| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | qingwei lin | -- | 960 | 2022-10-10 06:28:13 | | | |

| 2 | Conner Chen | + 40 word(s) | 1000 | 2022-10-11 02:33:48 | | |

Video Upload Options

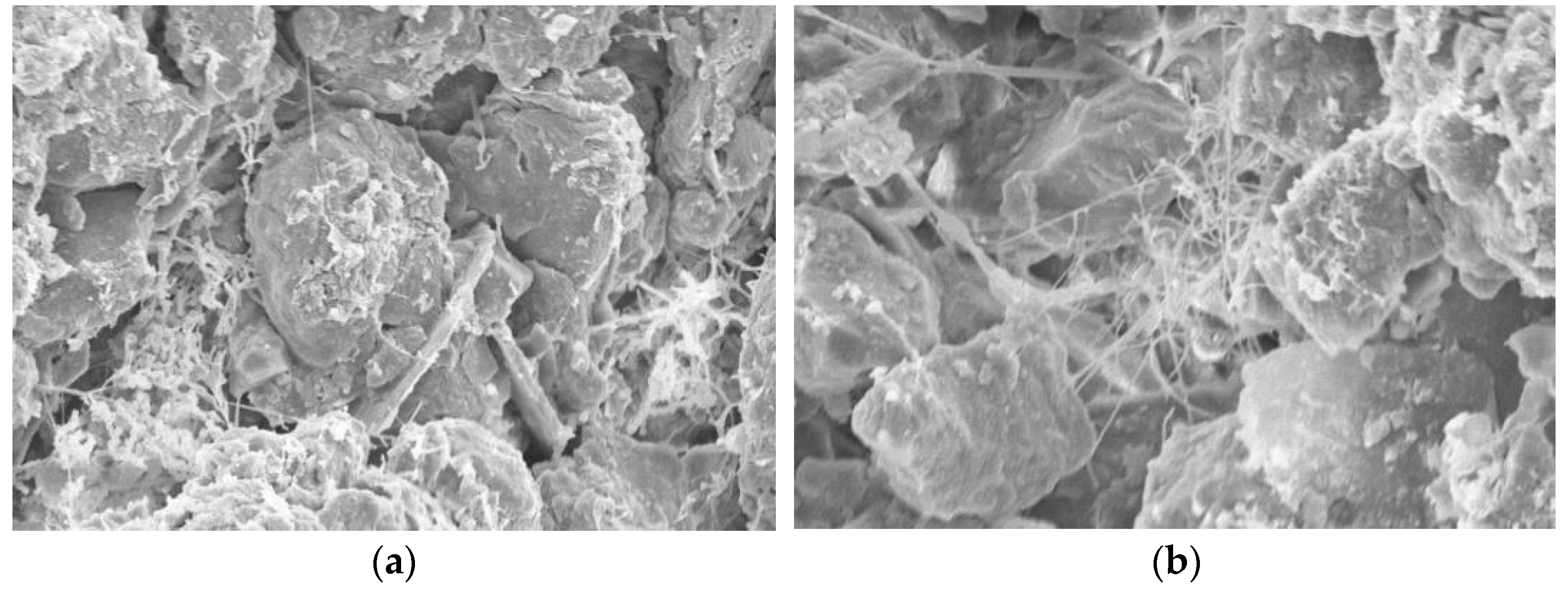

As an organic material with large reserves and environmental protection, the application of lignin in loess improvement can greatly improve the engineering properties of loess, such as water loss disintegration and water collapsibility. The microscopic results show that the incorporation of lignosulfonate produces a three-dimensional network structure, which can effectively cement loess particles and improve soil strength and impermeability, and the Quantity of this network structure depends on the amount of lignosulfonate.

1. Properties and Applications of Lignosulfonates

Lignosulfonate is based on lignin as raw material and the principle of the sulfite pulping process. It is the most abundant industrial lignin that is currently available. It has the advantages of stability, large reserves, environmental protection, and low cost. Lignosulfonate has strong dispersibility, cohesion, and chelation. The abundant phenolic hydroxyl groups endow lignin with excellent antioxidant, antibacterial and UV protection properties [1], these active sites are beneficial for the preparation of composite materials [2][3][4]; Polar functional groups such as hydroxyl and carboxyl can weaken the surface force when compounding with other materials [5][6][7][8]; sulfonic acid groups have good water solubility. The natural degradation process of lignin is very slow. At present, only white-rot fungi have been found to completely degrade lignin; therefore, the durability of lignosulfonate can be guaranteed after being incorporated into loess [9][10].

2. Analysis of the Lignosulfonate Reinforcement Mechanism

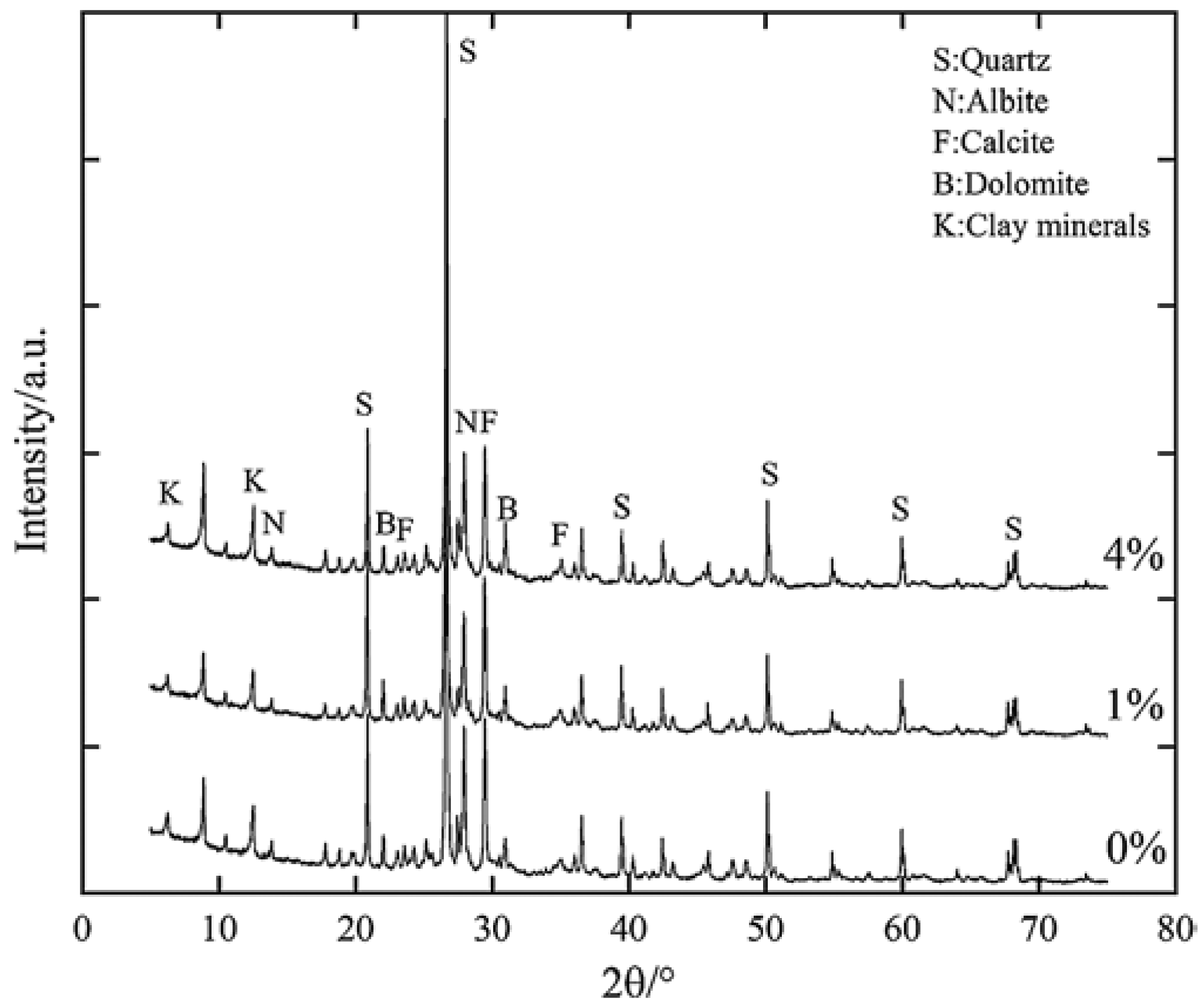

2.1. Mineral Composition Analysis

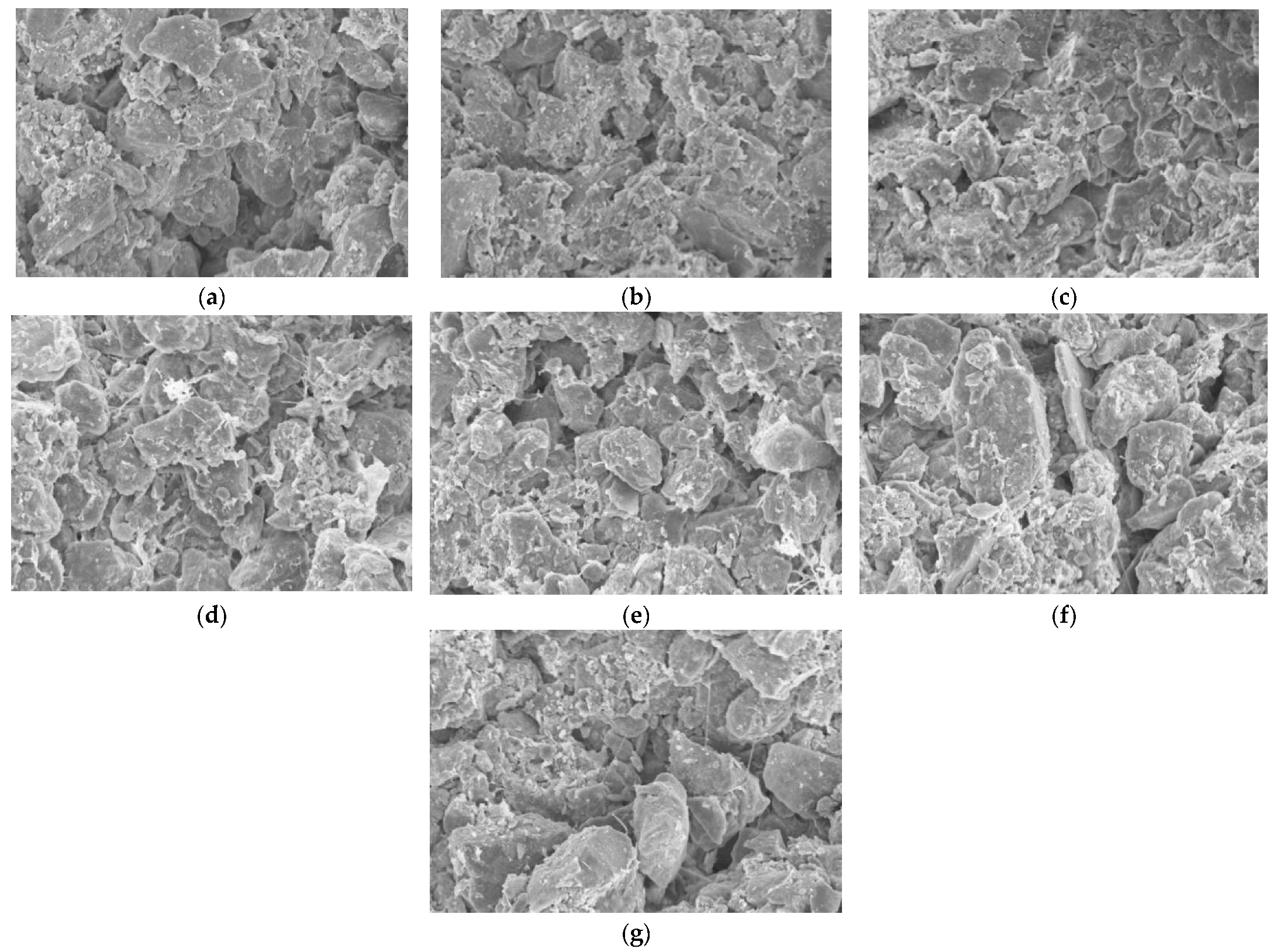

2.2. Microstructure Analysis

References

- Roopan, S.M. An overview of natural renewable bio-polymer lignin towards nano and biotechnological applications. Int. J. Biol. Macromol. 2017, 103, 508–514.

- Wang, H.; Yang, D.J.; Qian, Y.; Qiu, X.Q. Research progress in preparation and application of lignin based functional materials. Prog. Chem. Eng. 2019, 38, 434–448. (In Chinese)

- Guo, Y.F. Preparation and Application of Low-density Polyethylene-Lignin Composites for Construction Materials. Aging Appl. Synth. Mater. 2022, 51, 83–87. (In Chinese)

- Jedrzejczak, P.; Collins, M.N.; Jesionowski, T.; Klapiszewski, L. The role of lignin and lignin-based materials in sustainable construction-A comprehensive review. Int. J. Biol. Macromol. 2021, 187, 624–650.

- Wang, Z.; Liu, Q.J.; Liu, L.; Hu, Y.J.; Li, B.G. Research progress of lignin extraction and preparation of lignin adsorbents. Mod. Chem. Ind. 2022, 1–5. Available online: https://kns.cnki.net/kcms/detail/11.2172.TQ.20220418.1855.003.html (accessed on 20 September 2022). (In Chinese).

- Li, P.H.; Huang, L.J.; Li, J.Q.; Ren, J.P.; Wu, W.J. Progress on Application of Functional Lignin in Polymer Materials. Polym. Mater. Sci. Eng. 2022, 1–10. (In Chinese)

- Cui, H.; Luo, T.; Lv, G.J.; Jiang, S.X.; Li, C.T.; Kou, G.Z.; Yang, G.H. Research progress on the application of lignin/natural polysaccharide composites. Mod. Chem. Ind. 2021, 41, 35–39. (In Chinese)

- Ma, M.G.; Yuan, Q. Research Progress of Multifunctional Lignin-based Materials. J. Guangdong Univ. Technol. 2022, 39, 14–20, 62. (In Chinese)

- Chen, X.J.; Ding, X.; Xu, K.Y. State-of-the-Art Review of Lignin and Its Derivatives on the Soil Properties Modification. Geotech. Fundam. 2021, 35, 156–160. (In Chinese)

- Thevenot, M.; Dignac, M.F.; Rumpel, C. Fate of lignins in soils: A review. Soil Biol. Biochem. 2010, 42, 1200–1211.

- Vaiana, R.; Oliviero Rossi, C.; Perri, G. An Eco-Sustainable Stabilization of Clayey Road Subgrades by Lignin Treatment: An Overview and a Comparative Experimental Investigation. Appl. Sci. 2021, 11, 11720.

- Wang, W.L.; Wang, H.B.; Huo, J.C.; Lei, Y.L.; Lv, S.Z. Research progress on modification of lignosulfonate water reducer. Prog. Chem. Eng. 2011, 30, 1039–1044. (In Chinese)

- Jia, J.J.; Lei, Y.L.; Jiang, Y. Influence of Modified Calcium Lignosulfonate on early hydration of cement and mechanism discussion. Silic. Bull. 2018, 37, 3422–3426. (In Chinese)

- Tian, N.N.; Li, R.C.; Jiang, J.T.; Ni, H.G.; Zong, X.T.; Wang, Y.M.; Zong, L. Preparation of sodium lignosulfonate based hydrogel adsorbent and its adsorption performance on Congo red. J. Zhejiang Univ. Technol. 2022, 1–16. Available online: http://kns.cnki.net/kcms/detail/33.1338.ts.20220707.1144.014.html (accessed on 6 September 2022). (In Chinese).

- Qiu, X.Q.; Zhou, M.S.; Wang, W.X.; Xie, B.D.; Yang, D.J. Study on dispersing effect of Sodium Lignosulfonate with different molecular weight on pulverized coal. J. Fuel Chem. 2005, 2, 179–183. (In Chinese)

- Yang, D.J.; Li, H.J.; Bai, M.X.; Qiu, X. Structure and properties of sodium lignosulfonate dye dispersants with different molecular weights. J. Chem. Eng. 2014, 65, 4138–4144. (In Chinese)

- Wang, J.Y.; Qian, Y.; Zhou, Y.J.; Yang, D.J.; Qiu, X.Q. Atomic force microscopy mechanical test in lignosulfonate / silica inorganic particle system-from dispersion mechanism research to product design. Engineering 2021, 7, 223–241. (In Chinese)

- Nasrollahzadeh, M.; Issaabadi, Z.; Varma, R.S. Magnetic Lignosulfonate-Supported Pd Complex: Renewable Resource-Derived Catalyst for Aqueous Suzuki–Miyaura Reaction. ACS Omega 2019, 4, 14234–14241.

- He, Z.Q.; Fan, H.H.; Wang, J.Q.; Liu, G.; Wang, Z.N.; Yu, J.H. Experimental study of engineering properties of loess reinforced by lignosulfonate. Rock Soil Mech. 2017, 38, 731–739. (In Chinese)

- Wang, J.L.; Xue, M.; Zhao, C.K.; Yue, F.X. Influences of lignin fractionation on its utilization. CIESC J. 2022, 1–20. Available online: https://kns.cnki.net/kcms/detail/11.1946.TQ.20220314.1850.003.html (accessed on 20 September 2022). (In Chinese).

- Yan, Z.Y.; Chen, Y.H.; Wu, J.; Deng, Y.J.; Shen, K.Z.; Fang, G.G. Research progress on the application of lignin functional materials. Chin. J. Appl. Chem. Eng. 2022, 51, 491–495, 500. (In Chinese)

- Liu, Z.Z. Mechanical Properties and Reinforcement Mechanism of Lignin-Improved Loess; Lanzhou University: Gansu, China, 2020. (In Chinese)

- Wang, Q.; Liu, Z.Z.; Zhong, X.M.; Gao, Z.N.; Liu, F.Q. Dynamic Elastic Modulus and Damping Ratio of Lignin-Modified Loess. J. Renew. Mater. 2021, 9, 523–540.

- Wang, Q.; Zhong, X.M.; Ma, H.P.; Wang, S.Y.; Liu, Z.Z.; Guo, P. Microstructure and Reinforcement Mechanism of Lignin-Modified Loess. J. Mater. Civ. Eng. 2020, 32, 04020319.

- Hou, X.; Ma, W.; Li, G.Y.; Mu, Y.H.; Zhou, Z.W.; Wang, F. Effects of lignosulfonates on mechanical properties of Lanzhou loess. Rock Soil Mech. 2017, 38, 18–26. (In Chinese)

- Liu, Z.; Wang, Q.; Zhong, X.; Liu, F.; Liang, S.; Gao, Z. Water holding capacity and water stability of loess improved by lignin. Chin. J. Rock Mech. Eng. 2020, 39, 2582–2592. (In Chinese)

- Jiang, T.D. Lignin, 2nd ed.; Chemical Industry Press: Beijing, China, 2008. (In Chinese)

- Huang, Y. Wettability and Microscopic Properties of Lignin-Improved Loess; Chang’an University: Xi’an, China, 2021. (In Chinese)

- Liu, Z.Z.; Gao, N.; Ma, Z.J.; Liu, F.Q.; Liang, S.Y.; Zhong, X.M. Study on the mesoscopic characteristics of lignin-improved loess pores. In Proceedings of the 2019 National Annual Conference on Engineering Geology, Beijing, China, 11 October 2019; pp. 566–573. (In Chinese).