Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Li, Q.; Guo, J.; Zhang, C.; Yang, Y.; Ma, J.; Ren, Z. Construction of Arch Structure Model. Encyclopedia. Available online: https://encyclopedia.pub/entry/36504 (accessed on 07 February 2026).

Li Q, Guo J, Zhang C, Yang Y, Ma J, Ren Z. Construction of Arch Structure Model. Encyclopedia. Available at: https://encyclopedia.pub/entry/36504. Accessed February 07, 2026.

Li, Quansheng, Junting Guo, Cun Zhang, Yuliang Yang, Jianqi Ma, Zhaopeng Ren. "Construction of Arch Structure Model" Encyclopedia, https://encyclopedia.pub/entry/36504 (accessed February 07, 2026).

Li, Q., Guo, J., Zhang, C., Yang, Y., Ma, J., & Ren, Z. (2022, November 25). Construction of Arch Structure Model. In Encyclopedia. https://encyclopedia.pub/entry/36504

Li, Quansheng, et al. "Construction of Arch Structure Model." Encyclopedia. Web. 25 November, 2022.

Copy Citation

The application of the arch structure model focuses on the prediction and prevention of mining pressure and surface subsidence, and there are relatively few means to actively regulate overburden arch.

underground coal mining

arch structure model

unconsolidated layer arch

1. Introduction

The structure model of overlying strata in mining fields can be used to describe strata movement and predict mine disasters [1][2][3]; it is the foundation of safe mining in underground coal mines. The overburden structure theories and hypotheses proposed for mine pressure and rock strata control mainly include: key strata theory [4][5][6], transfer rock beam hypothesis [7], masonry beam theory (articulated rock block hypothesis) [8], hypothesis of pre-cracked beam [9], cantilever beam hypothesis [10], and the stress arch hypothesis [11]. These theories and hypotheses have been widely used and developed in coal mining. For example, the key strata theory has been applied in working face periodic pressure and support resistance prediction [4], the development of water flowing fracture zones [6], filling, mining, and surface subsidence [12][13], rockburst prevention and control [14], pressure relief mining and gas extraction [15], water inrush prediction from the floor [16], and grouting in separated layers [17]. The transfer rock beam hypothesis has led to important achievements in the innovation of mining methods and mining technologies, as well as the control practice of major accidents and disasters, such as the design of mining methods without coal pillars, the calculation of support resistance, the prediction of three-zone height, the prevention and control of rockburst, coal, and gas outburst, etc. [7][18]. Masonry beam theory, preformed fracture beam hypothesis and cantilever beam hypothesis all reveal the fracture and migration characteristics of overburden rock above the working face with the beam model, and provide the prediction model of mining pressure of the working face under specific geological conditions and mining parameters. The arch structure model, evolved on the basis of the beam model, can not only analyze the near-field mine pressure law, but also explain the characteristics of overburden and surface migration in the far field, which is widely used in the analysis of overburden fracture migration in coal mining. For example, in the process of coal seam mining, due to the existence of the stress arch, the adjacent coal seams will generate a stress increase zone and stress relief zone. If the adjacent coal seam is in the stress relief zone, the gas seepage capacity of the coal seam will be greatly improved, which is conducive to the gas drainage of the coal seam [19][20].

2. Construction of Arch Structure Model

2.1. Model of Unconsolidated Layer Arch Model

The geological conditions of the thick unconsolidated layer are widely distributed in some mining areas in East China and North China, such as Huainan, North Anhui, Huaibei, Yanzhou, Xinwen, Kailuan, and other mining areas. The maximum thickness of the unconsolidated layer in 48 coal mines is 752 m, the minimum is 100 m, and the average is 319 m. It is found, from this measurement, that in the mining of the shallow coal seam, the load of the thick unconsolidated layer (mainly viscous unconsolidated layer) does not act on the main roof at once, and there is an arch-bearing structure, as shown in Figure 1. Therefore, the load of the unconsolidated layer on bedrock cannot be simply equal to the weight of the unconsolidated layer, and it is necessary to study the evolution process of the unconsolidated layer arch model. At present, studies on the unconsolidated layer arch mainly focus on the geological conditions of the shallow buried thick unconsolidated layer, and analyze the influence of the unconsolidated layer arch on surface subsidence, fracture development, and the unconsolidated layer on bedrock load [21][22].

Figure 1. Unconsolidated layer arch structure in mining overburden. l–Span of arch structure; h–height of arch structure; H–burial depth of arch crown; ∑H–thickness of unconsolidated layer; ∑M–thickness of bedrock.

2.2. Arch Structure Model of Overlying Rock

- (1)

-

Linear arch (beam arch)

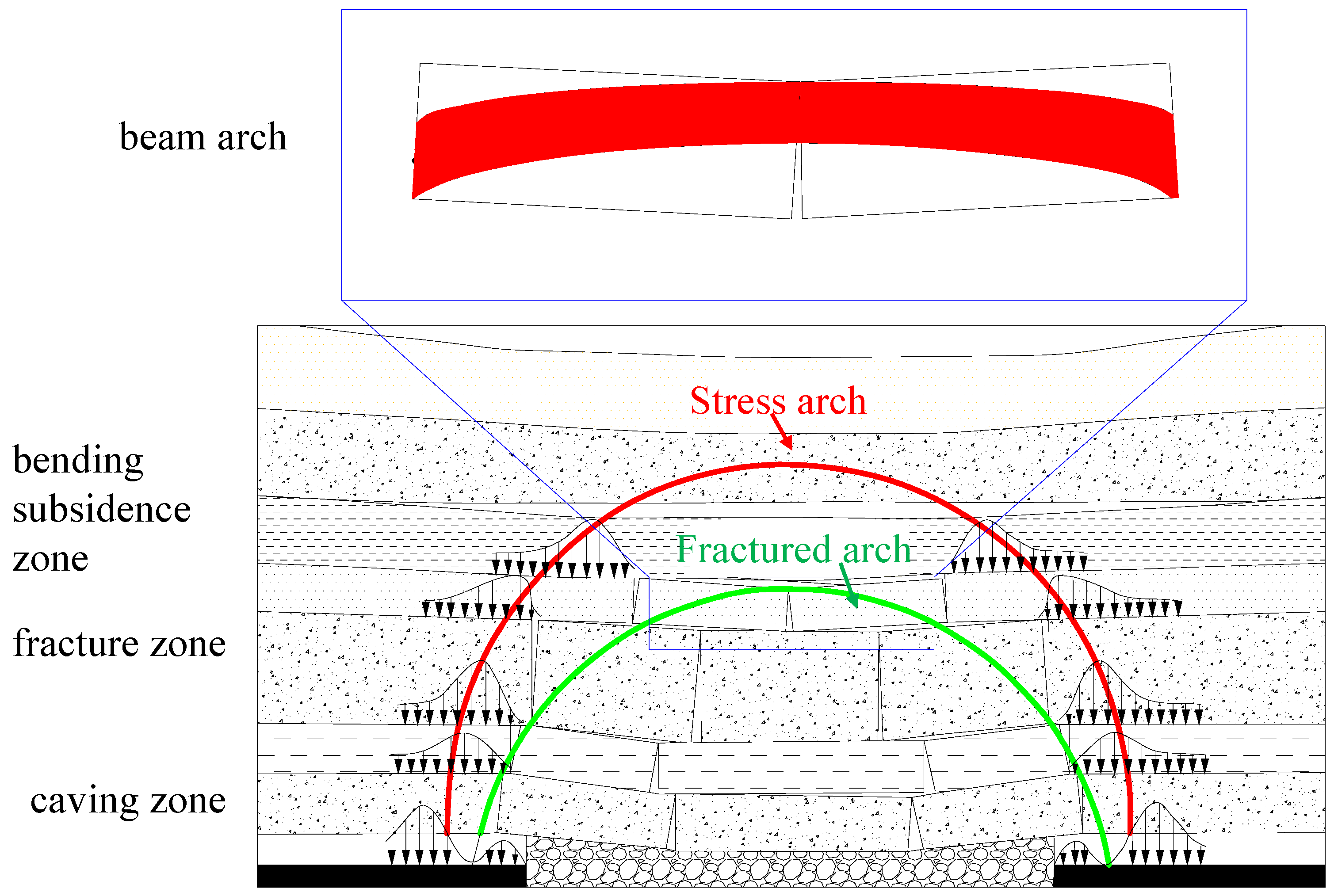

Beam theory is widely used in the analysis of overburden fracture and migration in coal mining. It is believed that once the flexural and tensile strength of the beam is exceeded, the yield failure will expand along the beam, and the effective thickness of the beam will be reduced due to transverse fracturing, which is an important conclusion of classical beam theory. However, the span of the arch structure formed during underground mining, surface subsidence, and transverse beam fracture is much longer than that predicted by classical beam theory. This behavior can be attributed to the formation of a linear arch in the beam, as a beam arch (or hinged arch). On the basis of specific geometric structure, the principal stress traces in a thick rock layer show an arch distribution. As shown in Figure 2, the resistance acting on both ends of the beam leads to the formation of stress arches in the beam [23]. In a given range of the thickness to span ratio, the beam arch can bear a higher load than that predicted by traditional beam theory. At present, the beam arch model is mainly applied to analyze the strong mining pressure phenomenon caused by thick and hard roof structures.

Figure 2. Overburden arch structure based on beam arch structure.

- (2)

-

Overburden arch (stress arch, fracture arch)

At present, the overburden arch (three-dimensional “shell”) model is mainly divided into the fracture arch and stress arch models [24][25][26][27]. The fracture arch is generally considered to be the top boundary of the overburden where the fracture occurs, so it usually has no thickness; the stress arch refers to the arch stress zone formed by the deflection of the overburden principal stress in the mining field, with a certain thickness [28], as shown in Figure 2. The double-arch model of overburden in mining fields is the mechanical manifestation of rock mass self-bearing characteristics and the compressive stress arch effect. Considering the traditional subzones of overburden in coal mining (caving zone, fracturing zone, and bending zone), the fracture arch can be considered as the range of the caving zone and fracturing zone, or as the boundary of the area where the caving zone and fracturing zone are located.

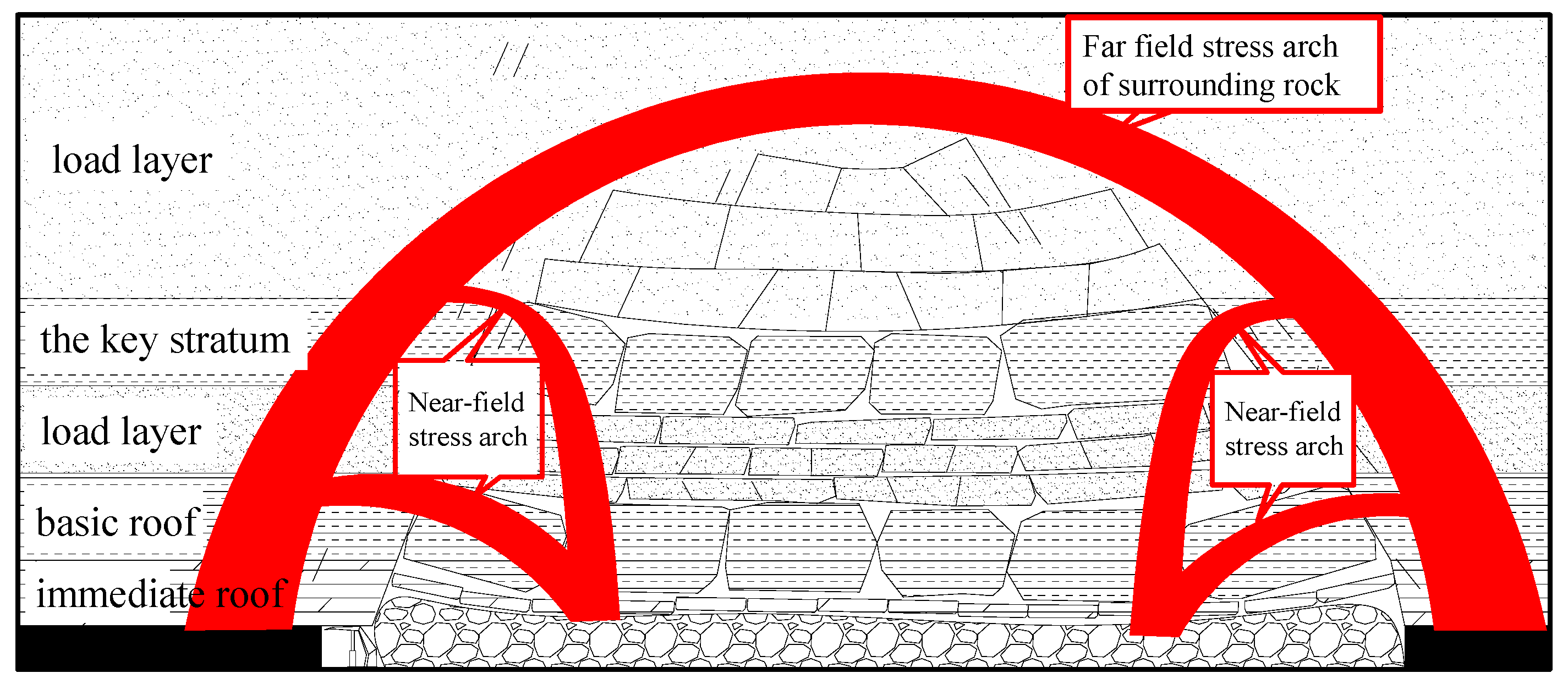

The stress arch is generally located in the upper part of the fracture arch, and is the bearing structure of the whole overburden. In fact, the stress arch is mainly caused by the stress relief of the fracture arch, which transfers the original bearing stress to the upper rock layer, and then forms the stress increasing area. Therefore, the stress arch has a certain thickness, which is the area enclosed by the stress in the overlying rock greater than the stress in the original rock. In addition, the stress arch can also be considered as the “far-field arch”, which controls the migration of the whole overburden and surface [27]. As shown in Figure 3, compared with the inclined fracture arch and stress arch of the working face (Figure 2), the near-field arch belongs to the evolution structure of an arch in the direction of advance. The near-field arch is mainly formed by periodic fracture of the main roof, and moves forward with the advance of the working face, accompanied by arch formation and arch breaking. The far-field arch is generally composed of the key stratum. With the advance of the working face, the span of the far-field arch in the direction of advance is constantly expanded, but the arch height is basically unchanged, and gradually evolves into a flat-top arch.

Figure 3. Evolution characteristics of far- and near-field stress arch in overburden.

References

- Chen, C.; Hu, Z. Research advances in formation mechanism of ground crack due to coal mining subsidence in China. J. China Coal Soc. 2018, 43, 810–823.

- Wang, J.; Yang, S.; Wei, W.; Zhang, J.; Song, Z. Drawing mechanisms for top coal in longwall top coal caving (LTCC): A review of two decades of literature. Int. J. Coal. Sci. Technol. 2021, 8, 1171–1196.

- Gao, R.; Kuang, T.; Zhang, Y.; Zhang, W.; Quan, C. Controlling mine pressure by subjecting high-level hard rock strata to ground fracturing. Int. J. Coal. Sci. Technol. 2021, 8, 1336–1350.

- Miao, X.; Qian, M. Advance in the key strata theory of mining rockmass. J. China Univ. Min. Technol. 2000, 29, 25–29.

- Qian, M. Theory and Practice of Surrounding Rock Control in Stope. Ground Press. Strat. Control 1999, Z1, 12–15.

- Qian, M.; Miao, X.; Xu, J. Theoretical study of key stratum in ground control. J. China Coal Soc. 1996, 3, 2–7.

- Song, Z.; Hao, J.; Shi, Y.; Tang, J.; Liu, J. An overview of connotation and development of practical ground pressure control theory. J. Shandong Univ. Sci. Technol. 2019, 38, 1–15.

- Li, C.; Zhang, Y.; Zuo, J.; Tang, S.J.; Liu, S.F. Floor failure mechanical behavior and partition characteristics under the disturbance of voussoir beam instability in deep coal mining. J. China Coal Soc. 2019, 44, 1508–1520.

- Xu, J. Strata control and scientific coal mining—a celebration of the academic thoughts and achievements of Academician Minggao Qian. J. Min. Saf. Eng. 2019, 44, 1508–1520.

- Qian, M.; Xu, J. Behaviors of strata movement in coal mining. J. China Coal Soc. 2019, 38, 1–15.

- Zou, X. A new interpretation of the pressure arch hypothesis. Mine Press. 1989, 1, 67–68.

- Zhang, J.; Li, J.; An, T.; Huang, Y. Deformation characteristic of key stratum overburden by raw waste backfilling with fully-mechanized coal minning technology. J. China Coal Soc. 2010, 35, 357–362.

- Yu, Q.; Zhang, H.; Deng, W.; Zou, Y. Analysis of influencing factors of surface skewed subsidence based on key strata theory. J. China Coal Soc. 2018, 43, 1322–1327.

- Jiang, F.; Wen, J.; Bai, W.; Wang, G.; Li, M. Rock burst risk in surrounding abscission layer of overlying high key strata in deep strip mining mines. J. China Univ. Min. Technol. 2018, 47, 40–47.

- Wang, H.; Fan, X.; Jia, J.; Hu, G.; Yuan, Z. Effects of key strata on protection when exploiting a steep-incline underlying a protecting stratum. J. China Univ. Min. Technol. 2011, 40, 23–28.

- Lu, H.; Meng, X.; Zhang, Y.; Yao, D. Mechanical analysis of water barrier performance of floor layered structure key stratum on coal face. J. China Univ. Min. Technol. 2020, 49, 1057–1066.

- Zhu, W.; Xu, J.; Lai, W.; Wang, Z. Research of isolated section-grouting technology for overburden bed separation space to reduce subsidence. J. China Coal Soc. 2007, 32, 458–462.

- Song, Z. Development status of mining engineering discipline in China and discussion on issues of its further development. Hazard Control. Tunn. Undergr. Eng. 2019, 1, 7–12.

- Yang, W.; Lin, B.Q.; Yan, Q.; Zhai, C. Stress redistribution of longwall mining stope and gas control of multi-layer coal seams. Int. J. Rock Mech. Min. Sci. 2014, 72, 8–15.

- Zhang, C.; Bai, Q.; Chen, Y. Using stress path-dependent permeability law to evaluate permeability enhancement and coalbed methane flow in protected coal seam: A case study. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 1–25.

- Wang, F.; Chen, S.; Xu, J.; Ma, B.; Ding, X.; Liu, Z. Research on ground control based on arch structure in unconsolidated layers theory. Coal Sci. Technol. 2020, 48, 130–138.

- Wang, F.; Xu, J.; Xie, J. Effect of arch structure in unconsolidated layers on failure of the overlying strata. J. China Univ. Min. Technol. 2019, 5, 975–983.

- Lou, J. Influence mechanism of beam-arch binary structure and strata characteristics on fracture and stress evolution of overlying strata in stope. Int. J. Rock Mech. Min. Sci. 2002, 39, 79–94.

- Xie, G. Mechanical characteristics of fully mechanized top-coal caving face and surrounding rock stress shell. J. China Coal Soc. 2005, 30, 309–313.

- Wang, L.; Xie, G.; Wang, J. Numerical investigation on the influence of surrounding rock stress shell on fractured field. J. China Coal Soc. 2015, 9, 2009–2014.

- Li, Z.; Yang, K.; Hua, X.; Li, Y.; Liu, Q. Disaster-causing mechanism of instability and “macroscopic-big-small” structures of overlying strata in longwall mining. J. China Coal Soc. 2020, 45, 541–550.

- Zhao, Y.; Yu, J.; Zhou, H.; Zhao, K.; Xiao, H. Characterization of pressure arching effect of arch shell surrounding rock considering deviation of principal stress axis. Chin. J. Geotech. Eng. 2021, 43, 1842–1850.

- Feng, J.; Zhou, Y.; Li, H.; Liu, C. Three kinds of basic structure of working face in near horizontal coal seam. J. China Coal Soc. 2016, 41, 2576–2587.

More

Information

Subjects:

Mining & Mineral Processing

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

3 times

(View History)

Update Date:

29 Nov 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No