Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nadia Nedjah | -- | 1944 | 2022-10-25 15:47:44 | | | |

| 2 | Camila Xu | Meta information modification | 1944 | 2022-10-27 09:48:22 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Nedjah, N.; Mourelle, L.D.M.; Lizarazu, M.S.D. Refrigeration Systems and Energy Efficiency. Encyclopedia. Available online: https://encyclopedia.pub/entry/31254 (accessed on 07 February 2026).

Nedjah N, Mourelle LDM, Lizarazu MSD. Refrigeration Systems and Energy Efficiency. Encyclopedia. Available at: https://encyclopedia.pub/entry/31254. Accessed February 07, 2026.

Nedjah, Nadia, Luiza De Macedo Mourelle, Marcelo Silveira Dantas Lizarazu. "Refrigeration Systems and Energy Efficiency" Encyclopedia, https://encyclopedia.pub/entry/31254 (accessed February 07, 2026).

Nedjah, N., Mourelle, L.D.M., & Lizarazu, M.S.D. (2022, October 25). Refrigeration Systems and Energy Efficiency. In Encyclopedia. https://encyclopedia.pub/entry/31254

Nedjah, Nadia, et al. "Refrigeration Systems and Energy Efficiency." Encyclopedia. Web. 25 October, 2022.

Copy Citation

Cooling towers constitute a fundamental part of refrigeration systems in power plants and large commercial buildings. Their main function is to treat the heat emitted by other equipment to cool down the temperature of the environment and/or processes. In the considered refrigeration system, cooling towers are coupled with compression chillers.

energy efficiency

cooling towers

swarm intelligence

multi-objective optimization

1. Introduction

In general, industrial processes generate heat. Often, this heat must be dealt with so it can be safely dissipated. As the main coolant, water is generally exploited to dissipate heat in refrigeration systems. However, the water used in such systems always returns at higher temperatures. It is then discarded or cooled down so that it can be reused. Whenever there is a lack of water, the second solution is always safer and more economic. The disposal of water used in a cooling process is an environmentally unsustainable practice, since the water, in these cases, usually ends at a high temperature, and its disposal under these conditions would impact the local underwater flora and fauna. Furthermore, taking into account the current challenges in obtaining potable water, the reuse of water in cooling towers is essential in terms of economic and environmental sustainability. The growing environmental concern with the inefficient use of electricity and its growing demand, along with the misuse of existing water resources, which are increasingly scarce, are leading the technical and scientific community to adopt premises and measures to achieve the maximum energy efficiency of industrial installations. Therefore, any cooling system requires the application of sophisticated mechanisms that allow achieving the best possible energy efficiency.

Currently, there is a scarcity of energy resources. In general, the availability of electricity in the energy matrix of any economy largely depends on the regular occurrence of rain in areas where hydroelectric plants are installed. When this does not happen, thermoelectric plants assume part of the energy demand. However, this alternative causes a significant increase in the cost of electricity, causing economic losses for industry in general. In addition to the scarcity of water resources for power generation, there is also the basic scarcity of water, which is used in large volumes and in various forms in the food and beverage, petrochemical, and power industries, for example. This is the case both for the purpose of directly obtaining the final product and for cooling purposes, hence the motivation behind this research work. The scarcity of water, and consequently, of electricity, causes a considerable increase in the final cost of products, and losses for the industrial and commercial sectors. This yields an even greater impact for industries or companies that do not apply strategies to reduce water and power requirements.

Cooling towers are used in refrigeration systems to cool down the temperature of the returning water so it can be reused in the refrigeration process. Thus, cooling towers are usually used in large buildings, such as commercial centers and high-class hotels. A cooling tower is usually coupled with chillers and pumps to move the water inside the refrigeration system. In addition, cooling towers include fans that allow correct circulation of the system’s used water. However, the chillers consume a large portion of the whole system’s energy [1]. Besides cooling towers, the considered refrigeration system includes other equipment that contributes to the system’s operation. Operational parameter adjustment of one of these pieces of equipment can cause ripple effects on the operation of the other equipment. It is clear that the effects can be either positive or negative.

2. Refrigeration Systems and Energy Efficiency

This section aims to present the basic functional concepts of the main equipment of the studied refrigeration system, so that it becomes possible to formalize the underlying optimization problem involving the cooling tower and the compression chillers. The concepts presented herein serve as a basis for the mathematical modeling of equipment, considering its thermodynamic principles of operation.

2.1. Cooling Tower

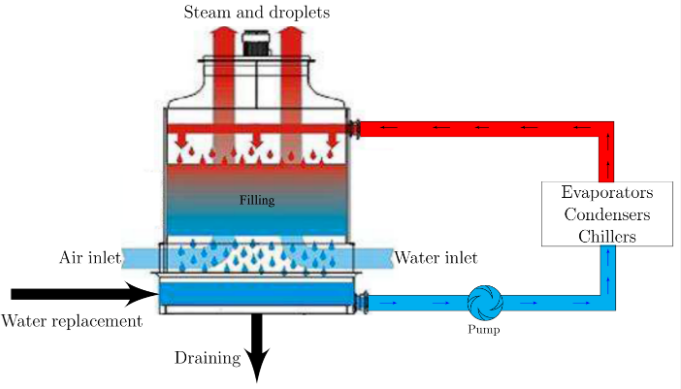

As the name suggests, cooling towers are equipment used for cooling water. This water usually comes from heat exchangers in process industries or from condensers in the case of electric generation plants. The reuse of this water is vital for the environmental and economic sustainability of the process. Cooling towers can be classified according to the used heat transfer method, relative flow between air and water, or draft. Figure 1 describes the structure and function of the modeled cooling tower. The cooling tower’s functionality consists of reducing the temperature of the inlet hot water to a reasonable degree to guarantee the correct operation of the remaining processing equipment of the refrigeration system.

Figure 1. Cooling tower structure and function.

It can be seen in Figure 1 that there is a need for chemical treatment in the water circuits of the tower, in order to avoid corrosion and accumulation of dirt, which causes an increase in the pressure drop, causing a greater energy consumption for the water lifting pumps. Corrosion causes small leaks, which increase the tower’s water consumption, leading to the need for interventions and unscheduled stops for maintenance.

A cooling tower can be classified as dry, wet, or mixed depending on the heat transfer method used. The heat exchange is considered dry when it is carried out in a closed circuit, with no direct contact between the two fluids. In this case, the fluids exchange heat through a surface, such as a metallic pipe. In wet heat exchange, there is direct contact between the fluids. This type of tower is also called an open system and uses the principle of evaporative cooling. On the other hand, the mixed or hybrid towers use the two mechanisms presented above, but there is the application of cold water (from another source) in the heat exchangers, favoring the evaporative thermal exchange. The cooling towers considered in this work are the wet type. In this case, the hot water is taken from the process to the sprinkler point, located at the top of the tower, through lifting pumps. After reaching this point, the hot water is released so that heat exchange occurs with the air flowing in the opposite direction. After performing the heat exchange, the cooled water descends through the filling to the bottom of the tower, returning to the process.

During the fall, after being released at the sprinkler point, the water comes into contact with the air stream, exchanging sensible and latent heat. It is known that part of the hot water that enters the tower evaporates. However, this water loss is not significant during operation whenever the tower’s setpoint is carefully configured [2]. Additionally, a cooling tower can be classified as counter-current flow or cross-flow depending on the relative flow between water and air streams. In cross-flow towers, the air enters through the side walls and passes through the filling practically horizontally. The water falls due to gravity on both sides of the tower, crossing the air current induced by the axial fan located at the top of the tower. In counter-current towers, the air enters through the base of the tower and crosses the filling in a vertical direction, contrary to the water flow. There is a higher pressure drop in the filling compared to cross-flow towers. This causes higher fan consumption. Counter-current flow towers are more efficient, since there is less possibility of internal air re-circulation. In addition, for this type of tower, the air spends more time in contact with the water, since the air intake is carried out at the bottom of the tower, allowing more efficient thermal exchange to take place.

Moreover, the draft cooling towers can be further classified as either natural or mechanical. A natural draft tower is usually larger, i.e., about 200 m in height and 100 m in diameter. In this kind of tower, the air flows naturally due to the gradual increase in air temperature as heat dissipation occurs (convection mechanism). This is also accelerated by their hyperbolic form. This shape causes the hot air to be accelerated along the rise, due to the area restriction along the path from the base of the tower to its top. On the other hand, mechanical draft towers are those that use fans to cause air circulation. They can be induced or forced draft. The basic difference is that in the former, the fans are positioned at the air outlet, usually at the top of the tower, whereas in the latter, the fans are positioned at ground level. The choice depends on several factors, such as available space, installation location, and average wind speed throughout the year in the region.

2.2. Compression Chiller

Chillers perform their main function of water cooling via a thermodynamic cycle. There are two types of chillers: compression and absorption chillers. The former takes advantage of a physical process, and the latter is based on physical/chemical principles. The studied refrigeration system is based on compression chillers.

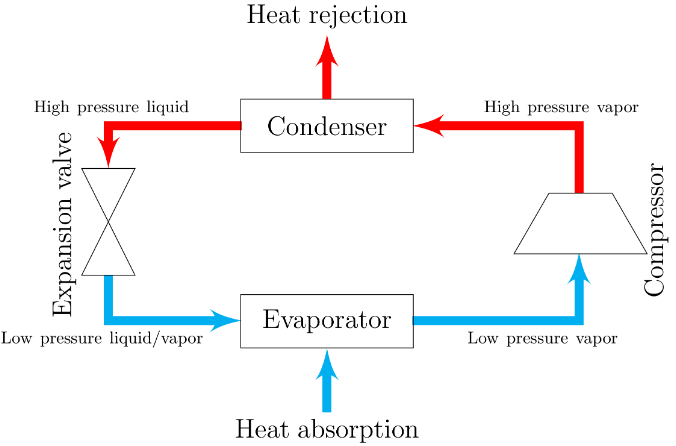

Compression chillers include a mechanical compressor driven by an electric motor. It is employed to compress the refrigerant gas of the chiller. Additionally, the chiller includes other equipment. The main pieces are the condenser, evaporator, and expansion valve [3]. The thermodynamic cycle of compression chillers is described in Figure 2.

Figure 2. Illustration of the operation cycle of a compression chiller.

The evaporator allows heat exchange to occur. It is composed of tubes. On one side, there is the passage of the refrigerant fluid, and on the other, the circulation of water to be refrigerated. Thus, the evaporator cools down the water, which is lifted by the circulation pumps. The evaporation of the refrigerant fluid is a phenomenon that happens once the thermal exchange with the process outlet water occurs. Note that this water circulates in the evaporator, causing the refrigerant fluid temperature to raise. Even though this process should be isobaric, in practice, a pressure reduction in the refrigerant fluid passing via the evaporator is inevitable. The compressor is able to compensate for this reduction and sends the fluid to the condenser. Note that after its passage through the evaporator, the refrigerant fluid goes to a vapor state, which then goes through the condenser.

The condenser may be air cooled or liquid cooled. For the first type, fans are employed to permit the circulation of the refrigerant gas via finned tubes. This allows the thermal exchange between the forced air and the refrigerant gas. For the second type of condenser, the water, circulating through the employed cooling tower, allows thermal exchange with the refrigerant gas. The coils located inside the condenser facilitate this exchange, which causes the condensation of the refrigerant gas. Then, the pumps lift the hot water to the cooling tower. After this, the condensed water returns to the chiller’s condenser. Note that the thermal exchange with the refrigerant vapor is a continuous process.

Moreover, an expansion/thermostatic valve is used in the chilling cycle. The valve is a device that allows direct expansion refrigeration. Thus, the fluid expansion occurs in the environment to be chilled. Thus, the thermodynamic cycle in a compression-based chiller starts with the refrigerant fluid being compressed by the compressor in the over-heated gas state. This increases its temperature and pressure. Then, the refrigerant fluid goes through the condenser, allowing the heat to be dissipated into the outside environment. This thermal exchange causes the refrigerant gas to cool down and liquefy. The refrigerant fluid then flows via the thermostatic valve, causing a pressure reduction which in turn causes a temperature drop. Lastly, the refrigerant fluid passes through the evaporator, absorbing the water’s heat and cooling it down, achieving the refrigeration goal. Then, the refrigerant fluid changes again to vapor, leaves the evaporator as super-heated vapor, and returns to the compressor, and the thermodynamic cycle restarts.

References

- Yu, K.; Hung, Y.; Hsieh, S.; Hung, S. Chiller Energy Saving Optimization Using Artificial Neural Networks. J. Appl. Sci. 2011, 16, 3008–3014.

- Alpina. Torres de Resfriamento de Agua; Technical Report; Alpina S/A Indústria e Comércio: São Bernardo do Campo, Brazil, 1978.

- ASHRAE. Handbook—HVAC Systems and Equipment; SI Edition; American Society of Heating, Refrigerating and Air Conditioning Engineers: Peachtree Corners, GA, USA, 2012.

More

Information

Subjects:

Engineering, Electrical & Electronic

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.4K

Revisions:

2 times

(View History)

Update Date:

27 Oct 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No