| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Camila Xu | -- | 2538 | 2022-10-24 01:30:59 |

Video Upload Options

Sound Transmission Class (or STC) is an integer rating of how well a building partition attenuates airborne sound. In the US, it is widely used to rate interior partitions, ceilings, floors, doors, windows and exterior wall configurations. Outside the US, the Sound Reduction Index (SRI) ISO index is used. The STC rating very roughly reflects the decibel reduction of noise that a partition can provide. The STC is useful for evaluating annoyance due to speech sounds, but not music or machinery noise as these sources contain more low frequency energy than speech. There are many ways to improve the sound transmission class of a partition, though the two most basic principles are adding mass and increasing the overall thickness. In general, the sound transmission class of a double leaf wall (e.g. two 4"-thick brick walls separated by a 2" airspace) is greater than a single wall of equivalent mass (e.g. homogeneous 8" brick wall).

1. Definition

The STC or sound transmission class is a single number method of rating how well wall partitions reduce sound transmission.[1] The STC provides a standardized way to compare products such as doors and windows made by competing manufacturers. A higher number indicates better sound than a lower number. The STC is a standardized theoretical measurement provided by ASTM E413 and E90 with the Field sound transmission class provided by ASTM E336-97 annex a1.[1]

Sound Isolation and Sound Insulation are used interchangeably, though the term "Insulation" is preferred outside the US.[2] The term "sound proofing" is typically avoided in architectural acoustics as it is a misnomer and connotes inaudibility.

2. Subjective Correlation

Through research, acousticians have developed tables that pair a given STC rating with a subjective experience. The table below is used to determine the degree of sound isolation provided by typical multi-family construction. Generally, a difference of one or two STC points between similar constructions is subjectively insignificant.[3]

| STC | What can be heard |

|---|---|

| 25 | Normal speech can be understood |

| 30 | Loud speech can be understood |

| 35 | Loud speech audible but not intelligible |

| 40 | Loud speech audible as a murmur |

| 45 | Loud speech heard but not audible |

| 50 | Loud sounds faintly heard |

| 60+ | Good soundproofing; most sounds do not disturb neighbouring residents.[4] |

Tables like the one above are highly dependent on the background noise levels in the receiving room: the louder the background noise, the greater the perceived sound isolation.[5]

3. Rating Methodology

3.1. Historical

Prior to the STC rating, the sound isolation performance of a partition was measured and reported as the average transmission loss of over the frequency range 128 to 4096 Hz or 256 to 1021 Hz.[6][7] This method is valuable at comparing homogeneous partitions that follow the mass law, but can be misleading when comparing complex or multi-leaf walls.

In 1961, the ASTM International Standards Organization adopted E90-61T, which served as the basis for the STC method used today. The STC standard curve is based on European studies of multi-family residential construction, and closely resembles the sound isolation performance of a 9"-thick brick wall.[8]

3.2. Current

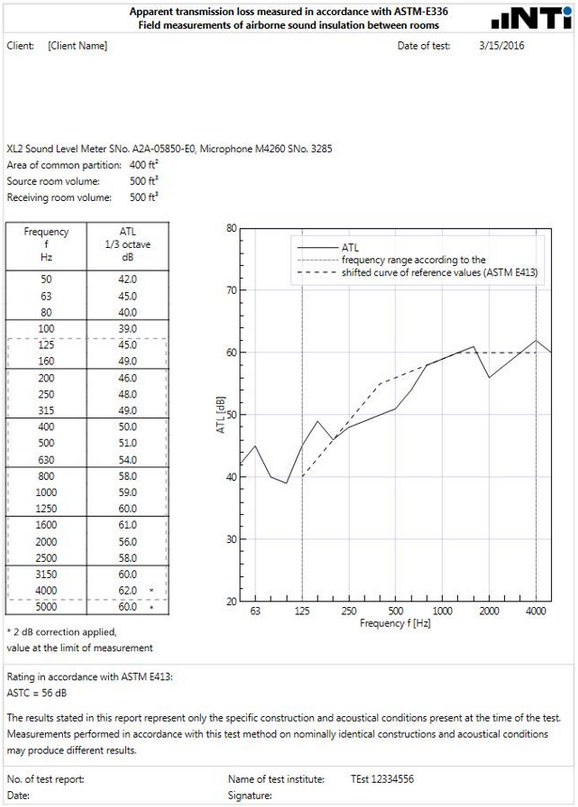

The STC number is derived from sound attenuation values tested at sixteen standard frequencies from 125 Hz to 4000 Hz. These Transmission Loss values are then plotted on a sound pressure level graph and the resulting curve is compared to a standard reference contour provided by the ASTM.[9]

Sound isolation metrics, such as the STC, are measured in specially-isolated and designed laboratory test chambers. There are nearly infinite field conditions that will affect sound isolation on site when designing building partitions and enclosures.

4. Factors Affecting Sound Transmission Class

4.1. Acoustic Medium

Sound travels through both the air and structure, and both paths must be considered when designing sound isolating walls and ceilings. To eliminate air borne sound all air paths between the areas must be eliminated. This is achieved by making seams airtight and closing all sound leaks. To eliminate structure-borne noise one must create isolation systems that reduce mechanical connections between those structures.[10]

4.2. Mass

Adding mass to a partition reduces the transmission of sound. This is often achieved by adding additional layers of gypsum. It is preferable to have non symmetrical leaves, for example with different thickness gypsum.[11] The effect of adding multiple layers of gypsum wallboard to a frame also varies depending on the framing type and configuration.[12] Doubling the mass of a partition does not double the STC, as the STC is calculated from a non-linear decibel sound transmission loss measurement.[13] So, whereas installing an additional layer of gypsum wallboard to a light-gauge (25-ga. or lighter) steel stud partition will result in about a 5 STC-point increase, doing the same on single wood or single heavy-gauge steel will result in only 2 to 3 additional STC points.[12] Adding a second additional layer (to the already 3-layer system) does not result in as drastic an STC change as the first additional layer.[14] The effect of additional gypsum wallboard layers on double- and staggered-stud partitions is similar to that of light-gauge steel partitions.

Due to increased mass, poured concrete and concrete blocks typically achieve higher STC values (in the mid STC 40s to the mid STC 50s) than equally thick framed walls.[15] However the additional weight, added complexity of construction, and poor thermal insulation tend to limit masonry wall partitions as a viable sound isolation solution in many building construction projects.

In recent years, gypsum board manufacturers have started to offer lightweight drywall board: Normal weight gypsum has a nominal density of 43pcf and lightweight drywall has a nominal density of 36pcf. This does not have a large effect on the STC rating, though lightweight gypsum can significantly degrade the low frequency performance of a partition as compared to normal weight gypsum.

4.3. Sound Absorption

Sound absorption entails turning acoustical energy into some other form of energy, usually heat.[16]

Adding absorptive materials to the interior surfaces of rooms, for example fabric-faced fiberglass panels and thick curtains, will result in a decrease of reverberated sound energy within the room. However, absorptive interior surface treatments of this kind do not significantly improve the sound transmission class.[17] Installing absorptive insulation, for example fiberglass batts and blow-in cellulose, into the wall or ceiling cavities does increase the sound transmission class significantly.[14] The presence of insulation in single 2x4 wood stud framing spaced 16" (406 mm) on-center results in only a few STC points. This is because a wall with 2x4 wood stud framing spaced 16" develops significant resonances which are not mitigated by the cavity insulation. In contrast, adding standard fiberglass insulation to an otherwise empty cavity in light-gauge (25-gauge or lighter) steel stud partitions can result in a nearly 10 STC-point improvement.

Other studies have shown that fibrous insulation materials, such as glassfiber or mineral wool, can increase the STC by 5 to 8 points.[11]

4.4. Stiffness

The effect of stiffness on sound isolation can relate to either the material stiffness of the sound isolating material or the stiffness caused by framing methods.

Framing Methods

Structurally decoupling the gypsum wallboard panels from the partition framing can result in a large increase in sound isolation when installed correctly. Examples of structural decoupling in building construction include resilient channels, sound isolation clips and hat channels, and staggered- or double-stud framing. The STC results of decoupling in wall and ceiling assemblies varies significantly depending on the framing type, air cavity volume, and decoupling material type.[18] Great care must be taken in each type of decoupled partition construction, as any fastener that becomes mechanically (rigidly) coupled to the framing can short-circuit the decoupling and result in drastically lower sound isolation results.[19]

When two leaves are rigidly tied or coupled by a stud, the sound isolation of the system depends on the stiffness of the stud. Light-gauge (25-gauge or lighter) provides better sound isolation than 16-20-gauge steel, and noticeably better performance than wood studs.[20] When heavy gauge steel or wood studs are spaced 16" on center, additional resonances form which further lower the sound isolation performance of a partition. For typical gypsum stud walls, this resonance occurs in the 100–160 Hz region and is thought to be a hybrid of the mass-air-mass resonance and a bending mode resonance caused when a plate is closely supported by stiff members.[21]

Single metal stud partitions are more effective than single wood stud partitions, and have been shown to increase the STC rating by up to 10 points. However, there is little difference between metal and wood studs when used in double stud partitions.[11] Double stud partitions have a higher STC than single stud.[11]

In certain assemblies, increasing the stud spacing from 16 to 24 inches increases the STC rating by 2 to 3 points.[11]

4.5. Damping

Though the terms sound absorption and damping are often interchangeable when discussing room acoustics, acousticians define these as two distinct properties of sound-isolating walls.

Several gypsum manufacturers offer specialty products which use constrained layer damping, which is a form viscous damping.[22][23] Damping generally increase the sound isolation of partitions, particularly at mid-and-high frequencies.

Damping is also used to improve the sound isolation performance of glazing assemblies. Laminated glazing, which consists of a Polyvinyl butyral (or PVB) inter-layer, performs better acoustically than a non-laminated glass of equivalent thickness.[24]

4.6. Sound Leakage

All holes and gaps should be filled and the enclosure hermetically sealed for sound isolation to be effective. The table below illustrates sound proofing test results from a wall partition that has a theoretical maximum loss of 40 dB from one room to the next and a partition area of 10 meters squared. Even small open gaps and holes in the partition have a disproportionate reduction in sound proofing. A 5% opening in the partition, which offers unrestricted sound transmission from one room to the next, caused the transmission loss to reduces from 40 dB to 13 dB. A 0.1% open area will reduce the transmission loss from 40 dB to 30 dB, which is typical of walls where caulking has not been applied effectively[25] Partitions that are inadequately sealed and contain back-to-back electrical boxes, untreated recessed lighting and unsealed pipes offer flanking paths for sound and significant leakage.[26]

Acoustic joint tapes and caulking have been used to improve sound isolation since the early 1930s.[27] Although the applications of tapes was largely limited to defense and industrial applications such as naval vessels and aircraft in the past, recent research has proven the effectiveness of sealing gaps and thereby improving the sound isolation performance of a partition.[28]

| Transmission loss | % of area open |

|---|---|

| 13 dB loss | 5% open |

| 17 dB loss | 2% open |

| 20 dB loss | 1% open |

| 23 dB loss | 0.5% open |

| 27 dB loss | 0.2% open |

| 30 dB loss | 0.1% open |

| 33 dB loss | 0.05% open |

| 37 dB loss | 0.02% open |

| 39.5 dB loss | Practical maximum loss |

| 40 dB loss | Theoretical maximum loss |

4.7. Flanking

Building codes typically allow for a 5-point tolerance between the lab-tested and field-measured STC rating; however, studies have shown that even in well-built and sealed installations the difference between the lab and field rating is highly dependent on the type of assembly.[29]

5. Special Variations of STC

By nature, the STC rating is derived from lab testing under ideal conditions. There are other versions of the STC rating to account for real-world conditions.

5.1. Composite STC

The net sound isolation performance of a wall containing multiple sound isolating elements such as doors, windows, etc.

5.2. Apparent Sound Transmission Class (ASTC)

The sound isolation performance of a wall measured in the field, normalized to account for different room finishes (i.e. compare the same wall measured in a bare living room and an acoustically dry recording booth).

5.3. Field Sound Transmission Class (FSTC)

The sound isolation performance of a specific elements in a wall, as measured in the field. This can be useful for measuring walls with doors, when you are interested in removing the influence of the door on the measured field STC.

5.4. Door Sound Transmission Class (DTC)

The sound isolation performance of doors when measured according to ASTM E2964 – 19.[30]

6. Legal and Practical Requirements

Section 1207 of International Building Code 2006 states that separation between dwelling units and public and service areas must achieve STC 50 (STC 45 if field tested) for both airborne and structure-borne. However, not all jurisdictions use the IBC 2006 for their building or municipal code. In jurisdictions where IBC 2006 is used, this requirement may not apply to all dwelling units.

7. Common Partition STC

Interior walls with 1 sheet of 1/2″ (13 mm) gypsum wallboard (drywall) on either side of 2x4 (90 mm) wood studs spaced 16" (406 mm) on-center with no fiberglass insulation filling each stud cavity have an STC of about 33.[31] When asked to rate their acoustical performance, people often describe these walls as "paper thin." They offer little in the way of privacy. Double stud partition walls are typically constructed with varying gypsum wallboard panel layers attached to both sides of double 2x4 (90 mm) wood studs spaced 16" (406 mm) on-center and separated by a 1" (25 mm) airspace. These walls vary in sound isolation performance from the mid STC-40s into the high STC-60s depending on the presence of insulation and the gypsum wallboard type and quantity.[14] Commercial buildings are typically constructed using steel studs of varying widths, gauges, and on-center spacings. Each of these framing characteristics have an effect on the sound isolation of the partition to varying degrees.[32]

| STC | Partition type |

|---|---|

| 27 | Single pane glass window (typical value) (Dual pane glass window range is 26–32)"STC Ratings". http://www.soundproofwindows.com/stc-ratings/. |

| 33 | Single layer of 1/2″ drywall on each side, wood studs, no insulation (typical interior wall) |

| 39 | Single layer of 1/2″ drywall on each side, wood studs, fiberglass insulation [33] |

| 44 | 4″ Hollow CMU (Concrete Masonry Unit) [34] |

| 45 | Double layer of 1/2″ drywall on each side, wood studs, batt insulation in wall |

| 46 | Single layer of 1/2″ drywall, glued to 6″ lightweight concrete block wall, painted both sides |

| 46 | 6″ Hollow CMU (Concrete Masonry Unit) [34] |

| 48 | 8″ Hollow CMU (Concrete Masonry Unit) [34] |

| 50 | 10″ Hollow CMU (Concrete Masonry Unit) [34] |

| 52 | 8″ Hollow CMU (Concrete Masonry Unit) with 2″ Z-Bars and 1/2″ Drywall on each side [35] |

| 54 | Single layer of 1/2″ drywall, glued to 8″ dense concrete block wall, painted both sides |

| 54 | 8″ Hollow CMU (Concrete Masonry Unit) with 1 1/2″ Wood Furring, 1 1/2″ Fiberglass Insulation and 1/2″ Drywall on each side [35] |

| 55 | Double layer of 1/2″ drywall on each side, on staggered wood stud wall, batt insulation in wall |

| 59 | Double layer of 1/2″ drywall on each side, on wood stud wall, resilient channels on one side, batt insulation |

| 63 | Double layer of 1/2″ drywall on each side, on double wood/metal stud walls (spaced 1″ apart), double batt insulation |

| 64 | 8″ Hollow CMU (Concrete Masonry Unit) with 3″ Steel Studs, Fiberglass Insulation and 1/2″ Drywall on each side [35] |

| 72 | 8″ concrete block wall, painted, with 1/2″ drywall on independent steel stud walls, each side, insulation in cavities |

8. STC Prediction

There are several commercially available software which predict the STC ratings of partitions using a combination of theoretical models and empirically-derived lab data. These programs can predict STC ratings within several points of a tested partition and are an approximation at best.[36]

9. Outdoor-Indoor Transmission Class (OITC)

The Outdoor–Indoor Transmission Class (OITC) is a standard used for indicating the rate of sound transmission from outdoor noise sources into a building. It is based on the ASTM E-1332 Standard Classification for Rating Outdoor-Indoor Sound Attenuation.[37] Unlike the STC, which is based on a noise spectrum targeting speech sounds, OITC uses a source noise spectrum that considers frequencies down to 80 Hz (aircraft/rail/truck traffic) and is weighted more to lower frequencies. The OITC value is typically used to rate, evaluate, and select exterior glazing assemblies.

References

- Ballou 2008, p. 72.

- Hopkins, Carl. (2016). Sound insulation.. Routledge. ISBN 978-1-138-13770-7. OCLC 933449409. http://www.worldcat.org/oclc/933449409

- Berendt, Raymond D. (1967). A guide to airborne, impact, and structure borne noise-control in multifamily dwellings. U.S. Dept. of Housing and Urban Development. OCLC 5863574. http://www.worldcat.org/oclc/5863574

- Bradley, J. S. (August 2001). "Deriving Acceptable Values for Party Wall Sound Insulation from Survey Results". The 2001 International Congress and Exhibition on Noise Control Engineering. The Hague, The Netherlands.

- Cavanaugh, W. J.; Farrell, W. R.; Hirtle, P. W.; Watters, B. G. (April 1962). "Speech Privacy in Buildings". The Journal of the Acoustical Society of America 34 (4): 475–492. doi:10.1121/1.1918154. ISSN 0001-4966. Bibcode: 1962ASAJ...34..475C. https://dx.doi.org/10.1121%2F1.1918154

- Knudsen, Vern O. (1988). Acoustical designing in architecture. Acoustical Society of America. ISBN 0-88318-267-X. OCLC 758181173. https://archive.org/details/acousticaldesign0000knud_n9x0.

- Chrisler, V. L. (1939). Sound insulation of wall and floor constructions. U.S. G.P.O.. OCLC 14104628. http://www.worldcat.org/oclc/14104628

- Northwood, T. D. (April 1962). "Sound‐Insulation Ratings and the New ASTM Sound‐Transmission Class". The Journal of the Acoustical Society of America 34 (4): 493–501. doi:10.1121/1.1918155. ISSN 0001-4966. Bibcode: 1962ASAJ...34..493N. https://dx.doi.org/10.1121%2F1.1918155

- Ballou 2008, pp. 72–73.

- Ballou 2008, p. 89.

- Ballou, Glen, editor. (2015-03-05). Handbook for sound engineers. ISBN 978-1-135-01665-4. OCLC 913880162. http://www.worldcat.org/oclc/913880162

- NRC IRC IR-761, http://archive.nrc-cnrc.gc.ca/obj/irc/doc/pubs/ir/ir761/ir761.pdf and Sound and Vibration Magazine March 2010, http://www.sandv.com/downloads/1003beti.pdf

- ASTM E413 Classification for Rating Sound Insulation, https://www.astm.org/Standards/E413.htm

- NRC IRC IR-761, http://archive.nrc-cnrc.gc.ca/obj/irc/doc/pubs/ir/ir761/ir761.pdf

- NRC IRC BRN-217, CiteSeerx: 10.1.1.5.8583 http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.5.8583

- Ballou 2008, p. 97.

- Brown, Steven M.; Niedzielski, Joseph; Spalding, G. Robert (1978). "Effect of sound‐absorptive facings on partition airborne‐sound transmission loss". The Journal of the Acoustical Society of America 63 (6): 1851–1856. doi:10.1121/1.381924. Bibcode: 1978ASAJ...63.1851B. https://dx.doi.org/10.1121%2F1.381924

- NRC IRC-IR 761, http://archive.nrc-cnrc.gc.ca/obj/irc/doc/pubs/ir/ir761/ir761.pdf

- LoVerde and Dong, Proceedings of 20th ICA 2010, https://www.acoustics.asn.au/conference_proceedings/ICA2010/cdrom-ICA2010/papers/p221.pdf

- Halliwell, R. E. (1998). Gypsum board walls : transmission loss data. Institute for Research in Construction. OCLC 155721225. http://www.worldcat.org/oclc/155721225

- Davy, John L.; Fard, Mohammad; Dong, Wayland; Loverde, John (February 2019). "Empirical corrections for predicting the sound insulation of double leaf cavity stud building elements with stiffer studs". The Journal of the Acoustical Society of America 145 (2): 703–713. doi:10.1121/1.5089222. ISSN 0001-4966. PMID 30823783. Bibcode: 2019ASAJ..145..703D. https://dx.doi.org/10.1121%2F1.5089222

- Shafer, Benjamin M.; Tinianov, Brandon (October 2011). "Use of damped drywall in architectural acoustics". The Journal of the Acoustical Society of America 130 (4): 2388. doi:10.1121/1.3654567. ISSN 0001-4966. Bibcode: 2011ASAJ..130R2388S. https://dx.doi.org/10.1121%2F1.3654567

- Tinianov, Brian D. (September 2005). "Two case studies: QuietRock QR‐530 drywall panels in new and remediated multifamily construction". The Journal of the Acoustical Society of America 118 (3): 1976. doi:10.1121/1.2097073. ISSN 0001-4966. https://dx.doi.org/10.1121%2F1.2097073

- Monsanto Company. (1986). Acoustical glazing design guide : laminated glass with Saflex plastic interlayer for superior sound control.. Monsanto Company. OCLC 38400395. http://www.worldcat.org/oclc/38400395

- Ballou 2008, pp. 77–78.

- "Archived copy". http://www.nrc-cnrc.gc.ca/eng/ibp/irc/bsi/85-accoustics.html. Acoustics in Practice

- Shafer, Benjamin M. (2013). "An overview of constrained-layer damping theory and application". Acoustical Society of America Journal. Proceedings of Meetings on Acoustics 133 (5): 065023. doi:10.1121/1.4800606. Bibcode: 2013ASAJ..133.3332S. https://dx.doi.org/10.1121%2F1.4800606

- Shafer, Benjamin M.; Tinianov, Brandon (2011). "Use of damped drywall in architectural acoustics". The Journal of the Acoustical Society of America 130 (4): 2388. doi:10.1121/1.3654567. Bibcode: 2011ASAJ..130R2388S. https://dx.doi.org/10.1121%2F1.3654567

- LoVerde, John; Dong, Wayland (2010). "Predictability of field airborne noise isolation from laboratory testing.". The Journal of the Acoustical Society of America 127 (3): 1741. doi:10.1121/1.3383509. ISSN 0001-4966. Bibcode: 2010ASAJ..127.1741L. https://dx.doi.org/10.1121%2F1.3383509

- Test Method for Measurement of the Normalized Insertion Loss of Doors, ASTM International, doi:10.1520/e2964-14 https://dx.doi.org/10.1520%2Fe2964-14

- NRC IRC IR-761, https://nrc-publications.canada.ca/eng/view/fulltext/?id=04ac8069-a5d2-4038-8787-da064b073e7f

- Sound and Vibration Magazine, March 2010, http://www.sandv.com/downloads/1003beti.pdf

- The Complete Photo Guide to Home Improvement. Creative Publishing international. July 2001. p. 194. ISBN 9780865735804. https://archive.org/details/completephotogui00crea. Retrieved 2011-10-01. "The Complete Photo Guide to Home Improvement."

- "STC RATINGS FOR MASONRY WALLS". Acoustics.com. http://www.stcratings.com/masonry.html. Retrieved 2011-10-01.

- "New Data Shows Masonry Wall and Precast Hollow Core Floor Systems Reaching High STC Ratings". Masonry Advisory Council. http://www.maconline.org/tech/materials/sswalls.pdf. Retrieved 2011-10-01.

- Horan, Daniel (2014). "Computer Modeling of STC- Options and Accuracy". Sound & Vibration (December): 8–11. http://www.cavtocci.com/wp-content/uploads/2015/02/1412hora.pdf.

- ASTM E1332-16 (2016). "Standard Classification for Rating Outdoor-Indoor Sound Attenuation". Conshohocken, PA: ASTM International. https://www.astm.org/Standards/E1332.htm.