| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Justyna Tomaszewska | + 1325 word(s) | 1325 | 2020-11-24 09:37:09 | | | |

| 2 | Vicky Zhou | + 8 word(s) | 1333 | 2020-12-17 02:47:43 | | | | |

| 3 | Vicky Zhou | + 8 word(s) | 1333 | 2020-12-17 02:48:12 | | | | |

| 4 | Catherine Yang | Meta information modification | 1333 | 2021-09-28 08:17:25 | | |

Video Upload Options

The Polish economy as the sixth largest EU economy, with its GDP per capita amounting to 71% of the EU average in 2018, painfully experiences the e ects of natural resource exhaustion, which includes rising prices and increasing dependence on foreign suppliers. The situation is particularly onerous in construction, which is among the most resource- and energy-consuming economic sectors, and which has already been struggling with severe labor shortages for the past few years. The domestic consumption of raw materials reveals an increasing trend, whose dynamics vary depending on the material group. For instance, between 2015 and 2018 the domestic consumption of non-alloy aluminum went up by 97.7%, plastics by 29.9%, float glass by 28.2%, metallurgical products by ca. 38.0%, wood-based materials (chipboard) by 25.6%, cement by 21.7%, and paper and cardboard by 10.0%, while the construction industry reported an increase as high as 23.2% in construction and assembly outputs.

Poland's economy as the sixth largest economy in the EU is painfully experiencing the effects of natural resource depletion, which extend to increasing prices and the growing dependence on foreign suppliers. The concept of the Circular Economy assumes the existence of an industrial economy which is renewable by assumption; its supreme objective is to ensure the effective flow of raw materials, power, labor and information so that it is possible to “rebuild” environmental and human resources.

1. Introduction

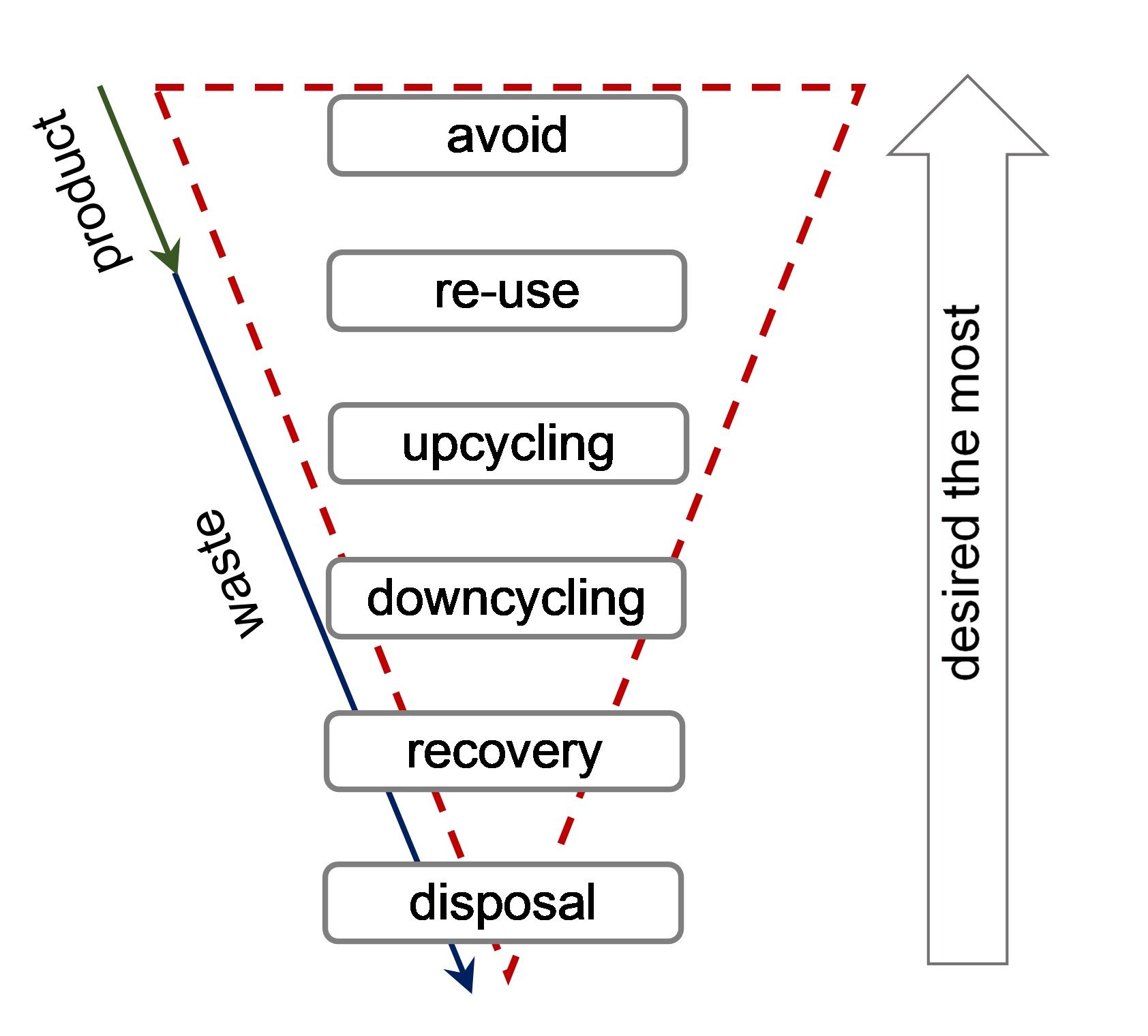

The implementation of essential changes in the way a domestic economy operates is a complex process. The transformation of the linear economy towards the Circular Economy (CE) is a challenge that many European countries, including Poland, currently face. Changes in product management at the final stage of their life cycle are what differentiate the linear economy from the CE. The essence of the CE concept for raw materials is to prevent waste generation, e.g., by extending a product’s life cycle or creating possibilities for repair [1][2]. When it is not possible to avoid waste generation, the product should be suitable for reuse or recycling, according to the waste management hierarchy shown in Figure 1 [3]. Intensive industrial development and the ever growing global population, which at present exceeds 7.8 billion and is forecast to reach 9 billion by 2037 and 10 billion in 2050 [4] are among the key factors responsible for the increase in the rate of natural resources consumption. This is encapsulated in the Earth overshoot day (EOD), which is the day when all natural resources, which could renew in a given year, are exhausted. In 2019, the EOD was on 29 July, which was the soonest in the history of humankind. In the EU, the situation was worse, with overshoot day occurring on 10 May and in Poland on 15 May. By comparison, Qatar’s EOD was on 11 February, while in Kirgizstan it was 26 December [5]. The volume of natural resource consumption in the EU, in 2014, was estimated at 7.4 billion tonnes (3.1 billion tonnes were used for power generation), of which 5.8 billion tonnes were from local mining, 0.9 billion tonnes were net import and only 0.7 billion tonnes were secondary raw materials [6]. OECD expects the global consumption of natural resources to double by 2060 compared to 2011 (when it amounted to 79 billion tonnes), if the current consumption rate is maintained. The emission of greenhouse gases is predicted to increase in the same period from 28 to 50 billion tonnes of CO2 equivalent [7].

Figure 1. Waste management hierarchy in the circular economy (CE) [3].

The Polish economy as the sixth largest EU economy, with its GDP per capita amounting to 71% of the EU average in 2018 [8], painfully experiences the effects of natural resource exhaustion, which includes rising prices and increasing dependence on foreign suppliers. The situation is particularly onerous in construction, which is among the most resource- and energy-consuming economic sectors, and which has already been struggling with severe labor shortages for the past few years. The domestic consumption of raw materials reveals an increasing trend, whose dynamics vary depending on the material group. For instance, between 2015 and 2018 the domestic consumption of non-alloy aluminum went up by 97.7%, plastics by 29.9%, float glass by 28.2%, metallurgical products by ca. 38.0%, wood-based materials (chipboard) by 25.6%, cement by 21.7%, and paper and cardboard by 10.0% [9], while the construction industry reported an increase as high as 23.2% in construction and assembly outputs [10].

With regard to the above, closing the circulation of raw materials in the economy seems to be the only way towards hampering natural environment devastation as a result of anthropogenic actions, especially in construction [11][12]. The concept of the CE assumes the existence of an industrial economy which is renewable by assumption; its supreme objective is to ensure the effective flow of raw materials, power, labor and information so that it is possible to “rebuild” environmental and human resources [1][13][14][15]. The EU predicts that the implementation of CE concepts will help to reduce CO2 emissions by 450 million tonnes by 2030, making 600 billion EUR in savings for enterprises (8% of annual turnover) and establishing 580,000 new jobs [16]. Therefore, it seems obvious that reaching the aforementioned targets requires a holistic approach, which engages actors across the supply chain at all stages of a product’s life cycle.

2. Circular Economy Roadmap

The draft Polish CE roadmap, adopted in September 2019 [17], is based on a model which assumes the coexistence of biological nutrients, designed to re-enter the biosphere safely and build natural capital, and technical nutrients, which are designed to circulate at high quality without entering the biosphere [1][18]. A dramatic decrease in the demand for primary raw materials, with a simultaneous reduction in the number of pollutants and generated waste are expected as the consequences of closing the biological and engineering loop. The actions included in the CE Roadmap are mandatory on a national level and foster the execution of four Polish priorities related to CE implementation [3], namely: (a) innovativeness, strengthening cooperation between the industry and science, and consequently the implementation of innovative solutions in the economy; (b) creating a secondary raw materials European market; (c) providing high-quality secondary raw materials; (d) service sector development. The provisions concerning the following measures are particularly important for the construction industry:

- Analysis of potential and legislative changes proposed to increase the economic use of incineration by-products. Over 78% of electrical energy in Poland is generated from lignite and hard coal. During incineration of these raw materials, however, gases and incineration by-products are generated, including ash, slag and dust. Incineration by-products are the source of many minerals whose potential is not fully exploited. Owing to their binding characteristics, they can be used for the production of construction materials, mainly cement and concrete (as Portland cement substitute), and in road and underground construction as an ingredient of embankments and other structural layers [19][20].

- Creating a platform dedicated to secondary raw materials, aimed at market actors, providing information about supply and demand, and trade.

- Extended producer responsibility (EPR), encouraging producers to design and make products with extended service life, and imposing the obligation to collect and manage waste from the same products as the ones launched.

- Identification of the environmental impact of products and services using, for example, the Life Cycle Assessment (LCA), Product Environmental Footprint (PEF) and Organization Environmental Footprint (OEF) methods [21].

- Identification of all streams of municipal waste, including post-consumer waste, previously not recorded but having an economic impact. This measure can be particularly useful in the context of the classification of waste (effective until 2018) generated during minor repairs, construction and demolition works by individuals, incorporating construction and demolition waste into the stream of municipal waste.

- Changes in public procurement law, which would generate demand for products and services according to CE business models and increasing the share of green public procurement.

- Analysis of the possibilities to implement reporting and inspection reliefs guidelines for entities that observe environmental standards, such as the EU Eco label and EMAS, and entities entered in the Polish Register of Cleaner Production and Responsible Entrepreneurship.

- The systematic assessment of the Polish economy transformation towards CE and the impact of the new economy model on the social and economic development of Poland will be carried out with two sets of indicators developed by state administration bodies in cooperation with public sector institutions and industry representatives as part of the “otoGOZ” programme [22].

References

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Thing, 1st ed.; North Point Press: New York, NY, USA, 2003.

- Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015.

- European Comission. Closing the Loop—An EU Action Plan for the Circular Economy COM(2015)614 Final. 2015. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 21 April 2020).

- Worldometers. Available online: https://www.worldometers.info/world-population/ (accessed on 17 April 2020).

- Earth Overshoot Day. Available online: https://www.overshootday.org/newsroom/country-overshoot-days/ (accessed on 3 May 2020).

- Mayer, A.; Haas, W.; Wiedenhofer, D.; Krausmann, F.; Nuss, P.; Blengini, G.A. Measuring Progress towards a Circular Economy: A Monitoring Framework for Economy-wide Material Loop Closing in the EU28. J. Ind. Ecol. 2019, 23, 62–76.

- OECD. Available online: https://www.oecd.org/ (accessed on 1 June 2020).

- Eurostat. Available online: https://ec.europa.eu/eurostat (accessed on 21 April 2020).

- Statistics Poland. Materials Management in 2018; Statistics Poland: Warsaw, Poland, 2019.

- Statistics Poland. Construction and Assembly Production in 2018; Statistics Poland: Warsaw, Poland, 2019.

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046.

- Clark, G. Evolution of the global sustainable consumption and production policy and the United Nations Environment Programme’s (UNEP) supporting activities. J. Clean. Prod. 2007, 15, 492–498.

- Ellen MacArthur Foundation. Circular Academy. Available online: http://www.circular.academy/circular-economy-some-definitions/ (accessed on 19 September 2019).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768.

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553.

- European Comission. Towards a Circular Economy: Closing the Loop of the Products Lifecycle. Available online: https://ec.europa.eu/commission/priorities/jobs-growth-and-investment/towards-circular-economy_en (accessed on 17 April 2020).

- Ministerstwo Rozwoju. Mapa Drogowa Transformacji w Kierunku Gospodarki o Obiegu Zamkniętym. 2019. Available online: https://www.gov.pl/web/rozwoj-praca-technologia/rada-ministrow-przyjela-projekt-mapy-drogowej-goz (accessed on 1 April 2020).

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013.

- Rajczyk, K. Popioły Lotne z Kotłów Fluidalnych i Możliwości ich Uszlachetniania; Instytut Materiałów Ceramicznych i Budowlanych: Opole, Poland, 2012.

- Rosiek, J. The implementation of Circular Economy Concept in the Polish Coal Combustion Products Sector—Selected problems. Econ. Environ. Stud. 2018, 18, 353–373.

- Sameer, H.; Weber, V.; Mostert, C.; Bringezu, S.; Fehling, E.; Wetzel, A. Environmental Assessment of Ultra-High-Performance Concrete Using Carbon, Material, and Water Footprint. Materials 2019, 12, 851.

- Gospostrateg “oto-GOZ”. Available online: https://archiwum.mpit.gov.pl/strony/zadania/zrownowazony-rozwoj/gospodarka-o-obiegu-zamknietym/gospostrateg-oto-goz/ (accessed on 20 April 2020).