Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Tabussam Tufail | -- | 3201 | 2022-11-19 16:15:32 | | | |

| 2 | Dean Liu | -5 word(s) | 3196 | 2022-11-21 03:33:23 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Tufail, T.; Ain, H.B.U.; Hussain, M.; Aadil, R.M.; Suleria, H.A.R. Cereal’s Bran. Encyclopedia. Available online: https://encyclopedia.pub/entry/35329 (accessed on 07 February 2026).

Tufail T, Ain HBU, Hussain M, Aadil RM, Suleria HAR. Cereal’s Bran. Encyclopedia. Available at: https://encyclopedia.pub/entry/35329. Accessed February 07, 2026.

Tufail, Tabussam, Huma Bader Ul Ain, Muzzamal Hussain, Rana Muhammad Aadil, Hafiz Ansar Rasul Suleria. "Cereal’s Bran" Encyclopedia, https://encyclopedia.pub/entry/35329 (accessed February 07, 2026).

Tufail, T., Ain, H.B.U., Hussain, M., Aadil, R.M., & Suleria, H.A.R. (2022, November 19). Cereal’s Bran. In Encyclopedia. https://encyclopedia.pub/entry/35329

Tufail, Tabussam, et al. "Cereal’s Bran." Encyclopedia. Web. 19 November, 2022.

Copy Citation

Cereal bran has functional components with high nutritional quality and immense nutritional characteristics. Despite its nutritional benefits, cereal bran is underutilized in food processing.

bioeconomy

sustainability

biowaste

bioactive compounds

1. Introduction

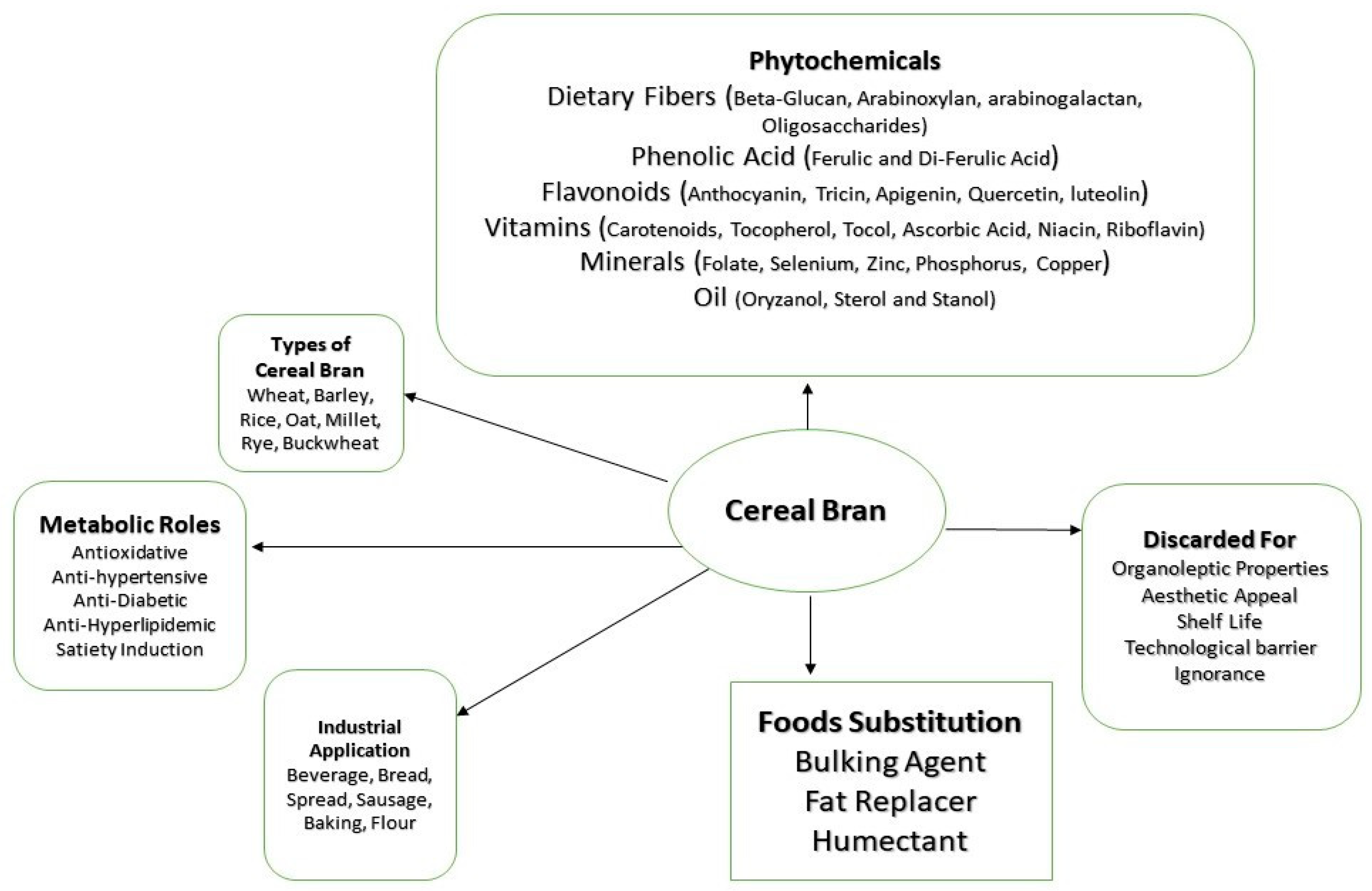

Cereal bran has functional components with high nutritional quality and immense nutritional characteristics. Despite its nutritional benefits, cereal bran is underutilized in food processing [1]. Parts of the starchy endosperm, pericarp, aleurone, testa, and germ contain fractions of cereal bran. The most widely consumed main cereals are sorghum, millet, barley, maize, rye, rice, oat, and wheat [2]. The dry matter of the kernel is approximately 3 to 30% bran, depending on the cereal crop type [3]. Cereal bran composition varies depending on crop type, kernel size, shape, bran layer thickness, grain storage state, and storage period prior to milling [4]. Vitamins (particularly vitamins B and E), bioactive compounds (ferulic acid, p-coumaric acid, and syringic acid), dietary fiber, and minerals are found in higher concentrations in cereal bran [5]. Protein, ash, fat, phosphorus, and niacin, the main components of bran, are all present in relatively high amounts. Cereal bran provides attributes such as thickening, emulsification gelling, and stabilization [6]. Furthermore, it has a variety of health and nutritional benefits. Global dietary guidelines recommend nutrient-dense components such as whole grains or wheat bran [7]. Cereal bran also has the commercial advantage of being used in food production as a source of dietary fiber without incurring the additional cost of dietary fiber extraction [8].

2. Sustainability of Cereal Bran

The term “Bioeconomy” refers to the application of biomaterials in bio-refineries employing non-food plants and trees for industrial purposes to sustainably produce and convert biomass for a variety of food, health, fibers, industrial, and energy products. Furthermore, the current management practices that discharge cereal-processing by-products into the environment are not sustainable. The reuse and valorization of their by-products is a major problem for the sustainable development of the agriculture and food sectors. Cereal by-products are a significant source of carbohydrates, proteins, lipids, vitamins, primarily B-complex and vitamin E, and inorganic and trace elements. Cereal bran is a rich and low-cost source of phytochemicals that may have use in nutraceuticals and pharmaceuticals. In the recent era, bran is increasingly added to food products because of its nutritional profile and physiological effects. Furthermore, different methods have also been suggested to improve sustainability recovery approaches in cereal by-products.

Efforts have been made to clarify various sustainable cereal residue management techniques in cereal systems in order to assist the development of a sustainable and economically viable advanced biofuels and bio-products sector.

3. Cereal’s Bran Properties

3.1. Physical Properties

The physical properties of cereal bran show that bran as a by-product is used to improve quality characteristics and safety aspects of bran-enriched products. Furthermore, when it comes to physicochemical parameters, the moisture content during storage is an important indicator that influences the quality of bran. The rate of development of fungus that causes the degradation of cereal bran depends partially on the level of moisture content. Likewise, there will be no growth of fungi at low moisture content. Fungal growth begins at approximately 14% moisture content or slightly above [9]. Nonetheless, due to the relatively high-fat content, moisture plays a critical role in cereal bran’s oxidative rancidity, particularly in rice bran [9]. This qualitative limitation has an impact on the utilization of cereal bran. To stabilize cereal bran, suitable methods employing particular nutritional inhibitors and inactivating enzymes could be used. Wet extrusion, dry extrusion, refrigeration, and microwave heating, as well as chemical treatments with acidic acetic and acidic calcium hydroxide hydrochloric technologies, are the most commonly used to stabilize cereal bran [10]. Microwave technology is commercially advanced and efficient, has a minimal processing time, and has a minimal impact on bran color, nutritional consistency, and functional properties [10]. In addition, bran contains essential fatty acids, ferulic acid derivatives, and tocopherols, and is a cheap source of protein [11]. The color of cereal bran is a significant physical factor in cereal grains because color influences the acceptability of food products, and as the color of bran varies between types, it indicates the presence of phytochemicals [10]. The purple color of rice bran has the highest content of anthocyanin in cereal grains, which include maize, wheat, and barley, among other blue and purple bran [12]. Bounded phenolics can be found in significant amounts in light brown rice bran [13].

Sustainable natural sources of anthocyanins, as one of the most abundant cereal bran, can be used as a common pigment (colorant) in natural colors in nutraceuticals and functional foods for health-promotion ingredients [13]. Furthermore, the use of colored cereal bran in food products may help to reduce unidentified usage adverse effects in food produced by synthetic colorants while promoting their nutritional characteristics. Cereal bran particle size is a measure of the degree to which their grains are milled. The distribution of particles is valuable on the basis of dietary fiber cereal bran possession in food processing with a critical outcome [14]. Its technical versatility is affected by bran particle size because of improvements in the bran’s physicochemical, rheological, swelling, water-absorption, and fat-binding properties. The particle size of cereal bran is caused by its low water-holding capacity and high oil-binding capability [15]. Furthermore, wheat flour functionality is influenced by the bran’s particle size [16]. In bran-enriched bread preparation, the size of the bran particles causes a rough texture (dark crimson color, even crust) and lowers the gas retention during proofing. Due to the negative effect of bran on wheat flour, it is important to evaluate standard particle sizes during the formulation of cereal-bran-enriched products. Previous researchers have shown that, in breadmaking with cereal-bran-enriched wheat flour, the most suitable particle size of cereal bran is 200 to 500 μm [17]. In cookie preparation, medium bran particle sizes (220 to 430 μm) improve the spread ratio, color, and nutritional and sensorial properties of cereal-bran-enriched cookies [18]. Wheat cake has the highest acceptability level of the wheat and oat bran particle size (<210 μm) [19]. Furthermore, the extraction of bioactive compounds from cereal bran does not affect particle size. Shelf life does not affect the particle size during storage of cereal-bran-enriched food products; rather, it seems that particle size affects the shelf life.

The degradation rate in wheat bran is high when the particle size is smaller, excluding finely milled bran (<0.40 mm), due to a halfway-deteriorating phenomenon demonstrated by unfractionated bran [20]. While this is dependent on the fat and moisture level of the bran, enzyme and/or microbe activity may be influenced by the bran’s accessible water and oxygen-taking capabilities. After grain milling, grading cereal bran in different particle sizes is crucial before marketing or use in order to analyze their technical impacts on processed foods. This is due to the consistency of the bran variation due to various milling processes and conditions that can influence cereal bran’s milled chemical composition and physical possessions. It is also useful to compare the quality of the incorporated product to bran food items from other case studies when it comes to explaining the accuracy of bran particle size during product development.

3.2. Chemical Compositions

Cereal bran is classified by its chemical composition, treatment, and particle size in different cereal varieties. Furthermore, rice bran has more ash fat than other cereal bran, while oat bran contains more protein than other cereal bran. The amino acid content of cereal bran proteins determines its nutritional profile. Furthermore, rice bran proteins have more beneficial amino acids than wheat bran proteins. Unlike other cereal bran, oat bran proteins have reduced tryptophan levels in leucine protein and proline compared to corn bran. Moreover, cereal bran proteins possess a nutritious and healthy amino acid composition [21][22]. The content of carbohydrates in rice bran is higher than in other cereal bran. However, the highest value is identified in maize bran. Table 1 shows the general chemical composition of cereal bran.

Cereal bran is the primary origin of cellulose, hemicellulose, and lignin as dietary fiber sources [22]. The main component that can alter digestibility, bioavailability, and nutrition is the insoluble dietary fiber from bran [6]. Corn bran has the highest amount of insoluble dietary fiber, followed by wheat and rice bran, whereas in other cereal bran, such as oat bran, the amount of insoluble dietary fiber is relatively smaller and soluble dietary fiber is higher [27]. Both soluble and insoluble functional dietary fibers involve differences in their technological and biochemical properties [22]. Moreover, cereal bran is also a good source of non-starch polysaccharides, especially arabinoxylans, and different phenolic compounds. Cereal β-glucans such as those found in oat bran are abundant in barley and oat bran, ranging from 6 to 18% (in dry matter) [28]. Furthermore, it was reported that the mineral profile of wheat bran is higher when compared to rice and oat bran, whereas the calcium content in both is higher than in maize bran. In addition, rice bran shows a higher amount of manganese, phosphorus, potassium, magnesium, and iron. In maize bran, sodium is higher compared to wheat bran, which, in turn, contains higher selenium, copper, and zinc. Compared to other cereal bran, rice bran contains a higher amount of phosphorus. Furthermore, phytic acid, as an anti-nutritional component, is observed to decrease the bioavailability of certain minerals, e.g., zinc, iron, and calcium. Since the 1990s, phytic acid has demonstrated health-promoting properties, specifically in the prevention of renal calculus, cancer, and diabetes [29]. Rice bran cereals contain more vitamins E and B than most bran cereals, making them a potential source for the human body’s physiological processes and metabolic pathways. In rice bran, tocopherols have an eminent amount of Vitamin E compared to tocotrienols. Therefore, tocotrienols have higher antioxidant activity compared to tocopherols [30]. Tocotrienols and seven tool isomers, namely, α-, β-, and π-tocotrienols (but not β-tocotrienols), are higher in rice bran, along with wheat and barley, when compared to other cereal bran [31]. Vitamin A is abundantly present in maize bran when compared to other cereal bran.

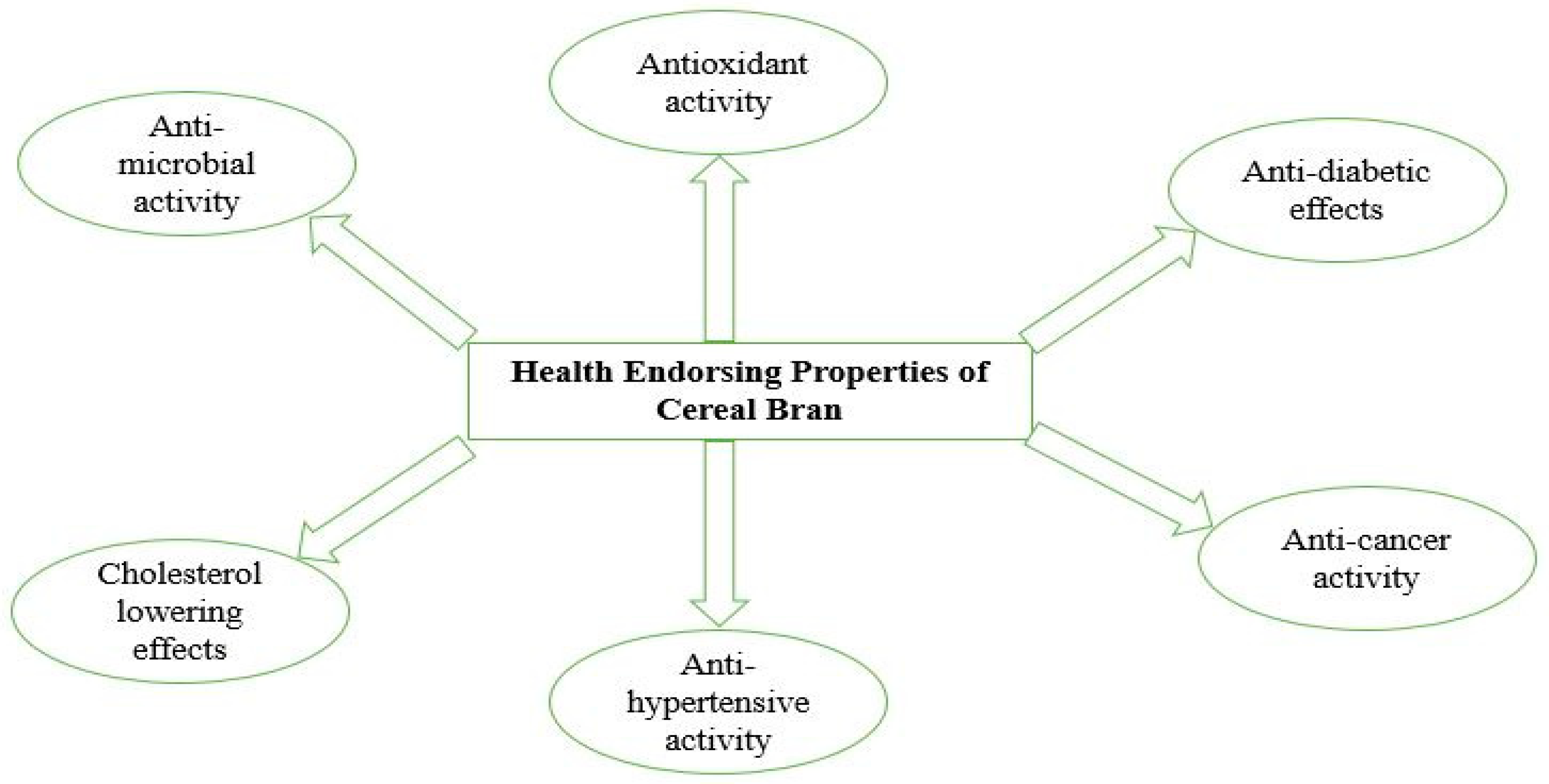

The oil contents of various cereal bran have shown that their key fatty acids are oleic, linoleic, and palmitic acids. In addition, rice bran has a higher content of squalene compared to other cereal bran oils; from rice bran, the extracted oil is rich in ÿ-oryzanols, tocotrienols, tocopherols, phytosterols, and polyphenols [32][33]. In comparison to other vegetable oils, grain oil is nutritionally superior because it contains more oryzanol, (omega-3 and omega-6) fatty acids and unsaponifiable fats [6]. Rice bran oil’s potential antioxidant activity and composition, in contrast to other cereal bran oils, grant it a longer shelf-life, and its low viscosity allows for easier oil absorption during cooking and considerably reduces calories [34]. Cereal bran has a higher antioxidant capacity than other milled fractions of cereals [35]. Cereal bran exhibits antioxidant, antibacterial, and anti-diabetic activities as a result of the above-mentioned composition (Figure 2) [36]. The phytochemical contents are also presented in Table 2. P-hydroxybenzoic acid, p-coumaric acid, ferulic acid (its derivatives), vanillic acid, feruloyl oligosaccharides, and syringic are found in wheat bran [37].

Figure 1. Health-endorsing properties of cereal bran.

For instance, avenanthramides are present in oat bran [43]. Flavonoids, anthocyanin, and phenolic acids are found in sorghum bran [44]. Folate, steryl ferulates, phenolic acids, alkylresorcinols, and lignans are found in rice bran [45]. P-coumaric acid, diferulic acid, and ferulic acid are present in maize bran, as well as ferulated arabinoxylans and hydroxycinnamic acid conjugates [46]. The bioactive compounds in whole grains are dominant in a fraction of cereal grains such as bran [2]. Furthermore, cereal bran has increased antioxidant qualities due to the above-mentioned profiles and is used as a natural preservative in different baked, meat, and confectionery products. Moreover, as a functional ingredient containing bioactive compounds, bran can also serve as an important raw material for the development of new functional foods [47]. Due to its bioactive composition, cereal bran has been proven to prevent health complications such as non-communicable diseases (NCDs), e.g., oxidative stress, obesity, and cardiovascular diseases [48]. When applied in food product development, cereal bran functions as a barrier to the delivery of bioactive components, which is essential for optimal health.

3.3. Microbiological Properties

Several studies revealed a high number of microorganisms between the pericarp and husk of cereal bran, and their metabolites may be used in further applications [48]. The use of various types of equipment during milling may increase impurities in the milling procedure and cause the development of pathogenic microorganisms (particularly fungi and bacterial pathogens) during the cooling, fermentation, and heat treatment of mill products. A clear indication is that cereal bran fermentation may help to control indigenous microorganisms [6][47]. There are also common procedures in certain regions to eliminate microbial contaminants and divide layers of bran outer 2–4%. Using more chemicals before processing may reduce the level of chemicals in bran layers.

4. Functional Characteristics of Cereal Bran

Cereal bran is involved in other innovative practical properties in food processing. The primary properties of cereal bran as a dietary fiber source are associated with its solubility, viscosity, water-binding capacity, organic-molecule-binding capability, mineral content, gel-forming ability, and oil-binding ability, affecting the end-product quality [49]. Bran has adequate capacity to absorb water and fat. The hydration properties of cereals, which are a source of dietary fiber, increase with temperature and are associated with higher dietary fiber solubility [22]. Cereal bran oil absorption is primarily related to the bran particle size [50], ranging from 0.25 to 0.59 g/mL, 148.4 to 383.7%, and 138.3 to 302.9%, regarding the bulk mass, absorption of water, and properties of cereal bran, respectively [10]. According to the aforementioned study, wheat bran has the largest capacity to bind water, fat, and water intensity, whereas barley bran is found in the uppermost bulk compactness. Cereal bran often differs in its levels of viscoelastic properties and solubility, and the food industry could utilize its physicochemical properties in the production of novel food materials containing the building of structures, gelling, and binding water [51]. In cereal bran, the solubility and insolubility of dietary fibers depend on their biochemical impact and technical functioning [22]. Low compactness contains insoluble dietary fibers, improves intestinal microbiota development, increases fecal bulk, reduces bowel transit, regulates plasma, and decreases glycemic reactions. In addition, most insoluble fibers are fermented in the large intestine, which helps to develop intestinal microbiota, for instance, species of probiotics [51]. Because of their increased oil absorption capacity, cereal bran has great potential in the food industry. There is technical evidence that may indicate emulsions are elevated-fat foods, whereas they can modify the viscosity, water-holding capacity, and texture of formulated foods such as additives to inhibit syneresis [6].

The uniqueness of cereal types has a direct impact on flour’s physical and chemical properties, resulting in variations in the rheological properties of dough if used as enriched flour. The bran of cereal greatly influences the water-binding capability of dough combined with differences in water absorption produced by gluten in the production of dough [52]. These outcomes regarding the properties of the dough include increased water absorption during the addition stage, in which the consistency of the addition process affects the refusal and enhancement time; improvement in the dough during the proofing process; the dough extension (extensibility decrease) properties change; and the dough structures improve (stiffer dough or decreased stickiness) [53][54]. When compared to barley brans and oat brans, cereal bran and wheat increased dough development time (DDT) when added to wheat flour in a proportion between 0 and 40%, while the dough quality in oat and barley blends significantly decreased from 8.5 to 4 min and 7.0 to 3.5 min, respectively.

The extension resistance for formulations gradually decreased as oat and barley bran increased, whereas up to 40% of wheat bran (3.11 to 10.00), rice bran (3.11 to 18.09), and barley bran (3.11 to 8.88) were used [55]. Another study found that incorporating wheat bran into baking products increased water absorption and decreased dough stability, extensibility, and peak viscosity. Baked products’ textures may be altered in addition to their rheological properties by adding cereal bran, as has been reported by previous studies [53]. In baking products, the incorporation of bran in wheat flour showed various technological, nutritional, and functional aspects. Technically, cereal bran influences the crumb structure, texture, and loaf volume [47]. Furthermore, cereal bran contains non-starch polysaccharides, which affect the development of a proper, strong gluten network, leading to rheological attributes and aggravation, as does the bread dough treatment, resulting in a hard crumb, bitter flavor, lower loaf volume, and dark color [6]. The composition and physicochemical characteristics of arabinoxylans influence their functionality [51]. In the production of bread, negative effects are induced due to unextractable arabinoxylans, while water-extractable arabinoxylans in wheat flour have positive effects on bread characteristics, including the texture of crumbs and the amount of bread. Furthermore, the dilution of gluten proteins and particle sizes can improve the final product and dough characteristics because the surface area and amount of ferulic acid increase, and the interaction between active components and gluten are also enhanced. Therefore, this impacts gluten development [53]. The particle size of the bran is affected by the functioning of the dough. There are often conflicting reports about the effect of bran fractions on dough formation in various research. For dough mixing, reduced resistance regarding the particle size of fine wheat bran has been reported [56], and as evaluated by a farinographic study, the necessity for dough mixing was reduced, associated with coarse bran. The consumption of fractions observed, according to Noort et al. [53], has the least negative impact on coarse bran. These results evaluate the impact of a particular size, which could be partly related to variability in bran description, physical uniqueness and bran structure, natural differences, or differences in the bread-baking procedure. The technological influence of cereal bran in food production has been enhanced by heat treatment and fermentation, particularly in cereal-based products [57]. The surface of bran roughness also impacted the rheological properties of dough but did not adversely impact the quality of bread preparation [58]. Wheat bran and rye were prepared using bioprocessing techniques such as fermentation with specialized specific yeasts and enzymatic processes [7]. The use of enzymes and microbes has enhanced bran technology in the baking industry; bran in wheat flour increases the loaf volume, improves shelf life, and improves crumb quality [47][59]. Regarding dough, carbon dioxide retention was enhanced by using fermented bran, and it was reported that the utilization of enzymes enhanced the dough’s stability. Amylolytic- and phytate-degrading enzymes associated with cereal bran treatment, according to Coda et al. [60], boosted the nutritional and technical consistency of bread. During bread preparation using wheat bran, the micronization technique improved technological properties [61]. The external bran division is influenced by coarse fiber parts. Pearling enhanced the nutritional consistency of wheat bran by exclusively modifying the functional properties with 10% enrichment [6]. Before adding cereal bran to the dough, the quantity of the loaf increased, and the quality of the bread improved by incorporating 12% bran in wheat bread [62]. The maize bran particle size is significantly decreased, and it may be micronized as well. Removing the microstructure results in a significant reduction in the bran matrix and an increase in the surface area [63]. Oil-holding, swelling, and water-holding capabilities, as well as cation exchange capability, were all increased by 140% and 90%, respectively. The usage of cereal bran in processing operations will be improved as a result of these improvements during food processing. The functional and technological aspects of cereal bran are shown in Figure 2.

Figure 2. Cereal bran as a functional product.

References

- Lebesi, D.M.; Tzia, C. Use of endoxylanase treated cereal brans for development of dietary fiber enriched cakes. Innov. Food Sci. Emerg. Technol. 2012, 13, 207–214.

- Gani, A.; Wani, S.M.; Masoodi, F.A.; Hameed, G. Whole-grain cereal bioactive compounds and their health benefits: A review. J. Food Process. Technol. 2012, 3, 146–156.

- Fišteš, A.; Došenovic, T.; Rakic, D.; Pajin, B.; Šereš, Z.; Simovic, Š.; Loncarevic, I. Statistical analysis of the basic chemical composition of whole grain flour of different cereal grains. Acta Univ. Sapientiae-Aliment. 2014, 7, 45–53.

- Górnaś, P.; Radenkovs, V.; Pugajeva, I.; Soliven, A.; Needs, P.W.; Kroon, P.A. Varied composition of tocochromanols in different types of bran: Rye, wheat, oat, spelt, buckwheat, corn, and rice. Int. J. Food Prop. 2016, 19, 1757–1764.

- Patel, S. Cereal bran: The next super food with significant antioxidant and anticancer potential. Mediterr. J. Nutr. Metab. 2012, 5, 91–104.

- Chinma, C.E.; Ramakrishnan, Y.; Ilowefah, M.; Hanis-Syazwani, M.; Muhammad, K. REVIEW: Properties of Cereal Brans: A Review. Cereal Chem. J. 2015, 92, 1–7.

- Delcour, J.A.; Rouau, X.; Courtin, C.M.; Poutanen, K.; Ranieri, R. Technologies for enhanced exploitation of the health-promoting potential of cereals. Trends Food Sci. Technol. 2012, 25, 78–86.

- Alan, P.A.; Ofelia, R.S.; Patricia, T.; Rosario Maribel, R.S. Cereal bran and wholegrain as a source of dietary fibre: Technological and health aspects. Int. J. Food Sci. Nutr. 2012, 63, 882–892.

- Hoseney, R.C. Principles of Cereal Science and Technology. American Association of Cereal Chemists; RC Hoseney Inc.: St. Paul, MN, USA, 1994; p. 170.

- Sharma, S.; Kaur, S.; Dar, B.N.; Singh, B. Storage stability and quality assessment of processed cereal brans. J. Food Sci. Technol. 2011, 51, 583–588.

- Singh, A.; Sharma, S. Bioactive components and functional properties of biologically activated cereal grains: A bibliographic review. Crit. Rev. Food Sci. Nutr. 2017, 57, 3051–3071.

- Galanakis, C.M. Food Waste Recovery: Processing Technologies and Industrial Techniques; Academic Press: Cambridge, MA, USA, 2015.

- Abdel-Aal, E.S.M.; Young, J.C.; Rabalski, I. Anthocyanin composition in black, blue, pink, purple, and red cereal grains. J. Agric. Food Chem. 2006, 54, 4696–4704.

- Min, B.; Anna, M.M.; Ming-Hsuan, C. Phytochemicals and antioxidant capacities in rice brans of different color. J. Food Sci. 2006, 76, 117–125.

- Nelson, A.L. High-Fiber Properties and Analyses. High-Fiber Ingredients; American Association of Cereal Chemists: St. Paul, MN, USA, 2001; pp. 29–44.

- Viuda-Martos, M.; López-Marcos, M.C.; Fernández-López, J.; Sendra, E.; López-Vargas, J.H.; Pérez-Álvarez, J.A. Role of fiber in cardiovascular diseases: Review. Compr. Rev. Food Sci. Food Saf. 2010, 9, 240–258.

- Doblado-Maldonado, A.F.; Pike, O.A.; Sweley, J.C.; Rose, D.J. Key issues and challenges in whole wheat flour milling and storage. J. Cereal Sci. 2012, 56, 119–126.

- Wang, N.; Hou, G.G.; Dubat, A. Effects of flour particle size on the quality attributes of reconstituted whole-wheat flour and Chinese southern-type steamed bread. LWT-Food Sci. Technol. 2017, 82, 147–153.

- Ozturk, S.; Ozboy, O.; Cavidoglu, I.; Koksel, H. Effects of brewers’ spent grain on the quality and dietary fibre content of cookies. J. Inst. Brew. 2002, 108, 23–27.

- Gómez, M.; Ruiz-París, E.; Oliete, B. Influence of flour mill streams on cake quality. Int. J. Food Sci.Tech. 2010, 45, 1794–1800.

- Galliard, T.; Gallagher, D.M. The effects of wheat bran particle size and storage period on bran flavor and baking quality of bran flour blends. J. Cereal Sci. 1988, 8, 147–154.

- Di Lena, G.; Vivanti, V.; Quaglia, G.B. Amino acid composition of wheat milling by-products after bioconversion by edible fungi mycelia. Food/Nahr. 1997, 41, 285–288.

- Brockmole, C.L.; Zabik, M.E. Wheat bran and middlings in white layer cakes. J. Food Sci. 1976, 41, 357–360.

- Curti, E.; Carini, E.; Bonacini, G.; Tribuzio, G.; Vittadini, E. Effect of the addition of bran fractions on bread properties. J. Cereal Sci. 2013, 57, 325–332.

- Yan, X.; Ye, R.; Chen, Y. Blasting extrusion processing: The increase of soluble dietary fiber content and extraction of soluble-fiber polysaccharides from wheat bran. Food Chem. 2015, 180, 106–115.

- Javed, M.M.; Zahoor, S.; Shafaat, S. Wheat bran as a brown gold: Nutritious value and its biotechnological applications. Afr. J. Microbiol. Res. 2012, 6, 724–733.

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterization, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421.

- Carter, J.F. Potential of flaxseed and flaxseed oil in baked goods and other products in human nutrition. Cereal Foods World 1993, 38, 753–759.

- Guleria, P.; Kumari, S.; Dangi, N. β-glucan: Health benefits and role in food industry-A review. J. ERS. TechEng. 2015, 8, 255–263.

- Canan, C.; Cruz, F.T.L.; Delaroza, F.; Casagrande, R.; Sarmento, C.P.M.; Shimokomaki, M.; Ida, E.I. Studies on the extraction and purification of phytic acid from rice bran. Food Compos. Anal. 2011, 24, 1057–1063.

- Packer, L. Nutrition and Biochemistry of the Lipophilic Antioxidants, Vitamin E and Carotenoids. In Nutrition, Lipids, Health, and Disease; Ong, A.S.H., Niki, E., Packer, L., Eds.; AOCS Press: Urbana, IL, USA, 1995; pp. 8–35.

- Ko, S.N.; Kim, C.J.; Kim, H.; Kim, C.T.; Chung, S.H.; Tae, B.S.; Kim, I.H. Tocol levels in milling fractions of some cereal grains and soybean. J. Am. Oil Chem. Soc. 2003, 80, 585–589.

- Tufail, T.; Saeed, F.; Arshad, M.U.; Afzaal, M.; Rasheed, R.; Bader Ul Ain, H.; Imran, M.; Abrar, M.; Farooq, M.A.; Shahid, M.Z. Exploring the effect of cereal bran cell wall on rheological properties of wheat flour. J. Food Process. Preserv. 2020, 44, e14345.

- Ghosh, M. Review on recent trends in rice bran oil processing. J. Am. Oil Chem. Soc. 2007, 84, 315–324.

- Chakrabarty, M.M. Rice bran: A new source for edible and industrial oil. In Proceedings of World Conference on Edible Fats and Oils Processing; Erickson, D.R., Ed.; AOCS Press: Urbana, IL, USA, 1989; pp. 331–340.

- Van Hung, P. Phenolic compounds of cereals and their antioxidant capacity. Crit. Rev. Food Sci. Nutr. 2016, 56, 25–35.

- Zhang, M.W.; Zhang, R.F.; Zhang, F.X.; Liu, R.H. Phenolic profiles and antioxidant activity of black rice bran of different commercially available varieties. J. Agric. Food Chem. 2010, 58, 7580–7587.

- Luthria, D.L.; Lu, Y.; John, K.M. Bioactive phytochemicals in wheat: Extraction, analysis, processing, and functional properties. J. Funct. Foods 2015, 18, 910–925.

- Fardet, A. New hypotheses for the health protective mechanisms of whole-grain cereals: What is beyond fibre? Nutr. Res. Rev. 2010, 23, 65–134.

- Kim, K.H.; Tsao, R.; Yang, R.; Cui, S.W. Phenolic acid profiles and antioxidant activities of wheat bran extracts and the effect of hydrolysis conditions. Food Chem. 2006, 95, 466–473.

- Brouns, F.; Hemery, Y.; Price, R.; Anson, N.M. Wheat aleurone: Separation, composition, health aspects, and potential food use. Crit. Rev. Food Sci. Nutr. 2012, 52, 553–568.

- Brewer, L.R.; Kubola, J.; Siriamornpun, S.; Herald, T.J.; Shi, Y.C. Wheat bran particle size influence on phytochemical extractability and antioxidant properties. Food Chem. 2014, 152, 483–490.

- Wang, J.; Sun, B.; Cao, Y.; Wang, C. Wheat bran feruloyl oligosaccharides enhance the antioxidant activity of rat plasma. Food Chem. 2010, 123, 472–476.

- Martinez-Tome, M.; Murcia, M.A.; Freha, N.; Ruggieri, S.; Jimenez, A.M.; Roses, F.; Parras, P. Evaluation of antioxidant capacity of cereal brans. J. Agric. Food Chem. 2004, 52, 4690–4699.

- Buitimea-Cantúa, N.E.; Torres-Chávez, P.I.; Ramírez-Wong, B.; Serna-Saldívar, S.O.; Rouzaud-Sández, O.; Rosas-Burgos, E.C.; Salazar-García, M.G. Phenolic compounds and antioxidant activity of extruded nixtamalized corn flour and tortillas enriched with sorghum bran. Cereal Chem. 2017, 94, 277–283.

- Katina, K.; Salmenkallio-Marttila, M.; Partanen, R.; Forssell, P.; Autio, K. Effects of sourdough and enzymes on staling of high-fibre wheat bread. LWT-Food Sci. Tech. 2006, 39, 479–491.

- Bento-Silva, A.; Patto, M.C.V.; do Rosário Bronze, M. Relevance, structure and analysis of ferulic acid in maize cell walls. Food Chem. 2018, 246, 360–378.

- Katina, K.; Juvonen, R.; Laitila, A.; Flander, L.; Nordlund, E.; Kariluoto, S.; Poutanen, K. Fermented wheat bran as a functional ingredient in baking. Cereal Chem. 2012, 89, 126–134.

- Rosenkvist, H.; Hansen, Å. Contamination profiles and characterisation of Bacillus species in wheat bread and raw materials for bread production. Int. J. Food Microb. 1995, 26, 353–363.

- Tungland, B.C.; Meyer, D. Nondigestible oligo-and polysaccharides (Dietary Fiber): Their physiology and role in human health and food. Compr. Rev. Food Sci. Food Saf. 2002, 1, 90–109.

- Caprez, A.; Arrigoni, E.; Amado, R.; Zeukom, H. Influence of different types of thermal treatment on the chemical composition and physical properties of wheat bran. J. Cereal Sci. 1986, 4, 233–239.

- Foschia, M.; Peressini, D.; Sensidoni, A.; Brennan, C.S. The effects of dietary fibre addition on the quality of common cereal products. J. Cereal Sci. 2013, 58, 216–227.

- Noort, M.W.J.; Van Haaster, D.; Hemery, Y.; Schols, H.A.; Hamer, R.J. The effect of particle size of wheat bran fractions on bread quality-evidence for fibre- protein interactions. J. Cereal Sci. 2010, 52, 59–64.

- Ktenioudaki, A.; Gallagher, E. Recent advances in the development of high-fibre baked products. Trends Food Sci. Technol. 2012, 28, 414.

- Tufail, T.; Saeed, F.; Pasha, I.; Umair Arshad, M.; Afzaal, M.; Bader Ul Ain, H.; Bashir, S.; Imran, M.; Zia Shahid, M.; Abdullah, M.; et al. Extraction, quantification, and biochemical characterization of cereal industry by-product cell wall. J. Food Process. Preserv. 2021, 45, e15023.

- Schmiele, M.; Jaekel, L.Z.; Patricio, S.M.C.; Steel, C.J.; Chang, Y.K. Rheological properties of wheat flour and quality characteristics of pan bread as modified by partial additions of wheat bran or whole grain wheat flour. Int. J. Food Sci. Tech. 2012, 47, 2141–2150.

- Zhang, D.; Moore, W.R. Effect of wheat bran particle size on dough rheological properties. J. Sci. Food Agric. 1997, 74, 490–496.

- Shogren, M.D.; Pomeranz, Y.; Finney, K.F. Counteracting the deleterious effects of fiber in bread making. Cereal Chem. 1980, 58, 142–144.

- Fendri, L.B.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Chaabouni, S.E.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT 2016, 73, 584–591.

- Coda, R.; Kärki, I.; Nordlund, E.; Heiniö, R.L.; Poutanen, K.; Katina, K. Influence of particle size on bioprocess induced changes on technological functionality of wheat bran. Food Microbiol. 2014, 37, 69–77.

- Sanz Penella, J.M.; Collar, C.; Haros, M. Effect of wheat bran and enzyme addition on dough functional performance and phytic acid levels in bread. J. Cereal Sci. 2008, 48, 715–721.

- Rizzello, C.G.; Coda, R.; Mazzacane, F.; Minervini, D.; Gobbetti, M. Micronized by-products from debranned durum wheat and sourdough fermentation enhanced the nutritional, textural and sensory features of bread. Food Res. Int. 2012, 46, 304–313.

- Nelles, E.; Randall, P.; Taylor, J. Improvement of brown bread quality by prehydration treatment and cultivar selection of bran. Cereal Chem. 1998, 75, 536–540.

More

Information

Subjects:

Food Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.4K

Revisions:

2 times

(View History)

Update Date:

22 Nov 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No