| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Beatrix Zheng | -- | 2732 | 2022-11-17 01:41:44 | | | |

| 2 | Beatrix Zheng | Meta information modification | 2732 | 2022-11-21 10:37:19 | | | | |

| 3 | Beatrix Zheng | -16 word(s) | 2716 | 2022-11-21 10:44:58 | | |

Video Upload Options

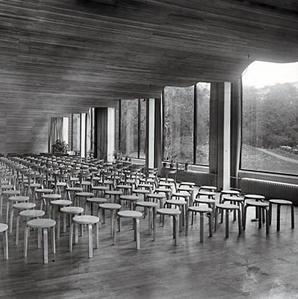

Architectural lighting design is a field within architecture, interior design and electrical engineering that is concerned with the design of lighting systems, including natural light, electric light, or both, to serve human needs. The aim of lighting design is the human response, to see clearly and without discomfort. The objective of architectural lighting design is to further the design of architecture or the experience of buildings and other physical structures.

1. History

Gas lighting was economical enough to light streets in major cities starting in the early 1800s, and was also used in some commercial buildings and in the homes of wealthy people. The gas mantle boosted the luminosity of utility lighting and of kerosene lamps. The next major drop in price came about with the incandescent light bulb powered by electricity.[1]

2. Concept

Architectural lighting design focuses on three fundamental aspects of the illumination of buildings or spaces. The first is the aesthetic appeal of a building, an aspect particularly important in the illumination of retail environments. Secondly, the ergonomic aspect: the measure of how much of a function the lighting plays. Thirdly is energy efficiency, ensuring that light is not wasted by over illumination which occurs either by illuminating vacant spaces unnecessarily or by providing more light than needed for the aesthetics or the task. Cultural factors also need to be considered; for example, bright lights was a mark of wealth through much of Chinese history.[2]

3. Day Lighting

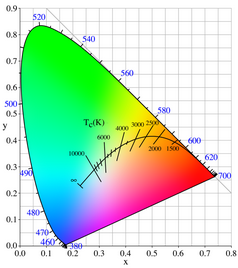

For colors based on black-body theory, blue occurs at higher temperatures, while red occurs at lower, cooler, temperatures. This is the opposite of the cultural associations attributed to colors, in which red represents hot, and blue cold.[3]

4. Fixtures

Lighting fixtures come in a wide variety of styles for various functions. The most important functions are as a holder for the light source, to provide directed light and to avoid visual glare. Some are very plain and functional, while some are pieces of art in themselves. Nearly any material can be used, so long as it can tolerate the excess heat and is in keeping with safety codes.

An important property of light fixtures is the luminous efficacy or wall-plug efficiency, meaning the amount of usable light emanating from the fixture per used energy, usually measured in lumen per watt. A fixture using replaceable light sources can also have its efficiency quoted as the percentage of light passed from the "bulb" to the surroundings. The more transparent the lighting fixture is, the higher efficacy. Shading the light will normally decrease efficiency but increase the directionality and the visual comfort probability.

The PH-lamps are a series of light fixtures designed by Danish designer and writer Poul Henningsen from 1926 onwards.[4] The lamp is designed with multiple concentric shades to eliminate visual glare, only emitting reflected light, obscuring the light source.[5]

5. Photometric Studies

Photometric studies (also sometimes referred to as "layouts" or "point by points") are often used to simulate lighting designs for projects before they are built or renovated. This enables architects, lighting designers, and engineers to determine whether a proposed lighting setup will deliver the amount of light intended. They will also be able to determine the contrast ratio between light and dark areas. In many cases these studies are referenced against Illuminating Engineering Society of North America (IESNA) or CIBSE recommended lighting practices for the type of application. Depending on the type of area, different design aspects may be emphasized for safety or practicality (i.e. such as maintaining uniform light levels, avoiding glare or highlighting certain areas). A specialized lighting design application is often used to create these, which typically combine the use of two-dimensional digital CAD drawings and lighting simulation software.

Color temperature for white light sources also affects their use for certain applications. The color temperature of a white light source is the temperature in kelvins of a theoretical black body emitter that most closely matches the spectral characteristics of the lamp. An incandescent bulb has a color temperature around 2800 to 3000 kelvins; daylight is around 6400 kelvins. Lower color temperature lamps have relatively more energy in the yellow and red part of the visible spectrum, while high color temperatures correspond to lamps with more of a blue-white appearance. For critical inspection or color matching tasks, or for retail displays of food and clothing, the color temperature of the lamps will be selected for the best overall lighting effect. Color may also be used for functional reasons. For example, blue light makes it difficult to see veins and thus may be used to discourage drug use.[6]

The color temperature of a light source is the temperature of an ideal black-body radiator that radiates light of comparable hue to that of the light source. Color temperature is a characteristic of visible light that has important applications in lighting, photography, videography, publishing, manufacturing, astrophysics, horticulture, and other fields. In practice, color temperature is only meaningful for light sources that do in fact correspond somewhat closely to the radiation of some black body, i.e., those on a line from reddish/orange via yellow and more or less white to blueish white; it does not make sense to speak of the color temperature of, e.g., a green or a purple light. Color temperature is conventionally stated in the unit of absolute temperature, the kelvin, having the unit symbol K.

For lighting building interiors, it is often important to take into account the color temperature of illumination. For example, a warmer (i.e., lower color temperature) light is often used in public areas to promote relaxation, while a cooler (higher color temperature) light is used to enhance concentration in offices.[7]

CCT dimming for LED technology is regarded as a difficult task, since binning, age and temperature drift effects of LEDs change the actual color value output. Here feedback loop systems are used for example with color sensors, to actively monitor and control the color output of multiple color mixing LEDs.[8]

The color temperature of the electromagnetic radiation emitted from an ideal black body is defined as its surface temperature in kelvins, or alternatively in mireds (micro-reciprocal kelvin).[9] This permits the definition of a standard by which light sources are compared.

7. Categorizing Different Lighting

| Temperature | Source |

|---|---|

| 1,700 K | Match flame, low-pressure sodium lamps (LPS/SOX) |

| 1,850 K | Candle flame, sunrise, sunset |

| 2,700–3,300 K | Incandescent lamps, soft-white fluorescent lamps |

| 3,000 K | Warm-white fluorescent lamps |

| 4,100–4,150 K | Moonlight,[10] cool-white fluorescent lamps |

| 5,000 K | Horizon daylight |

| 5,500–6,000 K | Vertical daylight, electronic flash |

| 6,200 K | Xenon short-arc lamp[11] |

| 6,500 K | Daylight, overcast, daylight fluorescent lamps |

| 6,500–10,500 K | LCD or CRT screen |

| 15,000–27,000 K | Clear blue poleward sky |

| These temperatures are merely characteristic; considerable variation may be present. |

|

To the extent that a hot surface emits thermal radiation but is not an ideal black-body radiator, the color temperature of the light is not the actual temperature of the surface. An incandescent lamp's light is thermal radiation, and the bulb approximates an ideal black-body radiator, so its color temperature is essentially the temperature of the filament.

Many other light sources, such as fluorescent lamps, or LEDs (light emitting diodes) emit light primarily by processes other than thermal radiation. This means that the emitted radiation does not follow the form of a black-body spectrum. These sources are assigned what is known as a correlated color temperature (CCT). CCT is the color temperature of a black-body radiator which to human color perception most closely matches the light from the lamp. Because such an approximation is not required for incandescent light, the CCT for an incandescent light is simply its unadjusted temperature, derived from the comparison to a black-body radiator.

8. Methods

For simple installations, hand-calculations based on tabular data can be used to provide an acceptable lighting design. More critical or optimized designs now routinely use mathematical modeling on a computer.

Based on the positions and mounting heights of the fixtures, and their photometric characteristics, the proposed lighting layout can be checked for uniformity and quantity of illumination. For larger projects or those with irregular floor plans, lighting design software can be used. Each fixture has its location entered, and the reflectance of walls, ceiling, and floors can be entered. The computer program will then produce a set of contour charts overlaid on the project floor plan, showing the light level to be expected at the working height. More advanced programs can include the effect of light from windows or skylights, allowing further optimization of the operating cost of the lighting installation. The amount of daylight received in an internal space can typically be analyzed by undertaking a daylight factor calculation.

The Zonal Cavity Method is used as a basis for both hand, tabulated, and computer calculations. This method uses the reflectance coefficients of room surfaces to model the contribution to useful illumination at the working level of the room due to light reflected from the walls and the ceiling. Simplified photometric values are usually given by fixture manufacturers for use in this method.

Computer modeling of outdoor flood lighting usually proceeds directly from photometric data. The total lighting power of a lamp is divided into small solid angular regions. Each region is extended to the surface which is to be lit and the area calculated, giving the light power per unit of area. Where multiple lamps are used to illuminate the same area, each one's contribution is summed. Again the tabulated light levels (in lux or foot-candles) can be presented as contour lines of constant lighting value, overlaid on the project plan drawing. Hand calculations might only be required at a few points, but computer calculations allow a better estimate of the uniformity and lighting level.

9. Light-Fixture Controls

- 0-10 V lighting control

- 3-way 2-circuit switch

- Bluetooth mesh (wireless lighting control)

- Digital Addressable Lighting Interface (DALI) dimmable

- Dimmer

- Light switch (often part of the light socket or power cord on portable fixtures)

- Lighting control system

- Motion detector

- Timer

- Touch

- X10 (industry standard) systems

10. Design Media

10.1. Terminology

Recessed light

The protective housing is concealed behind a ceiling or wall, leaving only the fixture itself exposed. The ceiling-mounted version is often called a downlight.

"Cans" with a variety of lamps

Jargon for inexpensive downlighting products that are recessed into the ceiling, or sometimes for uplights placed on the floor. The name comes from the shape of the housing. The term "pot lights" is often used in Canada and parts of the US.

Cove light

Recessed into the ceiling in a long box against a wall

Floor lamp

Troffer

Recessed fluorescent light fixtures, usually rectangular in shape to fit into a drop ceiling grid[12]

Surface-mounted light

The finished housing is exposed, not flush mount with surface.

Chandelier

Pendant light

Suspended from the ceiling with a chain or pipe[13]

Sconce

Provide up or down lights; can be used to illuminate artwork, architectural details; commonly used in hallways or as an alternative to overhead lighting

Track lighting fixture

Individual fixtures (called track heads) can be positioned anywhere along the track, which provides electric power.

Under-cabinet light

Mounted below kitchen wall cabinets

Emergency lighting or exit sign

Connected to a battery backup or to an electric circuit that has emergency power if the mains power fails

High- and low-bay lighting

Typically used for general lighting for industrial buildings and often big-box stores

Strip lights or Industrial lighting

Often long lines of fluorescent lamps used in a warehouse or factory

Outdoor lighting and landscape lighting

Used to illuminate walkways, parking lots, roadways, building exteriors and architectural details, gardens, and parks

Bollard

A type of architectural outdoor lighting that is a short, upright ground-mounted unit typically used to provide cutoff type illumination for egress lighting, to light walkways, steps, or other pathways

Street light

A type of outdoor pole-mounted light used to light streets and roadways; similar to pole-mounted flood lights but with a type II lens (side to side light distribution pattern) instead of type III[14]

Flood lighting

Usually pole- or stanchion-mounted; for landscape, roadways, and parking lots[15]

11. Lamp Types

Types of electric lighting include:

- Incandescent light bulbs

- Arc lamps

- Gas-discharge lamps (e.g. fluorescent and compact fluorescent lamps, neon lamps, metal halide lamps, modern photographic flashes)

- Lasers

- Light-emitting diodes (LEDs), including OLEDs

- Sulfur lamps

Different types of lights have vastly differing efficiencies and color of light. [1]

| Name | Optical spectrum | Nominal efficiency (lm/W) |

Lifetime (MTTF) (hours) |

Color temperature (kelvin) |

Color | Color rendering index |

|---|---|---|---|---|---|---|

| Incandescent light bulb | Continuous | 4-17 | 2-20000 | 2400-3400 | Warm white (yellowish) | 100 |

| Halogen lamp | Continuous | 16-23 | 3000-6000 | 3200 | Warm white (yellowish) | 100 |

| Fluorescent lamp | Mercury line + Phosphor | 52-100 (white) | 8000-20000 | 2700-5000* | White (various color temperatures), as well as saturated colors available | 15-85 |

| Metal halide lamp | Quasi-continuous | 50-115 | 6000-20000 | 3000-4500 | Cold white | 65-93 |

| Sulfur lamp | Continuous | 80-110 | 15000-20000 | 6000 | Pale green | 79 |

| High pressure sodium | Broadband | 55-140 | 10000-40000 | 1800-2200* | Pinkish orange | 0-70 |

| Low pressure sodium | Narrow line | 100-200 | 18000-20000 | 1800* | Yellow, no color rendering | 0 |

| Light-emitting diode | Line plus phosphor | 10-110 (white) | 50,000-100,000 | Various white from 2700 to 6000* | Various color temperatures, as well as saturated colors | 70-85 (white) |

| Induction Lamp (External Coil) | Mercury line + Phosphor | 70-90 (white) | 80,000-100,000 | Various white from 2700 to 6000* | Various color temperatures, as well as saturated colors | 70-85 (white) |

*Color temperature is defined as the temperature of a black body emitting a similar spectrum; these spectra are quite different from those of black bodies.

The most efficient source of electric light is the low-pressure sodium lamp. It produces, for all practical purposes, a monochromatic orange/yellow light, which gives a similarly monochromatic perception of any illuminated scene. For this reason, it is generally reserved for outdoor public lighting usages. Low-pressure sodium lights are favoured for public lighting by astronomers, since the light pollution that they generate can be easily filtered, contrary to broadband or continuous spectra.

11.1. Incandescent Light Bulb

The modern incandescent light bulb, with a coiled filament of tungsten, was commercialized in the 1920s developed from the carbon filament lamp introduced in about 1880. As well as bulbs for normal illumination, there is a very wide range, including low voltage, low-power types often used as components in equipment, but now largely displaced by LEDs

There is currently interest in banning some types of filament lamp in some countries, such as Australia planning to ban standard incandescent light bulbs by 2010, because they are inefficient at converting electricity to light. Sri Lanka has already banned importing filament bulbs because of high use of electricity and less light. Less than 3% of the input energy is converted into usable light. Nearly all of the input energy ends up as heat that, in warm climates, must then be removed from the building by ventilation or air conditioning, often resulting in more energy consumption. In colder climates where heating and lighting is required during the cold and dark winter months, the heat byproduct has at least some value.

11.2. Fluorescent Lamp

Fluorescent lamps consist of a glass tube that contains mercury vapour or argon under low pressure. Electricity flowing through the tube causes the gases to give off ultraviolet energy. The inside of the tubes are coated with phosphors that give off visible light when struck by ultraviolet energy.[16] have much higher efficiency than Incandescent lamps. For the same amount of light generated, they typically use around one-quarter to one-third the power of an incandescent.

11.3. LED Lamp

Solid state light-emitting diodes (LEDs) became widespread as indicator lights since the 1970s. With the invention of high-output LEDs by Shuji Nakamura[17], LEDs are now in use for general lighting applications.

Initially, due to relatively high cost per lumen, LED lighting was most used for lamp assemblies of under 10 W such as flashlights. Development of higher-output lamps was motivated by programs such as the U.S. L Prize, [18]culminating in the commercial availability of LED lamps suitable to replace incandescent and fluorescent lamps.

LED technology is useful for lighting designers because of its low power consumption, low heat generation, instantaneous on-and-off control, and in the case of single color LEDs, continuity of color throughout the life of the diode and relatively low cost of manufacture. See Light Emitting Diode full article for more on the technology itself. See LED lamps for more on the general use of LEDs in lighting.

References

- "Episode 534: The History of Light". NPR.org (Podcast). NPR. 2014-04-25. Retrieved 2017-11-11. https://www.npr.org/blogs/money/2014/04/25/306862378/episode-534-the-history-of-light

- Campanella, Thomas J. (24 October 2017). "Mapping the Edison Bulbs of Brooklyn". Citylab. The Atlantic. https://www.citylab.com/design/2017/10/mapping-the-edison-bulbs-of-brooklyn/543738/. Retrieved 25 October 2017.

- Chris George (2008). Mastering Digital Flash Photography: The Complete Reference Guide. Sterling Publishing Company. p. 11. ISBN 978-1-60059-209-6. https://books.google.com/books?id=j728wJySfyQC&dq=blue+cool+red+hot+color-temperature+sun.

- "The PH lamp", Design, Visit Denmark, archived from the original on 2012-02-15, https://web.archive.org/web/20120215054112/http://www.visitdenmark.com/uk/en-gb/menu/turist/inspiration/detkulturelledanmark/design/the-ph-lamp.htm .

- "Poul Henningsen". Louis Poulsen Lighting. Archived from the original on 2013-11-18. https://web.archive.org/web/20131118201306/http://www.louispoulsen.com/en/Designers/Poul%20Henningsen.aspx.

- Watts, Amanda (7 December 2017). "Gas station installs blue lights to combat drug use". CNN. http://www.cnn.com/2017/12/07/health/bathroom-blue-lights-trnd/index.html. Retrieved 16 January 2018.

- Rüdiger Paschotta (2008). Encyclopedia of Laser Physics and Technology. Wiley-VCH. p. 219. ISBN 978-3-527-40828-3. https://books.google.com/books?id=BN026ye2fJAC&pg=PA219&dq=lighting+color-temperature+relaxing&q=lighting%20color-temperature%20relaxing.

- Thomas Nimz, Fredrik Hailer and Kevin Jensen (2012). Sensors and Feedback Control of Multi-Color LED Systems. LED Professional. pp. 2–5. http://www.mazet.de/en/english-documents/english/featured-articles/sensors-and-feedback-control-of-multi-color-led-systems-1/download#.UX7VXYIcUZI. Retrieved 2015-03-14.

- Wallace Roberts Stevens (1951). Principles of Lighting. Constable. https://books.google.com/books?id=gH5RAAAAMAAJ&q=micro-reciprocal-degree+date:0-1960&dq=micro-reciprocal-degree+date:0-1960.

- Parrott, Steve. "Moonlighting: Landscape Lighting Design Imitates Nature". http://www.cast-lighting.com/search/1/display-document/71. Retrieved 2011-09-29.

- "OSRAM SYVLANIA XBO". Archived from the original on 2016-03-03. https://web.archive.org/web/20160303212115/http://assets.sylvania.com/assets/documents/ENGR_BLTN11.161355cc-1d94-4996-b6cd-a3001fea6f1a.pdf.

- "troffer – Illuminating Engineering Society". https://www.ies.org/definitions/troffer/.

- "suspended (pendant) luminaire – Illuminating Engineering Society". https://www.ies.org/definitions/suspended-pendant-luminaire/.

- "A Look at Outdoor Area Lighting". Oct 11, 2017. https://www.energy.gov/sites/prod/files/2017/10/f37/postings_10-11-17.pdf.

- "floodlight (exterior lighting) – Illuminating Engineering Society". https://www.ies.org/definitions/floodlight-exterior-lighting/.

- Perkowitz, Sidney; Henry, A. Joseph (23 November 1998). Empire of Light:: A History of Discovery in Science and Art. Joseph Henry Press. ISBN 978-0309065566. https://archive.org/details/empireoflighthis00perk_0. Retrieved 4 November 2014. "fluorescent lights mercury vapor excites."

- "The Nobel Prize in Physics 2014" (in en-US). https://www.nobelprize.org/prizes/physics/2014/nakamura/facts/.

- "L Prize Competition" (in en). https://www.energy.gov/eere/ssl/l-prize-competition.