial deposition rates of the co-sputtering sources, and the “optically equivalent” pure Ag-based layer thickness, and (b) the absorption coefficient spectra derived for several MDC composition types compared to the absorption of RF-sputtered pure Ag layer of similar thickness (about 20 nm).

Figure 1. (a) Plot of best-fitted MDC layer thicknesses and the optically equivalent fitted thicknesses of pure Ag layers and (b) the optical absorption coefficient spectra of MDC layers of slightly different thicknesses compared to the absorption of pure thin-film Ag layer.

Notably, the actual MDC layer thicknesses were found to be lower than the simple numerically calculated “apparent sum” thickness. For example, if Ag was deposited at 5.7 nm per minute and an additional 0.3 nm/min rate applied for the MgF2 deposition for the same process duration, the discrepancy between the “apparent sum” and the actual fitted thickness can then suggest that some degree of inter-solubility or the “compaction” of materials has been occurring during the nanocomposite formation process.

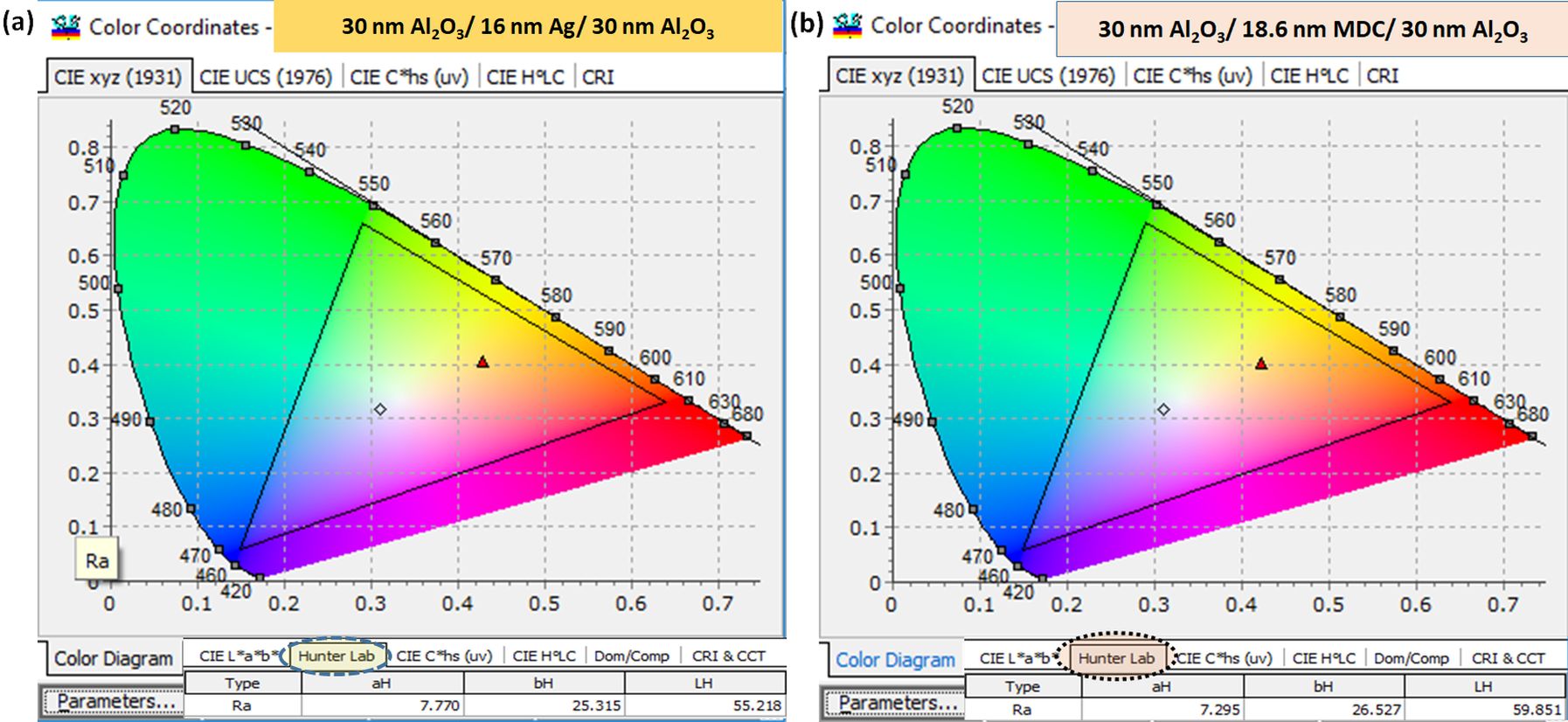

Figure 2 represents the chromaticity modeling results obtained from either a pure-Ag-based trilayer coating building block or an “optically equivalent” similar structure employing an MDC-based central layer[2].

Figure 2. Chromaticity diagram (CIE xyz 1931) obtained for the DMD type structures using OptiLayer Pro together with the Hunter L, a, b (simulated) values (a) 30 nm Al2O3 / 16 nm Ag / 30 nm Al2O3 trilayer, and (b) 30 nm Al2O3 / 18.6 nm MDC / 30 nm Al2O3 trilayer.

The modeled and experimentally measured chromaticity datasets confirm that using MDC-type layers instead of pure silver not only does not limit the available coating design and color selection options but also could lead to obtaining apparent color properties in coatings, which were not available from pure-Ag based designs.

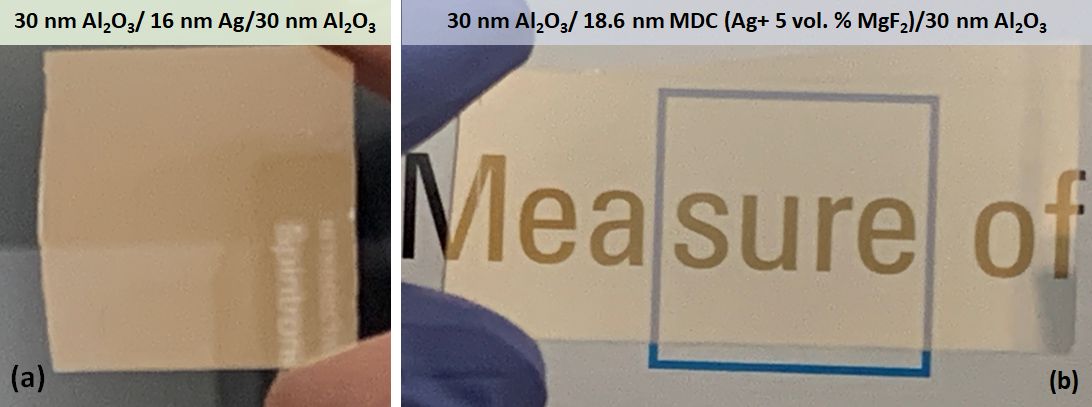

Images of the pure-Ag based trilayer and its optically equivalent MDC based analogue are shown in Figure 3.

Figure 3. Images of as-deposited DMD type structures; (a) 30 nm Al2O3 / 16 nm Ag / 30 nm Al2O3 trilayer, and (b) 30 nm Al2O3 / 18.6 nm MDC / 30 nm Al2O3 trilayer.

The RF-sputtered samples shown in Figure 3 were subjected to ambient-air exposure testing in normal lab conditions, followed by regularly repeated measurements of chromaticity coordinates.

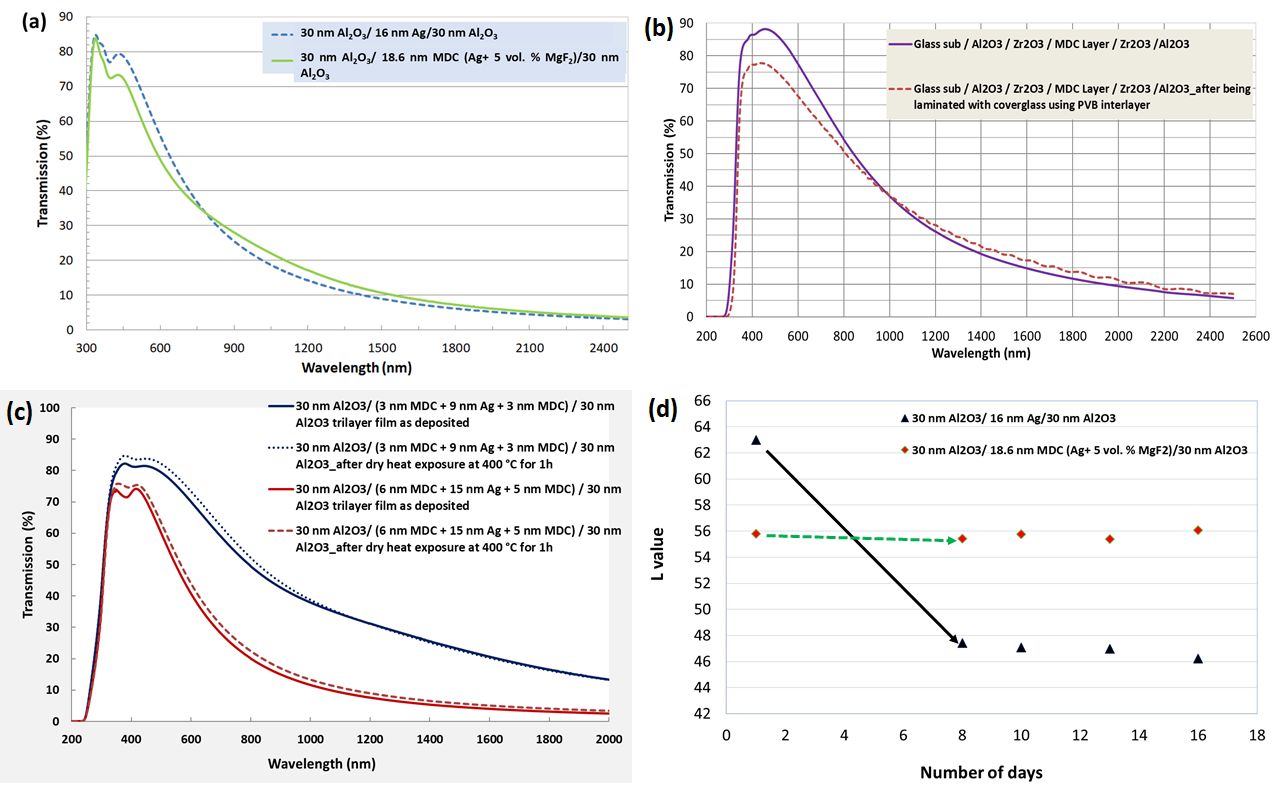

Figure 4 summarises the results of the optical transmission properties measurements, several environmental testing procedures obtained from several different types of the MDC based and pure silver-based coatings, showcasing the forward-looking features of advanced coating designs and material systems.

Figure 4. Measured transmission spectra for a range of DMD-type structures; (a) 30 nm Al2O3 / 16 nm Ag / 30 nm Al2O3 trilayer, compared with that of 30 nm Al2O3 / 18.6 nm MDC / 30 nm Al2O3 trilayer, (b) advanced five-layer DMD-type coating featuring suitability for PVB lamination, (c) MDC bracket layers used for protection of ultrathin Ag layer and dry heat testing results, and (d) color coordinate stability test results obtained with a conventional metal-dielectric and an MDC-based coating exposed to normal room air in lab conditions. The data (or at least a part of the total dataset shown) represented in parts (b), and (c) have not been so far published elsewhere.

The expected near-future application areas of MgF2-based and other MDC material system types include building energy efficiency, architectural glass coatings, heat shields, optical filters, and decorative coating products[3][4].

References

- Nur-E-Alam, M.; Rahman, M.M.; Basher, M.K.; Vasiliev, M.; Alameh, K.; Optical and Chromaticity Properties of Metal-Dielectric Composite-Based Multilayer Thin-Film Structures Prepared by RF Magnetron Sputtering. Coatings 2020, 10, 251.

- M. Vasiliev, M. Nur-E-Alam, K. Alameh. Energy Saving Coating Materials, Ch.3, Ch.4; Dalapati, D.K.; Sharma, M. , Eds.; Elsevier; Thomson Digital: Amsterdam, The Netherlands; Noida, India, 2020; pp. In press.

- Nur- E- Alam; Wade Lonsdale; Mikhail Vasiliev; Kamal Alameh; Mohammad Nur-E Alam; Application-Specific Oxide-Based and Metal–Dielectric Thin-Film Materials Prepared by Radio Frequency Magnetron Sputtering. Materials 2019, 12, 3448, 10.3390/ma12203448.

- Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Highly stable thin-film multilayers for thermal regulation and energy savings in smart cities. In Proceedings of the 16th IEEE International Conference on Smart Cities: Improving Quality of Life Using ICT, IoT & AI, Charlotte, NC, USA, 6–9 October 2019.