| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mehdi Safari | + 1710 word(s) | 1710 | 2020-11-18 21:25:55 | | | |

| 2 | Mehdi Safari | + 11 word(s) | 1721 | 2020-11-19 06:15:26 | | | | |

| 3 | Mehdi Safari | + 12 word(s) | 1722 | 2020-11-19 06:16:21 | | | | |

| 4 | Mehdi Safari | + 5 word(s) | 1715 | 2020-11-19 06:37:54 | | | | |

| 5 | Peter Tang | -65 word(s) | 1650 | 2020-11-19 07:50:43 | | | | |

| 6 | Jalal Joudaki | + 758 word(s) | 2408 | 2020-11-19 21:24:20 | | | | |

| 7 | Peter Tang | -67 word(s) | 2341 | 2020-11-20 03:45:38 | | | | |

| 8 | Mehdi Safari | + 5 word(s) | 2346 | 2020-11-21 04:59:39 | | |

Video Upload Options

Laser forming is an emerging manufacturing process capable of producing either uncomplicated and complicated shapes by employing a concentrated heating source. The heat source movement creates local softening, and a plastic strain will be induced during the rise of temperature and the subsequent cooling. This contactless forming process may be used for the simple bending of sheets and tubes or fabrication of doubly-curved parts. Different studies have been carried out over recent years to understand the mechanism of forming and predicting the bending angle. The analysis of process parameters and search for optimized manufacturing conditions are among the most discussed topics. This review describes the main recent findings in the laser forming of single and multilayer sheets, composite and fiber-metal laminate plates, force assisted laser bending, tube bending by laser beam, the optimization technique implemented for process parameters selection and control, doubly-curved parts, and the analytical solutions in laser bending. The main focus is set to the researches published since 2015.

1. Introduction

Sixty years have passed since the day Theodore H. Maiman built the first laser in 1960 at Hughes Research Laboratories. Since then, different types of laser were invented and improved for use in industries and laboratories. Two recent review papers are currently published and address various aspects of using laser technology. Dixit et al. [1] and Das and Biswas [2] published review papers on laser forming in 2015 and 2018, respectively. However, laser technology, applied in manufacturing technology, can be viewed from a completely different prism. The "LASER" acronym stands for Light Amplification by Stimulated Emission of Radiation. A single phase-coherent beam can be focused on a tiny spot, and according to the power of the laser source, different processes are developed. The low magnitude power leads to surface treatment and annealing of the workpiece; increasing the laser power leads to the melting of the workpiece and welding. High power lasers melt and evaporate the workpiece, and metal cutting happens. The number of photons controls the power of the laser and the frequency emitted from the light source. The ability for industrial applications varies from 100 W to more than 5 kW. Forming is another type of process, which can be implemented by laser technology. The workpiece can be a flat plate (sheet) or tube.

Laser beam irradiation induces thermal stresses into the worksheet. Temperature gradient mechanism (TGM), buckling mechanism (BM), and upsetting mechanism (UM) are three proposed mechanisms that happen during the laser beam irradiation [3][4]. The cooling of the sheet, at last, leads to bending the sheet due to residual stresses and corresponding strains. By increasing the temperature during laser beam irradiation, the physical properties of the sheet include yield strength, ultimate tensile strength, and the elastic (Young) modulus will also be decreased. The yield strength of the material decreases faster than the elastic modulus.

Consequently, the equivalent (von Mises, for instance) stress proportional to the elastic modulus overtakes the yield strength in some regions of the sheet. So, plastic deformation occurs over the irradiated zone. The amount of plastic deformation depends on both the pre-stress field and temperature distribution in the sheet. The more massive plastic strain will be obtained by higher peak temperatures and larger pre-stresses [5]. The laser beam specifications, the scan pattern, and the properties of the sheet determine the final shape of the workpiece. Reasonable attempts have been made by researchers in recent years to investigate the effect of laser irradiation path on the quality, productivity, and shape of the final workpiece. In the laser forming process, the heating of the workpiece is non-uniform and asymmetric. The beam irradiates from one point of the workpiece and scans along a defined path. The geometry condition is not constant along the heating line. So, an unwanted deformation will be created in the sheet called the "edge effect". This undesirable deformation reduces the forming accuracy. By introducing the laser forming technology, new applications responded in various industries. Bending of small parts with little bending angle (less than 1°), bending of complicated parts for aerospace industries such as tailor machined blanks (TMB), bending of low diameter tubes with minimum ovality and thickness variations, forming of composite parts with little delamination, and forming of doubly curved specimens to obtain the irradiating patterns which can be used in the flame forming of the dome and saddle-shaped parts in ship bodies are examples of the industrial applications of laser forming.

2. Laser Bending of Monolithic Sheets

Sheet bending is a vital manufacturing process which can be done using laser technology. The sheet is scanned along a straight line, and local heating of one of the sheet's surfaces leads to the plastic deformation of the sheet due to the stress gradient over the thickness direction. The process parameters affecting the bend angle are laser characteristics (laser power, spot size, scan speed, pulsed or continuous irradiation), the number of irradiation passes, material type, and the geometrical dimension of the sheet (thickness, width, length). The literature survey shows that laser power is the most influential process parameters in the laser forming process. The coating of the sheet is also necessary. Graphite is a typical coating that absorbs the irradiated beam effectively. The retention of heat in the coating layer for a longer duration affects the out-of-plane bending and minimizes the residual stresses [6]. The rougher surface (such as sandblasted surfaces) and thicker coating layer increase the absorptivity of the laser beam and lead to higher bending angle [7]. Microstructural observation using electron backscatter diffraction (EBSD) technique shows that the grain size does not influence the final bending angle [8]. Cement and lime are two other coatings used in experiments, and the results show that the cement coating creates more deformation and bending than the lime coating [9][10]. Pulsed or continuous irradiation of the laser beam is also essential. Pulsed irradiation beam with overlapping the pulses increases the bending angle, and the existence of a gap between the pulses reduces the final bending angle [11].

3. Laser Bending of Bi-Layer and Tailored Blanks

The previous section discussed the forming of single, monolayer, homogenous sheets. The properties and thickness of the sheet were assumed as constant. However, different properties of the sheet can be obtained by increasing the number of layers (bi-layer sheets or multilayer sheets), manufacturing a composite sheet, or different thickness or material (tailor welded blanks (TWB), tailor machined blanks (TMB)). Doing so, the laser-induced bending mechanism and magnitude of bending will be different. Safari et al. [12] investigated the laser bending of tailor machined blanks (TMB) experimentally. Tailor-made blanks are sheet metal assemblies with different thicknesses and/or materials and/or surface coatings. The laser melts the sheet, and bending happens due to plastic deformation during solidification. The thickness affects the bending angle. Different thickness, start point of scan, and absorbed power by the sheet (laser power and scanning speed) influence the bending magnitude of the TMB sheet. The thick-to-thin irradiation path creates a higher bending angle in comparison to the thin-to-thick irradiation path. Increasing the laser power, reducing the laser scan speed and irradiation of the laser beam from the back of the sheet (the side of the sheet that the step does not rely on) enhances the bending angle of tailor machined blanks. The bending angle of laser formed tailor machined blanks can be predicted by the artificial neural network (ANN) [13].

4. Laser Forming of Composite Sheets

The effect of material type and layers configuration on the laser-formed sheets were discussed in previous sections. In this section, the laser forming of composite sheets will be discussed. The type of composite is essential. Fiber and matrix have different mechanical properties (yield strength, stress-strain behavior) and physical properties (melting point, density, conductivity). Seyedkashi et al. [14] investigated the laser forming of three-layered SUS430/C11000/SUS430 laminated composite sheets. The copper mid-layer has higher thermal conductivity than the stainless steel 430 sheets. The plastic strain, along with the thickness and the shear stress between the layers, is more complicated than a single monolithic layer. Warping is another problem in the laser bending of composite samples. During the laser forming of stainless steel-carbon steel composite plate in ANSYS software, the non-uniform heat distribution and different heat conductivity and heat loss produce a warping force which causes undesirable deformation of composite in addition to the edge effect [15]. The sequence of layers is also important and affects the bending angle of the multilayer composite samples [16].

Fiber–Metal Laminates (FML) are made of different layers of metal and composite material. The difference between the properties of fiber, matrix, and metal leads to complicated plastic deformation, bending, and unpredictability. The complicated deformation mechanisms, interfacial delamination, and thermal alteration of the layers are three main challenges in the laser forming of FMLs. However, using the experimental test and using an artificial neural network tool made it possible to predict the behavior of FMLs during the laser bending process [17][18]. Moreover, the deformation of FMLs can be predicted using Eigen-strain field prediction [19][20]. The composites are divided into three categories, polymer matrix composite (PMC), ceramic matrix composite (CMC), and metal matrix composite (MMC). By increasing the use of MMC parts and the easy fabrication of PMC parts, more study is needed to fabricate the MMC and PMC made parts by laser beam technology. The use of MMC materials is increasing rapidly in the aerospace industry.

5. Force Assisted laser Bending

To increase the bending angle of laser formed sheets, applying an external force is a helpful solution. The applied force causes more bending, and sharp bending angles can be obtained [21]. The springback phenomenon is crucial, and the accuracy of forming is affected by the change in the angle of the bent sample after unloading. The springback has a close relation to the distribution of induced residual stresses during forming. The external force (bending moment) is created by a hydraulically driven tool, preload weight, or a screw-driven rod [22][23][24]. Fuzzy logic models and trained artificial neural network (ANN) with verified FEM models can predict the bending angle [25][26]. Figure 2 shows the mechanism of applying an external force for laser-assisted bending of titanium samples.

6. Laser Tube Bending

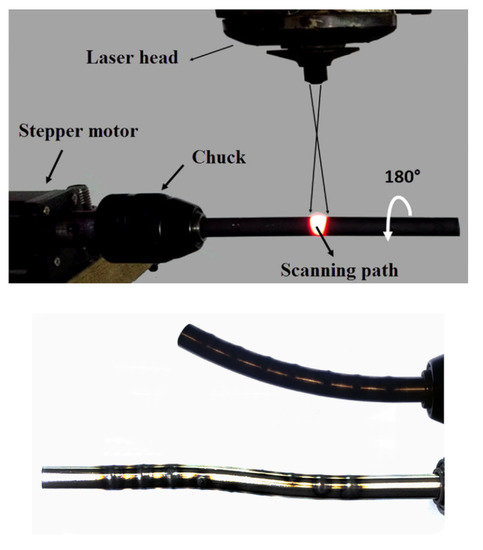

Tube bending was always a challenge in conventional bending. Usually, an internal plug is inserted inside the tube, and bending happens. However, a laser beam can also be used for tube bending. The laser beam is irradiated on the tube surfaces and may result in 2D or 3D tube bending. The amount of research about tube bending is low in comparison to laser sheet metal forming. The effects of the irradiating length and the number of irradiating passes on tube bending have been studied. Three primary defects of the laser tube bending are lateral bending angle (especially when the scanning path is complicated like spirals), ovality, and thickness variation. The tube bending angle increased by increasing the irradiation length and number of passes. Moreover, the ovality percentage and the thickness variation will be increased by increasing the irradiation length [27]. The circular scanning method can be used for 2D and 3D tube bending. A scanning strategy has been developed to determine the scanning path using direct and reverse solution [28]. The effect of process parameters is like sheet metal forming, and the bending angle of the tube increases by increasing the laser power and beam diameter and with a decrease in the travel speed [29]. Figure 1 shows two samples of laser tube forming. Laser beam absorption can also be performed to improve the obtainable bending angle [30]. Different materials, such as carbon steel, stainless steel, and nickel tubes, can be formed and used in various industries such as aerospace industries, engines, heat exchangers, and air conditioners [27][28][29][30][31][32][33].

The size of the tube is another essential process parameter. Normal sizes, such as ½ and ¾ inch tubes, can be formed using a laser beam without difficulties. However, the laser forming of micro-tubes (for example, a tube with 635 μm outer diameter) needs more precise tools and controlled conditions [32][34]. The micro-tubes are thin-walled structures, due to high thermal conductivity and quick heat dissipation from the irradiated zone, short pulse, and high power laser beams utilized for inducing plastic strain and tube bending. It seems that researchers only focus on the bending of round tubes. Rectangular tubes, especially the 3D bending of them, is an attractive subject of study. The ovality of 2D and 3D laser-formed tubes and thinning of the tube is also important and needs more investigation.

7. Doubly Curved Parts

The laser beam irradiation path is an important parameter that can be used for shaping complicated parts like bowl-shaped surfaces, cylindrical surfaces, saddle-shaped surfaces, and 3D intricate shapes. In laser bending of sheets, the beam is irradiated along a straight line and bend the sample. But using different scanning paths like spiral movement, concentric circles, crossed lines, spider pattern movement, and other developed scanning strategies make a complicated plastic strain field in the sheets and form the sheet to the desired shape. The tolerance of forming is a challenge that affects the effectiveness of the laser forming process. The curved parts can be used in shipbuilding, a cranial prosthesis (from Ti-6Al-4V titanium alloy for use in the skull) [35], Origami Spoon [36][37], and cylindrical shells. Gisario et al. [38] used radial paths to fabricate a dome from a flat stainless steel blank.

8. Other Applications of Laser Beam Technology

A short pulse laser beam can be employed to fabricate micro-sized parts like MEMS parts [39]. Metal foams can be formed by laser forming [40][41][42][43][44][45][46][47][48]. Metal foams are a new category of materials which has a low density and good geometrical flexibility. Instead of applying a mechanical load, the laser irradiation heat produces a temperature gradient along with the thickness. The results show that the temperature gradient mechanism (TGM) is the primary mechanism of the closed-cell metal foams [42]. Stiffened parts and reinforced panels can be formed by laser beam irradiation [49][50][51]. The laser beam can be used in various processes like laser peen forming (LPF) [52][53][54][55][56], laser shock peening (LSP) [57][58], Laser solid forming (LSF) [59][60], laser folding [61], modification of mechanically bent parts (correction of spring back, over-bending or distortion of sheet [62]) and measuring the bending angle [63].

The entry is from 10.3390/met10111472

References

- Dixit U.S.; Joshi S.N.; Kant R. Laser forming systems: a review. Int. J. Mechatr. Manuf. Sys. 2015, 8, 160–205, doi: 10.1504/IJMMS.2015.073077.

- Das B.; Biswas P. A review of plate forming by line heating. J. Ship. Prod. Des. 2018, 34, 155–167.

- Kant, R.; Bhuyan, P.M.; Joshi, S.N. Experimental Studies on TGM and BM Dominated Curvilinear Laser Bending of Aluminum Alloy Sheets. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December 2014; Joshi S., Dixit U., Eds.; Springer: New Delhi, India, 2015; pp. 69–91, doi: 10.1007/978-81-322-2352-8_5.

- Roohi A.H.; Moslemi Naeini H.; Hoseinpour Gollo M.; Shahbazi Karami J.; Imani Shahabad Sh. Effects of temperature gradient magnitude on bending angle in laser forming process of aluminium alloy sheets. J. Comput. Appl. Res. Mech. Eng. 2016, 5, 97–109, doi: 10.22061/jcarme.2016.423.

- Xu, L.; Li, W.; Wang, X.; Wan M.; Jiang M. Plastic deformation behavior in laser bending of elastic preloaded metal plate. Inte. J. Adv. Manuf. Tech. 2017, 90, 3397–3406, doi: 10.1007/s00170-016-9643-8.

- Rattan A.; Jasra Y.; Saxena R.K. Prediction of bending behavior for laser forming of lime coated plain carbon steel using finite element method. Materials today: Proc. 2020, 28, 1943–1950, doi: 10.1016/j.matpr.2020.05.411.

- Abedi H.R.; Hoseinpour Gollo M. An experimental study of the effects of surface roughness and coating of Cr2O3 layer on the laser-forming process. Opt. Laser Technol. 2019, 109, 336–347, doi: 10.1016/j.optlastec.2018.07.064.

- Fidder, H.; Admiraal, J.P.J.; Ocelík, V.; De Hosson, J.T.M. In situ digital image correlation observations of laser forming. Metals 2020, 10, 17–35, doi: 10.3390/met10010017.

- Gautam, S.S.; Singh S.K.; Dixit U.S. Laser Forming of Mild Steel Sheets Using Different Surface Coatings. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December, 2014; Joshi S., Dixit U., Eds.; Springer: New Delhi, India, 2015; pp. 17–39, doi: 10.1007/978-81-322-2352-8_2.

- Fetene, B.N.; Dixit, U.S.; Liao, H. Laser bending of friction stir processed and cement-coated sheets. Mater. Manuf. Process. 2017, 32, 1628–1634, doi: 10.1080/10426914.2017.1279321.

- Maji, K.; Pratihar, D.K.; Nath, A.K. Numerical and Experimental Studies on Pulsed Laser Forming of Sheet Metal. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December 2014; Joshi S., Dixit U., Eds.; Springer: New Delhi, India, 2015; 55–67, doi: 10.1007/978-81-322-2352-8_4.

- Safari, M.; Mostaan, H.; Farzin, M. Laser bending of tailor machined blanks: effect of start point of scan path and irradiation direction relation to step of the blank. Alex. Eng. J. 2016, 55, 1587–1594, doi: 10.1016/j.aej.2016.01.010.

- Safari, M.; Joudaki, J. Prediction of bending angle for laser forming of tailor machined blanks by neural network. Iranian J. Mater. Form. 2018, 5, 47–57, doi: 10.22099/ijmf.2018.28561.1097

- Seyedkashi, S.M.H.; Hoseinpour Gollo, M.; Biao, J.; Moon, Y.H. Laser bendability of SUS430/C11000/SUS430 laminated composite and its constituent layers. Met. Mater. Int. 2016, 22, 527–534, doi: 10.1007/s12540-016-5711-8.

- Li, Z.; Wang, X. Numerical simulation of warping deformation on metal composite plate during laser bending. J. Inf. Laser Eng. 2018, 47, 506004–0506010, doi: 10.3788/IRLA201847.0506004.

- Liu, H.; Zhang, W.; Gau, J.T.; Shen, Z.; Ma, Y.; Zhang, G.; Wang, X. Feature size effect on formability of multilayer metal composite sheets under microscale laser flexible forming. Metals 2017, 7, 275–294, doi: 10.3390/met7070275.

- Gisario, A.; Mehrpouya, M.; Rahimzadeh, A.; De Bartolomeis, A.; Barletta, M. Prediction model for determining the optimum operational parameters in laser forming of fiber-reinforced composites. Adv. Manuf. 2020, 8, 242–251, doi: 10.1007/s40436-020-00304-3.

- Gisario, A.; Barletta, M. Laser forming of glass laminate aluminium reinforced epoxy (GLARE): On the role of mechanical, physical and chemical interactions in the multi-layers material. Opt. Laser. Eng. 2018, 110, 364–376, doi: 10.1016/j.optlaseng.2018.06.013.

- Zhang, Z.; Hu, Y.; Yao, Z. Shape prediction for laser peen forming of fiber metal laminates by experimentally determined eigenstrain ASME. J. Manuf. Sci. Eng. 2017, 139, 041004–041013, doi: 10.1115/1.4034891.

- Zhang, Z.; Hu, Y.; Yao, Zhenqiang. An Experiment-Based Model to Determine Eigenstrain in Fibre Metal Laminates Induced by Laser Peen Forming. In Volume 1: Processing, Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, USA, June 27–July 1 2016; Paper No: MSEC2016-8544, V001T02A027, doi: 10.1115/MSEC2016-8544. https://asmedigitalcollection.asme.org/MSEC/proceedings- abstract/MSEC2016/49897/V001T02A027/268523 (accessed on 3 November 2020).

- Gisario, A.; Mehrpouya, M.; Venettacci, S.; Barletta, M. Laser-assisted bending of titanium grade-2 sheets: experimental analysis and numerical simulation. Opt. Laser. Eng. 2017, 92, 110–119, doi: 10.1016/j.optlaseng.2016.09.004.

- Gisario, A.; Barletta, M.; Venettacci, S. Improvements in springback control by external force laser-assisted sheet bending of titanium and aluminum alloys. Opt. Laser Technol. 2016, 86, 46–53, doi: 10.1016/j.optlastec.2016.06.013.

- Gisario, A.; Barletta, M.; Venettacci, S.; Veniali, F. Laser-assisted bending of sharp angles with small fillet radius on stainless steel sheets: analysis of experimental set-up and processing parameters. laser. Manuf. Mater. Process. 2015, 2, 57–73, doi: 10.1007/s40516-015-0006-3.

- Nowak, Z.; Nowak, M.; Widłaszewski, J.; Kurp, P. Experimental and Numerical Investigation on Laser-Assisted Bending of Pre-Loaded Metal Plate. In AIP Conference Proceedings Vol. 1922, Proceedings of the 22nd International Conference on Computer Methods in Mechanics, Lublin, Poland, 13–16 September 2017; AIP publishing: NY, USA; 140006 doi: 10.1063/1.5019148.

- Ponticelli, G.S.; Guarino, S.; Giannini, O. A fuzzy logic-based model in laser-assisted bending springback control. Int. J. Adv. Manuf. Technol. 2018, 95, 3887–3898, doi: 10.1007/s00170-017-1482-8.

- Fetene, B.N.; Shufen, R.; Dixit, U.S. FEM-based neural network modeling of laser-assisted bending. Neural. Comput. Appl. 2018, 29, 69–82, doi: 10.1007/s00521-016-2544-9.

- Safari, M. A study on the laser tube bending process: effects of the irradiating length and the number of irradiating passes. Iranian J. Mater. Form. 2020, 7, 46–53, doi: 10.22099/ijmf.2019.34213.1133.

- Khandandel, S.E.; Seyedkashi, S.M.H.; Moradi, M. A novel path strategy design for precise 2D and 3D laser tube forming process; experimental and numerical investigation. Optik, 2020, 206, 164302, doi: 10.1016/j.ijleo.2020.164302.

- Li, F.; Liu, S.; Shi, A.; Shi, Q.; Li, Y. Research on laser thread form bending of stainless steel tube. Int. J. Precis. Eng. Manuf. 2019, 20, 893–903, doi: 10.1007/s12541-019-00068-2.

- Imhan, K.I.; Baharudin, B.T.H.T.; Zakaria, A.; Ismail, M.I.S.B.; Alsabti, N.M.H.; Ahmad, A.K. Improve the material absorption of light and enhance the laser tube bending process utilizing laser softening heat treatment. Opt. Laser Technol. 2018, 99, 15–18, doi: 10.1016/j.optlastec.2017.09.040.

- Imhan, K.I.; Baharudin, B.T.H.T.; Zakaria, A.; Ismail, M.I.S.B.; Alsabti, N.M.H.; Ahmad, A.K. Investigation of material specifications changes during laser tube bending and its influence on the modification and optimization of analytical modeling. Opt. Laser Technol. 2017, 95, 151–156, doi: 10.1016/j.optlastec.2017.04.030.

- Che Jamil, M.S.; Imam Fauzi, E.R.; Juinn, C.S.; Sheikh, M.A. Laser bending of pre-stressed thin-walled nickel micro-tubes. Opt. Laser Technol. 2015, 73, 105–117, doi: 10.1016/j.optlastec.2015.04.012.

- Keshtiara, M.; Golabi, S.; Tarkesh Esfahani, R. Multi-objective optimization of stainless steel 304 tube laser forming process using GA. Eng. Comput. 2019, 1–17, doi: 10.1007/s00366-019-00814-0.

- Folkersma, G.; Brouwer, D.; Römer, G. Microtube laser forming for precision component alignment. ASME. J. Manuf. Sci. Eng. 2016, 138, 081012-1–081012-6, doi:10.1115/1.4033389.

- Cook, F.; Celentano, D.; Ramos-Grez, J. Experimental-numerical methodology for the manufacturing of cranial prosthesis via laser forming. Int. J. Adv. Manuf. Technol. 2016, 86, 2187–2196, doi: 10.1007/s00170-015-8316-3.

- Gisario, A.; Mehrpouya, M.; Venettacci, S.; Mohammadzadeh, A.; Barletta, M. Laser Origami (LO) of three-dimensional (3D) components: experimental analysis and numerical modelling. J. Manuf. Process. 2016, 23, 242–248, doi: 10.1016/j.jmapro.2016.05.005.

- Mehrpouya, M.; Huang, H.; Venettacci, S.; Gisario, A. Laser Origami (LO) of three-dimensional (3D) components: experimental analysis and numerical modeling-part II, J. Manuf. Process. 2019, 39, 192–199, doi: 10.1016/j.jmapro.2019.02.026.

- Gisario, A.; Barletta, M.; Venettacci, S.; Veniali, F. Progress in tridimensional (3d) laser forming of stainless steel sheets. Laser Manuf. Mater. Process. 2015, 2, 148–163, doi: 10.1007/s40516-015-0012-5.

- Manouchehry nya, R.; Peirovi, S.; Alipour, R.; FarokhiNejad, A. Finite element analysis of micro scale laser bending of a steel sheet metal subjected to short pulse shock wave. Proc. Manuf. 2015, 2, 397–401, doi: 10.1016/j.promfg.2015.07.070.

- Bucher, T.; Cardenas, S.; Verma, R.; Li, W.; Lawrence Yao, Y. Laser forming of sandwich panels with metal foam cores. ASME. J. Manuf. Sci. Eng. 2018, 140, 111015-1–111015-12, doi: 10.1115/1.4040959.

- Roohi, A.H.; Moslemi Naeini, H.; Hoseinpour Gollo, M.; Soltanpour, M.; Bruschi, S.; Ghiotti, A. Forming of closed-cell aluminum foams under thermal loadings: experimental investigation. Int. J. Adv. Manuf. Technol. 2018, 95, 3919–3928, doi: 10.1007/s00170-017-1501-9

- Zhang, M.; Chen, C.; Huang, Y.; Zou, T. Bending processing and mechanism of laser forming pure aluminum metal foam. Int. J. Adv. Manuf. Technol. 2018, 94, 1849–1856, doi: 10.1007/s00170-017-0976-8

- Zhang, M.; Jun Chen, C.; Brandal, G.; Bian, D.; Lawrence Yao, Y. Experimental and numerical investigation of laser forming of closed-cell aluminum foam. ASME. J. Manuf. Sci. Eng. 2016, 138, 021006-1–021006-8, doi: 10.1115/1.4030511.

- Bucher, T.; Young, A.; Zhang, M.; Chen, C.J.; Lawrence Yao, Y. Thermally induced mechanical response of metal foam during laser forming. ASME. J. Manuf. Sci. Eng. 2018, 140, 041004-1–041004-12, doi: 10.1115/1.4038995.

- Bucher, T.; Young, A.; Zhang, M.; Chen, C.J., Yao, L.Y. Bending Mechanism Analysis for Laser Forming of Metal Foam. In Volume 1: Processes. Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June, 2017; Paper No: MSEC2017-3026, V001T02A060, doi: 10.1115/MSEC2017-3026. https://asmedigitalcollection.asme.org/MSEC/proceedings-abstract/MSEC2017/50725/V001T02A060/268607 (accessed on 3 November 2020).

- Mohammad Shahid, R.; Srinu, T.; Datta, S.; Saha, P. Investigating the Effect of Process Parameters and Scan Strategy During Laser Forming of Thin Open Celled Aluminium Foam. In Volume 4: Processes. Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, TX, USA, 18–22 June, 2018; Paper No: MSEC2018-6591, V004T03A059, doi: 10.1115/MSEC2018-6591. https://asmedigitalcollection.asme.org/MSEC/proceedings-abstract/MSEC2018/51388/V004T03A059/277111, (accessed on 3, November 2020).

- Bucher, T.; Zhang, M.; Chen, C.J.; Verma, R.; Li, W.; Lawrence Yao, Y. Laser forming of metal foam sandwich panels: effect of panel manufacturing method. ASME. J. Manuf. Sci. Eng. 2019, 141, 051006-1–051006-11, doi: 10.1115/1.4043194.

- Bucher, T.; Finn, C.; Verma, R.; Li, W.; Lawrence Yao, Y. 3D laser forming of metal foam sandwich panels. ASME. J. Manuf. Sci. Eng. 2020, 142, 081008-1–081008-11, doi: 10.1115/1.4047242.

- Fu, S.; Yang, L.; Zhang, H.; Wang, Y.; Chi, G. Laser forming of the panel with crossed reinforcing bars. Int. J. Precis. Eng. Manuf. 2017, 92, 3673–3692, doi: 10.1007/s00170-017-0438-3.

- Fu, S.; Yang, L.; Zhang, H.; Wang, Y.; Chi G.; Ding, Y. Numerical simulation of the twist deformation for the stiffened panel with laser forming. Int. J. Precis. Eng. Manuf. 2018, 19, 1569–1582, doi: 10.1007/s12541-018-0185-x.

- Hu, Y.; Xie, Y.; Wu, D.; Yao, Z. Quantitative evaluation of specimen geometry effect on bending deformation of laser peen forming. Int. J. Mech. Sci. 2019, 150, 404–410, doi: 10.1016/j.ijmecsci.2018.10.040.

- Fu, S.; Yang, L.; Zhang, H.; Wang, Y.; Chi, G. Analyses of effects of process parameters on laser bending of stiffened panels. Int. J. Precis. Eng. Manuf. 2018, 19, 593–604, doi: 10.1007/s12541-018-0072-5.

- Luo, M.; Hu, Y.; Qian, D.; Yao, Z. Numerical modeling and mechanism analysis of hybrid heating and shock process for laser-assisted laser peen forming. ASME. J. Manuf. Sci. Eng. 2018, 140, 111009-1–111009-10, doi: 10.1115/1.4040914.

- Sagisaka, Y.; Yamashita, K.; Ueta, H. Efficiency improvement of thin-sheet-metal bending by femtosecond laser peen forming. Proc. Manuf. 2018, 15, 1314–1321, doi: 10.1016/j.promfg.2018.07.353.

- Hu, Y.; Luo, M.; Yao, Z. Increasing the capability of laser peen forming to bend titanium alloy sheets with laser-assisted local heating. Mater. Design. 2016, 90, 364–372, doi: 10.1016/j.matdes.2015.10.128.

- Hu, Y.; Zheng, X.; Wang, D.; Zhang, Z.; Xie, Y.; Yao, Z. Application of laser peen forming to bend fibre metal laminates by high dynamic loading. J. Mater. Process. Tech. 2015, 226, 32–39, doi: 10.1016/j.jmatprotec.2015.07.003.

- Tan, H.; Chen, Y.; Feng, Z.; Hou, W.; Fan, W.; Lin, X. A real-time method to detect the deformation behavior during laser solid forming of thin-wall structure. Metals 2020,10, 508, doi: 10.3390/met10040508.

- Wang, X.; Li, C.; Ma, Y.; Shen, Z.; Sun, X.; Sha, C.; Gao, S.; Li, L.; Liu, H. An experimental study on micro clinching of metal foils with cutting by laser shock forming. Materials 2016, 9, 571, doi: 10.3390/ma9070571.

- Lazarus, N.; Smith, G.L. Laser folding in a roll-to-roll manufacturing process. Lasers Manuf. Mater. Process. 2018, 5, 237–247, doi: 10.1007/s40516-018-0064-4.

- Chakraborty, S.S.; More, H.; Racherla, V.; Nath, A.K. Modification of bent angle of mechanically formed stainless steel sheets by laser forming. J. Mater. Process. Tech. 2015, 222, 128–141, doi: 10.1016/j.jmatprotec.2015.02.044.

- Thomsen, A.N.; Kristiansen, M.; Kristiansen, E.; Endelt, B. Online measurement of the surface during laser forming. Int. J. Adv. Manuf. Technol. 2020, 107, 1569–1579, doi: 10.1007/s00170-020-04950-6.

- Peng, C.; Xiao, Y.; Wang, Y.; Guo, W. Effect of laser shock peening on bending fatigue performance of AISI 9310 steel spur gear. Opt. Laser Technol. 2017, 94, 15–24, doi: 10.1016/j.optlastec.2017.03.017.

- Shen, N.; Ding, H. Surface integrity analysis of laser peen micro-bending without protective coating, Proc. CIRP 2016, 45, 315–318, doi: 10.1016/j.procir.2016.02.061.