Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Amadou Sakhir Syll | -- | 1260 | 2022-11-07 09:07:29 | | | |

| 2 | Sirius Huang | Meta information modification | 1260 | 2022-11-08 06:35:03 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Syll, A.S.; Kanakubo, T. Bond Strength Deterioration Due to Corrosion. Encyclopedia. Available online: https://encyclopedia.pub/entry/33263 (accessed on 07 February 2026).

Syll AS, Kanakubo T. Bond Strength Deterioration Due to Corrosion. Encyclopedia. Available at: https://encyclopedia.pub/entry/33263. Accessed February 07, 2026.

Syll, Amadou Sakhir, Toshiyuki Kanakubo. "Bond Strength Deterioration Due to Corrosion" Encyclopedia, https://encyclopedia.pub/entry/33263 (accessed February 07, 2026).

Syll, A.S., & Kanakubo, T. (2022, November 07). Bond Strength Deterioration Due to Corrosion. In Encyclopedia. https://encyclopedia.pub/entry/33263

Syll, Amadou Sakhir and Toshiyuki Kanakubo. "Bond Strength Deterioration Due to Corrosion." Encyclopedia. Web. 07 November, 2022.

Copy Citation

Corrosion of the reinforcement affects more than the cross-sectional area of the rebar. The volume of steel also increases due to expansive corrosion products, leading to the cracking, delamination, and spalling of concrete. As a result, the bond capacity between concrete and rebar is affected. Researchers have extensively examined the impact of corrosion on the bond strength between concrete and rebar to propose empirical, theoretical, or numerical predictive models.

bond strength

corrosion of steel bar

concrete

1. Introduction

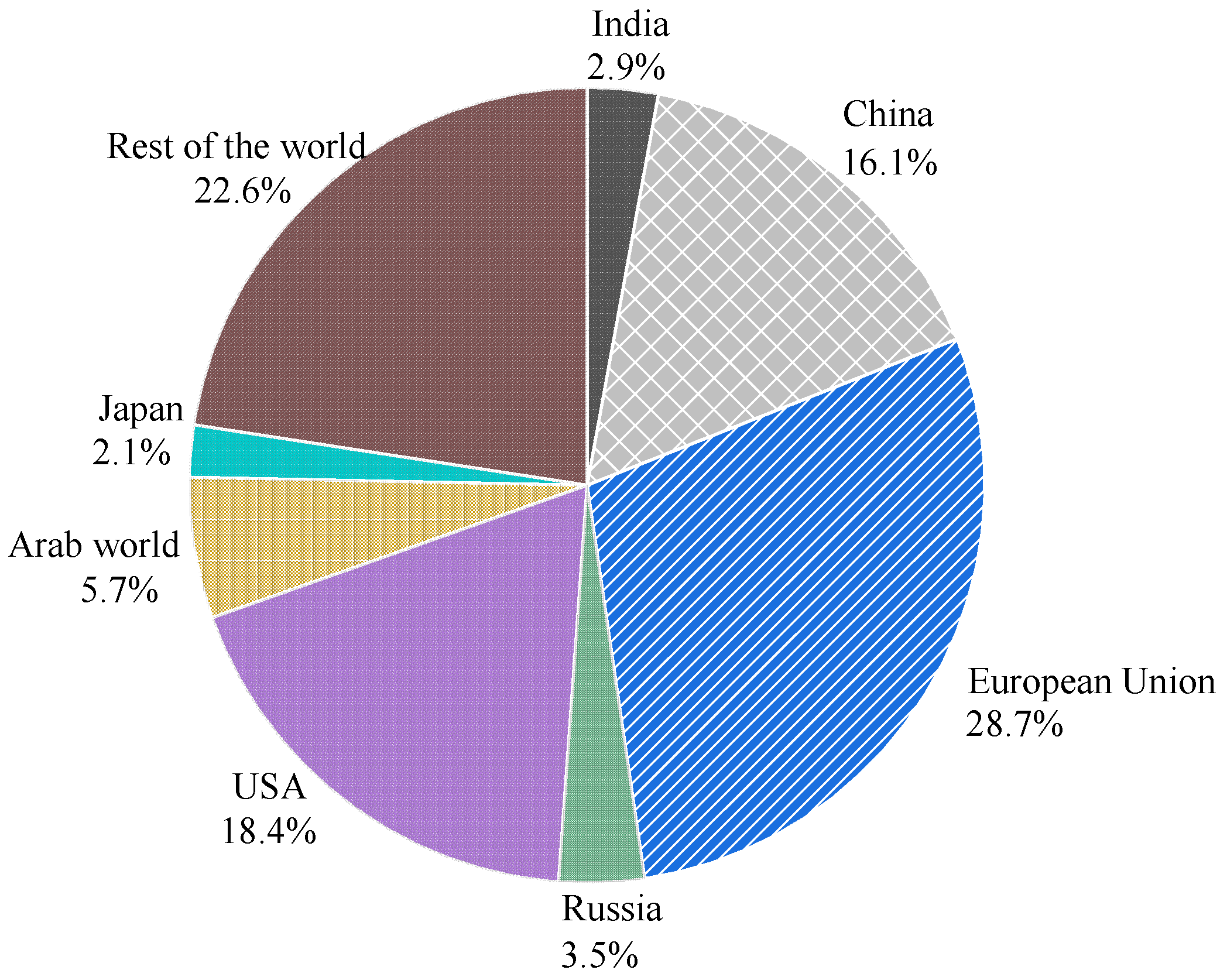

In recent decades, corrosion has been identified as the most common cause that threatens the durability of reinforced concrete (RC). In recent decades, corrosion has been identified as the most common cause that threatens the durability of reinforced concrete (RC) under an aggressive environment. This generates enormous direct and indirect expenses [1][2]. The National Association of Corrosion Engineers (NACE) [3] reported that corrosion causes an annual loss of USD 2.5 trillion worldwide. Figure 1 shows the annual loss share in different countries.

Figure 1. Economic loss due to corrosion.

The researchers demonstrated that the bond is more vulnerable to corrosion. Auyeung et al. [4] confirmed that the bond strength degradation of an unconfined concrete specimen with a corroded steel reinforcing bar (rebar) is much more critical than the cross-section loss. According to their findings, a diameter reduction of 2% could result in a bond loss of 80%. The investigation by Li and Zheng [5] also reveals that the structural degradation of the bond varies more than the loss in stiffness and strength. Thus, corrosion-induced bond deterioration becomes highly topical. However, the bond mechanisms between rebar and concrete are quite complex due to many influential factors. The perplexity may increase when the impact of corrosion on the bond is also investigated. Although researchers have extensively studied this subject, several knowledge gaps remain. In addition, the proposed models for bond strength degradation due to rebar corrosion are dispersed in the literature.

2. Bond Strength Deterioration Due to Corrosion

2.1. Corrosion of the Main Rebar

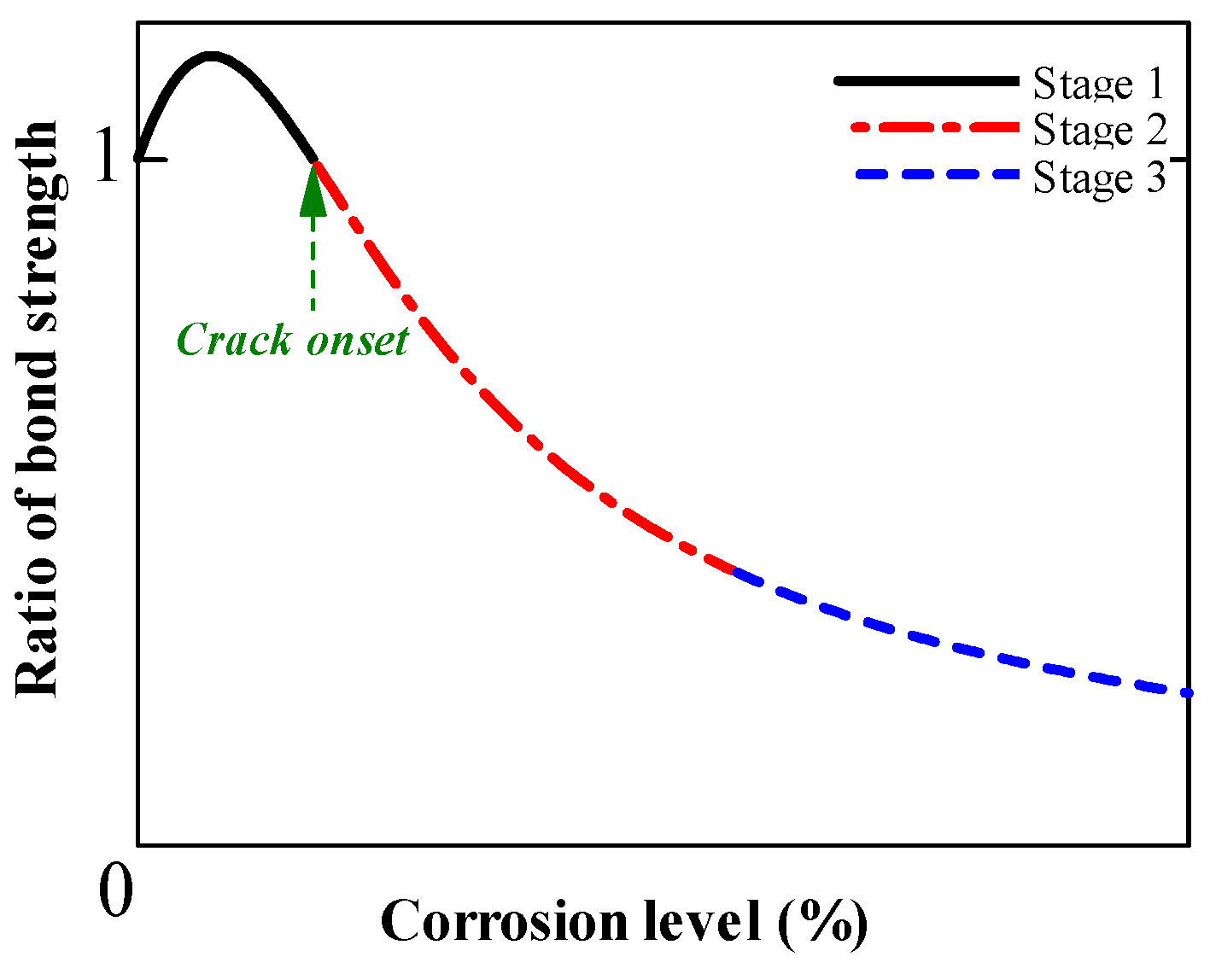

Several investigations have examined the impact of longitudinal rebar corrosion on bond strength [6][7][8][9][10][11]. The findings point to a general trend of bond strength deterioration owing to corrosion. Figure 2 shows the bond strength ratio of corroded rebar to non-corroded rebar at various degrees of corrosion. Three stages characterize the degradation trend. In stage 1 (low levels of corrosion), the production of expansive corrosion products could improve confinement to the rebar, increasing the bond strength. Expansive materials can crack the concrete cover as corrosion develops, rapidly decreasing bond strength (stage 2). In stage 3 (high levels of corrosion), the bond strength did not alter with increasing mass loss, asymptotically approaching a limit. Significant rib deterioration would result in friction-type behavior comparable to plain bars [12][13][14][15]. As a result, the bond strength slowly decreases in stage 3.

Figure 2. Degradation of bond strength with corrosion level.

2.2. Essential Factors Affecting the Bond Strength of Corroded Specimens

The selected articles revealed that several factors affect the bond strength deterioration, including the type of corrosion (uniform/ pitting, due to chloride or carbonation; wet or dry environment); the amount of stirrup; the position of the main bar; concrete cover; bar diameter and concrete strength. However, this work included only three factors (concrete strength, concrete cover-to-rebar diameter ratio, and stirrup). These factors were selected because the authors considered them to have the most significant influence. Moreover, the selected influencing factors are rather clearly definable.

2.2.1. Influence of Concrete Strength

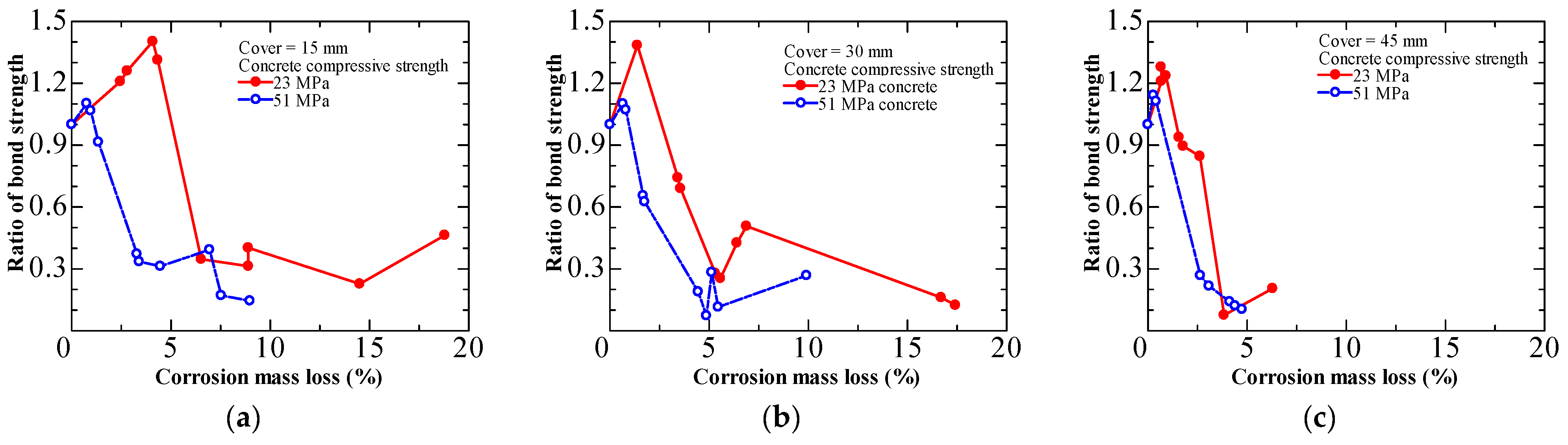

The bond performance of sound RC elements is proportional to the strength of the concrete. Increased concrete strength leads to increased bond strength. Yalciner et al. [16][17] investigated the effect of concrete strength on bond loss due to corrosion. They conducted a pull-out test on unconfined specimens with two different concrete strengths (23 MPa and 51 MPa). The results summarized in Figure 3 demonstrated that corroded specimens with higher concrete strength showed a more substantial bond strength degradation. This is probably because the brittleness of the corroded specimens caused an abrupt loss of bond strength. Corrosion products do not diffuse rapidly into concrete pores because of the excellent resistance to permeability in high-strength concrete. Therefore, the accumulation of expansive products around the rebar leads to more significant induced crack widths, leading to a more severe deterioration of the bond strength [18][19].

Figure 3. Influence of concrete strength on bond deterioration from Yalciner et al. [16]: (a) cover = 15 mm; (b) cover = 30 mm; (c) cover = 45 mm.

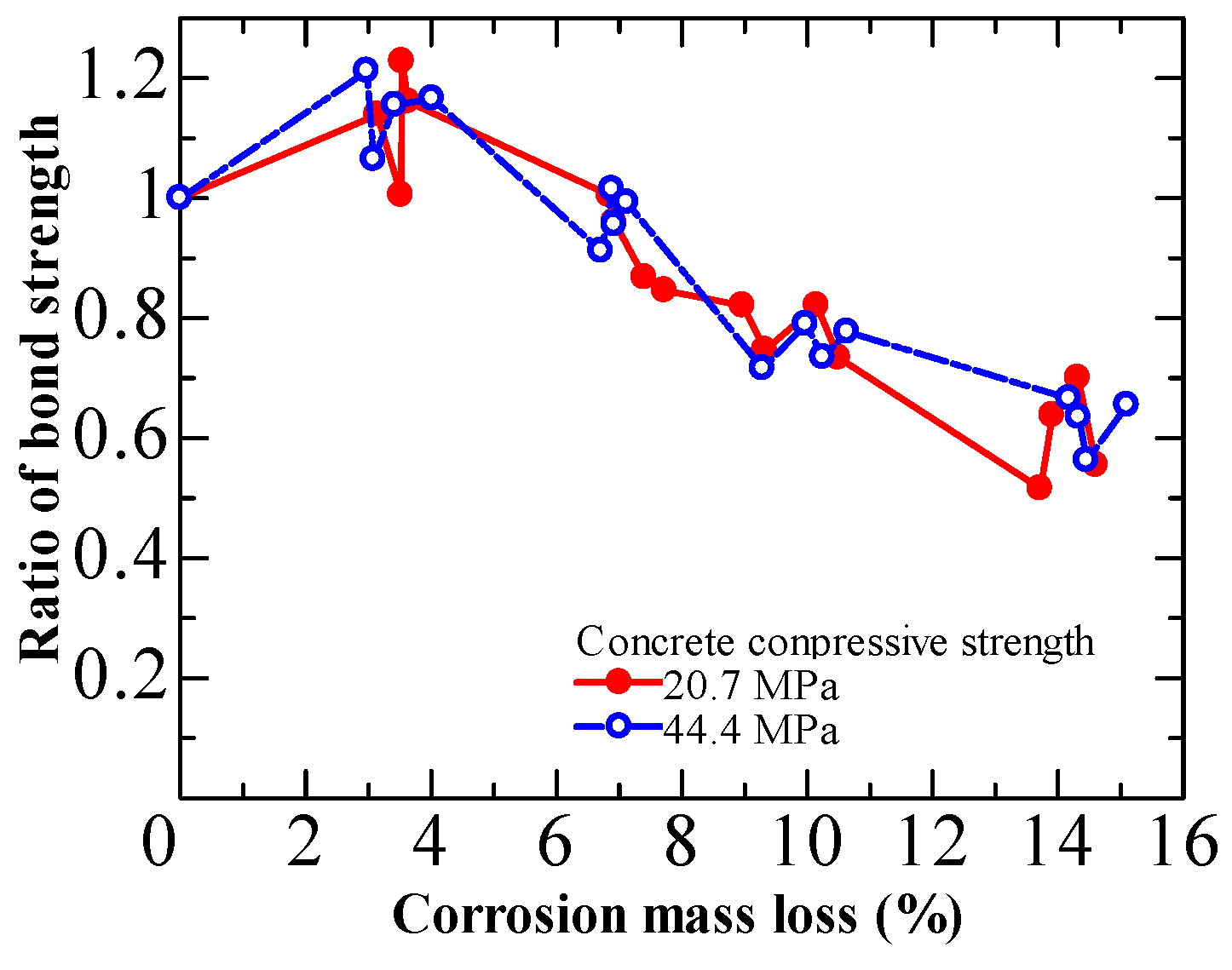

Figure 4 shows the results of Zhou et al. [20][21]. They examined the effect of concrete strength on bond degradation using two different concrete mixes (20.7 MPa and 44.4 MPa) in specimens with stirrups. In contrast, they discovered that the compressive strength of the concrete did not affect the bond degradation trend. They emphasized that the mixing of different failure modes can complicate the observation of the concrete strength effect.

Figure 4. Influence of concrete strength on bond deterioration from Zhou et al. [18].

2.2.2. Influence of the Cover-to-Rebar Diameter Ratio c/d

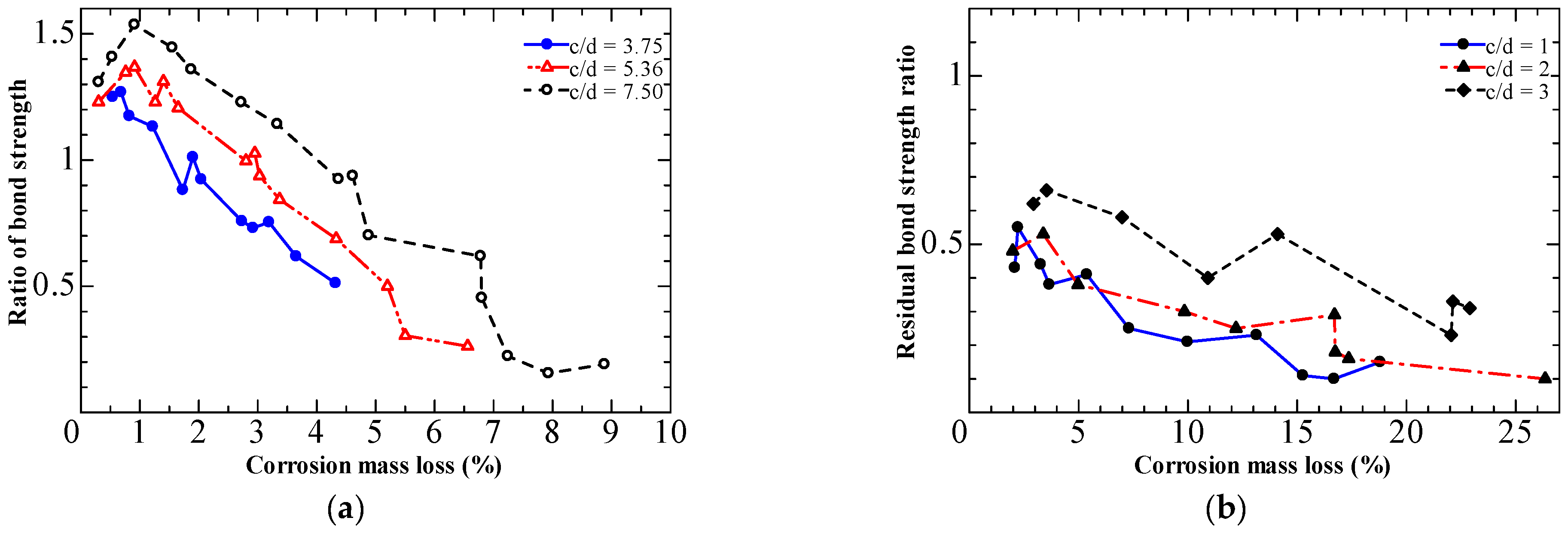

The concrete cover thickness c to steel bar diameter d (c/d) ratio is frequently regarded as a crucial element influencing bond strength. The bond strength was observed to increase as c/d increased. However, this increase is limited; for example, the bond strength will remain stable when c/d ≥ 3 in the specimen without stirrups [22]. Al-Sulaimani et al. [7] performed a pull-out using corroded specimens where three cover-to-diameter ratios (c/d) ratios of 3.75, 5.36, and 7.5 were adopted over 20, 14, and 10-mm bars, respectively. Data showed that 4% of corrosion is needed to start cracking for a c/d ratio of 7; however, about 1% is necessary to crack specimens with a c/d ratio of 3. They suggested that the ratio of cover-to-diameter (c/d) could be considered a significant factor that expresses corrosion protection.

Furthermore, Al-Sulaimani et al. [7] showed that bond deterioration is more severe in specimens with a smaller c/d, as shown in Figure 5a. The results of Amleh et al. [8] shown in Figure 5b are consistent with those of Al-Sulaimni et al. Concrete can still transfer stress across cracks. As a result of the residual confinement, the specimens with a more significant concrete cover demonstrated stronger bond strength.

2.2.3. Influence of Stirrups

The influence of stirrups on the deterioration of the bond as a result of corrosion is twofold. Studies showed that the stirrup could increase concrete confinement, limiting the width of cracks due to corrosion [23][24][25][26][27]. Second, several authors investigated the effect of stirrup corrosion on bond degradation. Fang et al. [14][15] performed a centric pull-out test on corroded specimens with and without stirrups. They discovered that a moderate corrosion rate (about 4%) had no significant influence on bond strength. However, bond degradation was observed when the degree of corrosion was greater than 6%. Zhou et al. [28] focused on the effect of corroded stirrups on the bond performance of reinforced concrete. They concluded that the bond strength improved when the degree of stirrup corrosion was less than 10%. However, bond degradation was observed when the degree of stirrup corrosion reached 15%. These findings are likely related to the corroded stirrup that produces hoop stress that acts inside and outside. This stress can crack the cover and add more confinement to the core concrete where the tested rebar is located [29][30][31]. As a result, the bond strength can increase.

Earlier studies have recognized that an adequate amount of stirrups can maintain the bond even in cracked concrete. However, stirrups often have a minor concrete cover and are the most vulnerable to corrosion. Furthermore, Hanjari et al. [32] concluded that considerable bond degradation occurs only when the stirrup corrosion is extremely high. However, some stirrup legs are fractured at pitting points or almost consumed by uniform corrosion in such extreme situations.

References

- Mahmoodreza Soltani, A.S.; Brennan, A. A State-of-the-Art Review of Bending and Shear Behaviors of Corrosion-Damaged Reinforced Concrete Beams. ACI Struct. J. 2019, 116, 53–64.

- Palsson, R.; Mirza, M.S. Mechanical Response of Corroded Steel Reinforcement of Abandoned Concrete Bridge. ACI Struct. J. 2002, 99, 157–162.

- Koch, G.; Varney, J.; Thompson, N.; Moghissi, O.; Gould, M.; Payer, J. International Measures of Prevention, Application, and Economics of Corrosion Technologies Study. NACE Int. 2016, 216, 2–3.

- Auyeung, Y.; Balaguru, P.; Lan, C. Bond Behavior of Corroded Reinforcement Bars. ACI Mater. J. 2000, 97, 214–220.

- Li, C.Q.; Zheng, J.J. Propagation of Reinforcement Corrosion in Concrete and Its Effects on Structural Deterioration. Mag. Concr. Res. 2005, 57, 261–271.

- Almusallam, A.A.; Al-Gahtani, A.S.; Aziz, A.R. Rasheeduzzafar Effect of Reinforcement Corrosion on Bond Strength. Constr. Build. Mater. 1996, 10, 123–129.

- Al-Sulaimani, G.J.; Kaleemullah, M.; Basunbul, I.A.; Rasheeduzzafar. Influence of Corrosion and Cracking on Bond Behavior and Strength of Reinforced Concrete Members. ACI Struct. J. 1990, 87, 220–231.

- Amleh, L.; Mirza, S. Corrosion Influence on Bond between Steel and Concrete. ACI Struct. J. 1999, 96, 415–423.

- Banba, S.; Abe, T.; Nagaoka, K.; Murakami, Y. Evaluation Method for Bond-Splitting Behavior of Reinforced Concrete with Corrosion Based on Confinement Stress of Concrete against Corrosion Expansion. J. Adv. Concr. Technol. 2014, 12, 7–23.

- Ma, Y.; Guo, Z.; Wang, L.; Zhang, J. Experimental Investigation of Corrosion Effect on Bond Behavior between Reinforcing Bar and Concrete. Constr. Build. Mater. 2017, 152, 240–249.

- Jiang, C.; Wu, Y.-F.; Dai, M.-J. Degradation of Steel-to-Concrete Bond Due to Corrosion. Constr. Build. Mater. 2018, 158, 1073–1080.

- Choi, Y.S.; Yi, S.-T.; Kim, M.Y.; Jung, W.Y.; Yang, E.I. Effect of Corrosion Method of the Reinforcing Bar on Bond Characteristics in Reinforced Concrete Specimens. Constr. Build. Mater. 2014, 54, 180–189.

- Coccia, S.; Imperatore, S.; Rinaldi, Z. Influence of Corrosion on the Bond Strength of Steel Rebars in Concrete. Mater. Struct. 2016, 49, 537–551.

- Fang, C.; Lundgren, K.; Chen, L.; Zhu, C. Corrosion Influence on Bond in Reinforced Concrete. Cem. Concr. Res. 2004, 34, 2159–2167.

- Fang, C.; Lundgren, K.; Plos, M.; Gylltoft, K. Bond Behaviour of Corroded Reinforcing Steel Bars in Concrete. Cem. Concr. Res. 2006, 36, 1931–1938.

- Yalciner, H.; Eren, O.; Sensoy, S. An Experimental Study on the Bond Strength between Reinforcement Bars and Concrete as a Function of Concrete Cover, Strength and Corrosion Level. Cem. Concr. Res. 2012, 42, 643–655.

- Hakan, Y.; Khaled, M. Experimental Study on the Bond Strength of Different Geometries of Corroded and Uncorroded Reinforcement Bars. J. Mater. Civ. Eng. 2017, 29, 05017002.

- Chung, L.; Jay Kim, J.-H.; Yi, S.-T. Bond Strength Prediction for Reinforced Concrete Members with Highly Corroded Reinforcing Bars. Cem. Concr. Compos. 2008, 30, 603–611.

- Zhou, H.; Qiao, M.; Du, Y.; Liu, J.; Zhou, Y.; Mo, Y.; Xing, F.; Zhao, Y. Bond Degradation of Rebar and Concrete Confined with Corroded Stirrups: Effects of Concrete Grade and Casting Position. Mag. Concr. Res. 2022, 74, 1039–1055.

- Zhou, H.; Liang, X.; Wang, Z.; Zhang, X.; Xing, F. Bond Deterioration of Corroded Steel in Two Different Concrete Mixes. Struct. Eng. Mech. 2017, 63, 725–734.

- Zhou, H.J.; Liang, X.B.; Zhang, X.L.; Lu, J.L.; Xing, F.; Mei, L. Variation and Degradation of Steel and Concrete Bond Performance with Corroded Stirrups. Constr. Build. Mater. 2017, 138, 56–68.

- Wu, Y.F.; Zhao, X.M. Unified Bond Stress Slip Model for Reinforced Concrete. J. Struct. Eng. 2013, 139, 1951–1962.

- Lin, H.; Zhao, Y.; Yang, J.-Q.; Feng, P.; Ozbolt, J.; Ye, H. Effects of the Corrosion of Main Bar and Stirrups on the Bond Behavior of Reinforcing Steel Bar. Constr. Build. Mater. 2019, 225, 13–28.

- Lin, H.; Zhao, Y. Effects of Confinements on the Bond Strength between Concrete and Corroded Steel Bars. Constr. Build. Mater. 2016, 118, 127–138.

- Moodi, Y.; Sohrabi, M.R.; Mousavi, S.R. Corrosion effect of the main rebar and stirrups on the bond strength of RC beams. Structures 2021, 32, 1444–1454.

- Tondolo, F. Bond Behaviour with Reinforcement Corrosion. Constr. Build. Mater. 2015, 93, 926–932.

- Zheng, Y.; Zheng, S.-S.; Yang, L.; Dong, L.-G.; Zhang, Y.-B. Experimental Study and Analytical Model of the Bond Behavior of Corroded Reinforcing Steel Bars in Concrete. Constr. Build. Mater. 2022, 327, 126991.

- Zhou, H.; Lu, J.; Xv, X.; Dong, B.; Xing, F. Effects of Stirrup Corrosion on Bond–Slip Performance of Reinforcing Steel in Concrete: An Experimental Study. Constr. Build. Mater. 2015, 93, 257–266.

- Feng, Q.; Zhang, Y.; Visintin, P.; Xu, R. Stirrup Effects on the Bond Properties of Corroded Reinforced Concrete. Mag. Concr. Res. 2021, 73, 1151–1166.

- Moodi, Y.; Sohrabi, M.R.; Mousavi, S.R. Effects of Stirrups in Spliced Region on the Bond Strength of Corroded Splices in Reinforced Concrete (RC) Beams. Constr. Build. Mater. 2020, 230, 116873.

- Arnaud Castel, I.K.; François, R.; Gilbert, R.I. Modeling Steel Concrete Bond Strength Reduction Due to Corrosion. ACI Struct. J. 2016, 113, 973–982.

- Hanjari, K.Z.; Coronelli, D.; Lundgren, K. Bond Capacity of Severely Corroded Bars with Corroded Stirrups. Mag. Concr. Res. 2011, 63, 953–968.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.4K

Revisions:

2 times

(View History)

Update Date:

08 Nov 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No