Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Yaroslav Blikharskyy | -- | 1442 | 2022-10-18 22:34:06 | | | |

| 2 | Catherine Yang | Meta information modification | 1442 | 2022-10-19 02:51:46 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Blikharskyy, Y.; Kopiika, N.; Khmil, R.; Selejdak, J.; Blikharskyy, Z. Digital Image Correlation Methodology Evolution. Encyclopedia. Available online: https://encyclopedia.pub/entry/29971 (accessed on 07 February 2026).

Blikharskyy Y, Kopiika N, Khmil R, Selejdak J, Blikharskyy Z. Digital Image Correlation Methodology Evolution. Encyclopedia. Available at: https://encyclopedia.pub/entry/29971. Accessed February 07, 2026.

Blikharskyy, Yaroslav, Nadiia Kopiika, Roman Khmil, Jacek Selejdak, Zinoviy Blikharskyy. "Digital Image Correlation Methodology Evolution" Encyclopedia, https://encyclopedia.pub/entry/29971 (accessed February 07, 2026).

Blikharskyy, Y., Kopiika, N., Khmil, R., Selejdak, J., & Blikharskyy, Z. (2022, October 18). Digital Image Correlation Methodology Evolution. In Encyclopedia. https://encyclopedia.pub/entry/29971

Blikharskyy, Yaroslav, et al. "Digital Image Correlation Methodology Evolution." Encyclopedia. Web. 18 October, 2022.

Copy Citation

Reliable assessment and prediction of the technical condition of reinforced concrete structures require accurate data of the stress–strain state of the structure at all stages of loading. The most appropriate technique to obtain such information is digital image correlation. Digital image correlation is a class of contactless methods which includes the following stages: obtaining an image from a studied physical object, saving it in digital form, and further analysis in order to obtain the necessary information about the stress–strain state of the structure.

digital image correlation

structure performance

stress–strain state

1. General Review

Digital image correlation has come through multistage development and evolution, until reaching the form of high-precision technology, which is widely used today. A detailed analysis of the historical background of measurement methods based on image analysis is presented in studies of [1][2][3][4].

The early measurement methods, which were further developed in the DIC-concept, were discussed by Doyle [3] and Gruner [4]. The historical background of modern measurement methods based on image analysis date back to the writings of Leonardo da Vinci in 1480–1492. Most of the works during the following three centuries were dedicated to formulating mathematical principles and algorithms. Specifically, the work of Heinrich Lambert (The Free Perspective, 1759), which had the greatest impact on photography science, should be highlighted. The first practical implementation was performed by Daguerre in 1837 [1]. Afterwards, the photographic methods sparked wide interest in scientific research. Konecny [5] proposed dividing the field of photogrammetry into four different phases: plane photogrammetry (1850–1900), analog photogrammetry (1900–1950), analytical photogrammetry (1950–1985) and digital photogrammetry (1985–present).

During these four stages, the photogrammetric theoretical approaches obtained mathematical representation. Thus, Sturms and Haick in 1883 proposed transition algorithms between projective geometry and perspective imaging [1]. Among the most fundamental contributions of this period are the fundamental geometry of photogrammetry by Sebastian Finsterwald (1899) and projective equations for stereo-imaging which are fundamental to the analytical phase, developed by Otto von Gruber (1924) [1]. Earl Church is known as the author of analytical solutions to the equations of photogrammetry in terms of direction cosines (1945). In addition, Schreier et al. [1] highlighted the research of Dr. Hellmut Schmid (1953), which initiated the development of modern multi-station analytical photogrammetry using matrix notation, and studied the issue of error propagation and reduction.

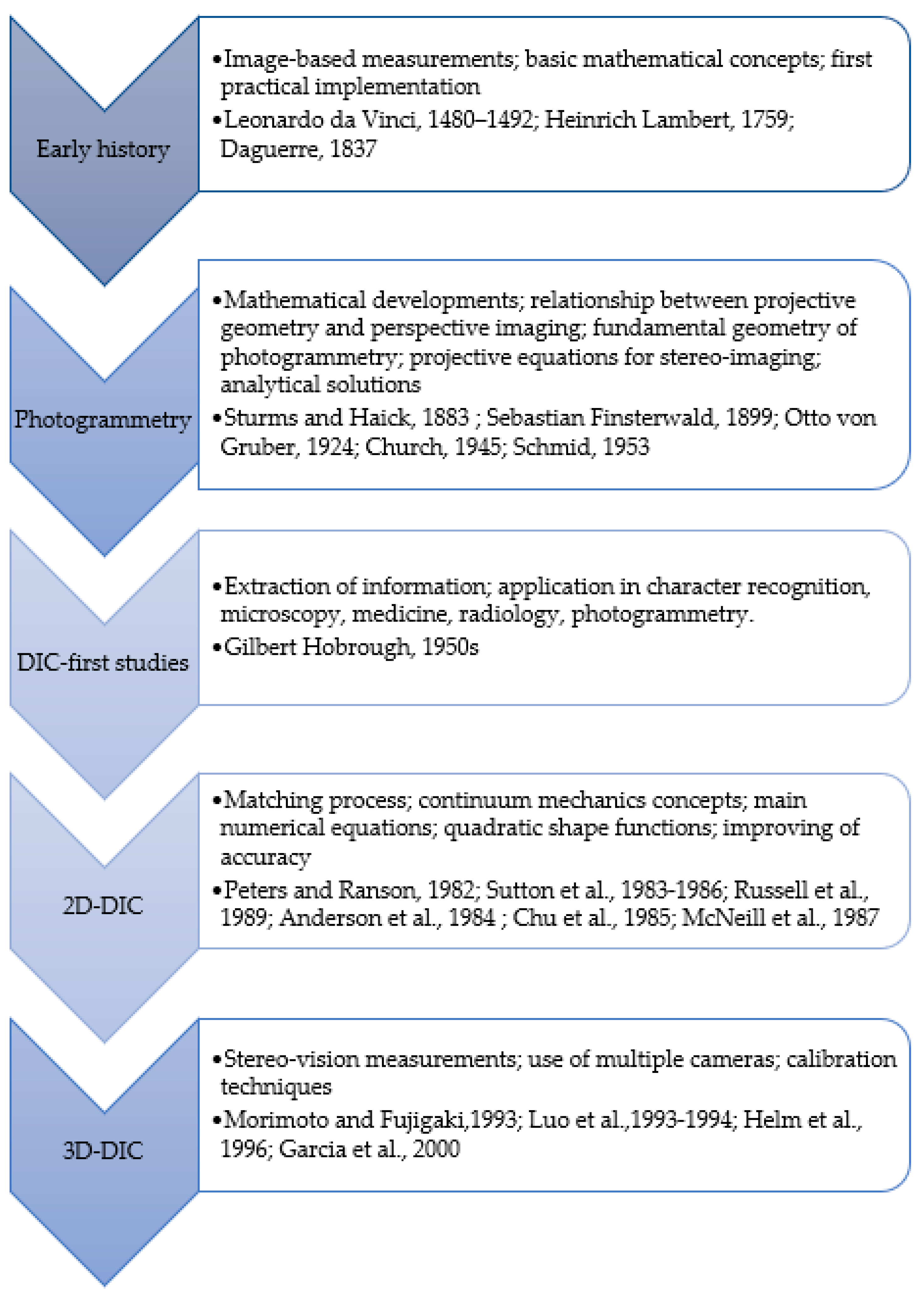

The general scheme of DIC-method evolution, indicating the main stages and contributions is shown on Figure 1.

Figure 1. Evolution of DIC concept [1].

2. First Studies on Digital Image Correlation

Most of the studies of this early period were dedicated to extracting 3D information of objects through comparison of photographic records [1]. One of the first works dedicated to image correlation could be assigned to Gilbert Hobrough, who in the early 1950s analyzed the specifics of different points of view by comparing analog presentation of photographs, thus becoming one of the first scientists who made an attempt to extract positional information from the image correlation and introduced the matching process [6]. Extensive analysis of DIC technology from 1955 to 1979, conducted by Rosenfeld [7], identified its application in character recognition, microscopy, medicine, radiology and photogrammetry, whereas DIC usage for engineering issues during these years was rather rare [1][7]. Nevertheless, experimental approaches in solid mechanics were rapidly developing toward methods of holography, laser spectral photography and interferometry, which caused significant evolution in coherent light sources’ measurement technologies [6]. The difficulties, thus, evolved in nonlinearity of the recording process and complexity in information extracting.

3. 2D-DIC—From Early Research Till Today

The next stage of optical method development was to the formulation of the main principles for digitally recording images containing measurement data. In addition, algorithms for analyzing digital images and extracting data with high precision were proposed [1].

Among authors who worked on computer-based image processing techniques were Peters and Ranson in 1982 [8], who proposed to use to ultrasonic waves and their reflection before and after loading, thus obtaining full-field digital “images”. In addition, the idea of “matching process” was presented, using continuum mechanics concepts to indicate deformations in small areas.

An important step towards developing the optical method, known today as 2D-digital image correlation (2D-DIC) was made by Sutton et al. in 1983 [9]. They developed main numerical equations and experimentally confirmed the feasibility to use this technique in engineering issues. Sutton et al. in later work (1986 [10]) also proposed using gradient search methods in order to increase the accuracy of subset-matching. Among the authors who studied the possibility of DIC for various engineering issues are Anderson et al. [11] and Chu et al. [12]. Thus, it was shown that the correlation technique provides reliable accuracy for planar translations, rotations and deformations of solid bodies [11][12]. During the 1980s, scientific interest in DIC methodology rapidly increased, and theoretical approaches and procedures were validated, updated and modified. Russell et al. [13] in 1989 combined X-ray radiography and the DIC-method in order to measure internal deformation in composite material and study transverse strain fields [1]. The 1990s was the decade of scientific research on the possibility to measure surface deformations in planar components. For example, cracking processes were studied by McNeill et al. [14] in term of stress intensity factor determination. In addition, the use of image correlation enables tracking the local crack tip plastic zone, caused by “three-dimensional effects” [15].

Further development of the method was conducted by Lyons [16] and Liu et al. [17], who researched the stress–strain state with the use of DIC at high temperature. In addition, according to [1], this period could be characterized by increased interest in DIC to study fracture performance in various materials: metals [18][19][20], plastics [21][22], wood [23] and ceramics [24]. Among the later works are articles by Choi and Shah [25][26], where the concrete was studied and works [27][28], which provided detailed investigations of composites.

Since 2000, the DIC technique has extended to a wide range of engineering issues and tasks. Thus, a great number of research works were conducted, dedicated to improving the matching process accuracy during image recognition. For example, higher order spline interpolation functions were proposed by Schreier et al. in [29]. The same assumptions and propositions were made by Lu and Cary [30], as well as by Schreier and Sutton [31]. Authors in [30][31] noted the applicability of quadratic shape functions for study of non-uniform strain fields [1]. In addition, the investigation of Réthoré et al. [32][33] focused on development of “extended 2D-DIC”, the methodology combining the analytical FEM model and high-precision results, obtained with the use of image correlation

Simultaneously, another area of scientific interest of this period included studies of mechanical properties of materials: elastic [34][35] and hyperelastic properties [36], as well as the properties on a microscale [37].

4. 3D-DIC, the Complex Approach to Image Processing

Additional attention should be paid to development of the 3D-DIC method, which provided the possibility of shape and motion measurements. In the case of plane measurements conducted with 2D-DIC, the accuracy of the results can significantly decrease because of even a small out-of-plane motion and curvature effects. This factor had a great impact on estimated deformation results. and from the 1970s to the 1990s, studies examined stereo-vision measurements and the use of multiple cameras.

The application of multiple cameras with subsequent increased accuracy was proven in the works of Morimoto and Fujigaki [38] and Luo et al. [39][40]. Thus, the efficiency of deforming a rectangular grid and FFT methods was confirmed [38]. In addition, as shown by Luo et al. [39][40], two-camera stereo vision is the appropriate method for three-dimensional measurements of the cracking process.

It is necessary to note certain limitations of the 3D-DIC methodologies of the described period [1]. There were motions in calibration process due to manual components and cases of triangulation mismatching, and the square subsets in both cameras remained square. Remarkably, Helm et al. [41] proposed using a specific grid for motion calibration and introduced appropriate constraints to take into account the presence of epipolar lines. In addition, the method included the effect of perspective on subset shape [1][41].

Specific interest was paid to calibration techniques. For example, Devy et al. [42] proposed representing accurate calculation of differences between the model-based and actual measured image plane locations through the squared reprojection errors’ sum which was an influential factor for 3D calibration. In addition, the author in [42] introduced a number of internal and external correction parameters.

A rather remarkable approach was proposed by Lavest et al. [43], who turned back to photogrammetry methods, noting the bundle adjustment was a promising flexible calibration technique, providing accurate results. The same approach was discussed in the work of Garcia et al. [44], who improved the method by changing the number of constraints and reducing the family of calibration parameter solutions. In studies of this period, an important step was the extension of the single camera calibration method to the case of a stereo-camera system. In general, it was identified that the important feature of a reliable calibration procedure is comprehensive consideration of the camera system, rather than separately, which was an important stage in the process of 3D-DIC development.

References

- Schreier, H.; Orteu, J.J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer Science & Business Media: New York, NY, USA, 2009; 322p.

- Vegera, P.; Vashkevych, R.; Blikharskyy, Y.; Khmil, R. Development Methodology of Determinating Residual Carrying Capacity of Reinforced Concrete Beams with Damages Tensile Reinforcement which Occurred During Loading. East. -Eur. J. Enterp. Technol. 2021, 4, 6–17.

- Doyle, F. The historical development of analytical photogrammetry. Photogramm. Eng. 1964, 30, 259–265.

- Gruner, H. Reinhard Hugershoff. Photogramm. Eng. 1971, 37, 939–947.

- Konecny, G. The international society for photogrammetry and remote sensing—75 years old, or 75 years young. Photogramm. Eng. Remote Sens. 1985, 51, 919–933.

- Hobrough, G.L. The Photogrammetric Record; John Wiley & Sons: Hoboken, NJ, USA, 2003; Volume 18, pp. 337–340.

- Rosenfeld, A. From image analysis to computer vision: An annotated bibliography, 1955–1979. Comput. Vis. Image Underst. 2001, 84, 298–324.

- Peters, W.H.; Ranson, W.F. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 427–431.

- Sutton, M.A.; Wolters, W.J.; Peters, W.H.; Ranson, W.F.; McNeill, S.R. Determination of displacements using an improved digital correlation method. Image Vis. Comput. 1983, 1, 133–139.

- Sutton, M.A.; Cheng, M.Q.; Peters, W.H.; Chao, Y.J.; McNeill, S.R. Application of an optimized digital correlation method to planar deformation analysis. Image Vis. Comput. 1986, 4, 143–150.

- Anderson, J.; Peters, W.H.; Sutton, M.A.; Ranson, W.F.; Chu, T.C. Application of digital correlation methods to rigid body mechanics. Opt. Eng. 1983, 22, 738–742.

- Chu, T.C.; WFRanson, W.F.; Sutton, M.A.; Peters, W.H. Applications of digital-image correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244.

- Russell, S.S.; Sutton, M.A.; Chen, H.S. Image correlation quantitative NDE of impact and fabrication damage in a glass fiber reinforced composite system. J. Mater. Eval. 1989, 47, 550–561.

- McNeill, S.R.; Peters, W.H.; Sutton, M.A. Estimation of stress intensity factor by digital image correlation. Eng. Fract. Mech. 1987, 28, 101–112.

- Sutton, M.A.; Turner, J.L.; Chao, Y.J.; Bruck, H.A.; Chae, T.L. Experimental investigations of three-dimensional effects near a crack tip using computer vision. Int. J. Fract. 1992, 53, 201–228.

- Lyons, J.S.; Liu, J.; Sutton, M.A. High-temperature deformation measurements using digital-image correlation. Exp. Mech. 1996, 36, 64–70.

- Liu, J.; Sutton, M.A.; Lyons, J.S. Experimental characterization of crack tip deformations in alloy 718 at high temperatures. ASME J. Eng. Mater. Technol. 1998, 120, 71–78.

- Dai, Y.Z.; Tay, C.J.; Chiang, F.P. Determination of the plastic zone by laser-speckle correlation. Exp. Mech. 1991, 31, 348–352.

- Tong, W. Strain characterization of propagative deformation bands. J. Mech. Phys. Solids 1998, 46, 2087–2102.

- Tong, W. Detection of plastic deformation patterns in a binary aluminum alloy. Exp. Mech. 1997, 37, 452–459.

- Umezaki, E.; Futase, K. Deformation behaviour of the cross-section of a heat-sealed area in plastic film used for liquid package bags. J. Strain Anal. Eng. Des. 1997, 32, 29–35.

- Lu, H.; Zhang, X.; Knauss, W.G. Uniaxial, shear, and poisson relaxation and their conversion to bulk relaxation: Studies on polymethyl methacrylate. Polym. Compos. 1997, 18, 211–222.

- Zink, A.G.; Davidson, R.W.; Hanna, R.B. Strain measurement in wood using a digital image correlation technique. Wood Fiber Sci. 1995, 27, 346–359.

- Coburn, D.; Slevin, J.A. Development of a digital speckle correlation system for use in the non-destructive testing of advanced engineering ceramics. Key Eng. Mater. 1993, 86, 237–244.

- Choi, S.; Shah, S.P. Measurement of deformations on concrete subjected to compression using image correlation. Exp. Mech. 1997, 37, 307–313.

- Choi, S.; Shah, S.P. Fracture mechanism in cement-based materials subjected to compression. J. Eng. Mech. 1998, 124, 94–102.

- Gonzalez, J.; Knauss, W.G. Strain inhomogeneity and discontinuous crack growth in a particulate composite. J. Mech. Phys. Solids 1998, 46, 1981–1995.

- Ha, K.; Schapery, R.A. A three-dimensional viscoelastic constitutive model for particulate composites with growing damage and its experimental validation. Int. J. Solids Struct. 1998, 35, 3497–3517.

- Schreier, H.W.; Braasch, J.; Sutton, M.A. Systematic errors in digital image correlation caused by intensity interpolation. Opt. Eng. 2000, 39, 2915–2921.

- Lu, H.; Cary, D. Deformation measurements by digital image correlation: Implementation of a second-order displacement gradient. Exp. Mech. 2000, 40, 393–400.

- Schreier, H.W.; Sutton, M.A. Systematic errors in digital image correlation due to undermatched subset shape functions. Exp. Mech. 2002, 42, 303–310.

- Réthoré, J.; Hild, F.; Roux, S. Shear-band capturing using a multiscale extended digital image correlation technique. Comput. Methods Appl. Mech. Eng. 2007, 196, 5016–5030.

- Réthoré, J.; Roux, S.; Hild, F. From pictures to extended finite elements: Extended digital image correlation (X-DIC). Comptes Rendus Mécanique 2007, 335, 131–137.

- Geymonat, G.; Hild, F.; Pagano, S. Identification of elastic parameters by displacement field measurement. Comptes Rendus Mécanique 2002, 330, 403–408.

- Lecompte, D.; Smits, A.; Sol, H.; Vantomme, J.; Hemelrijck, D. Van. Mixed numerical experimental technique for orthotropic parameter identification using biaxial tensile tests on cruciform specimens. Int. J. Solids Struct. 2007, 44, 1643–1656.

- Giton, M.; Caro-Bretelle, A.S.; Ienny, P. Hyperelastic behaviour identification by a forward problem resolution: Application to a tear test of a silicone-rubber. Strain 2006, 42, 291–297.

- Héripré, E.; Dexet, M.; Crépin, J.; Gélébart, L.; Roos, A.; Bornert, M.; Caldemaison, D. Coupling between experimental meaurements and polycrystal finite element calculations for micromechanical study of metallic materials. Int. J. Plast. 2007, 23, 1512–1539.

- Morimoto, Y.; Fujigaki, M. Automated analysis of 3-D shape and surface strain distributions of a moving object using stereo vision. Opt. Lasers Eng. 1993, 18, 195–212.

- Luo, P.F.; Chao, Y.J.; Sutton, M.A. Application of stereo vision to three-dimensional deformation analyses in fracture experiments. Opt. Eng. 1994, 33, 981–990.

- Luo, P.F.; Chao, Y.J.; Sutton, M.A.; Peters, W.H. Accurate measurement of three-dimensional deformations in deformable and rigid bodies using computer vision. Exp. Mech. 1993, 33, 123–132.

- Helm, Y.J.D.; McNeill, S.R.; Sutton, M.A. Improved three-dimensional image correlation for surface displacement measurement. Opt. Eng. 1996, 35, 1911–1920.

- Devy, M.; Garric, V.; Orteu, J.-J. Camera calibration from multiple views of a 2D object using a global non linear minimization method. In Proceedings of the International Conference on Intelligent Robots and Systems (IROS’97), Grenoble, France, 11 September 1997.

- Lavest, J.M.; Viala, M.; Dhome, M. Do we really need an accurate calibration pattern to achieve a reliable camera calibration? In Proceedings of the European Conference on Computer Vision, Frieburg, Germany, 2–6 June 1998; pp. 158–174.

- Garcia, D.; Orteu, J.-J.; Devy, M. Accurate calibration of a stereovision sensor: Comparison of different approaches. In Proceedings of the 5th Workshop on Vision, Modeling, and Visualization (VMV’2000), Saarbrücken, Germany, 22–24 November 2000; pp. 25–32.

More

Information

Subjects:

Engineering, Civil

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.6K

Revisions:

2 times

(View History)

Update Date:

19 Oct 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No