Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Khurram Iqbal Ahmad Khan | -- | 2707 | 2022-09-26 13:39:18 | | | |

| 2 | Dean Liu | + 4 word(s) | 2711 | 2022-09-28 04:14:44 | | | | |

| 3 | Dean Liu | -133 word(s) | 2578 | 2022-10-13 09:42:31 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Khan, K.I.A.; Ullah, F. Resilient Capabilities to Tackle Supply Chain Risks. Encyclopedia. Available online: https://encyclopedia.pub/entry/27595 (accessed on 07 February 2026).

Khan KIA, Ullah F. Resilient Capabilities to Tackle Supply Chain Risks. Encyclopedia. Available at: https://encyclopedia.pub/entry/27595. Accessed February 07, 2026.

Khan, Khurram Iqbal Ahmad, Fahim Ullah. "Resilient Capabilities to Tackle Supply Chain Risks" Encyclopedia, https://encyclopedia.pub/entry/27595 (accessed February 07, 2026).

Khan, K.I.A., & Ullah, F. (2022, September 26). Resilient Capabilities to Tackle Supply Chain Risks. In Encyclopedia. https://encyclopedia.pub/entry/27595

Khan, Khurram Iqbal Ahmad and Fahim Ullah. "Resilient Capabilities to Tackle Supply Chain Risks." Encyclopedia. Web. 26 September, 2022.

Copy Citation

Increased globalization and disruptions caused by pandemics are contributing towards complexity of the supply chain (SC) across all industries. The construction sector is not an exception, and is faced with similar SC disruptions. This has increased the integration issues of the construction SC. Therefore, it is important to manage the complexities in integrating SC risks and resilient capabilities (RCs) to enable a resilient SC in construction.

construction supply chain

resilient capabilities

simulation modeling

supply chain resilience

1. Introduction

Increased globalization and high regard for innovation have made modern supply chains (SCs) more complex, uncertain, and interdependent. This has resulted in widespread interrelated risks with respect to inter and intra-organizational perspectives [1]. This interconnectedness and advancement in the global economy unfolds numerous benefits and ensures better living standards in various developed countries. However, it has intensified the SC risks to a greater extent [2].

SC disruptions have severely affected different countries in the world. The effects are more pronounced in developing countries. Although the SC problems of the developed and developing countries are similar, the poor performance of construction projects has more adverse effects on the long-term socio-economic and national development of the developing countries [3]. Various issues such as poor health and safety, environmental concerns, cost overruns, and poor work quality seriously disturb the project performance of developing countries compared to developed economies [4]. Further, the SC of the developing countries is subjected to secondary disruptions that are not common for developed countries, such as unskilled or untrained workforce, poor governance, corruption, bribery, and other such practices [5].

Nevertheless, in line with the global development initiatives, developing countries must uplift and improve their state of affairs. Accordingly, for an improved living standard, developing countries have started to strengthen their infrastructure. However, with the growing construction sector, proper knowledge about managing complexities related to the SC risks and building resilience in the construction SCs is needed. Accordingly, this research targets developing countries to investigate the understanding of construction SC risks and incorporate resilience in the relevant SCs to move towards a more globally developed construction industry and SCs.

Various risks are present in SCs worldwide, including socio-economic, political, technological, and natural disasters. These risks have made it difficult for organizations to understand and confront every aspect of this global marketplace leaving the doors open for unintended consequences and project failures [6]. Moreover, in a globalized world, where every industry is interconnected in one way or the other, risks are beyond any single organization’s control. Therefore, an error by one organization can send cascading effects out into the other sectors and become the primary cause of their disruption through a ripple effect [7]. Therefore, managing risks has become increasingly important across the SCs to reap holistic benefits and avoid collective damages.

The construction industry is dependent on a strong and uninterrupted SC. It suffers a lot because of interdependent risks and their associated consequences. Such risks provide the basis for deviation from project objectives. The associated poor project performance causes other great losses in relation to the construction project quality, time, and cost [8][9][10]. The transient nature of the project-based SC with interrelated risks makes interdependencies of the construction SCs unique compared to the other industries [11].

Similarly, the highly fragmented nature of the construction industry also reduces the organizations’ visibility to identify risks that may occur within the SC network. To handle ever-increasing complexities and interdependencies within the SC is challenging for a single entity to assess and control [1][12]. Consequently, to overcome disruptions across the SC, it is important for an entity to carefully explore the dynamics of the effects between its prevailing risks and resilient capabilities (RCs). The inability of the associated construction companies to view the SC operations collectively and their related risks makes them more vulnerable to unintended disruptions [13]. Therefore, the main challenge is to make the entire system resilient enough to survive the disruptive events and continue to progress stably.

SCs must be resilient enough to prevent or control disruptions [14]. SC resilience refers to the system’s preparedness for any uncertain environment and stability of operations to have proper command over the entire structure and function [15]. Accordingly, RCs are the characteristics of an organization that helps it foresee and alleviate disruptions [16]. Furthermore, removing risks with the help of effective capabilities makes the SCs more resilient to disruptions [1].

RC, such as flexibility of any task, is defined by its ability to consider the aftereffects of various uncertain situations it may face and be prepared to tackle such situations [17]. In construction, it is the capability to quickly adjust demands/supplies or the means of receiving inputs/delivering outputs of the project in case of any disruption [1]. For example, flexibility in construction can be enhanced by using the standardized components in various finished products during construction, as it can save cost and time and address the risk of being stocked out. Contrary to that, SC can achieve flexibility on the demand side by quickly increasing its storage capacity or distribution services without stocking surplus volumes to fulfill the unpredictable customer demands [18]. Another RC is the system’s efficiency. The system’s efficiency is the capability to fulfill the demands of customers keeping in mind the scope, time, and quality of the project but with minimum expenses and wastage. Furthermore, it is the ability to yield superior outputs with minimum resources [17]. For example, the system’s efficiency can be increased with the help of waste elimination as it helps the construction projects to be completed within the cost, and on time and with reduced harmful effects on the environment.

2. Construction Supply Chain Risks

Disruptions confronted by SCs have sparked the interest of different researchers. SC disruption is a spontaneous and unforeseen incident by which the usual stream of materials and goods is interrupted [19][20][21]. The presence of such disturbances having an adverse effect on SCs obviously puts them at risk [22]. Typical risk management practices seem ineffective because they rely on risk identification and statistical information [23]. Therefore, there is an urge to develop effective and efficient SC capabilities that can help to resist and withstand disruptions. Accordingly, an integrated and proactive approach is needed to evaluate SC’s reaction to disruptions alongside the typical pre- and post-disruption phases.

A precise and comprehensive definition of SC risks was given by Pettit et al. [16] as “fundamental factors that make an enterprise susceptible to disruptions”. Thus, decreasing the likelihood and severity of such risk factors can help the construction organization make SC more resilient and stable [24]. Different researchers in the past have addressed various SC risks. Wagner and Neshat [25] divided the SC risks into three groups: supply, demand, and SC structure. The supply risks are connected to the supply base and the supplier (portfolio, financial status, entire network among different suppliers) [19]. Demand risks are downstream operations in SC that involve the customer (financial status), the product (lifecycle, features), and the distribution and transportation systems adapted to serve the end customers. Finally, the SC structure risks arise due to the disintegrated SCs. For example, the ‘supplier or customer disruptions’ is a key concern in construction as inept contractors, sub-contractors, and suppliers can decelerate the project progress, making the SC more vulnerable to disruptions in project delivery [16]. Similarly, the supply–production–distribution chain is highly interrelated in delivering construction projects which can instigate vulnerability in the SC as materials are linked with labor, information, technology, and finance to complete the project [26]. Therefore, to mitigate disruptive events in construction projects, it is important to cope with vulnerability within the SCs.

SC risks have been grouped into seven main categories by Pettit et al. [16]: turbulence (i.e., natural disasters, price fluctuations, political instability); threats (i.e., theft, terrorism); connectivity (i.e., inter-relationships with external entities); external pressures (i.e., innovation and price pressures from competitors); resource limits (i.e., production and distribution capacity and suppliers availability); sensitivity (i.e., product and process reliability); and supplier or customer disruptions. These are further divided into 39 sub-factors. Despite the different category terminology used, there is an overlap of risk factors between Pettit et al. [16], and Wagner and Neshat [25].

Other researchers classified SC risks as financial risks (i.e., price fluctuations, price pressures). Construction organizations of developing countries suffering from these financial risks face cost overruns, affecting the project scope and performance and resulting in a loss in business opportunities. Other risks include operational risks (i.e., supplier disruptions, products availability); strategic risks (i.e., vast supply network, unproductive planning); hazards risks (i.e., natural disasters) [27][28]; demand and supply risks (i.e., customer disruptions, demand unpredictability) [29]; organizational risks (i.e., risks resulting due to the organization itself and are under its direct control); and external risks (ahead of the company and its SC’s control) [30][31][32]. Overall, poor information handling, inability to manage different stakeholders, and failure to control cost, time, and quality constraints by the construction organization affect the project performance and brings SC risks. Badea et al. [33][34] identified 16 potential SC risks that can cause cost, time, and quality problems in construction projects. The most critical are competitive cost, delivery, procurement, material quality, and delay risk. Chan et al. [34] identified 11 key SC risks in the Ghana construction industry, including price fluctuation, instability of interest rates, shortages of material, and unexpected changes in demand, as the most crucial ones.

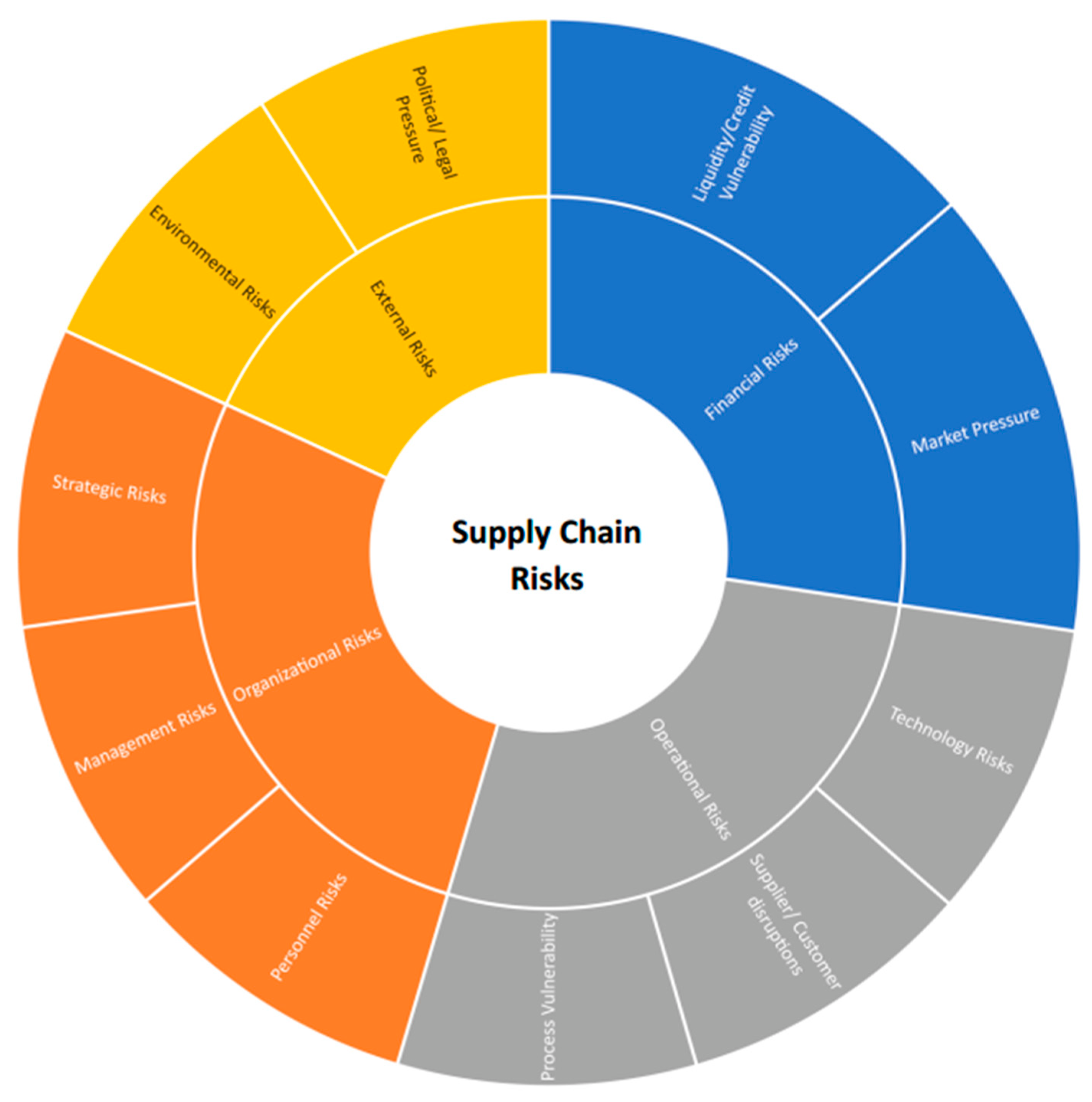

The vulnerability may derive from sub-factors within the organization, external to the organization but within the SC network, or from factors external to the SC network. Figure 1 presents an overview of risk factors in construction SCs based on the above categorization. These risk factors were incorporated in the survey described in the methodology part to determine the area in which the SC members are most vulnerable in an attempt to build SC resilience.

Figure 1. Supply chain risks.

3. Supply Chain Resilient Capabilities of Construction Organizations

According to Peck [35], the ability of an organization to change and restore itself according to any disruptive event is termed its resilience. It is an important skill that supplements typical risk management practices as it deals with several risks and includes various risk management mechanisms [15][23]. Resilience is a vast topic comprising disruptions, risks, and capabilities to mitigate the risks. Removing risks with the help of effective capabilities makes the SCs more resilient to disruptions. Such capabilities can either prevent or mitigate an actual disruption and its effects or make the entire SC acclimate to that disruption [1]. Most SC resilience literature seems to cover multi-sectoral issues. Researchers such as McManus [30] and Pettit et al. [36] have focused on the performance and capability of organizations to survive, adapt, and grow in the face of disruptions.

While the research on SC resilience is growing, more research in the construction industry context is required. Currently, the research related to construction SC resilience is limited. Among the few relevant studies, Abas et al. [13] targeted the critical risk factors affecting the construction SC and assessed the different success factors to realize their direct impact on the successful execution of construction projects. Similarly, Pettit, et al. [16] created a process flow to support different organizations in their resilience journey through the recommended SC Resilience Assessment and Management (SCRAM) tool. The authors investigated 14 RCs, including flexibility in sourcing and order fulfillment, capacity, efficiency, adaptability, visibility, anticipation, recovery, dispersion, collaboration, market position, organization, security, and financial strength. This helped the case study organizations to analyze their current SC resilience state and devise a proactive strategy rather than waiting for the next disruption.

Christopher and Peck [32] investigated four basic RCs: risk management in organizations, agility, re-engineering, and collaboration. Other secondary factors explained by the author were SC availability, efficiency, flexibility, redundancy, velocity, and visibility. Sheffi and Rice Jr [24] explored different risks faced by the SCs to pinpoint the main RCs needed to mitigate the identified risks. RCs such as flexibility, collaboration, redundancy, security, and customer relationship management are the center of attention for the researcher. Meng [37] stated that risk allocation is a crucial RC for construction SC. A proper risk management team can educate all the stakeholders about the possible risks in the project. According to Ryciuk [38], developing trust with a supplier is a key to establishing a successful construction SC. Similarly, Luo et al. [39] stated that effective communication is the most important RC for successful SC in construction projects.

The discussion above shows several common RCs identified by existing studies. Among them, flexibility and system efficiency are the important ones. The current study also assessed other main RCs (such as adaptability, capacity, and visibility) identified by previous researchers. The considered RCs are interrelated [40][41]. Therefore, it is important to understand the trade-offs between appropriate RCs to mitigate critical risks related to construction SCs. This is an under-researched area that previous researchers have not properly investigated [1][30][36][42][43]. Accordingly, it has been targeted in the current study.

4. Construction Complexity and System Dynamics

The construction industry is highly dependent on an interrupted SC and suffers a lot because of interdependent risks arising from the complexities of the SC process. Such risks provide the basis for deviation from project objectives resulting in poor overall project performance that has a snowball effect on quality, time, and cost [8][9]. Overall, construction processes are unpredictable, non-linear, and dynamic, making them susceptible to various disruptions [44]. The transient nature of the project-based SC with interrelated risks makes interdependencies of the construction SCs unique compared to the other industries [11]. Similarly, the highly fragmented construction industry reduces the organizations’ visibility to identify risks that may take place within the SC network [1].

The SD approach uses a non-linear feedback system to sort out the complicated relationships between various constructs. As a result, it presents the complex data in a more organized and simple way [45]. Built on the ST and feedback control theory, the SD approach assesses the dynamic behavior of the system using qualitative (CLDs) and quantitative (SD modeling and simulations) practices [46]. Computer simulation technology is used to dynamically examine the system’s changing trends, which helps make decisions and action plans and verify the validity of working strategy and decisions taken. SD is one such technology based on system modeling [47]. Thus, it helps reduce complexity to boost the system’s productivity [48]. In addition, the SD approach helps smooth the decision-making process and assess the problem with different viewpoints and timelines to devise a proper strategy.

Different researchers have leveraged the SD approach for addressing various complex phenomena. Lee et al. [49] discussed the complexity and uncertainty of construction projects resulting in re-work due to errors and changes. Peng et al. [50] studied the effects of post-seismic disruptions on inventory and transportation rates in SCs. Risks effects, as well as their mitigation scenarios in chemical SC transportation, were studied by Li et al. [51]. Keilhacker and Minner [52] used the SD simulation model to test various ways to abate risks in rare earth elements SC.

Khan et al. [48] and Naveed and Khan [53] used the ST and SD approach to manage the information complexity in construction projects. Ghufran et al. [54] used the SD approach to determine the challenges in adopting sustainable SC management in the construction industry. Amin et al. [55] identified the barriers to information management and factors affecting the adoption of collaborative technologies in construction using the SD approach. However, when it comes to construction SC risks and RCs integration and quantification using the SD approach, the research is limited, if not nonexistent. Thus, the SD approach was selected to assess the complex and interdependent relations between SC risks and RCs in the current study. It aims to bridge the literature gap in addressing the criticality of the construction SC management risks from resilience perspectives using the SD approach.

References

- Abidin, N.A.Z.; Ingirige, B. The dynamics of vulnerabilities and capabilities in improving resilience within Malaysian construction supply chain. Constr. Innov. 2018, 18, 412–432.

- Kosansky, A.; Taus, M. Managing for Catastrophes: Building a Resilient Supply Chain. Supply Chain Manag. Rev. 2014. Available online: https://www.scmr.com/article/managing_for_catastrophes_building_a_resilient_supply_chain (accessed on 25 August 2022).

- Ofori, G. New Perspectives on Construction in Developing Countries; Routledge: London, UK, 2012.

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623.

- Abdul-Rahman, H.; Rahim, F.A.M.; Mohd, M.S. A study on quality management during the pre-construction stage of design-and-build projects. In Proceedings of the CME 25 Conference Construction Management and Economics—‘Past, Present and Future’, Reading, UK, 16–18 July 2007; p. 753.

- Swedberg, R. The structure of confidence and the collapse of Lehman Brothers. In Markets on Trial: The Economic Sociology of the US Financial Crisis: Part A; Emerald Group Publishing Limited: Bradford, UK, 2010.

- Wildgoose, N. Avoiding the Pitfalls of Supply Chain Disruptions; Zurich: Zurich, Switzerland, 2011.

- Le-Hoai, L.; Lee, Y.D.; Lee, J.Y. Delay and Cost Overruns in Vietnam Large Construction Projects: A Comparison with Other Selected Countries. KSCE J. Civ. Eng. 2008, 12, 367–377.

- Mehdi Riazi, S.; Skitmore, M.; Cheung, F. The use of supply chain management to reduce delays: Malaysian public sector construction projects. In Proceedings of the 6th Nordic Conference on Construction Economics and Organisation—Shaping the Construction/Society Nexus, Volume 2: Transforming Practices; Widen, K., Klakegg, O.J., Lindahl, G.A., Gottlieb, S.C., Kahkonen, K.E., Haugbolle, K., Eds.; Danish Building Research Institute, Aalborg University: Aalborg, Denmark, 2011; pp. 403–414.

- Maqsoom, A.; Zahoor, I.; Ashraf, H.; Ullah, F.; Alsulami, B.T.; Salman, A.; Alqurashi, M. Nexus between Leader–Member Exchange, Paternalistic Leadership, and Creative Behavior in the Construction Industry. Sustainability 2022, 14, 7211.

- Loosemore, M.; Teo, M.M.M. Crisis preparedness of construction companies. J. Manag. Eng. 2000, 16, 60–65.

- Ghufran, M.; Khan, K.I.A.; Ullah, F.; Nasir, A.R.; Al Alahmadi, A.A.; Alzaed, A.N.; Alwetaishi, M. Circular Economy in the Construction Industry: A Step towards Sustainable Development. Buildings 2022, 12, 1004.

- Abas, M.; Khattak, S.B.; Habib, T.; Nadir, U. Assessment of critical risk and success factors in construction supply chain: A case of Pakistan. Int. J. Constr. Manag. 2020, 1–9.

- Jüttner, U.; Peck, H.; Christopher, M. Supply chain risk management: Outlining an agenda for future research. Int. J. Logist. Res. Appl. 2003, 6, 197–210.

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143.

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring Supply Chain Resilience: Development of a Conceptual Framework. J. Bus. Logist. 2010, 31, 1–21.

- Olsson, N.O. Management of flexibility in projects. Int. J. Proj. Manag. 2006, 24, 66–74.

- Pettit, T.J. Supply Chain Resilience: Development of a Conceptual Framework, an Assessment Tool and an Implementation Process; Ohio State University: Columbus, OH, USA, 2008.

- Svensson, G. A conceptual framework for the analysis of vulnerability in supply chains. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 731–750.

- Kleindorfer, P.R.; Saad, G.H. Managing disruption risks in supply chains. Prod. Oper. Manag. 2009, 14, 53–68.

- Hendricks, K.B.; Singhal, V.R.; Zhang, R. The effect of operational slack, diversification, and vertical relatedness on the stock market reaction to supply chain disruptions. J. Oper. Manag. 2009, 27, 233–246.

- Craighead, C.W.; Blackhurst, J.; Rungtusanatham, M.J.; Handfield, R.B. The severity of supply chain disruptions: Design characteristics and mitigation capabilities. Decis. Sci. 2007, 38, 131–156.

- Fiksel, J.; Polyviou, M.; Croxton, K.L.; Pettit, T.J. From Risk to Resilience: Learning to Deal with Disruption. MIT Sloan Manag. Rev. 2015, 56, 79–86.

- Sheffi, Y.; Rice, J.B., Jr. A supply chain view of the resilient enterprise. MIT Sloan Manag. Rev. 2005, 47, 41.

- Wagner, S.M.; Neshat, N. Assessing the vulnerability of supply chains using graph theory. Int. J. Prod. Econ. 2010, 126, 121–129.

- Benton, W.; McHenry, L.F. Construction Purchasing & Supply Chain Management; McGraw-Hill: New York, NY, USA, 2010.

- Blos, M.F.; Quaddus, M.; Wee, H.; Watanabe, K. Supply chain risk management (SCRM): A case study on the automotive and electronic industries in Brazil. Supply Chain Manag. Int. J. 2009, 14, 247–252.

- Perez-Franco, R.; Singh, M.; Sheffi, Y. Expressing a Firm’s Supply Chain Strategy: A Framework and a Method. Manuscr. Draft. Mass. Inst. Technol. 2010. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.399.3040&rep=rep1&type=pdf (accessed on 25 August 2022).

- Chowdhury, M.; Hossan, M.; Dewan, M.N.A.; Quaddus, M. Supply chain resilience to mitigate disruptions: A QFD approach. In Proceedings of the 16th Pacific Asia Conference on Information Systems, Ho Chi Minh City, Vietnam, 11–15 July 2012.

- McManus, S.T. Organisational Resilience in New Zealand. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2008.

- Einarsson, S.; Rausand, M. An approach to vulnerability analysis of complex industrial systems. Risk Anal. 1998, 18, 535–546.

- Christopher, M.; Peck, H. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 1–14.

- Badea, A.; Prostean, G.; Goncalves, G.; Allaoui, H. Assessing risk factors in collaborative supply chain with the analytic hierarchy process (AHP). Procedia-Soc. Behav. Sci. 2014, 124, 114–123.

- Chan, A.P.C.; Darko, A.; Olanipekun, A.O.; Ameyaw, E.E. Critical barriers to green building technologies adoption in developing countries: The case of Ghana. J. Clean. Prod. 2018, 172, 1067–1079.

- Peck, H. Drivers of supply chain vulnerability: An integrated framework. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 210–232.

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. Ensuring Supply Chain Resilience: Development and Implementation of an Assessment Tool. J. Bus. Logist. 2013, 34, 46–76.

- Meng, X. The effect of relationship management on project performance in construction. Int. J. Proj. Manag. 2012, 30, 188–198.

- Ryciuk, U. Identification of factors related to trust formation in construction supply chains. Procedia Eng. 2017, 182, 627–634.

- Luo, W.; Shi, Y.; Venkatesh, V. Exploring the factors of achieving supply chain excellence: A New Zealand perspective. Prod. Plan. Control. 2018, 29, 655–667.

- Wedawatta, G.; Ingirige, B. A conceptual framework for understanding resilience of construction SMEs to extreme weather events. Built Environ. Proj. Asset Manag. 2016, 6, 428–443.

- Juttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259.

- Zsidisin, G.A.; Wagner, S.M. Do Perceptions Become Reality? The Moderating Role of Supply Chain Resiliency on Disruption Occurrence. J. Bus. Logist. 2010, 31, 1–20.

- Rasul, N.; Malik, M.S.A.; Bakhtawar, B.; Thaheem, M.J. Risk assessment of fast-track projects: A systems-based approach. Int. J. Constr. Manag. 2021, 21, 1099–1114.

- Bertelsen, S. Complexity–Construction in a New Perspective; IGLC-11: Blacksburg, VA, USA, 2003; Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.509.5436&rep=rep1&type=pdf (accessed on 25 August 2022).

- Forrester, J.W. System dynamics: The foundation under systems thinking. Sloan Sch. Management. Mass. Inst. Technol. 1999, 10, 1–3. Available online: http://static.clexchange.org/ftp/documents/system-dynamics/SD2011-01SDFoundationunderST.pdf (accessed on 28 August 2022).

- Sterman, J.D. System dynamics modeling: Tools for learning in a complex world. Calif. Manag. Rev. 2001, 43, 8–25.

- Feng, Y. System dynamics modeling for supply chain information sharing. Phys. Procedia 2012, 25, 1463–1469.

- Khan, K.I.A.; Flanagan, R.; Lu, S.-L. Managing information complexity using system dynamics on construction projects. Constr. Manag. Econ. 2016, 34, 192–204.

- Lee, S.; Peña-Mora, F.; Park, M. Web-enabled system dynamics model for error and change management on concurrent design and construction projects. J. Comput. Civ. Eng. 2006, 20, 290–300.

- Peng, M.; Peng, Y.; Chen, H. Post-seismic supply chain risk management: A system dynamics disruption analysis approach for inventory and logistics planning. Comput. Oper. Res. 2014, 42, 14–24.

- Li, C.Y.; Ren, J.; Wang, H.Y. A system dynamics simulation model of chemical supply chain transportation risk management systems. Comput. Chem. Eng. 2016, 89, 71–83.

- Keilhacker, M.L.; Minner, S. Supply chain risk management for critical commodities: A system dynamics model for the case of the rare earth elements. Resour. Conserv. Recycl. 2017, 125, 349–362.

- Naveed, F.; Khan, K.I.A. Investigating the influence of information complexity on construction quality: A systems thinking approach. Eng. Constr. Archit. Manag. 2021, 29, 1427–1448.

- Ghufran, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R.; Ullah, F. Adoption of Sustainable Supply Chain Management for Performance Improvement in the Construction Industry: A System Dynamics Approach. Architecture 2021, 1, 161–182.

- Amin, F.; Khan, K.I.A.; Ullah, F.; Alqurashi, M.; Alsulami, B.T. Key Adoption Factors for Collaborative Technologies and Barriers to Information Management in Construction Supply Chains: A System Dynamics Approach. Buildings 2022, 12, 766.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

3 times

(View History)

Update Date:

13 Oct 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No