| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Beatrix Zheng | -- | 3988 | 2022-10-11 01:33:55 |

Video Upload Options

A flow battery, or redox flow battery (after reduction–oxidation), is a type of electrochemical cell where chemical energy is provided by two chemical components dissolved in liquids that are pumped through the system on separate sides of a membrane. Ion exchange (accompanied by flow of electric current) occurs through the membrane while both liquids circulate in their own respective space. Cell voltage is chemically determined by the Nernst equation and ranges, in practical applications, from 1.0 to 2.43 volts. A flow battery may be used like a fuel cell (where the spent fuel is extracted and new fuel is added to the system) or like a rechargeable battery (where an electric power source drives regeneration of the fuel). While it has technical advantages over conventional rechargeables, such as potentially separable liquid tanks and near unlimited longevity, current implementations are comparatively less powerful and require more sophisticated electronics. The energy capacity is a function of the electrolyte volume and the power is a function of the surface area of the electrodes.

1. Construction Principle

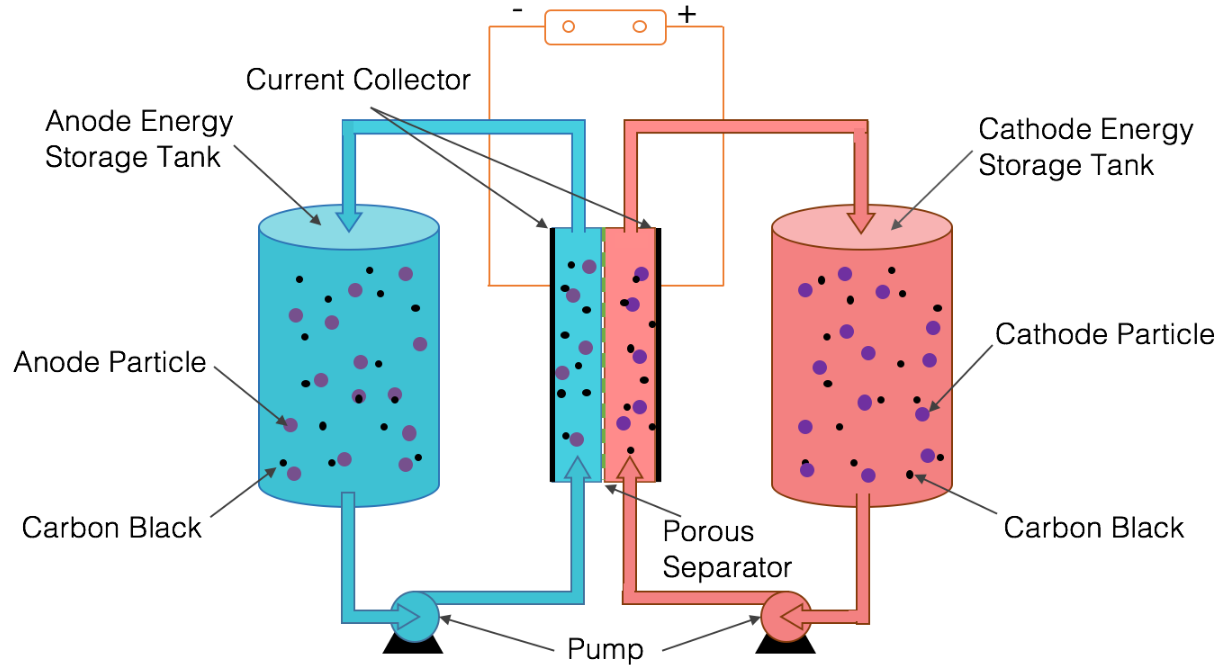

A flow battery is a rechargeable fuel cell in which an electrolyte containing one or more dissolved electroactive elements flows through an electrochemical cell that reversibly converts chemical energy directly to electricity. Electroactive elements are "elements in solution that can take part in an electrode reaction or that can be adsorbed on the electrode."[1] Additional electrolyte is stored externally, generally in tanks, and is usually pumped through the cell (or cells) of the reactor, although gravity feed systems are also known.[2] Flow batteries can be rapidly "recharged" by replacing the electrolyte liquid (in a similar way to refilling fuel tanks for internal combustion engines) while simultaneously recovering the spent material for recharging. Many flow batteries use carbon felt electrodes due to its low cost and adequate electrical conductivity, although these electrodes somewhat limit power density due to their low inherent activity towards many redox couples.[3][4]

In other words, a flow battery is an electrochemical cell, with the property that the ionic solution (electrolyte) is stored[5] outside of the cell (instead of in the cell around the electrodes) and can be fed into the cell in order to generate electricity. The total amount of electricity that can be generated depends on the volume of electrolyte in the tanks.

Flow batteries are governed by the design principles established by electrochemical engineering.[6]

2. Types

Various types of flow cells (batteries) have been developed, including inorganic flow battery[7] and organic flow batteries.[8] Under each category, flow battery design can be further classified into full flow batteries, semi-flow batteries, and membraneless flow batteries. The fundamental difference between conventional batteries and flow cells is that energy is stored in the electrode material in conventional batteries, while in flow cells it is stored in the electrolyte. Patent Classifications for Flow Batteries have not been fully developed as of 2021. Cooperative Patent Classification considers RFBs as a subclass of regenerative fuel cells (H01M8/18), even though it is more appropriate to consider fuel cells as a subclass of flow batteries.

2.1. Inorganic Flow Batteries

Inorganic full-flow RFBs

The redox (reduction–oxidation) cell is a reversible cell in which redox-active species are in fluid (liquid or gas) media. Redox flow batteries are rechargeable (secondary) cells.[9] Because they employ heterogeneous electron transfer rather than solid-state diffusion or intercalation they are more similar to fuel cells rather than to conventional batteries (such as lead-acid or lithium-ion). The main reason Fuel Cells are not considered to be batteries, is because originally (in the 1800's) fuel cells emerged as a means to produce electricity directly from fuels (and air) via a non-combustion electrochemical process. Later, particularly in the 1960's and 1990's, rechargeable fuel cells (i.e. H2/O2, such as unitized regenerative fuel cells in NASA's Helios Prototype) were developed.

Examples of redox flow batteries are the vanadium redox flow battery, polysulfide bromide battery (Regenesys), and uranium redox flow battery.[10] Redox fuel cells are less common commercially although many systems have been proposed.[11][12][13][14]

Vanadium redox flow batteries are the most marketed flow batteries at present, due to the advantages they provide over other chemistries, despite limited energy and power densities. Since they use vanadium at both electrodes, they do not suffer cross-contamination. The limited solubility of vanadium salts, however, offsets this advantage in practice. More importantly for the commercial success of VRFBs is actually an almost perfect match of the voltage window of carbon/aqueous acid interface with the working voltage range of the vanadium redox-couples. This assures the durability of the low-cost carbon electrodes and low-impact of side reactions, such as H2 and O2 evolutions, resulting in record-long calendar (many years) and cycle(15,000–20,000 cycles) lives, which in turn results in a record low levelized cost of energy (LCOE, i.e. the system cost divided by the usable energy, the cycle life, and round-trip efficiency). The long lifetimes of flow batteries allow for the amortization of their relatively high capital cost (due to vanadium, carbon felts, bipolar plates, membranes). The levelized cost of energy for VRFBs is in the order of a few tens of $ cents or € cents per kWh, much lower than of solid-state batteries and not so far from the targets of $0.05 and €0.05, stated by US and EC government agencies.[15] The major challenges for the broad implementation include: low abundance and high costs of V2O5 (> $30 / Kg), the raw materials for VRFB; parasite reactions including hydrogen and oxygen evolution; and precipitation of V2O5 during cycling. It is the major driving force to develop alternative flow battery technologies.

Traditional flow battery chemistries have both low specific energy (which makes them too heavy for fully electric vehicles) and low specific power (which makes them too expensive for stationary energy storage). However a high power of 1.4 W/cm2 was demonstrated for hydrogen-bromine flow batteries, and a high specific energy (530 Wh/kg at the tank level) was shown for hydrogen-bromate flow batteries[16][17][18]

Inorganic semi-flow RFBs

The hybrid flow battery uses one or more electroactive components deposited as a solid layer.[19] The major disadvantage is the loss decoupled energy and power as seen in full flow batteries from using a solid state electrode. The cell contains one battery electrode and one fuel cell electrode. This type is limited in energy by the electrode surface area. Hybrid flow batteries include the zinc-bromine, zinc–cerium,[20] soluble lead–acid,[21] and iron-salt flow batteries. Weng et al.[22] reported a vanadium-metal hydride rechargeable hybrid flow battery with an experimental OCV of 1.93 V and operating voltage of 1.70 V, relatively high values among rechargeable flow batteries with aqueous electrolytes. This hybrid battery consists of a graphite felt positive electrode operating in a mixed solution of VOSO4and H2SO4, and a metal hydride negative electrode in KOH aqueous solution. The two electrolytes of different pH are separated by a bipolar membrane. The system demonstrated good reversibility and high efficiencies in coulomb (95%), energy (84%), and voltage (88%). They reported further improvements of this redox couple with achievements of increased current density, inclusion of larger 100 cm2 electrodes, and the operation of 10 large cells in series. Preliminary data using a fluctuating simulated power input tested the viability toward kWh scale storage.[23] In 2016, a high energy density Mn(VI)/Mn(VII)-Zn hybrid flow battery was proposed.[24]

A prototype zinc-polyiodide flow battery demonstrated an energy density of 167 Wh/l (watt-hours per liter). Older zinc-bromide cells reach 70 Wh/l. For comparison, lithium iron phosphate batteries store 233 Wh/l. The zinc-polyiodide battery is claimed to be safer than other flow batteries given its absence of acidic electrolytes, nonflammability and operating range of −4 to 122 °F (−20 to 50 °C) that does not require extensive cooling circuitry, which would add weight and occupy space. One unresolved issue is zinc buildup on the negative electrode that can permeate the membrane, reducing efficiency. Because of the Zn dendrite formation, Zn-halide batteries cannot operate at high current density (> 20 mA/cm2) and thus have limited power density. Adding alcohol to the electrolyte of the ZnI battery can help with the problem.[25] The drawbacks of Zn/I RFB lie at the high cost of Iodide salts (> $20 / Kg); limited area capacity of Zn deposition also losing the decoupled energy and power; and Zn dendrite formation.

When the battery is fully discharged, both tanks hold the same electrolyte solution: a mixture of positively charged zinc ions (Zn2+) and negatively charged iodide ion, (I−). When charged, one tank holds another negative ion, polyiodide, (I−3). The battery produces power by pumping liquid from external tanks into the battery's stack area where the liquids are mixed. Inside the stack, zinc ions pass through a selective membrane and change into metallic zinc on the stack's negative side.[26] To further increase the energy density of the zinc-iodide flow battery, bromide ions (Br–) are used as the complexing agent to stabilize the free iodine, forming iodine-bromide ions (I2Br−) as a means to free up iodide ions for charge storage.[27]

Proton flow batteries (PFB) integrate a metal hydride storage electrode into a reversible proton exchange membrane (PEM) fuel cell. During charging, PFB combines hydrogen ions produced from splitting water with electrons and metal particles in one electrode of a fuel cell. The energy is stored in the form of a solid-state metal hydride. Discharge produces electricity and water when the process is reversed and the protons are combined with ambient oxygen. Metals less expensive than lithium can be used and provide greater energy density than lithium cells.[28][29]

2.2. Organic Flow Batteries

Compared to redox flow batteries that are inorganic, such as vanadium redox flow batteries and Zn-Br2 batteries, which have been developed for decades, organic redox flow batteries emerged in 2009. The primary appeal of organic redox flow batteries lies in the tunable redox properties of the active components. As of 2021, organic RFB experience low durability (i.e. calendar or cycle life, or both). For this reason, only inorganic RFB have been demonstrated on a commercial scale. [30]

Organic redox flow batteries can be further classified into aqueous (AORFBs) and non-aqueous (NAORFBs).[31][32] AORFBs use water as solvent for electrolyte materials while NAORFBs employ organic solvents. AORFBs and NAORFBs can be further divided into total and hybrid organic systems. The former use only organic electrode materials, while the latter use inorganic materials for anode or cathode. In larger-scale energy storage, lower solvent cost and higher conductivity give AORFBs greater commercial potential, as well as offering safety advantages from water-based electrolytes. NAORFBs instead provide a much larger voltage window and occupy less physical space.

pH neutral AORFBs

pH neutral AORFBs are operated at pH7 conditions, typically using NaCl as a supporting electrolyte. At pH neutral conditions, organic and organometallic molecules are more stable than at corrosive acidic and alkaline conditions. For example, K4[Fe(CN)], a common catholyte used in AORFBs, is not stable in alkaline solutions but is at pH neutral conditions.[33]

AORFBs used methyl viologen as an anolyte and 4-hydroxy-2,2,6,6-tetramethylpiperidin-1-oxyl as a catholyte at pH neutral conditions, plus NaCL and a low-cost anion exchange membrane. This MV/TEMPO system has the highest cell voltage, 1.25 V, and, possibly, lowest capital cost ($180/kWh) reported for AORFBs. The aqueous liquid electrolytes were designed as a drop-in replacement for current systems without replacing existing infrastructure. A 600-milliwatt test battery was stable for 100 cycles with nearly 100 percent efficiency at current densities ranging from 20 to 100 mA/cm2, with optimal performance rated at 40–50 mA, at which about 70% of the battery's original voltage was retained.[34][35] Neutral AORFBs can be more environmentally friendly than acid or alkaline AORFBs while showing electrochemical performance comparable to corrosive RFBs. The MV/TEMPO AORFB has an energy density of 8.4 Wh/L with the limitation on the TEMPO side. Viologen-based flow batteries have been mainly developed by Liu’s group at Utah State University. In 2019, the group reported an ultralight sulfonate-viologen/ferrocyanide AORFB stable for 1000 cycles at an energy density of 10 Wh/L, so far the most stable, energy dense AORFB.[36]

Acidic AORFBs

Quinones and their derivatives are the basis of many organic redox systems.[37][38][39] In one study, 1,2-dihydrobenzoquinone-3,5-disulfonic acid (BQDS) and 1,4-dihydrobenzoquinone-2-sulfonic acid (BQS) were employed as cathodes, and conventional Pb/PbSO4 was the anolyte in a hybrid acid AORFB. Quinones accept two units of electrical charge, compared with one in conventional catholyte, implying that such a battery could store twice as much energy in a given volume.

Another quinone. 9,10-Anthraquinone-2,7-disulfonic acid (AQDS), has been evaluated.[40] AQDS undergoes rapid, reversible two-electron/two-proton reduction on a glassy carbon electrode in sulfuric acid. An aqueous flow battery with inexpensive carbon electrodes, combining the quinone/hydroquinone couple with the Br2/Br− redox couple, yields a peak galvanic power density exceeding 6,000 W/m2 at 13,000 A/m2. Cycling showed > 99% storage capacity retention per cycle. Volumetric energy density was over 20 Wh/L.[41] Anthraquinone-2-sulfonic acid and anthraquinone-2,6-disulfonic acid on the negative side and 1,2-dihydrobenzoquinone- 3,5-disulfonic acid on the positive side avoids the use of hazardous Br2. The battery was claimed to last for 1,000 cycles without degradation.[42] While this system appears robust, it has a low cell voltage (ca. 0.55 V) and a low energy density (< 4 Wh/L).

Hydrobromic acid used as an electrolyte has been replaced with a less toxic alkaline solution (1 M KOH) and ferrocyanide.[43] The higher pH is less corrosive, allowing the use of inexpensive polymer tanks. The increased electrical resistance in the membrane was compensated increased voltage. The cell voltage was 1.2 V.[44][45] The cell's efficiency exceeded 99%, while round-trip efficiency measured 84%. The battery offered an expected lifetime of at least 1,000 cycles. Its theoretic energy density was 19 Wh/L.[46] Ferrocyanide's chemical stability in high pH KOH solution without forming Fe(OH)2 or Fe(OH)3 needs to be verified before scale-up.

Integrating both anolyte and catholyte in the same molecule has been examined. Such bifunctional analytes[47] or combi-molecules[48] allow the same material to be used in both tanks. In one tank it is an electron donor, while in the other it is an electron recipient. This has relevant advantages such as diminishing the effect of crossover.[49] Thus, quinone diaminoanthraquinone[49] and indigo-based[47] molecules as well as TEMPO/phenazine[48] combining molecules are potential electrolytes for the development of symmetric redox-flow batteries (SRFB).

Another approach adopted a Blatter radical as the donor/recipient. It endured 275 charge and discharge cycles in tests, although it was not water-soluble.[50]

Alkaline AORFBs

Quinone molecules have been used as anolytes in alkaline AROFBs. Another anolyte candidate is fluorenone, reengineered to increase its water solubility. A reversible ketone (de)hydrogenation demonstration cell operated continuously for 120 days over 1,111 charging cycles at room temperature without a catalyst, retaining 97% percent capacity. The cell offers more than double the energy density of vanadium-based systems.[51][52] The major challenge for alkaline AORFBs is the lack of a stable catholyte, holding their energy densities below 5 Wh/L. All reported alkaline AORFBs use excess potassium ferrocyanide catholyte because of the stability issue of ferrocyanide in alkaline solutions.

Metal-organic flow batteries use organic ligands to improve the properties of redox-active metals. The ligands can be chelates like EDTA, and can enable the electrolyte to be in neutral or alkaline conditions under which metal aquo complexes would otherwise precipitate. By blocking the coordination of water to the metal, organic ligands can inhibit metal-catalyzed water-splitting reactions, resulting in higher voltage all-aqueous systems. For example, the use of chromium coordinated to 1,3-propanediaminetetraacetate (PDTA), gave cell potentials of 1.62 V vs. ferrocyanide and a record 2.13 V vs. bromine.[53] Metal-organic flow batteries may be known as coordination chemistry flow batteries, which represents the technology behind Lockheed Martin's Gridstar Flow technology.[54]

Oligomer RFBs

Oligomer redox-species RFB have been proposed to reduce the crossover of the electroactive species, while using low cost membranes. Such redox-active oligomers are known as redoxymers. One system uses organic polymers and a saline solution with a cellulose membrane. The prototype underwent 10,000 charging cycles while retaining substantial capacity. The energy density was 10 Wh/l.[55] Current density reached 100 milliamperes/cm2.[56]

Another oligomer RFB employs viologen and TEMPO redoxymers in combination with low-cost dialysis membranes. Functionalized macromolecules (similar to acrylic glass or Styrofoam) dissolved in water are the active electrode material. The size-selective nanoporous membrane works like a strainer and is produced much more easily and at lower cost than conventional ion-selective membranes. It retains the big "spaghetti"-like polymer molecules, while allowing small counterions to pass.[57] The concept may solve the high cost of traditional Nafion membrane, but the design and synthesis of redox active polymer with high water solubility is not trivial. So far, RFBs with oligomer redox-species have not demonstrated competitive area-specific power. It is not clear whether low operating current density is an intrinsic feature of large redox-molecules or not.

2.3. Membraneless

A membraneless battery[58] relies on laminar flow in which two liquids are pumped through a channel, where they undergo electrochemical reactions to store or release energy. The solutions stream through in parallel, with little mixing. The flow naturally separates the liquids, eliminating the need for a membrane.[59]

Membranes are often the most costly and least reliable components of batteries, as they can be corroded by repeated exposure to certain reactants. The absence of a membrane enables the use of a liquid bromine solution and hydrogen: this combination is problematic when membranes are used, because they form hydrobromic acid that can destroy the membrane. Both materials are available at low cost.[60] The design uses a small channel between two electrodes. Liquid bromine flows through the channel over a graphite cathode and hydrobromic acid flows under a porous anode. At the same time, hydrogen gas flows across the anode. The chemical reaction can be reversed to recharge the battery – a first for any membraneless design.[60] One such membraneless flow battery published in August 2013 produced a maximum power density of 0.795 mW/cm2, three times as much power as other membraneless systems— and an order of magnitude higher than lithium-ion batteries.[60]

In 2018, a macroscale membraneless redox flow battery capable of recharging and recirculation of the same electrolyte streams for multiple cycles has been demonstrated. The battery is based on immiscible organic catholyte and aqueous anolyte liquids, which exhibits high capacity retention and Coulombic efficiency during cycling.[61]

2.4. Nano-Network

Lithium–sulfur system arranged in a network of nanoparticles eliminates the requirement that charge moves in and out of particles that are in direct contact with a conducting plate. Instead, the nanoparticle network allows electricity to flow throughout the liquid. This allows more energy to be extracted.[62]

2.5. Other Redox Flow Battery Chemistries

Other flow-type batteries include the zinc–cerium hybrid flow battery, the zinc–bromine hybrid flow battery, and the hydrogen bromine battery.

2.6. Other Flow-Type Batteries

Semi-solid

In a semi-solid flow cell, the positive and negative electrodes are composed of particles suspended in a carrier liquid. The positive and negative suspensions are stored in separate tanks and pumped through separate pipes into a stack of adjacent reaction chambers, where they are separated by a barrier such as a thin, porous membrane. The approach combines the basic structure of aqueous-flow batteries, which use electrode material suspended in a liquid electrolyte, with the chemistry of lithium-ion batteries in both carbon-free suspensions and slurries with conductive carbon network.[64][65][66] The carbon free semi-solid redox flow battery is also sometimes referred to as Solid Dispersion Redox Flow Battery.[67] Dissolving a material changes its chemical behavior significantly. However, suspending bits of solid material preserves the solid's characteristics. The result is a viscous suspension that flows like molasses.[68]

Redox-Targeted Solids

Flow batteries with redox-targeted solids (ROTS), also known as solid energy boosters (SEBs), is another recent development. [69]

In these batteries either posolyte or negolyte or both (a.k.a. redox fluids), come in contact with a one or more solid electroactive materials, stored in tanks outside the power stack. The redox fluids comprise one or more redox couples, with redox potentials flanking the redox potential of the solid electroactive material. Such RFBs with Solid Energy Boosters (SEBs) combine the high specific energy advantage of conventional batteries (such as lithium-ion) with the decoupled energy-power advantage of flow batteries. SEB(ROTS) RFBs have several advantages compared to semi-solid RFBs, such as no need to pump viscous slurries, no precipitation /clogging , higher area-specific power, longer durability, wider chemical design space.

3. Chemistries

A wide range of chemistries have been tried for flow batteries.[70]

| Couple | Max. cell voltage (V) | Average electrode power density (W/m2) | Average fluid energy density | Cycles |

|---|---|---|---|---|

| Hydrogen–lithium bromate | 1.1 | 15,000 | 750 Wh/kg | |

| Hydrogen–lithium chlorate | 1.4 | 10,000 | 1400 Wh/kg | |

| Bromine-hydrogen | 1.07 | 7,950 | ||

| Iron–tin | 0.62 | < 200 | ||

| Iron–titanium | 0.43 | < 200 | ||

| Iron–chromium | 1.07 | < 200 | ||

| Iron–Iron | 1.21 | < 1000 | 20 Wh/L | 10,000 |

| Organic (2013) | 0.8 | 13,000 | 21.4 Wh/L | 10 |

| Organic (2015) | 1.2 | 7.1 Wh/L | 100 | |

| MV-TEMPO | 1.25 | 8.4 Wh/L | 100 | |

| Sulfonate viologen (NH4)4[Fe(CN)6] | 0.9 | > 500 | 10 Wh/L | 1,000 |

| Metal-organic–ferrocyanide[53] | 1.62 | 2,000 | 21.7 Wh/L | 75 |

| Metal-organic–bromine[53] | 2.13 | 3,000 | 35 Wh/L | 10 |

| Vanadium–vanadium (sulphate) | 1.4 | ~800 | 25 Wh/L | |

| Vanadium–vanadium (bromide) | 50 Wh/L | 2,000[70] | ||

| Sodium–bromine polysulfide | 1.54 | ~800 | ||

| Sodium–potassium[71] | ||||

| Sulfur-oxygen-salt[72] | ||||

| Zinc–bromine | 1.85 | ~1,000 | 75 Wh/kg | > 2,000 |

| Lead–acid (methanesulfonate) | 1.82 | ~1,000 | ||

| Zinc–cerium (methanesulfonate) | 2.43 | < 1,200–2,500 | ||

| Zn-Mn(VI)/Mn(VII) | 1.2 | 60 Wh/L[24] |

4. Advantages

Redox flow batteries, and to a lesser extent hybrid flow batteries, have the advantages of

- flexible layout (due to separation of the power and energy components)

- long cycle life (because there are no solid-to-solid phase transitions)

- quick response times

- no need for "equalisation" charging (the overcharging of a battery to ensure all cells have an equal charge)

- no harmful emissions.

Some types also offer easy state-of-charge determination (through voltage dependence on charge), low maintenance and tolerance to overcharge/overdischarge.

They are safe because

- they typically do not contain flammable electrolytes

- electrolytes can be stored away from the power stack.

These technical merits make redox flow batteries a well-suited option for large-scale energy storage.

5. Disadvantages

The two main disadvantages are

- low energy density (you need large tanks of electrolyte to store useful amounts of energy)

- low charge and discharge rates (compared to other industrial electrode processes). This means that the electrodes and membrane separators need to be large, which increases the cost of power.

Flow batteries typically have a higher energy efficiency than fuel cells, but lower than lithium-ion batteries.[73]

6. Applications

Flow batteries are normally considered for relatively large (1 kWh – 10 MWh) stationary applications.[74] These are for:

- Load balancing – where the battery is attached to an electrical grid to store excess electrical power during off-peak hours and release electrical power during peak demand periods. The common problem limiting the use of most flow battery chemistries in this application is their low areal power (operating current density) which translates into a high cost of power.

- Storing energy from renewable sources such as wind or solar for discharge during periods of peak demand.[75]

- Peak shaving, where spikes of demand are met by the battery.[76]

- UPS, where the battery is used if the main power fails to provide an uninterrupted supply.

- Power conversion – because all cells share the same electrolyte(s). Therefore, the electrolyte(s) may be charged using a given number of cells and discharged with a different number. Because the voltage of the battery is proportional to the number of cells used the battery can therefore act as a very powerful DC–DC converter. In addition, if the number of cells is continuously changed (on the input and/or output side) power conversion can also be AC/DC, AC/AC, or DC–AC with the frequency limited by that of the switching gear.[77]

- Electric vehicles – Because flow batteries can be rapidly "recharged" by replacing the electrolyte, they can be used for applications where the vehicle needs to take on energy as fast as a combustion engined vehicle.[78][79] A common problem found with most RFB chemistries in the EV applications is their low energy density which translated into a short driving range. Flow batteries based on highly soluble halates are a notable exception.[80]

- Stand-alone power system – An example of this is in cellphone base stations where no grid power is available. The battery can be used alongside solar or wind power sources to compensate for their fluctuating power levels and alongside a generator to make the most efficient use of it to save fuel.[81][82]

References

- Science-Dictionary.org. "Electroactive Substance " 14 May 2013. http://chemistry.science-dictionary.org/Electrochemistry-Dictionary/electroactive_substance%7Cpublisher=Science-Dictionary.org

- Fujii, Toshinobu; Takashi Hirose & Naoki Kondou, "Metallohalogen secondary battery", JP patent S5671271A, published 1981-06-13 http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=JPS5671271A

- Aaron, Douglas (2013). "In Situ Kinetics Studies in All-Vanadium Redox Flow Batteries". ECS Electrochemistry Letters 2 (3): A29–A31. doi:10.1149/2.001303eel. https://dx.doi.org/10.1149%2F2.001303eel

- McCreery, Richard L. (July 2008). "Advanced Carbon Electrode Materials for Molecular Electrochemistry" (in EN). Chemical Reviews 108 (7): 2646–2687. doi:10.1021/cr068076m. ISSN 0009-2665. PMID 18557655. https://dx.doi.org/10.1021%2Fcr068076m

- "Researchers Drastically Reduce The Cost of Redox Flow Batteries [$25 Per kWh"]. 29 January 2021. https://techreportarticles.com/site/news/energy/researchers-drastically-reduce-the-cost-of-redox-flow-batteries-25-per-kwh/.

- Arenas, L.F.; Ponce de León, C.; Walsh, F.C. (June 2017). "Engineering aspects of the design, construction and performance of modular redox flow batteries for energy storage". Journal of Energy Storage 11: 119–153. doi:10.1016/j.est.2017.02.007. https://eprints.soton.ac.uk/406710/1/Eng_RFB_Review_20_Feb_2017_eprints.pdf.

- Hu, B.; Luo, J.; DeBruler C.; Hu, M; Wu, W.; Liu, T. L. (2019). Redox Active Inorganic Materials for Redox Flow Batteries in Encyclopedia of Inorganic and Bioinorganic Chemistry: Inorganic Battery Materials. pp. 1–25.

- Luo, J.; Hu, B.; Hu, M.; Liu, T. L.. "Status and Prospects of Organic Redox Flow Batteries towards Renewable Energy Storage". ACS Energy Lett. 2019, 4: 2220–2240. doi:10.1021/acsenergylett.9b01332. https://pubs.acs.org/doi/abs/10.1021/acsenergylett.9b01332.

- Linden, D.; Reddy, T.B. (2002). Handbook of Batteries (Eds.). McGraw-Hill.

- Shiokawa, Y.; Yamana, H.; Moriyama, H. (2000). "An Application of Actinide Elements for a Redox Flow Battery". Journal of Nuclear Science and Technology 37 (3): 253–256. doi:10.1080/18811248.2000.9714891. https://dx.doi.org/10.1080%2F18811248.2000.9714891

- Borchers, William, "Process of transforming chemical energy of fuel into electrical energy", US patent 567959, published 1896-09-22 http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=US567959

- Nernst, Walther, "Brennstoffelement mit unangreifbaren Elektroden [Fuel cell with impregnable electrodes]", DE patent 264026, published 1912-06-15 http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=DE264026

- Keefer, Richard Mackay, "Redox fuel cell regenerated with sugar", US patent 3682704, published 1972-08-08 http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=US3682704

- Kummer, J. T.; Oei, D. -G. (1985). "A chemically regenerative redox fuel cell. II". Journal of Applied Electrochemistry 15 (4): 619–629. doi:10.1007/BF01059304. https://dx.doi.org/10.1007%2FBF01059304

- Spagnuolo, G.; Petrone, G.; Mattavelli, P.; Guarnieri, M. (2016). "Vanadium Redox Flow Batteries: Potentials and Challenges of an Emerging Storage Technology". IEEE Industrial Electronics Magazine 10 (4): 20–31. doi:10.1109/MIE.2016.2611760. https://dx.doi.org/10.1109%2FMIE.2016.2611760

- Cho, Kyu Taek; Tucker, Michael C.; Ding, Markus; Ridgway, Paul; Battaglia, Vincent S.; Srinivasan, Venkat; Weber, Adam Z. (2015). "Cyclic Performance Analysis of Hydrogen/Bromine Flow Batteries for Grid-Scale Energy Storage". ChemPlusChem 80 (2): 402–411. doi:10.1002/cplu.201402043. https://dx.doi.org/10.1002%2Fcplu.201402043

- Yu; Tolmachev, V. (2013). "Hydrogen-halogen electrochemical cells: A review of applications and technologies". Russian Journal of Electrochemistry 50 (4): 301–316. doi:10.1134/S1023193513120069. https://dx.doi.org/10.1134%2FS1023193513120069

- Tolmachev, Yuriy V. (2015). "Energy cycle based on a high specific energy aqueous flow battery and its potential use for fully electric vehicles and for direct solar-to-chemical energy conversion". Journal of Solid State Electrochemistry 19 (9): 2711–2722. doi:10.1007/s10008-015-2805-z. https://dx.doi.org/10.1007%2Fs10008-015-2805-z

- Bartolozzi, M. (1989). "Development of redox flow batteries. A historical bibliography". Journal of Power Sources 27 (3): 219–234. doi:10.1016/0378-7753(89)80037-0. Bibcode: 1989JPS....27..219B. https://dx.doi.org/10.1016%2F0378-7753%2889%2980037-0

- Leung, P. K.; Ponce-De-León, C.; Low, C. T. J.; Shah, A. A.; Walsh, F. C. (2011). "Characterization of a zinc–cerium flow battery". Journal of Power Sources 196 (11): 5174–5185. doi:10.1016/j.jpowsour.2011.01.095. Bibcode: 2011JPS...196.5174L. https://dx.doi.org/10.1016%2Fj.jpowsour.2011.01.095

- Krishna, M.; Fraser, E. J.; Wills, R. G. A.; Walsh, F. C. (2018-02-01). "Developments in soluble lead flow batteries and remaining challenges: An illustrated review". Journal of Energy Storage 15: 69–90. doi:10.1016/j.est.2017.10.020. ISSN 2352-152X. http://www.sciencedirect.com/science/article/pii/S2352152X17303870.

- J. Electrochem. Soc. 2013 volume 160, issue 9, A1384-A1389

- J. Electrochem. Soc. 2016 volume 163, issue 1, A5180-A5187

- Colli, Alejandro N.; Peljo, Pekka; Girault, Hubert H. (2016). "High energy density MnO4−/MnO42− redox couple for alkaline redox flow batteries". Chemical Communications 52 (97): 14039–14042. doi:10.1039/C6CC08070G. PMID 27853767. http://infoscience.epfl.ch/record/222916/files/c6cc08070g.pdf.

- Borghino, Dario (27 February 2015). "High-performance flow battery could rival lithium-ions for EVs and grid storage". Gizmag.

- White, Frances (25 February 2015). "New flow battery to keep big cities lit, green and safe". R&D. http://www.rdmag.com/videos/2015/02/new-flow-battery-keep-big-cities-lit-green-and-safe.

- Weng, Guo-Ming (2017). "Unlocking the capacity of iodide for high-energy-density zinc/polyiodide and lithium/polyiodide redox flow batteries". Energy & Environmental Science 10 (3): 735–741. doi:10.1039/C6EE03554J. https://dx.doi.org/10.1039%2FC6EE03554J

- "Proton flow battery simplifies hydrogen power". Gizmag.com. http://www.gizmag.com/proton-flow-battery-hydrogen-electricity-rmit/30818.

- Andrews, J.; Seif Mohammadi, S. (2014). "Towards a 'proton flow battery': Investigation of a reversible PEM fuel cell with integrated metal-hydride hydrogen storage". International Journal of Hydrogen Energy 39 (4): 1740–1751. doi:10.1016/j.ijhydene.2013.11.010. https://dx.doi.org/10.1016%2Fj.ijhydene.2013.11.010

- M.Aziz et al. Electrolyte Lifetime in Aqueous Organic Redox Flow Batteries: A Critical Review. Chemical Reviews 2020, 120, 6467-6489.

- Brushett, Fikile; Vaughey, John; Jansen, Andrew (2012). "An All‐Organic Non‐aqueous Lithium‐Ion Redox Flow Battery" (in en). Advanced Functional Materials 2 (11): 1390–1396. doi:10.1002/aenm.201200322. https://dx.doi.org/10.1002%2Faenm.201200322

- Bamgbopa, Musbaudeen O.; Shao-Horn, Yang; Almheiri, Saif (2017). "The potential of non-aqueous redox flow batteries as fast-charging capable energy storage solutions: demonstration with an iron–chromium acetylacetonate chemistry" (in en). Journal of Materials Chemistry A 5 (26): 13457–13468. doi:10.1039/c7ta02022h. ISSN 2050-7488. https://dx.doi.org/10.1039%2Fc7ta02022h

- Luo, J.; Sam, A.; Hu, B.; DeBruler C.; Liu, T. L.. "Unraveling pH Dependent Cycling Stability of Ferricyanide / Ferrocyanide in Redox Flow Batteries". Nano Energy 2017, 42: 215–221. https://linkinghub.elsevier.com/retrieve/pii/S2211285517306614.

- Moss, Richard (22 December 2015). "New flow battery projected to cost 60% less than existing standard". http://www.gizmag.com/pnnl-low-cost-sustainable-flow-battery/41028.

- Liu, Tianbiao; Wei, Xiaoliang; Nie, Zimin; Sprenkle, Vincent; Wang, Wei (1 November 2015). "A Total Organic Aqueous Redox Flow Battery Employing a Low Cost and Sustainable Methyl Viologen Anolyte and 4-HO-TEMPO Catholyte" (in en). Advanced Energy Materials 6 (3): 1501449. doi:10.1002/aenm.201501449. ISSN 1614-6840. https://dx.doi.org/10.1002%2Faenm.201501449

- Luo, J.; Hu, B.; DeBruler C.; Zhao, Y., Yuan B. Hu, M. Wu, W. Liu, T. L.. "Unprecedented Capacity and Stability of Ammonium Ferrocyanide Catholyte in pH Neutral Aqueous Redox Flow Batteries". Joule 4: 149–163. https://www.cell.com/joule/fulltext/S2542-4351(18)30472-0.

- Gong, K; Fang, Q; Gu, S; Li, F.S.Y.; Yan, Y (2015). "Nonaqueous redox-flow batteries: organic solvents, supporting electrolytes, and redox pairs" (in en). Energy and Environmental Science 8 (12): 3515–3530. doi:10.1039/C5EE02341F. https://dx.doi.org/10.1039%2FC5EE02341F

- Xu, Y.; Wen, Y.; Cheng, J.; Yanga, Y.; Xie, Z.; Cao, G. In World Non-Grid-Connected Wind Power and Energy Conference, 2009. WNWEC 2009 IEEE: Nanjing, China, 2009, p 1.

- Xu, Yan; Wen, Yue-Hua; Cheng, Jie; Cao, Gao-Ping; Yang, Yu-Sheng (2010). "A study of tiron in aqueous solutions for redox flow battery application". Electrochimica Acta 55 (3): 715–720. doi:10.1016/j.electacta.2009.09.031. ISSN 0013-4686. https://dx.doi.org/10.1016%2Fj.electacta.2009.09.031

- WALD, MATTHEW L. (8 January 2014). "From Harvard, a Cheaper Storage Battery". New York Times. https://www.nytimes.com/2014/01/09/business/energy-environment/from-harvard-a-cheaper-storage-battery.html.

- "Harvard team demonstrates new metal-free organic–inorganic aqueous flow battery; potential breakthrough for low-cost grid-scale storage". 11 January 2014. http://www.greencarcongress.com/2014/01/20140111-qbfb.html.

- Szondy, David (29 June 2014). "New water-based organic battery is cheap, rechargeable and eco-friendly". Gizmag. http://www.gizmag.com/organic-redox-flow-battery/32739.

- "A rechargeable battery to power a home from rooftop solar panels". https://phys.org/news/2015-09-rechargeable-battery-power-home-rooftop.html.

- Matthew Gunther,ChemistryWorld. "Flow Battery Could Smooth Irregular Wind and Solar Energy Supply". Scientific American. http://www.scientificamerican.com/article/flow-battery-could-smooth-irregular-wind-and-solar-energy-supply/.

- Alkaline quinone flow battery Lin et al. Science 2015 349 (6255), p. 1529

- Borghino, Dario (30 September 2015). "Greener, safer flow battery could store renewable energy on the cheap". http://www.gizmag.com/alkaline-flow-battery/39606/.

- Carretero-González, Javier; Castillo-Martínez, Elizabeth; Armand, Michel (2016). "Highly water-soluble three-redox state organic dyes as bifunctional analytes" (in en). Energy & Environmental Science 9 (11): 3521–3530. doi:10.1039/C6EE01883A. ISSN 1754-5692. https://dx.doi.org/10.1039%2FC6EE01883A

- Winsberg, Jan; Stolze, Christian; Muench, Simon; Liedl, Ferenc; Hager, Martin D.; Schubert, Ulrich S. (2016-11-11). "TEMPO/Phenazine Combi-Molecule: A Redox-Active Material for Symmetric Aqueous Redox-Flow Batteries" (in en). ACS Energy Letters 1 (5): 976–980. doi:10.1021/acsenergylett.6b00413. ISSN 2380-8195. https://dx.doi.org/10.1021%2Facsenergylett.6b00413

- Potash, Rebecca A.; McKone, James R.; Conte, Sean; Abruña, Héctor D. (2016). "On the Benefits of a Symmetric Redox Flow Battery" (in en). Journal of the Electrochemical Society 163 (3): A338–A344. doi:10.1149/2.0971602jes. ISSN 0013-4651. https://dx.doi.org/10.1149%2F2.0971602jes

- Lavars, Nick (2022-03-17). "Symmetrical flow battery may strike right balance for grid-scale storage" (in en-US). https://newatlas.com/energy/symmetrical-flow-battery-grid-scale-storage/.

- Lavars, Nick (21 May 2021). "Candle compound brings high density to grid-scale battery technology" (in en-US). https://newatlas.com/energy/redox-flow-battery-fluorenone-high-density-grid-scale-pnnl/.

- Feng, Ruozhu; Zhang, Xin; Murugesan, Vijayakumar; Hollas, Aaron; Chen, Ying; Shao, Yuyan; Walter, Eric; Wellala, Nadeesha P. N. et al. (2021-05-21). "Reversible ketone hydrogenation and dehydrogenation for aqueous organic redox flow batteries" (in en). Science 372 (6544): 836–840. doi:10.1126/science.abd9795. ISSN 0036-8075. PMID 34016776. Bibcode: 2021Sci...372..836F. https://www.science.org/doi/10.1126/science.abd9795.

- Robb, Brian H.; Farrell, Jason M.; Marshak, Michael P. (2019). "Chelated Chromium Electrolyte Enabling High-Voltage Aqueous Flow Batteries" (in en). Joule 3 (10): 2503–2512. doi:10.1016/j.joule.2019.07.002. https://dx.doi.org/10.1016%2Fj.joule.2019.07.002

- "Energy Storage: GridStar Flow". https://www.lockheedmartin.com/en-us/capabilities/energy/energy-storage.html.

- "Chemists present an innovative redox-flow battery based on organic polymers and water". Phys.org. 21 October 2015. http://phys.org/news/2015-10-chemists-redox-flow-battery-based-polymers.html.

- Janoschka, Tobias; Martin, Norbert; Martin, Udo; Friebe, Christian; Morgenstern, Sabine; Hiller, Hannes; Hager, Martin D.; Schubert, Ulrich S. (2015). "An aqueous, polymer-based redox-flow battery using non-corrosive, safe, and low-cost materials". Nature 527 (7576): 78–81. doi:10.1038/nature15746. PMID 26503039. Bibcode: 2015Natur.527...78J. https://dx.doi.org/10.1038%2Fnature15746

- Janoschka, Tobias; Martin, Norbert; Martin, Udo; Friebe, Christian; Morgenstern, Sabine; Hiller, Hannes; Hager, Martin D.; Schubert, Ulrich S. (2015). "An aqueous, polymer-based redox-flow battery using non-corrosive, safe, and low-cost materials". Nature 527 (7576): 78–81. doi:10.1038/nature15746. PMID 26503039. Bibcode: 2015Natur.527...78J. https://dx.doi.org/10.1038%2Fnature15746

- Bamgbopa, Musbaudeen O.; Almheiri, Saif; Sun, Hong (2017). "Prospects of recently developed membraneless cell designs for redox flow batteries". Renewable and Sustainable Energy Reviews 70: 506–518. doi:10.1016/j.rser.2016.11.234. ISSN 1364-0321. https://dx.doi.org/10.1016%2Fj.rser.2016.11.234

- Braff, William A.; Bazant, Martin Z.; Buie, Cullen R. (2013). "New rechargeable flow battery enables cheaper, large-scale energy storage". Nature Communications 4: 2346. doi:10.1038/ncomms3346. PMID 23949161. Bibcode: 2013NatCo...4.2346B. http://www.kurzweilai.net/new-rechargeable-flow-battery-enables-cheaper-large-scale-energy-storage. Retrieved 20 August 2013.

- Braff, W. A.; Bazant, M. Z.; Buie, C. R. (2013). "Membrane-less hydrogen bromine flow battery". Nature Communications 4: 2346. doi:10.1038/ncomms3346. PMID 23949161. Bibcode: 2013NatCo...4.2346B. https://dx.doi.org/10.1038%2Fncomms3346

- Bamgbopa, Musbaudeen O.; Shao-Horn, Yang; Hashaikeh, Raed; Almheiri, Saif (2018). "Cyclable membraneless redox flow batteries based on immiscible liquid electrolytes: Demonstration with all-iron redox chemistry". Electrochimica Acta 267: 41–50. doi:10.1016/j.electacta.2018.02.063. ISSN 0013-4686. https://dx.doi.org/10.1016%2Fj.electacta.2018.02.063

- "Nanoparticle Networks Promise Cheaper Batteries for Storing Renewable Energy". 24 April 2014. https://www.technologyreview.com/2014/04/24/13447/nanoparticle-networks-promise-cheaper-batteries-for-storing-renewable-energy/.

- Qi, Zhaoxiang; Koenig, Gary M. (2017). "Review Article: Flow battery systems with solid electroactive materials" (in en). Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena 35 (4): 040801. doi:10.1116/1.4983210. ISSN 2166-2746. Bibcode: 2017JVSTB..35d0801Q. https://dx.doi.org/10.1116%2F1.4983210

- Qi, Zhaoxiang; Koenig, Gary M. (2017-05-12). "Review Article: Flow battery systems with solid electroactive materials". Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena 35 (4): 040801. doi:10.1116/1.4983210. ISSN 2166-2746. Bibcode: 2017JVSTB..35d0801Q. https://dx.doi.org/10.1116%2F1.4983210

- Duduta, Mihai (May 2011). "Semi-Solid Lithium Rechargeable Flow Battery". Advanced Energy Materials 1 (4): 511–516. doi:10.1002/aenm.201100152. https://dx.doi.org/10.1002%2Faenm.201100152

- Qi, Zhaoxiang; Koenig Jr., Gary M. (2016-08-15). "A carbon-free lithium-ion solid dispersion redox couple with low viscosity for redox flow batteries". Journal of Power Sources 323: 97–106. doi:10.1016/j.jpowsour.2016.05.033. Bibcode: 2016JPS...323...97Q. https://dx.doi.org/10.1016%2Fj.jpowsour.2016.05.033

- Qi, Zhaoxiang; Liu, Aaron L.; Koenig Jr, Gary M. (2017-02-20). "Carbon-free Solid Dispersion LiCoO2 Redox Couple Characterization and Electrochemical Evaluation for All Solid Dispersion Redox Flow Batteries". Electrochimica Acta 228: 91–99. doi:10.1016/j.electacta.2017.01.061. https://dx.doi.org/10.1016%2Fj.electacta.2017.01.061

- Chandler, David L. (23 August 2011). "Go with the Flow – Cambridge Crude". Technology Review. http://www.technologyreview.com/article/425107/go-with-the-flow/.

- {{ (2) Redox-Targeting-Based Flow Batteries for Large-Scale Energy Storage. Advanced Materials 2018, 30, 13. (3) Redox targeting-based flow batteries. Journal of Physics D-Applied Physics 2019, 52, 17. (4) Redox Targeting Improves Flow Batteries. Joule 2019, 3, 2066-2067. (5) Single-Molecule Redox-Targeting Reactions for a pH-Neutral Aqueous Organic Redox Flow Battery. Angewandte Chemie-International Edition 2020, 59, 14286-14291. (6) Redox targeting of energy materials. Current Opinion in Electrochemistry 2021, 29, 7. (7) Redox Targeting of Energy Materials for Energy Storage and Conversion. Advanced Materials 2021, 2104562 (2104519). }}

- Badwal, Sukhvinder P. S.; Giddey, Sarbjit S.; Munnings, Christopher; Bhatt, Anand I.; Hollenkamp, Anthony F. (24 September 2014). "Emerging electrochemical energy conversion and storage technologies". Frontiers in Chemistry 2: 79. doi:10.3389/fchem.2014.00079. PMID 25309898. Bibcode: 2014FrCh....2...79B. http://www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=4174133

- Bush, Steve (20 July 2018). "Room-temperature flow battery uses liquid sodium-potassium alloy". https://www.electronicsweekly.com/news/research-news/flow-battery-uses-liquid-sodium-potassium-alloy-2018-07/.

- Li, Zheng; Sam Pan, Menghsuan; Su, Liang; Tsai, Ping-Chun; Badel, Andres F.; Valle, Joseph M.; Eiler, Stephanie L.; Xiang, Kai et al. (2017-10-11). "Air-Breathing Aqueous Sulfur Flow Battery for Ultralow-Cost Long-Duration Electrical Storage". Joule 1 (2): 306–327. doi:10.1016/j.joule.2017.08.007. https://dx.doi.org/10.1016%2Fj.joule.2017.08.007

- ""Evaluation of redox flow batteries goes beyond round-trip efficiency: A technical review"". Journal of Energy Storage 16: 108-116. 2018. doi:10.1016/j.est.2018.01.005. https://dx.doi.org/10.1016%2Fj.est.2018.01.005

- Service, R.F. (2 November 2018). "Advances in flow batteries promise cheap backup power". Science 362 (6414): 508–509. doi:10.1126/science.362.6414.508. PMID 30385552. Bibcode: 2018Sci...362..508S. https://dx.doi.org/10.1126%2Fscience.362.6414.508

- REDT Energy. "Storing Renewable Energy". http://www.redtenergy.com/applications/renewable-energy.

- [1]

- in Spaziante, Placido Maria; Krisada Kampanatsanyakorn & Andrea Zocchi, "System for storing and/or transforming energy from sources at variable voltage and frequency", WO patent 03043170, published 2003-05-22 http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=WO03043170

- "Electric Vehicle Refuelling System (EVRS) used in conjunction with Vanadium Redox Flow Technology". REDT Energy Storage. http://www.poweringnow.com/applications/electric-vehicles.

- Antony Ingram. "nanoFLOWCELL-powered Quant e-Limo approved for german road trials". Fox News. http://www.foxnews.com/leisure/2014/07/18/nanoflowcell-powered-quant-e-limo-approved-for-german-road-trials/?intcmp=obnetwork.

- Tolmachev, Yuriy V.; Piatkivskyi, Andrii; Ryzhov, Victor V.; Konev, Dmitry V.; Vorotyntsev, Mikhail A. (2015). "Energy cycle based on a high specific energy aqueous flow battery and its potential use for fully electric vehicles and for direct solar-to-chemical energy conversion". Journal of Solid State Electrochemistry 19 (9): 2711–2722. doi:10.1007/s10008-015-2805-z. https://dx.doi.org/10.1007%2Fs10008-015-2805-z

- Talk by John Davis of Deeya energy about their flow battery's use in the telecomms industry on YouTube https://www.youtube.com/watch?v=GbLRKN3srUs

- "Performance Testing of Zinc-Bromine Flow Batteries for Remote Telecom Sites". http://www.sandia.gov/ess/publications/SAND2013-2818C.pdf.