| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Azam Nekahi | -- | 2384 | 2022-11-01 09:59:55 | | | |

| 2 | Rita Xu | -6 word(s) | 2378 | 2022-11-01 10:11:00 | | |

Video Upload Options

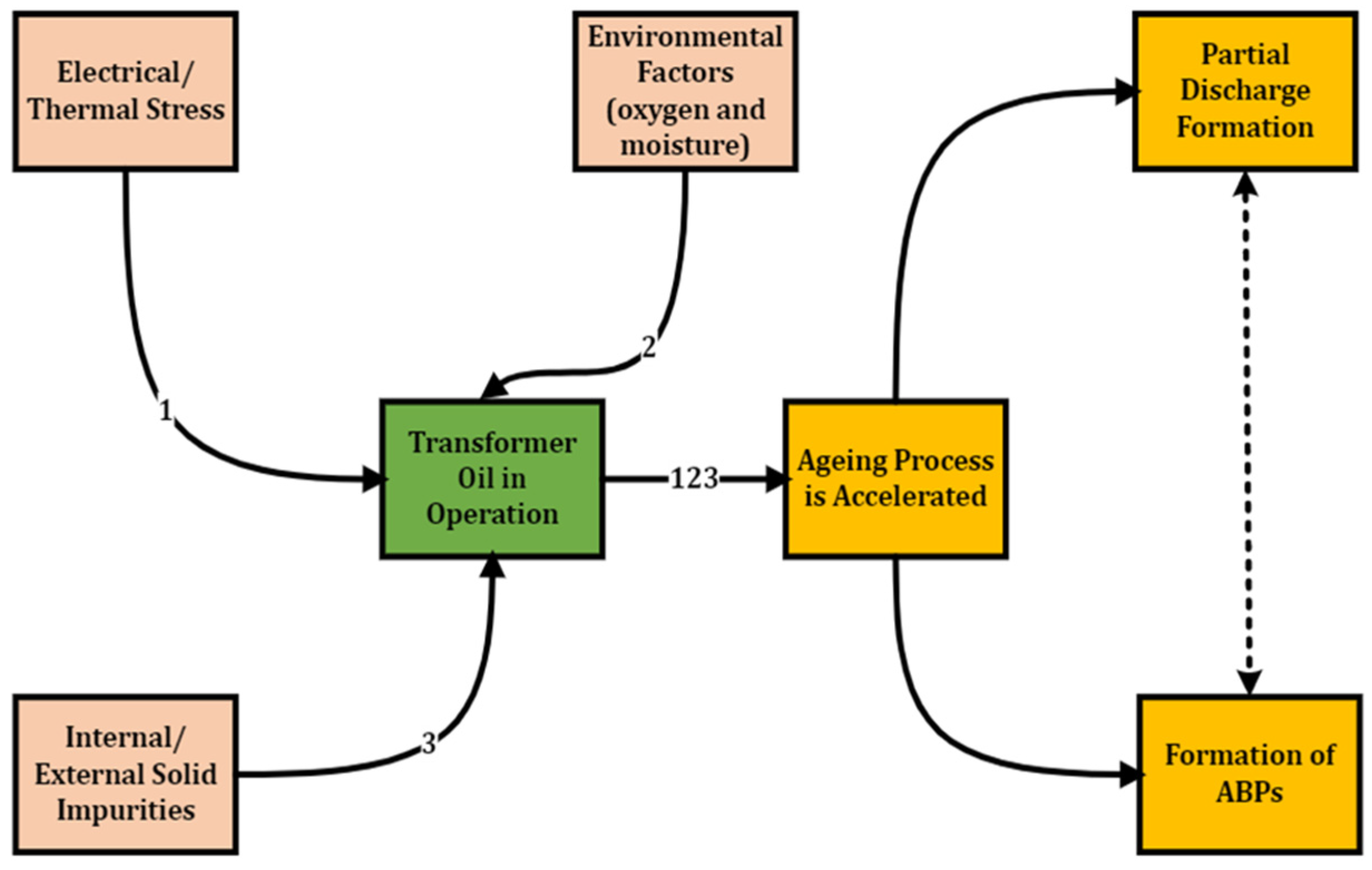

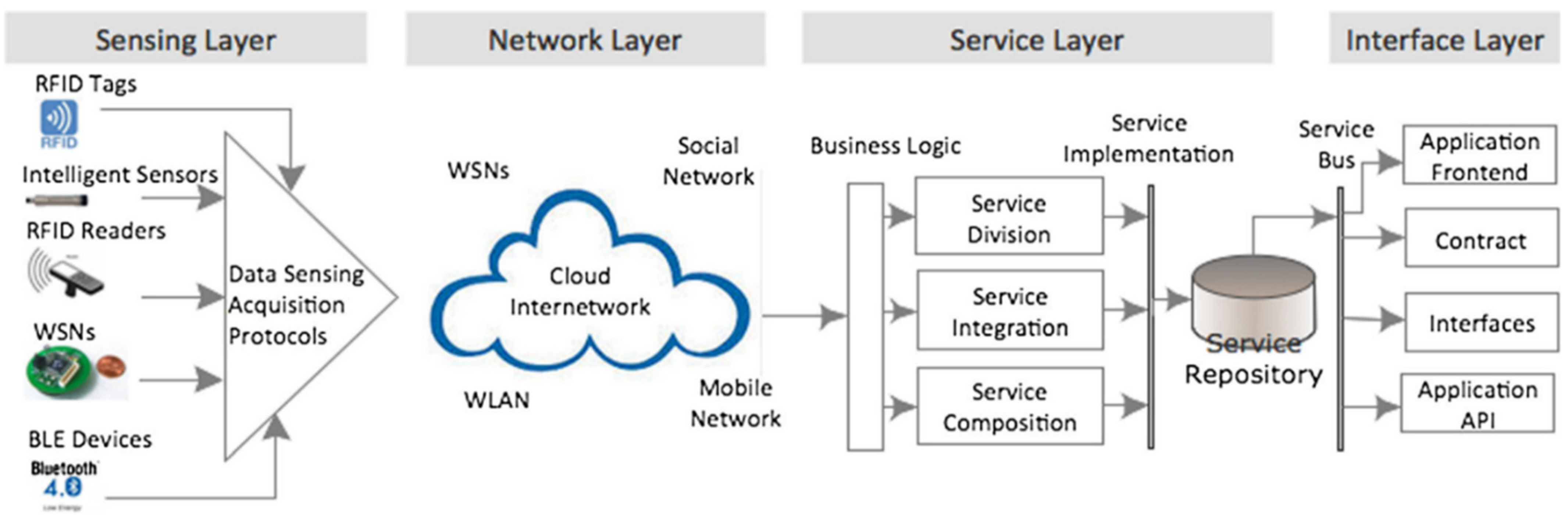

Transformers play an essential role in power networks, ensuring that generated power gets to consumers at the safest voltage level. However, they are prone to insulation failure from ageing, which has fatal and economic consequences if left undetected or unattended. Traditional detection methods are based on scheduled maintenance practices that often involve taking samples from in situ transformers and analysing them in laboratories using several techniques. This conventional method exposes the engineer performing the test to hazards, requires specialised training, and does not guarantee reliable results because samples can be contaminated during collection and transportation. Researchers review the transformer oil types and some traditional ageing detection methods, including breakdown voltage (BDV), spectroscopy, dissolved gas analysis, total acid number, interfacial tension, and corresponding regulating standards. In addition, a review of sensors, technologies to improve the reliability of online ageing detection, and related online transformer ageing systems. A non-destructive online ageing detection method for in situ transformer oil is a better alternative to the traditional offline detection method. Moreover, when combined with the Internet of Things (IoT) and artificial intelligence, a prescriptive maintenance solution emerges, offering more advantages and robustness than offline preventive maintenance approaches

1. Introduction

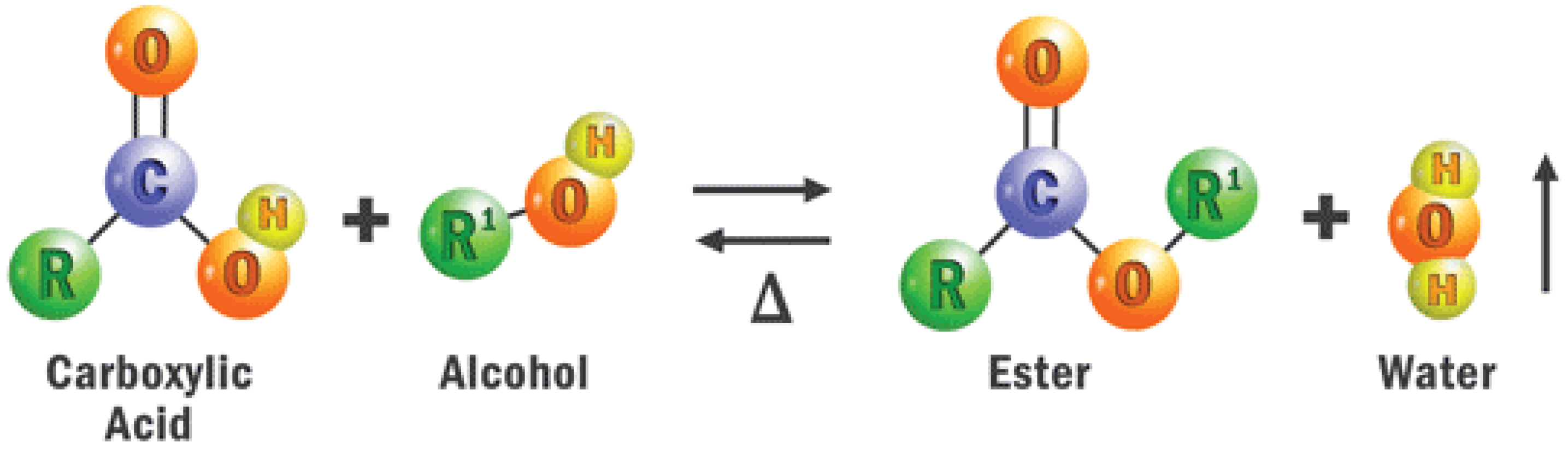

2. Types of Transformer Oil

3. IoT and Online Ageing Detection

4. Example of Related Systems

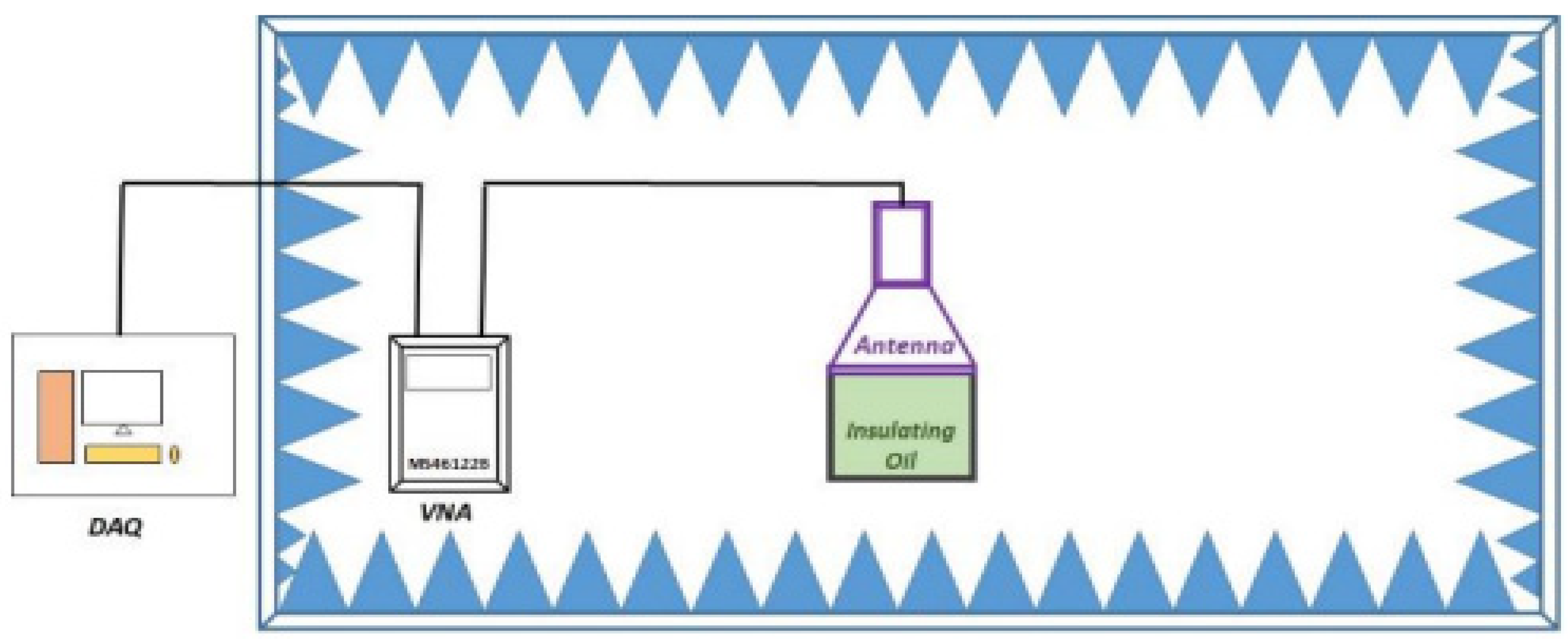

4.1. A Non-Destructive, Non-Intrusive Design Using an Antenna

4.2. An Intrusive Ageing Detection Design Using a Cross-Capacitance Sensor

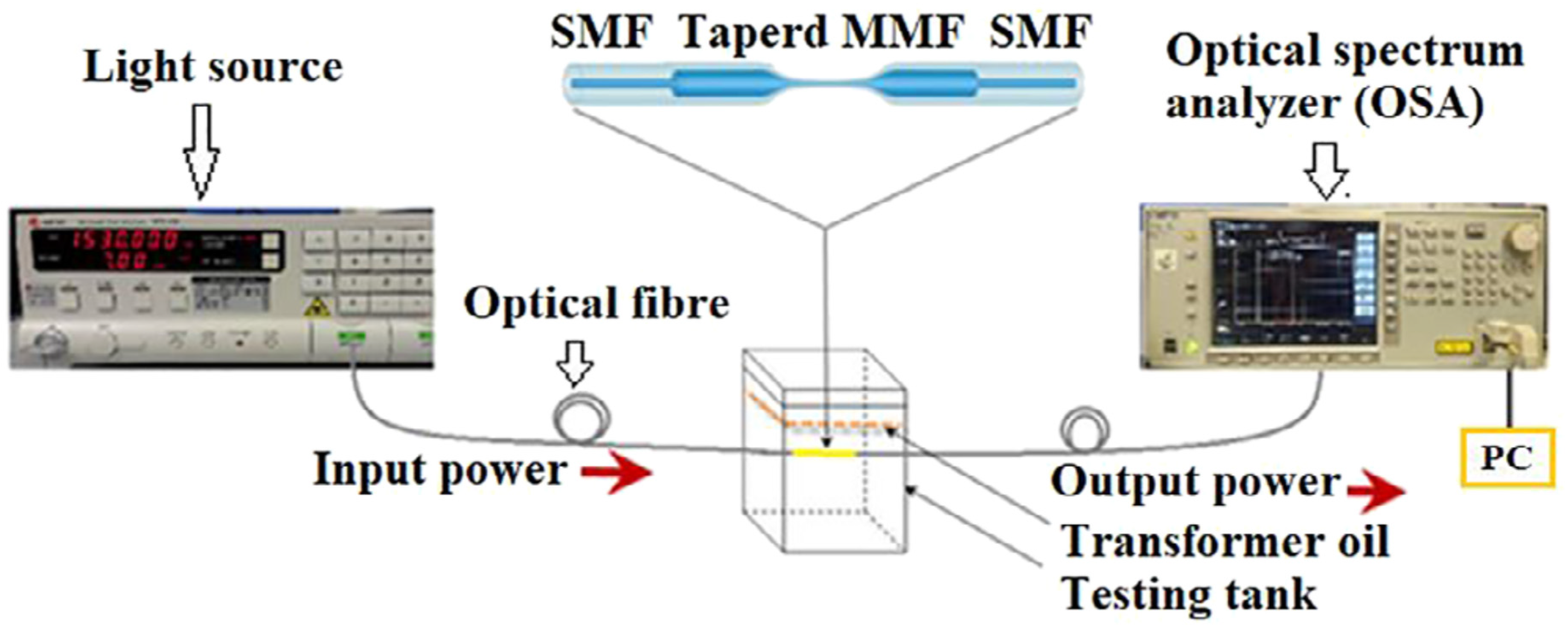

4.3. An Intrusive Ageing Detection Design Using Fibre Optic Technology

References

- Khalil, M. Qualitative and Quantitative FMECA on 220 kV Power Transformers. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–8.

- Balamurugan, S.; Ananthanarayanan, R. Condition Monitoring Techniques of Dielectrics in Liquid Immersed Power Transformers—A Review. In Proceedings of the 2018 IEEE Industry Applications Society Annual Meeting (IAS), Portland, OR, USA, 23–27 September 2018; pp. 1–7.

- Paul, D.; Goswami, A.K. Determination of Health Index of Insulating Oil of In-Service Transformer & Reactors based on IFT Predicted by Multi-Gene Symbolic Regression. IEEE Trans. Ind. Appl. 2022, 58, 5935–5943.

- Martins, M.A.G.; Gomes, A.R. Comparative study of the thermal degradation of synthetic and natural esters and mineral oil: Effect of oil type in the thermal degradation of insulating kraft paper. IEEE Electr. Insul. Mag. 2012, 2, 22–28.

- Hadjadj, Y.; Fofana, I.; Sabau, J.; Briosso, E. Assessing insulating oil degradation by means of turbidity and UV/VIS spectrophotometry measurements. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2653–2660.

- Wang, Z.; Chen, W.; Zhou, W.; Zhang, R.; Song, R.; Yang, D. A Few-shot Learning Method for Aging Diagnosis of Oil-paper Insulation by Raman Spectroscopy Based on Graph Theory. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1892–1900.

- Alshehawy, A.; Mansour, D.-E.; Ghali, M.; Lehtonen, M.; Darwish, M. Photoluminescence Spectroscopy Measurements for Effective Condition Assessment of Transformer Insulating Oil. Processes 2021, 9, 732.

- Qian, Y.; Wang, Y.; Zhao, Y.; Fan, S.; Fu, Q.; Wang, H. Application of Infrared Spectroscopy in Oil Quality Detection. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4.

- Sangineni, R.; Nayak, S.K.; Becerra, M. A Non-intrusive and Non-destructive Technique for Condition Assessment of Transformer Liquid Insulation. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 693–700.

- Razzaq, A.; Zainuddin, H.; Hanaffi, F.; Chyad, R.M.; Abdul Razak, H.; Latiff, A.A. Measurement of ester-based transformer oil aging using tapered single mode-multimode-single mode fiber structure. Microw. Opt. Technol. Lett. 2020, 62, 559–564.

- Rao, U.M.; Fofana, I.; Betie, A.; Senoussaoui, M.L.; Brahami, M.; Briosso, E. Condition monitoring of in-service oil-filled transformers: Case studies and experience. IEEE Electr. Insul. Mag. 2019, 35, 33–42.

- Mihajlovic, D.; Ivancevic, V.; Vasovic, V.; Lukic, J. Cellulose Degradation and Transformer Fault Detection by the Application of Integrated Analyses of Gases and Low Molecular Weight Alcohols Dissolved in Mineral Oil. Energies 2022, 15, 5669.

- Polužanski, V.; Kartalović, N.; Nikolić, B. Impact of Power Transformer Oil-Temperature on the Measurement Uncertainty of All-Acoustic Non-Iterative Partial Discharge Location. Materials 2021, 14, 1385.

- Sarathi, R.; Koperundevi, G. Understanding the Discharge Activities in Transformer Oil under AC and DC Voltage Adopting UHF Technique. Int. J. Chem. Mol. Eng. 2008, 2, 49–56.

- Niasar, M.G.; Edin, H.; Wang, X.; Clemence, R. Partial Discharge Characteristics Due to Air and Water Vapor Bubbles in Oil. Int. Symp. High Volt. Eng. 2011, 11–21. Available online: https://www.researchgate.net/publication/264561918_Partial_discharge_characteristics_due_to_air_and_water_vapor_bubbles_in_oil (accessed on 13 June 2022).

- Alshehawy, A.M.; Mansour, D.-E.A.; Ghali, M. Condition Assessment of Aged Transformer Oil Using Photoluminescence-Based Features. In Proceedings of the 2021 IEEE 5th International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Kozhikode, India, 3–5 December 2021; pp. 282–285.

- Sai, R.S.; Rafi, J.; Farook, S.; Kumar, N.; Parthasarathy, M.; Bakkiyaraj, R.A. Degradation studies of electrical, physical and chemical properties of aged transformer oil. J. Phys. Conf. Ser. 2020, 1706, 012056.

- Munajad, A.; Subroto, C. Fourier Transform Infrared (FTIR) Spectroscopy Analysis of Transformer Paper in Mineral Oil-Paper Composite Insulation under Accelerated Thermal Aging. Energies 2018, 11, 364.

- Bandara, K.; Ekanayake, C.; Saha, T.K. Compare the performance of natural ester with synthetic ester as transformer insulating oil. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 975–978.

- Perrier, C.; Marugan, M.; Beroual, A. DGA comparison between ester and mineral oils. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1609–1614.

- Mehta, D.M.; Kundu, P.; Chowdhury, A.; Lakhiani, V.K.; Jhala, A.S. A review of critical evaluation of natural ester vis-a-vis mineral oil insulating liquid for use in transformers: Part II. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1705–1712.

- Gockenbach, E.; Borsi, H. Natural and Synthetic Ester Liquids as alternative to mineral oil for power transformers. In Proceedings of the 2008 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008; pp. 521–524.

- Jing, Y.; Timoshkin, I.V.; Wilson, M.P.; Given, M.J.; MacGregor, S.J.; Wang, T.; Lehr, J.M. Dielectric properties of natural ester, synthetic ester midel 7131 and mineral oil diala D. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 644–652.

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25.

- Housel, T. Synthetic Esters: Engineered to Perform. 2022. Available online: https://www.machinerylubrication.com/Read/29703/synthetic-esters-perform (accessed on 6 September 2022).

- Maharana, M.; Nayak, S.K.; Sahoo, N. Karanji oil as a potential dielectrics liquid for transformer. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1871–1879.

- Naranpanawe, W.M.L.B.; Fernando, M.A.R.M.; Kumara, J.R.S.S.; Naramapanawa, E.M.S.N.; Kalpage, C.S. Performance analysis of natural esters as transformer liquid insulation-Coconut, castor and sesame oils. In Proceedings of the 2013 IEEE 8th International Conference on Industrial and Information Systems, Kandy, Sri Lanka, 17–20 December 2013; pp. 105–109.

- Li, S.; Xu, L.D.; Zhao, S. The internet of things: A survey. Inf. Syst. Front. 2014, 17, 243–259.

- Smanchat, S. Internet of things: A review of applications and technologies. Suranaree J. Sci. Technol. 2014, 21, 359–374.

- Lo, C.; Chen, C.; Zhong, R.Y. A review of digital twin in product design and development. Adv. Eng. Inform. 2021, 48, 101297.

- Bandyopadhyay, D.; Sen, J. Internet of Things: Applications and Challenges in Technology and Standardization. Wirel. Pers Commun. 2011, 58, 49–69.

- Razali, M.A.A.; Kassim, M.; Sulaiman, N.A.; Saaidin, S. A ThingSpeak IoT on Real Time Room Condition Monitoring System. In Proceedings of the 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS), Shah Alam, Malaysia, 20 June 2020; pp. 206–211.

- Nasution, T.H.; Muchtar, M.A.; Seniman, S.; Siregar, I. Monitoring temperature and humidity of server room using Lattepanda and ThingSpeak. J. Phys. Conf. Ser. 2019, 1235, 12068.

- Miry, A.H.; Aramice, G.A. Water monitoring and analytic based thingspeak. Int. J. Electr. Comput. Eng. (Malacca Malacca) 2020, 10, 3588.

- Kelechi, A.H.; Alsharif, M.H.; Agbaetuo, C.; Ubadike, O.; Aligbe, A.; Uthansakul, P.; Kannadasan, R.; Aly, A.A. Design of a Low-Cost Air Quality Monitoring System Using Arduino and ThingSpeak. Comput. Mater. Contin. 2022, 70, 151–169.

- Sachenko, A.; Osolinskyi, O.; Bykovyy, P.; Dobrowolski, M.; Kochan, V. Development of the Flexible Traffic Control System Using the LabView and ThingSpeak. In Proceedings of the 2020 IEEE 11th International Conference on Dependable Systems, Services and Technologies (DESSERT), Kyiv, Ukraine, 14–18 May 2020; pp. 326–330.

- Ravindran, V.; Ponraj, R.; Krishnakumar, C.; Ragunathan, S.; Ramkumar, V.; Swaminathan, K. IoT-Based Smart Transformer Monitoring System with Raspberry Pi. In Proceedings of the 2021 Innovations in Power and Advanced Computing Technologies (i-PACT), Malaya, Kuala Lumpur, 27–29 November 2021; pp. 1–7.

- Mahanta, D.K.; Rahman, I. IoT Based Transformer Oil Temperature Monitoring System. In Proceedings of the 2022 International Conference on Sustainable Computing and Data Communication Systems (ICSCDS), Erode, India, 7–9 April 2022; pp. 975–978.

- Rahman, O.; Islam, T.; Ahmad, A.; Parveen, S.; Kheraand, N.; Khan, S.A. Cross Capacitance Sensor for Insulation Oil Testing. IEEE Sens. J. 2021, 21, 20980–20989.