Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Theodoros Varzakas | -- | 2887 | 2022-10-31 13:35:56 | | | |

| 2 | Dean Liu | -5 word(s) | 2882 | 2022-11-01 02:46:21 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Cruz, R.M.S.; Krauter, V.; Krauter, S.; Agriopoulou, S.; Weinrich, R.; Herbes, C.; Scholten, P.B.V.; Uysal-Unalan, I.; Sogut, E.; Kopacic, S.; et al. Bioplastics for Food Packaging. Encyclopedia. Available online: https://encyclopedia.pub/entry/32113 (accessed on 07 February 2026).

Cruz RMS, Krauter V, Krauter S, Agriopoulou S, Weinrich R, Herbes C, et al. Bioplastics for Food Packaging. Encyclopedia. Available at: https://encyclopedia.pub/entry/32113. Accessed February 07, 2026.

Cruz, Rui M. S., Victoria Krauter, Simon Krauter, Sofia Agriopoulou, Ramona Weinrich, Carsten Herbes, Philip B. V. Scholten, Ilke Uysal-Unalan, Ece Sogut, Samir Kopacic, et al. "Bioplastics for Food Packaging" Encyclopedia, https://encyclopedia.pub/entry/32113 (accessed February 07, 2026).

Cruz, R.M.S., Krauter, V., Krauter, S., Agriopoulou, S., Weinrich, R., Herbes, C., Scholten, P.B.V., Uysal-Unalan, I., Sogut, E., Kopacic, S., Lahti, J., Rutkaite, R., & Varzakas, T. (2022, October 31). Bioplastics for Food Packaging. In Encyclopedia. https://encyclopedia.pub/entry/32113

Cruz, Rui M. S., et al. "Bioplastics for Food Packaging." Encyclopedia. Web. 31 October, 2022.

Copy Citation

The huge negative impact that the disposal of so-called “single-use plastics” has on the environment is propelling the market to search for new solutions, and requires initiatives to drive faster responses from the scientific community, the industry, and governmental bodies for the adoption and implementation of new materials. Bioplastics are an alternative group of materials that are partly or entirely produced from renewable sources. Some bioplastics are biodegradable or even compostable under the right conditions.

food packaging

bioplastics

environmentally-friendly

1. Introduction

Packaging is an integral part and enabler of modern food systems. As a result, there is hardly any food item today that is not packaged at least once on its way from farm to fork [1][2]. The background to this is the underlying and essential service functions that it performs. Even the most trivial function, namely containment, is what makes liquid foodstuffs, for example, manageable and transportable in the first place—a key function for the modern economy. Moreover, and most importantly, it provides protection to the food, thus, enabling high levels of food quality, safety, and security to be achieved. This is rounded off by the functions of communication (e.g., information about the product) and convenience (e.g., easy-to-open) [3].

The needs of a food product are strongly dependent on the type of packaging (e.g., design, type of construction) and packaging material chosen (e.g., paper, glass, metal, and corrugated or non-corrugated cardboard, plastic, and composite materials with more than one material, such as plastic-coated cardboard). Hence, careful consideration of the material’s properties is a key step in designing packaging that is fit for its purpose and, thus, effective. Properties include features, such as a barrier against gasses (e.g., oxygen, carbon dioxide, water vapor), physical and mechanical strength, aroma, fat, lightness, and migration, as well as hygiene and, as a result, are strongly dependent on the nature of the material itself [3][4][5].

Taking a closer look at plastic materials, it quickly becomes clear this material group comprises a wide range of different materials, including polyolefins, such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), each with very different properties. Accordingly, they also offer a wide range of advantages and disadvantages. In terms of suitability for packaging applications, it can be said that plastics are often preferred because of their lightness, formability, low cost, versatile and controllable properties (e.g., mechanical, physical, and chemical properties, barrier, color, temperature stability, and sealability), convenience (e.g., transportability and resistance to breakage) and usability in the preparation of multilayer materials [3][4][5]. Despite the, per se, very good suitability, it is above all the environmental aspect and the careless handling of raw materials and packaging waste, such as (marine) litter, microplastics, limited recyclability and (bio)degradability, and the use of fossil resources, that pose a major disadvantage and have been the focus of public and political debate in recent decades [6][7][8][9].

Among different sectors, the packaging sector is the main user of plastics (around 40%). For example, plastic packaging in the European Union (EU) makes up around 60% of post-consumer plastic waste [10]. Most of the packaging is used only once, and the lack of reuse associated with failures in the recycling systems contribute to generating huge amounts of solid wastes that are discarded, contributing to a negative impact on land and marine environments [11]. On average, the amount of plastic packaging waste generated per capita increased from 27 kg to 35 kg between 2009 and 2019 [12].

The EU is trying to solve these problems with approaches, such as circular economy and bioeconomy, to promote innovation and research for guaranteeing resource utilization efficiency. The circular economy highlights the 4R concept (reduce, reuse, recycle, and recover), and stresses that sustainable production and consumption of resources should be developed and used where the evidence clearly shows that they are more sustainable compared to conventional petrochemical plastic production. The bio-economy is related to the renewable part of managing agricultural waste [8][13]. Furthermore, the United Nations 2030 Agenda for Sustainable Development aims, among other goals, to substantially reduce waste generation through prevention, reduction, recycling, and reuse (Goal 12.5) and to prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities, including marine debris and nutrient pollution (Goal 14.1) [14].

Thus, one of the challenges to our society is to decrease the amount of durable and non-biodegradable packaging materials, such as glass, metal, and mainly plastic, and to find new solutions. The search for viable alternatives with suitable packaging properties is continuously under study, and the reduction in these wastes can be achieved with the development of new environmentally friendly packaging systems [11].

New packaging systems with bioplastics have been developed in the last two decades. This packaging includes materials derived from renewable resources and/or biodegradable polymers, and ranges from flexible films to rigid materials that have a high potential to produce sustainable packaging. These bio-materials are usually blended to control and achieve desirable mechanical, physical, and barrier properties [15].

2. Definitions and Regulations

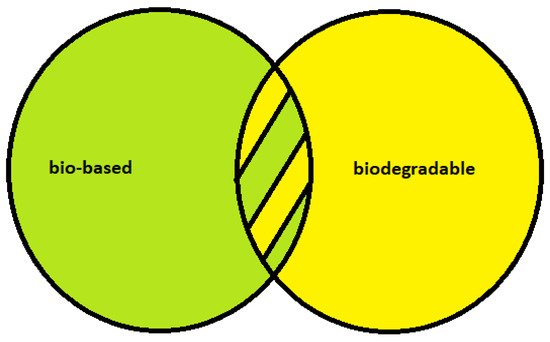

According to the European Bioplastics Organization (EBO), the term ‘bioplastics’ refers to both the bio-based origin of plastic and/or its biodegradable character (Figure 1) [16]. Those derived from plant-based materials (also known as biomass) are bio-based plastics according to the European Standard EN 16575 from 2014 [17][18]. However, it is not only bio-based plastics that are biodegradable, and not all types of bio-based plastics are biodegradable [17].

Figure 1. Bioplastics are bio-based, biodegradable, or both (adapted from European Bioplastics [16]).

Hence, researchers should appropriately define the vocabulary surrounding bio-plastics. From a chemical point of view, and in contrast to the most frequently used types of plastics worldwide (polyolefins are by far the most abundant [19]), the vast majority of substances among biopolymers are linked via heteroatom bonds. This is due to the fact that selective linkage of C–C bonds is chemically very challenging, and regioselective cleavage of non-polarized bonds even more so [20][21]. In nature, reversibility and energetically favorable activatability are essential in the enzymatically catalyzed biosynthesis of structural and storage polymers (in fact the utilization of artificial enzymes for chemical synthesis is an increasingly studied field, with the potential to shift synthetic chemistry toward more environmentally friendly and less energy-intense methods) [22]. This is usually based on nucleophilic substitution of carbon centers (mostly carbonyl or acetals/ketals) positively polarized by doubly- or singly-bound oxygen, with the linkage of C–O or C–N hetero bonds. In addition, the monomer building blocks must be capable of aqueous solvation to enable polymerization and are activated with suitable leaving groups to provide the energy needed for biosynthesis (typically nucleotide activation of building blocks, such as carbohydrates or amino acids). The substitution reactions are catalyzed by selective enzymes, such as peptidyl transferases [23], glycosyl transferases [24], or polyester synthases [25], while enzymatic polymerization, as well as artificial enzymes, are also important objects of research [26][27]. Less polar monomers, such as lignin precursor molecules, are typically conjugated with polar compounds, such as carbohydrates, to enable transport in the cytosol, which is mandatory for the further biosynthesis of wood [28]. This results in the classes of substances available as biopolymers, most of which are derived from functionalized carbonyl groups. These include carboxylic acid derivatives, such as proteins or polyesters, and acetals/ketals, such as carbohydrates. Due to the aforementioned requirements for monomers and enzymatic reactions, namely water solubility and the possibility of forming hetero-bonds, an increased functionalization with polar groups, such as alcohols, amines, or carboxylic acids, is found and, thus, a tendency towards the polar character is identified. This results in significant physicochemical properties of the material due to the increased intra- and intermolecular interactions, which influence processability, barrier properties, and several other factors. These properties include higher crystallinity and melting or glass transition temperatures, whereby the intermolecular interactions outweigh the intramolecular interactions due to strong hydrogen bonds (strong interactions lead to higher heat resistance but also a higher tendency of water absorption) in the extreme case of carbohydrates. This results in decomposition instead of melting, and the number of hydrogen bonds must, therefore, be reduced either by additives, e.g., when obtaining thermoplastic starch (TPS), or by chemical modifications to enable thermoplastic processability [29]. An important exception to this is lignin, which contains a mixture of phenolic ethers and radically linked carbons, i.e., it is comparable to phenolic resins, such as Bakelite, can be used as a basis for similar materials, and, thus, has a much more apolar character, as well as poor water solubility [30][31][32]. The typical thermoset networks are, therefore, particularly stable and also require organisms capable of degrading lignin to expend more energy than other biopolymers. This, and the inhomogeneity of the material, also depending on the starting material, have led to the fact that lignin has hardly been used for packaging so far, despite its abundance and inexpensive availability. Nevertheless, it has a lot of potentials to be utilized for water vapor barrier functionality [33].

In relation to the bio-based origin, there is no general agreement on a specific reference limit; however, threshold values of renewable content that mark the bio-based nature of a material can be found in national regulations [34]. For example, the United States Department of Agriculture (USDA) BioPreferred Program depended on product category factors to determine a wide range of minimum acceptable bio-based content of between 7–95% [35]. However, certifiers, such as the certification organization of TÜV Rheinland, the German Technical Inspection Association, and DIN, the German Institute for Standardization (DIN CERTCO), and the Technical Inspection Association (TÜV) AUSTRIA Belgium, provide standardized labels that indicate the biomass content of bio-based materials [34][36].

According to the European Commission (EC) policy recommendation, waste-to-energy (WtE) processes respect the waste hierarchy, making co-combustion processes energy-efficient techniques. This leads to the maximization of the circular economy’s contribution to decarbonization [37].

The EU has addressed the problem of plastic food packaging in its plastic strategy and Circular Economy Action Plan [38]. The transition towards a circular economy is offered as a comprehensive solution for the plastic crisis. This requires various collaborations and the engagement of different societal actors, such as citizens and consumers, authorities, policymakers, and non-governmental organizations (NGOs), whose aim is the creation of novel producing methodologies for packaging materials and the manufacturing of sustainable foods.

The negative environmental impacts have raised increasing concerns, both in public media forums and in the cabinets of policymakers [8]. Several policies and regulation measures include the reduction or ban of single-use plastics [39]. Voluntary measures, such as collaborative commitments [40] and pacts [41] to foster the circular economy of plastics, have been proposed by public and private bodies to address the problems caused by plastic food packaging.

Since the establishment of the United Nations’ 17 sustainable development goals (SDGs) [42], many companies have advocated sustainable practices. These goals aim to make use of renewable sources without causing impacts on human health (SDG3), climate change (SDG13), to preserve life below water in oceans, seas, and marine resources for sustainable development (SDG14), and to protect life on land (SDG15). Circularity is one of these goals which aims to tackle SDG11 (sustainable cities and communities) and SDG12 (responsible production and consumption). However, the transition toward environmentally-friendly plastics following the adoption of the SDGs is still slow and requires country-specific policies.

This is due to the many choices and approaches followed by producers, consumers, and policy-makers. A shift towards the circularity and sustainability of plastics is required.

Policy measures are essential for the management of plastic waste and mitigation of its generation. They should be enforced at all stages of collection, storage, transportation, and final disposal or recycling. Of course, these policies should be financially sustainable, and technically sustainable, and should incorporate social, legal, and environmental aspects [43].

These measures will include prevention strategies for the reduction in waste and control of types of waste and materials through bans, restrictions, and control strategies by the adoption of standards and protocols, and practices on the ground. Allocation of different roles and responsibilities for each party among stakeholders is also essential [44][45][46].

The Chinese waste import ban of 2017 showed the highest impact on the reduction in plastic waste. This pushed several countries to find other solutions for their plastic waste.

Table 1 shows the percentage of imports and exports of plastic waste referring to some European and non-European countries, while Table 2 shows the countries with regulations about types of banned plastic materials.

The EU-28 represents the largest exporter of plastic waste, accounting for around one-third of all exports of plastic waste from 1988 to 2016 [49]. Most of this waste has now been halved and re-routed to Vietnam, Thailand, and Malaysia [50].

Table 2. Countries with regulations about types of banned plastic materials.

| Countries | Level | Types of Banned Plastic Materials | References |

|---|---|---|---|

| Canada, Costa Rica, Taiwan, Belize, India, and the USA (California and Florida) | National bans | Single-use plastics (SUPs), including plastic bags, straws, and cutlery | [51] |

| The Netherlands, Tanzania, Australia, Italy, South Korea, New Zealand, the UK, the USA, and Canada | National bans | Microbead plastics | |

| 25 African countries | National bans | Plastic bags | [52] |

| Australia | National bans | Lightweight plastic bags | |

| Papua New Guinea | National bans | Nonbiodegradable plastic bags |

Retailers have taken voluntary actions to reduce plastic bag consumption within the European Union. For instance, many supermarkets have voluntarily abolished the provision of (free) plastic bags (such as in Austria and Lithuania) and others have introduced a value of around EUR 0.05–0.10 per single-use plastic bag (Belgium, Estonia, France, Germany, Hungary, Latvia, the Netherlands, Portugal, Sweden, Slovakia, and the UK) or have substituted them with biodegradable plastic bags (Austria, France, and Sweden) or used alternative bags made of cotton, hessian, or linen. Plastic pollution of the environment can be reduced by interventions, such as ‘Operation Clean Sweep’, organized by non-governmental organizations (NGOs) to clean beaches and drains [53]. Reusable bags are produced by NGOs who sell them to finance their activities in part. Raising awareness through media campaigns or billboards to remind customers to reuse their bags is another strategy adopted by the UK. Finally, paying customers a small amount of money (around EUR 0.10) if they do not take any plastic bags is supported in the UK [43].

Extended producer responsibility (EPR) is another policy mechanism that aims to mitigate the risks associated with waste management. With EPR, the mitigation of the environmental impacts of products throughout their lifecycle stages is accomplished by producers who are legally and financially responsible. Indeed, EPR can help in plastic pollution prevention and mitigation by limiting the health, safety, environmental, and social impacts of plastic products [54]. However, difficulties with enforcement have been reported.

Hence, the implementation of recycling processes and the development of biodegradable plastics are some of these strategies. Europe halved its monthly plastic waste export with these restrictions (from 300 to 150 kton) [48] and, in 2019, the Basel Convention called for more domestic solutions in dealing with (hazardous) waste [55]. This is signed by 187 countries worldwide (excluding the US, among others).

At the European level, the new EU Green Deal 2020 is targeting (illegal) waste exports to third countries. At the same time, a regulatory framework for biodegradable and bio-based plastics is set to be implemented aiming at the local improvement of waste management techniques and leading to the push of recycling processes forward, hence, reducing the need for biodegradable plastics. The development of both circular and bio-economies will be implemented by the amelioration of rural areas with a new financial plan [56].

Financially speaking, setting clear criteria for the assessment of green investment funds is one of the goals of the 2018 EU regulation facilitating sustainable investment in this direction [57][58]. Europe imposes fees to discourage plastic production under the extended producer responsibility (EPR) concept [59]. Moreover, the European Chemical Agency (ECHA) has recently discussed intentionally-added microplastics (e.g., microbeads in cosmetics) by the provision of a socio-economic assessment [60].

Substances of very high concern (SVHCs, i.e., carcinogenic, mutagenic, or toxic for reproduction, or CMR, and persistent and/or bio-accumulative substances) are being banned by the REACH regulation at the EU level [61][62] due to the cumulative and detrimental effects of (micro) plastics. In the future, the EU Green Deal [6], as well as the REACH registration of polymers, might aid in the classification and management of hazardous substances in (new) waste streams.

Currently, California law wants to phase out plastics that cannot be compostable or recyclable, but even this legislation faces bureaucratic resistance [63]. Other countries, such as China, support research on biodegradable plastics via funding, but also have limited policies [64].

California developed policy concepts in 2013 to make the producers of selected products responsible not only for recycling but also for litter prevention and mitigation. This new policy required a reduction in their products’ total volume in the environment by 95% in 11 years [54]. Bureaucracy might be a major obstacle in achieving these goals. Moreover, it might work well for some products but not for others. Difficulties with enforcement might also occur, and the problem of data scarcity has been reported in developing countries [65].

Finally, political will might be lacking due to countries having other priorities. Some ways to promote the political will are to make this the priority of the country analyzing the impact of environmental changes on health and society. Governments should employ tools that allow all consumers to enhance their awareness of the management of plastic and plastic waste. Consumers should change habits and lifestyles that require plastic usage, e.g., by means of a reduction in the reliance on single-use plastics or through source preparation and social awareness, and public education programs should also be included [43].

References

- HLPE. Nutrition and food systems. A report by the High-Level Panel of Experts on Food Security and Nutrition of the Committee on World Food Security, Rome. 2017. Available online: https://www.fao.org/3/i7846e/i7846e.pdf (accessed on 12 April 2022).

- Van Alfen, N.K. Encyclopedia of Agriculture and Food Systems; Academic Press: Cambridge, MA, USA, 2014; pp. 232–249.

- Robertson, G.L. Food Packaging—Principles and Practice, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2012; p. 736.

- Singh, P.; Wani, A.A.; Langowski, H.-C. Food Packaging Materials: Testing & Quality Assurance; CRC Press: New York, NY, USA, 2017; p. 356.

- Soroka, W. Fundamentals of Packaging Technology, 5th ed.; Institute of Packaging Professional: Herndon, VA, USA, 2014.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A new Circular Economy Action Plan. For a Cleaner and More Competitive Europe COM (2020) 98 Final, Brussels. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 2 February 2022).

- Circularity Gap Report 2022: Five Years of Analysis by Circle Economy, European Circular Economy Stakeholder 1878 Platform. Available online: https://circulareconomy.europa.eu/platform/en/knowledge/circularity-gap-report-2022-five-years-analysis-circle-economy (accessed on 27 March 2022).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A European Strategy for Plastics in a Circular Economy COM/2018/028 Final, Brussels. 2018. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 2 February 2022).

- United Nations. Resolution Adopted by the General Assembly on 25 September 2015: Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E (accessed on 2 February 2022).

- Bakri, A.A.; Nordenfelt, M.; Ajdic, T.; Nail, E.L. Recycling Food Packaging and Food Waste in Plastic Revolution; The European Economic and Social Committee: Bruxelles, Belgium, 2021.

- Bonilla, J.; Talón, E.; Atarés, L.; Vargas, M.; Chiralt, A. Effect of the Incorporation of Antioxidants on Physicochemical and Antioxidant Properties of Wheat Starch–Chitosan Films. J. Food Eng. 2013, 118, 271–278.

- Eurostat. Packaging Waste Statistics. Consulted in October. 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Packaging_waste_statistics (accessed on 10 May 2022).

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural Waste: Review of the Evolution, Approaches and Perspectives on Alternative Uses. Glob. Ecol. Conserv. 2020, 22, e00902.

- United Nations (UN) General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development; Resolution Adopted by the General Assembly A/RES/70/1. 2015. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_70_1_E.pdf (accessed on 10 May 2022).

- Jariyasakoolroj, P.; Leelaphiwat, P.; Harnkarnsujarit, N. Advances in Research and Development of Bioplastic for Food Packaging. J. Sci. Food Agric. 2020, 100, 5032–5045.

- European Bioplastics. What Are Bioplastics? Available online: https://www.european-bioplastics.org/bioplastics (accessed on 22 August 2021).

- Iacovidou, E.; Gerassimidou, S. Sustainable Packaging and the Circular Economy: An EU Perspective. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2018.

- Hahladakis, J.N.; Iacovidou, E.; Gerassimidou, S. Plastic Waste in a Circular Economy. In Plastic Waste and Recycling; Elsevier: Oxford, UK, 2020; pp. 481–512.

- Plastics—The Facts 2021. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 10 May 2022).

- Guengerich, F.P.; Yoshimoto, F.K. Formation and Cleavage of C-C Bonds by Enzymatic Oxidation-Reduction Reactions. Chem. Rev. 2018, 118, 6573–6655.

- Chen, F.; Wang, T.; Jiao, N. Recent Advances in Transition-Metal-Catalyzed Functionalization of Unstrained Carbon-Carbon Bonds. Chem. Rev. 2014, 114, 8613–8661.

- Kobayashi, S.; Uyama, H.; Kimura, S. Enzymatic Polymerization. Chem. Rev. 2001, 101, 3793–3818.

- Beringer, M.; Rodnina, M.V. The Ribosomal Peptidyl Transferase. Mol. Cell 2007, 26, 311–321.

- Luley-Goedl, C.; Nidetzky, B. Glycosides as Compatible Solutes: Biosynthesis and Applications. Nat. Prod. Rep. 2011, 28, 875–896.

- Rehm, B.H.A. Polyester Synthases: Natural Catalysts for Plastics. Biochem. J. 2003, 376, 15–33.

- Behabtu, N.; Kralj, S. Enzymatic Polymerization Routes to Synthetic–Natural Materials: A Review. ACS Sustain. Chem. Eng. 2020, 8, 9947–9954.

- Douka, A.; Vouyiouka, S.; Papaspyridi, L.-M.; Papaspyrides, C.D. A Review on Enzymatic Polymerization to Produce Polycondensation Polymers: The Case of Aliphatic Polyesters, Polyamides and Polyesteramides. Prog. Polym. Sci. 2018, 79, 1–25.

- Samuels, A.L.; Rensing, K.H.; Douglas, C.J.; Mansfield, S.D.; Dharmawardhana, D.P.; Ellis, B.E. Cellular Machinery of Wood Production: Differentiation of Secondary Xylem in Pinus contorta Var. latifolia. Planta 2002, 216, 72–82.

- Ganster, J.; Fink, H.-P. Cellulose and Cellulose Acetate. In Bio-Based Plastics; John Wiley & Sons Ltd: Chichester, UK, 2013; pp. 35–62.

- Meister, J.J. Modification of Lignin. J. Macromol. Sci. Part C Polym. Rev. 2002, 42, 235–289.

- Alma, M.H.; Kelley, S.S. Conversion of barks of several tree species into bakelite-like thermosetting materials by their phenolysis. J. Polym. Eng. 2000, 20, 365–380.

- Bai, Y.; Gao, Z. Water-Resistant Plywood Adhesives Prepared from Phenolated Larch Bark in the Presence of Various Combination Catalysts. J. Appl. Polym. Sci. 2012, 126, E374–E382.

- Zadeh, E.M.; O’Keefe, S.F.; Kim, Y.-T. Utilization of Lignin in Biopolymeric Packaging Films. ACS Omega 2018, 3, 7388–7398.

- Bioplastics, European. Frequently Asked Questions on Bioplastics. Available online: https://docs.european-bioplastics.org/publications/EUBP_FAQ_on_bioplastics.pdf (accessed on 10 May 2022).

- USDA. Voluntary Labeling Program for Bio-Based Products; United States Department of Agriculture (USDA): Washington, DC, USA, 2011; pp. 3789–3813.

- Gerassimidou, S.; Martin, O.V.; Chapman, S.P.; Hahladakis, J.N.; Iacovidou, E. Development of an Integrated Sustainability Matrix to Depict Challenges and Trade-Offs of Introducing Bio-Based Plastics in the Food Packaging Value Chain. J. Clean. Prod. 2021, 286, 125378.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: The Role of Waste-To-Energy in the Circular Economy COM/2017/034 Final, Brussels. 2017. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A52017DC0034 (accessed on 11 May 2022).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: Closing the Loop—An EU Action Plan for the Circular Economy COM/2015/0614 Final, Brussels. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52015DC0614 (accessed on 11 May 2022).

- European Parliament and Council of the European Union. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment; Official Journal of the European Union: Brussels, Belgium, 2019; Volume 155.

- Ellen MacArthur Foundation. Global Commitment. A Circular Economy for Plastic in which It Never Becomes Waste. 2020. Available online: https://www.newplasticseconomy.org/projects/global-commitment (accessed on 16 September 2020).

- European Plastics Pact. The European Plastics Pact. Bringing Together Frontrunner Companies and Governments to Accelerate the Transition toward Circular Plastics Economy. 2020. Available online: https://europeanplasticspact.org/ (accessed on 16 September 2020).

- United Nations. The Sustainable Development Goals Report; United Nations: New York, NY, USA, 2020.

- Nikiema, J.; Asiedu, Z. A Review of the Cost and Effectiveness of Solutions to Address Plastic Pollution. Environ. Sci. Pollut. Res. Int. 2022, 29, 24547–24573.

- Shin, S.-K.; Um, N.; Kim, Y.-J.; Cho, N.-H.; Jeon, T.-W. New Policy Framework with Plastic Waste Control Plan for Effective Plastic Waste Management. Sustainability 2020, 12, 6049.

- Nikiema, J.; Mateo-Sagasta, J.; Asiedu, Z.; Saad, D.; Lamizana, B. Water Pollution by Macroplastics and Microplastics: A Review of Technical Solutions from Source to Sea; United Nations Environment Programme (UNEP): Nairobi, Kenia, 2020; Available online: https://www.unep.org/resources/report/water-pollution-plastics-and-microplastics-review-technical-solutions-source-sea (accessed on 27 July 2022).

- EU. A European Strategy for Plastics in a Circular Economy. 2018. Available online: https://www.europarc.org/wp-content/uploads/2018/01/Eu-plastics-strategy-brochure.pdf (accessed on 30 July 2022).

- PlasticAtlas. Plastic Atlas 2019: Facts and Figures about the World of Synthetic Polymers; Heinrich Boll Foundation: Berlin, Germany, 2019.

- Filiciotto, L.; Rothenberg, G. Biodegradable Plastics: Standards, Policies, and Impacts. ChemSusChem 2021, 14, 56–72.

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese Import Ban and Its Impact on Global Plastic Waste Trade. Sci. Adv. 2018, 4, eaat0131.

- European Environment Agency (EEA). Plastics, the Circular Economy and Europe′s Environment—A Priority for Action; European Environment Agency: Copenhagen, Denmark, 2021.

- Hira, A.; Pacini, H.; Attafuah-Wadee, K.; Vivas-Eugui, D.; Saltzberg, M.; Yeoh, T.N. Plastic Waste Mitigation Strategies: A Review of Lessons from Developing Countries. J. Dev. Soc. 2022, 38, 336–359.

- UNEP (United Nations Environment Programme). Single-Use Plastics: A Roadmap for Sustainability. 2018. Available online: https://www.unep.org/resources/report/single-use-plastics-roadmap-sustainability (accessed on 27 July 2022).

- Lam, C.-S.; Ramanathan, S.; Carbery, M.; Gray, K.; Vanka, K.S.; Maurin, C.; Bush, R.; Palanisami, T. A Comprehensive Analysis of Plastics and Microplastic Legislation Worldwide. Water Air Soil Pollut. 2018, 229, 345.

- Eriksen, M.; Thiel, M.; Prindiville, M.; Kiessling, T. Microplastic: What Are the Solutions? In The Handbook of Environmental Chemistry; Springer: Cham, Switzerland, 2018; pp. 273–298. ISBN 9783319616148.

- United Nations. Report of the Conference of the Parties to the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal on the Work of Its Fourteenth Meeting. In Proceedings of the 14th Meeting of the Conference of the Parties to the Basel Convention (COP14), Geneva, Switzerland, 29 May–10 April 2019. UNEP/CHW.14/28.

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal COM(2019) 640 Final, Brussels. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 22 May 2022).

- European Commission. Proposal for a Regulation of the European Parliament and of the Council on the Establishment of a Framework to Facilitate Sustainable Investment COM(2018) 253 Final, Brussels. 2018. Available online: https://ec.europa.eu/transparency/regdoc/rep/1/2018/EN/COM-2018-353-F1-EN-MAIN-PART-1.PDF (accessed on 22 May 2022).

- Legislative Train Schedule. Available online: https://www.europarl.europa.eu/legislative-train (accessed on 22 May 2022).

- Monier, V.; Hestin, M.; Cavé, J.; Laureysens, I.; Watkins, E.; Reisinger, H.; Porsch, L. Development of Guidance on Extended Producer Responsibility (EPR). 2014. Available online: https://ec.europa.eu/environment/archives/waste/eu_guidance/pdf/Guidance%20on%20EPR%20-%20Final%20Report.pdf (accessed on 22 May 2022).

- European Chemicals Agency (ECHA). Annex XV Restriction Report: Proposal of Restriction for Intentionally Added Microplastics. 2019. Available online: https://echa.europa.eu/documents/10162/05bd96e3-b969-0a7c-c6d0-441182893720 (accessed on 22 May 2022).

- European Chemicals Agency (ECHA). Authorisation-ECHA. 2019. Available online: https://echa.europa.eu/substances-of-very-high-concernidentification-explained (accessed on 22 May 2022).

- Kubicki, M. Guidance on the Preparation of an Application for Authorisation; European Chemicals Agency: Helsinki, Finland, 2011.

- Singh, M. Most Ambitious US Law to Tackle Single-Use Plastics Faces Make-Or-Break Moment. 2019. Available online: http://www.theguardian.com/us-news/2019/sep/13/california-plastics-legislation-singleuse (accessed on 22 May 2022).

- OECD. Policies for Bioplastics in the Context of a Bioeconomy. 2013. Available online: https://www.oecd-ilibrary.org/science-and-technology/policies-for-bioplastics-in-the-context-of-a-bioeconomy_5k3xpf9rrw6den (accessed on 22 May 2022).

- Ugorji, C.; van der Ven, C. Trade and the Circular Economy: A Deep Dive into Plastics Action in Ghana. 2021. Available online: https://globalplasticaction.org/wp-content/uploads/Ghana_NPAP_Trade_and_Circular_Economy.pdf (accessed on 30 July 2022).

More

Information

Subjects:

Food Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

01 Nov 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No