Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ali Majdi | -- | 2747 | 2022-09-25 10:19:38 | | | |

| 2 | Beatrix Zheng | + 1 word(s) | 2748 | 2022-09-26 04:21:59 | | | | |

| 3 | Beatrix Zheng | Meta information modification | 2748 | 2022-09-26 09:55:15 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ahmad, J.; Majdi, A.; Deifalla, A.F.; Qureshi, H.J.; Saleem, M.U.; Qaidi, S.M.A.; El-Shorbagy, M.A. Mechanical Strength and Durability of Dune Sand. Encyclopedia. Available online: https://encyclopedia.pub/entry/27562 (accessed on 07 February 2026).

Ahmad J, Majdi A, Deifalla AF, Qureshi HJ, Saleem MU, Qaidi SMA, et al. Mechanical Strength and Durability of Dune Sand. Encyclopedia. Available at: https://encyclopedia.pub/entry/27562. Accessed February 07, 2026.

Ahmad, Jawad, Ali Majdi, Ahmed Farouk Deifalla, Hisham Jahangir Qureshi, Muhammad Umair Saleem, Shaker M. A. Qaidi, Mohammed A. El-Shorbagy. "Mechanical Strength and Durability of Dune Sand" Encyclopedia, https://encyclopedia.pub/entry/27562 (accessed February 07, 2026).

Ahmad, J., Majdi, A., Deifalla, A.F., Qureshi, H.J., Saleem, M.U., Qaidi, S.M.A., & El-Shorbagy, M.A. (2022, September 25). Mechanical Strength and Durability of Dune Sand. In Encyclopedia. https://encyclopedia.pub/entry/27562

Ahmad, Jawad, et al. "Mechanical Strength and Durability of Dune Sand." Encyclopedia. Web. 25 September, 2022.

Copy Citation

According to the authors’ best information, the majority of research focuses on other waste materials, such as recycling industrial waste (glass, silica fume, marble and waste foundry sand), etc. However, some researchers suggest dune sand as an alternative material for concrete production, but knowledge is still scarce. Therefore, a comprehensive overview is required on dune sand to evaluate its current progress as well as its effects on the strength and durability properties of concrete.

dune sand

compressive strength

tensile strength

fine aggregate

durability

1. Mechanical Strength

1.1. Compressive Strength

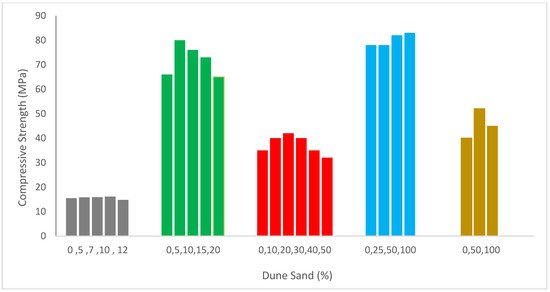

Figure 1 shows concrete compressive capacity with dune sand’s substitution. It can be noted that the compressive capacity of concrete was enhanced up to a certain extent by the substitution of dune sand and then decreased. According to certain researchers [1][2], when the dune sand replacement ratio rose, concrete’s compressive capacity decreased. Due to the dune sand particles’ smooth surfaces and rounded shapes, the binding strength between the cement paste and dune sand may have been reduced [3]. In contrast, several studies [4][5] found that the strength improved to a specific replacement ratio for the dune sand but declined beyond that point. According to Luo et al. [2], high aggregate compactness might cause a rise in strength. According to previous research, dune sand may affect the compactness of aggregates and the strength of the link between dune sand and cement paste. Additionally, the impact of dune sand on each side has a different effect on compressive strength.

It was found that replacing 40% and 50% of the natural dune sand with waste ceramic aggregate resulted in the biggest gain in compressive and flexural capacity when compared to reference mortar. At a 40% and 50% mix ratio of ceramic under various curing conditions, the compressive strength of dune sand ceramic mortar achieves excellent strength [11]. The findings show that as dune sand content rises, concrete strength typically declines. As fine particles have a larger surface area, more grout is required to cover their surface, which results in a loss in strength [1].

The compressive capacity of mortar improves initially with an increase in the dune sand replacement ratio before decreasing and peaking at a 20 percent replacing ratio [7]. According to Appa Rao [12], at a constant water/binder ratio of 0.5, adding silica fume to a mortar up to the point where it replaces 30 percent of the cement results in an increase in compressive strengths [13]. These findings reveal that the development of compressive capacity as a function of time (7, 28 and 90 days) reveals that the compressive capacity is low for all samples during the first seven days but then dramatically rise over the succeeding periods. This is caused by the kinetics of the time-dependent reactions between dune sand powder and portlandite and the hydration of cement [6]. In accordance with the water/binder ratio, Kwan [14] demonstrated that adding silica fume to a mortar with up to 15% of the cement replacement amount results in an increase in compressive strengths after 28 days [15]. Based on these findings, the researchers can conclude that adding the fiber and applying a heat treatment boosted the compressive and flexural capacity. The quantity of dune sand rose, and the compressive strength somewhat improved [16]. Linear connections between compressive capacity and fine dune sand % with respectable correlation coefficients demonstrate that compressive capacity rises as dune sand percentage increases [8]. The findings suggest that when the rate of dune sand replacement increases, the compressive capacity of specimens initially rises and subsequently falls. At curing ages of 7 days and 28 days, respectively, the compressive capacity of the specimen including 50% dune sand improves by 3.87 percent and 10.64 percent compared to the specimen containing 0% dune sand.

The compressive capacity increased the percentage of dune sand. However, the highest strength loss was just around 25% [1]. According to a study, concrete’s compressive strength declines by 39% when the substitute ratio reaches 100%, but it increases with the addition of single or hybrid fibers. In contrast, sand dunes have a negative impact on compressive capacity, particularly when the proportion increases by more than 40% [17]. The research has shown that dune sand may be utilized as an affordable and easily accessible substitute for sea sand and can therefore assist in stopping the negative impacts on the ecosystem caused by excessive sea sand mining [18].

A study reported no significant changes in the amount of addition or dune sand percent on the setting time of mixes. The pastes’ original consistency was dramatically reduced by the addition of dune sand. Due to their higher fineness than that of ordinary Portland cement (OPC), dune sand powder acts as a lubricant by reducing the intergranular vacuum. This cement has a lot of vacuums that need to be filled with water before they can set in the convenience of the mortar. Therefore, in order to decrease the intergranular vacuum and hence the need for water in cement, it is required to enhance the quantities of tiny and big particles. The intergranular vacuums will be filled with the dune sand powder, reducing the need for water [6].

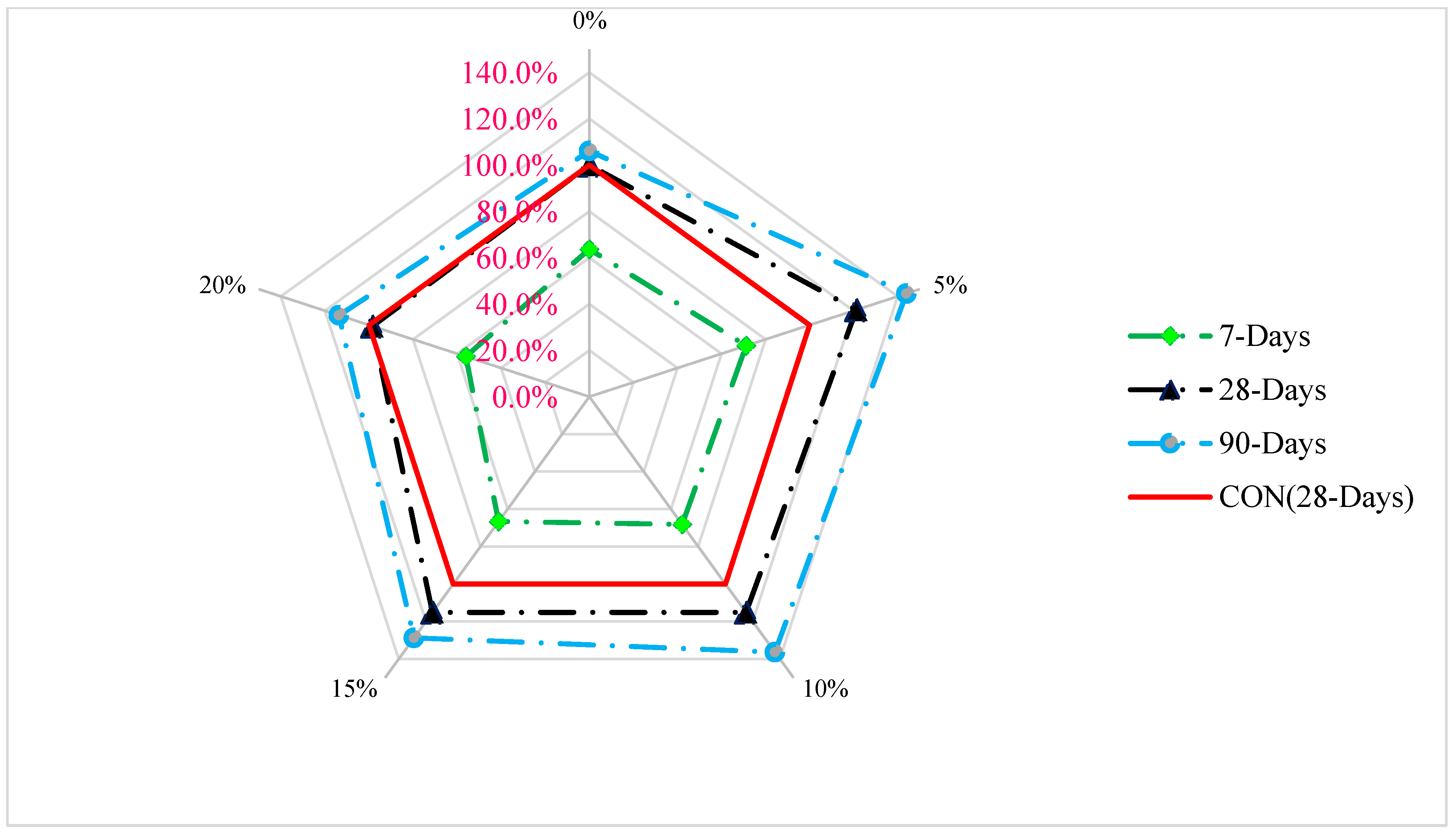

A comparative investigation of compressive capacity with different dune sand dosages at various curing days is shown in Figure 2.

Figure 2. Compressive strength age relation [6].

As a reference mix, the compressive capacity of control concrete on day 28 of curing was used to evaluate the compressive strength of different dosages of dune sand at various curing days. For a comparative study, five percent of the recommended dune sand dosage was considered. Compressive strength during seven days of curing is 29% less than the reference compressive strength (concrete at 28 days controls compressive capacity with a 5% replacement of dune sand). The compressive strength with a 5% substitute of dune sand is 21% higher than the reference concrete’s compressive strength after 28 days of curing. Compressive capacity is 43% more than the reference concrete at the same dosage of 5% dune sand replacement. Additionally, with a 20 percent replacement of dune sand, the compressive strength at 28 days is the same as the reference concrete’s compressive capacity, but by 90 days, it is 14 percent higher than the reference strength.

1.2. Tensile Strength

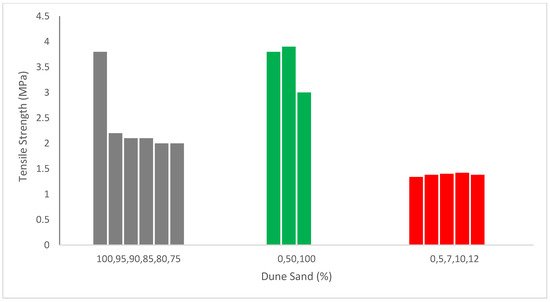

Figure 3 illustrates the tensile capacity of concrete with the substitution of dune sand. It can be noted that the tensile capacity of concrete reduced with the substitution of dune sand as reported by Abadou et al. [19].

The modulus of elasticity and tensile capacity of concrete is not significantly negatively impacted by increasing the amount of dune sand in concrete [1]. The DS/FA (Dune sand/Fly ash) ratio of 10% was ideal for compressive and tensile capacity under the mixed circumstances of this investigation. The strength differential might be more than 10%, depending on the DS/FA ratio [20]. Since the compressive capacity has greatly increased and the tensile strengths have only marginally diminished, it was possible to create a material that may be considered when constructing pavement constructions by adding dune sand and lime to permeable asphalt [9]. At all evaluated ages up to 44 percent, the recycled aggregate made from concrete waste used to make the dune sand mortar had lower tensile strength than the specimen mortar. When compared to ordinary mortar, the integration of concrete waste aggregates does not seem to have a substantial influence on tensile strength [19]. The tensile and flexural capacity decreased by 29.3 percent and 21.1 percent for splitting and flexural capacity, respectively, and at a slower pace than the compressive strength as the sand dune rate increased. The ratio (40 percent DS without fibers) attained the greatest tensile capacity of 4 MPa (22.3 percent more than the reference samples), according to the tensile capacity data at the age of 28 days.

On the other hand, Figure 3 shows that the tensile capacity of concrete rises as the dune sand content rises, according to Rennani et al. and Leila et al. [8][10]. Similarly, 60 percent dune sand increased tensile strength by 0.91 percent, which is equal to the reference concrete. The mechanical qualities of the hybrid concrete were enhanced by the inclusion of steel fibers, which can make up for much of the lost strength caused by the rise in sand dunes ratios [17]. The tensile strength of the hybrid mixture is 40.2 percent higher than 100 percent dune sand without fibers when dune sand is completely replaced by 100 percent rather than sand with 1 percent fibers [17]. Fiber increased tensile strength due to the prevention of cracks [21]. Even if the cracks appear, the propagation of cracks is restricted by the fibers [22].

1.3. Flexural Strength

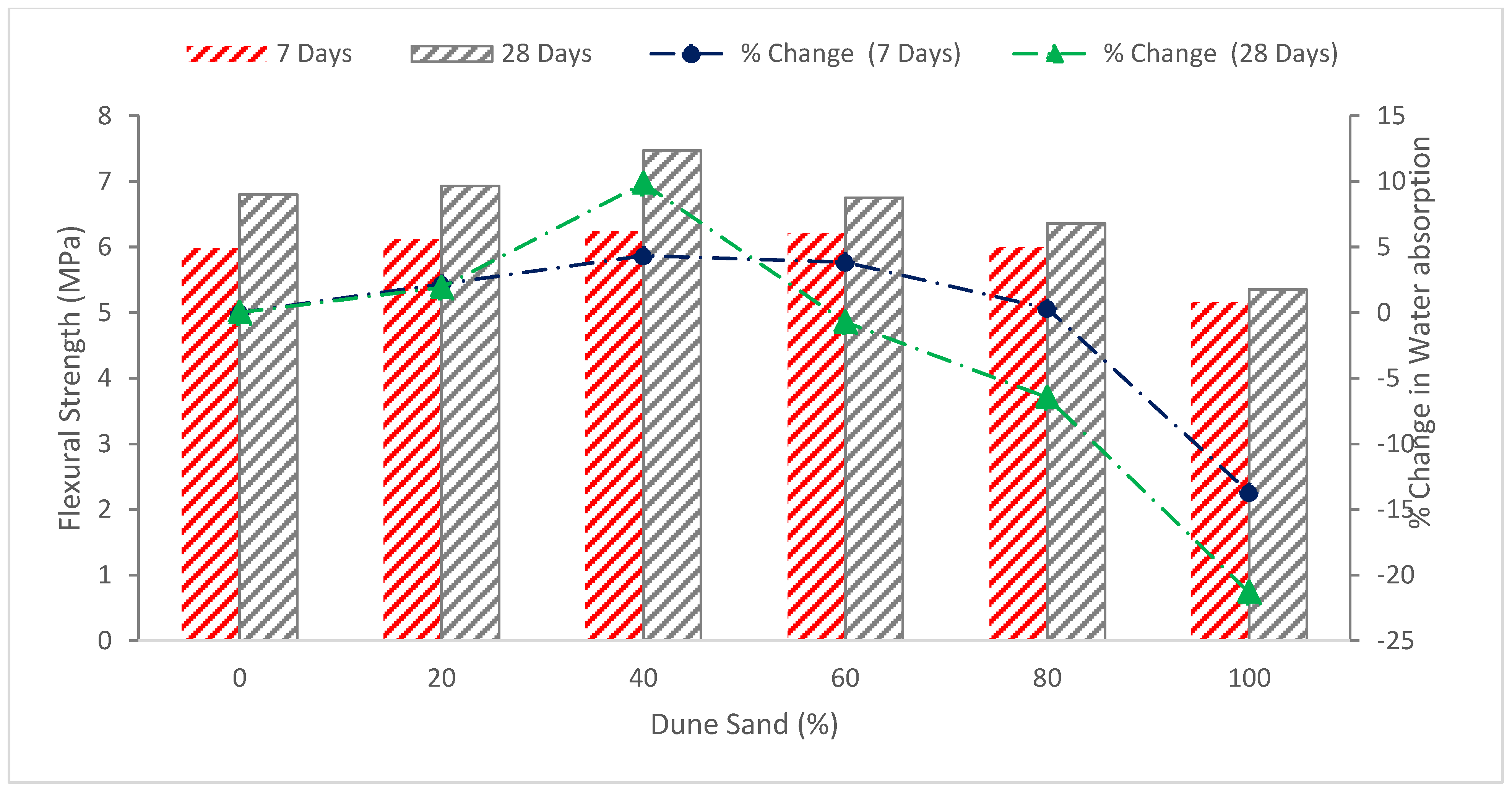

Figure 4 reveals the flexural capacity of concrete with the substitution of dune sand. It can be noted that flexural capacity improved by up to 20% with substitution of dune sand. A study reported that the flexural strengths were increased by using waste materials as aggregate. It was found that replacing 40% and 50% of the natural dune sand with waste ceramic aggregate resulted in the biggest gain in compressive and flexural strength when compared to reference mortar [11]. According to the experimental findings, mechanical properties were best when dune sand replacement was 50%. The flexural strength of self-compacting mortar had not been significantly decreased by the replacement of dune sand [23].

Figure 4. Flexural strength: data source [17].

The 40% substitution of dune had the maximum flexural strength at seven days, which is 4.3 percent higher than the reference sample. At the same time, the flexural capacity is reduced by 13.7 percent less than the reference specimen when dune sand is substituted 100 percent (completely replaced the sand). The 40 percent dune sand in concrete shows the maximum flexural strength (7.47 MPa) at the age of 28 days, which is 9.85 percent higher than the reference sample. When the dune sand ratio is enhanced, the flexural capacity decreases. At a replacement ratio of 100 percent dune, flexural strength decreased by 21.3 percent when associated to the blank concrete (without dune sand). The rise in fineness of the sand particles in the concrete is the cause of the decreased flexural capacity. However, the flexural capacity of concrete with dune sand substituted was significantly enhanced with the addition of fibers. A concrete mixture of 20% dune sand along with 1% steel fibers achieved the highest flexural capacity of 10.07 MPa at the age of 28 days, which is 45.3 percent higher than the reference concrete [17]. Few researchers considered flexural strength in their studies. Therefore, a more detailed investigation is required.

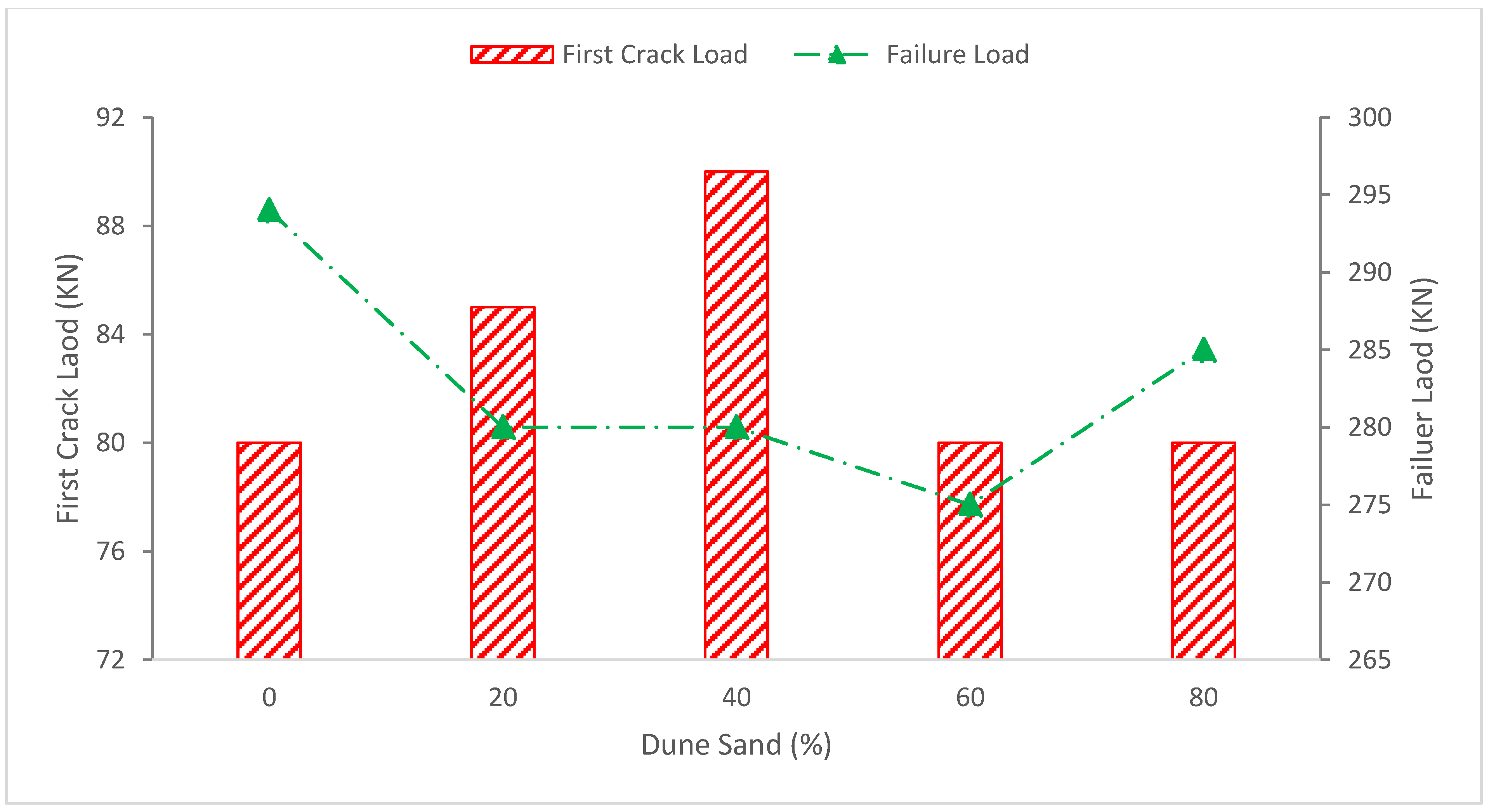

Flexural and flexure–shear fractures are clearly visible, and the crack patterns of the regular beam resemble those of dune sand beams. It was determined that the presence of the dune may have delayed the initial fracture since it occurred at a force of around 80 KN, as shown in Figure 5, the central flexural zone. Shear fractures began to appear in both shear spans at the supports at a load of around 130 KN, although their dispersion in the shear spans varied. All beams broke in flexure shear at a load of around 280 KN, and the ultimate failure took place near the load point for concrete crushing in the compression zone. Figure 5 shows the failure load for every beam, and it can be inferred that the presence of dune sand may lower the failure load of beams. Although the leading shear crack direction and failure mechanisms varied, the initial fracture, failure load and shear cracks did not.

Figure 5. First crack load and failure load: data source [24].

2. Durability

2.1. Dry Density

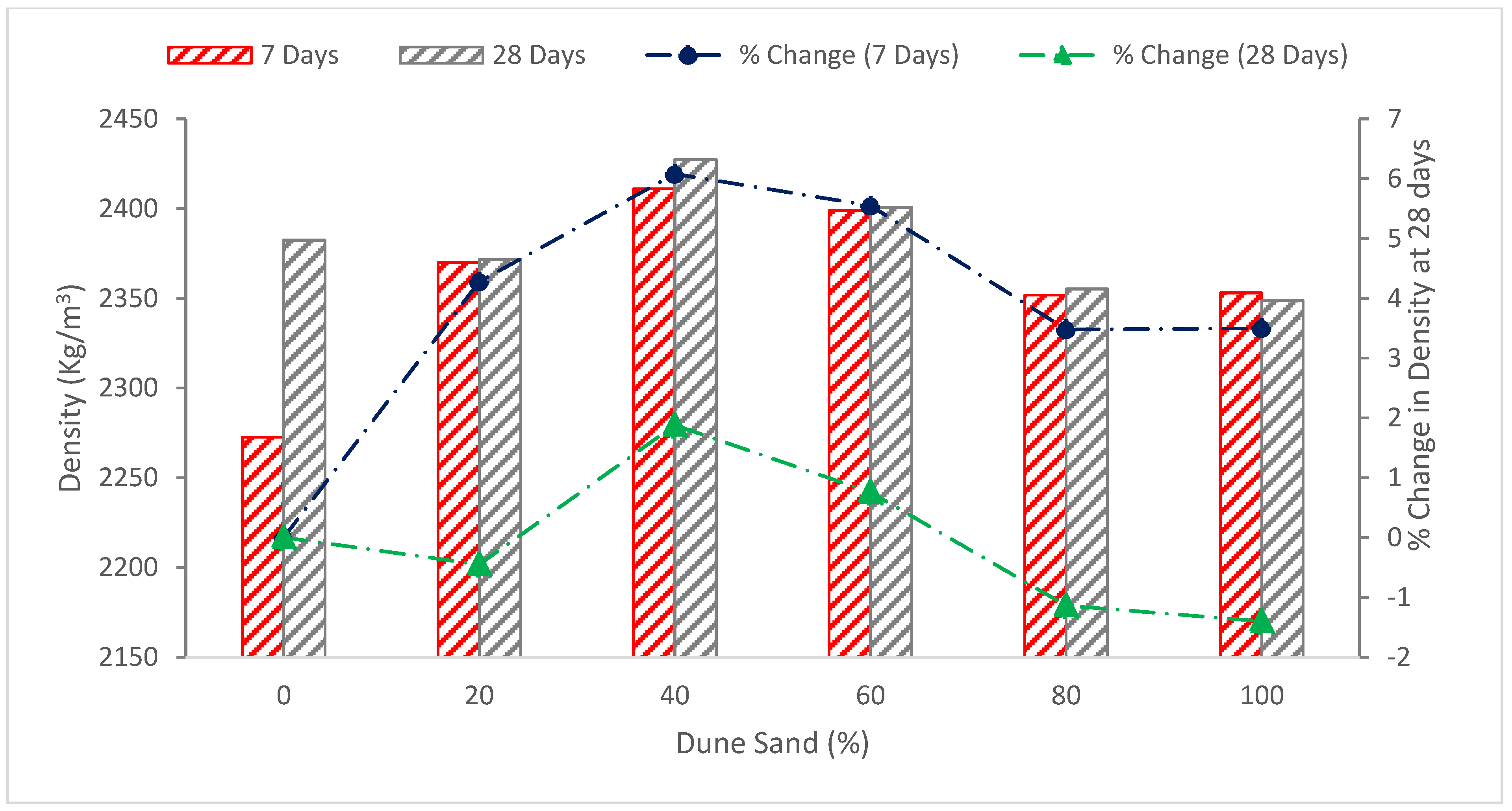

The addition of dune sand to the concrete mixture increased the density at replacement ratios of 40 and 60 percent, with the replacement ratio of 40 percent dune sand. The recording density is 2427.35 kg/m3 with a growth of its quantity 1.88 percent more than the blank concrete, while the replacement ratio is 60 percent, and the increase in density is 0.76%, as associated with the control concrete. Partial substitution of dune with natural sand helped increase the density due to the softness of the dune sand, their spherical form and their overlap between gravel and sand grains, which helped fill all the spaces and holes within the concrete [17]. A study also reported that the filler materials increased the density of concrete due to filling cavities in concrete components, leading to more dense concrete [25]. However, when the percentage of dune sand is raised to 80% and 100%, the density falls, as shown in Figure 6. It might be possible that a higher dose of dune sand reduced the density due to a lack of flowability. The less flowable concrete required more compaction energy as compared to more workable concrete. Therefore, more chance of voids in less workable concrete, which adversely affect the density of concrete. A study also claims that filler material decreased the density of concrete at a higher substitution ratio due to lack of flowability [26].

Figure 6. Dry density: data source [17].

2.2. Water Absorption

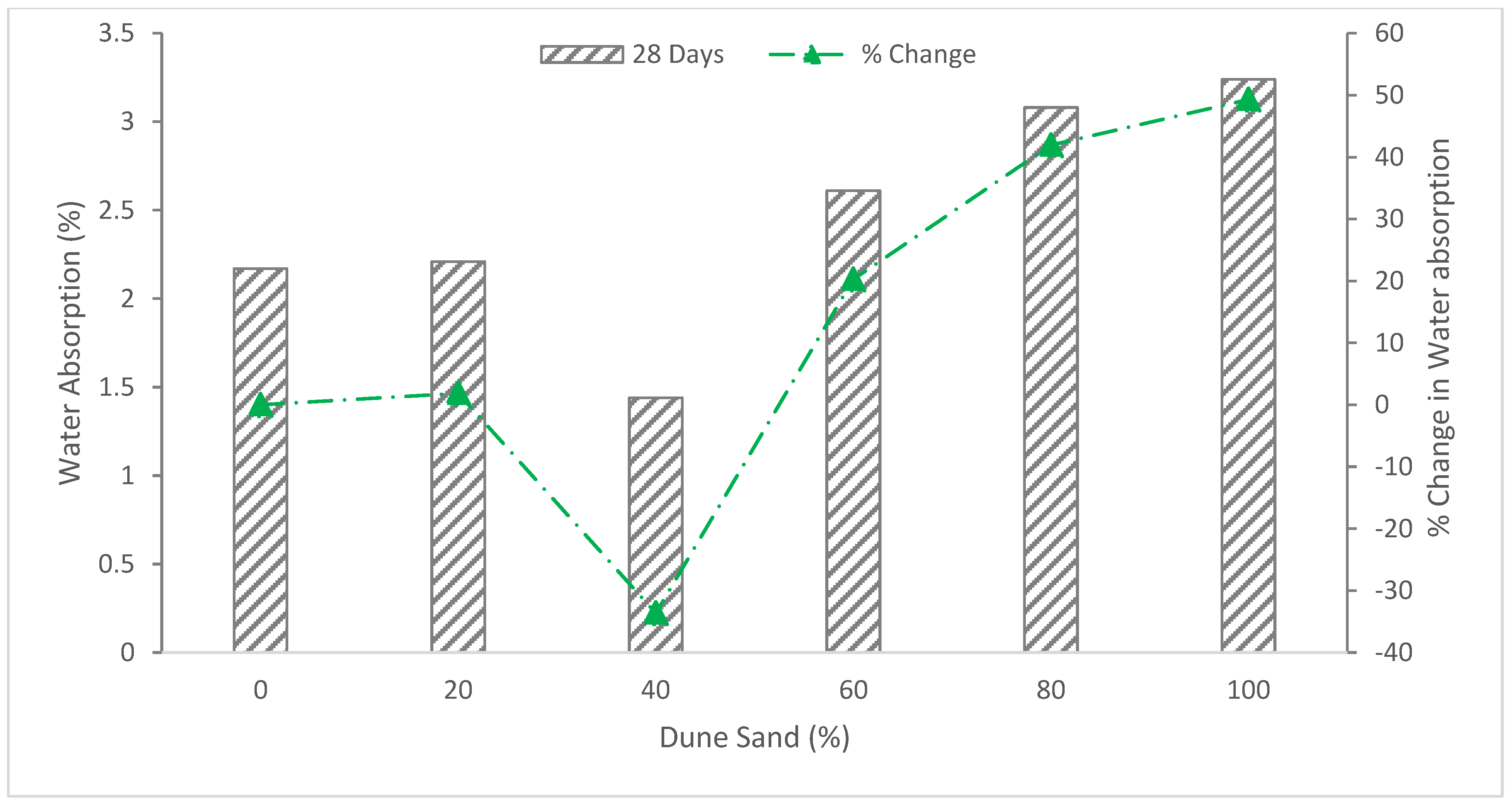

Figure 7 shows the water absorption of concrete with the substitution of dune sand as fine aggregate at 28 days.

Figure 7. Water absorption: data source [17].

The 40% substitution of dune sand with fine aggregate shows the lowest water absorption rate of 1.44 percent, which is 33.6 percent less than the reference mixture. The decrease in water absorption is due to the micro-filling voids effect of dune sand, which fill the voids, leading to more dense concrete. According to CEB 1989;192, this specimen is regarded as excellent concrete because of its low water absorption. The rate at which water is absorbed increases when the dune sand concentration rises by 60%, 80%, and 100%. The absorption rate at 80% and 100% substitution of dune sand are 41.9 and 49.3 percent, respectively, which is more than the reference mixture, and the concrete quality is medium, according to CEB 1989;192. A similar finding is also reported by other researchers that the quality of concrete decreased at a higher substitution ratio of dune sand [1]. It could be caused by the fineness of the dune sand grains, which absorb more mixing water and have a larger surface area, creating holes or spaces that, in turn, speed up the rate of absorption.

2.3. Ultrasonic Pulse Velocity (UPV)

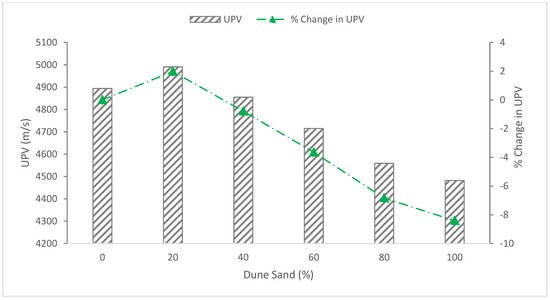

The findings showed that all concrete mixes had pulse velocities between 4400 and 6100 m/s, which is consistent with excellent and homogenous concrete quality as defined by BS1881, 1983, Part 116. The reference specimen shows a pulse velocity rate of 4894 m/s, and the concrete quality satisfies the requirements of IS code BS1881, 1983. As shown in Figure 8, the pulsing velocity for a concrete mixture of 20% dune sand is 1.98 percent higher than that of the reference specimen (0% dune sand), and it decreases with increasing dune sand content for the ratios 40%, 60%, 80% and 100%. This is consistent with the absorption and density test results, which also show a decrease with increasing dune sand content due to the fineness of the dune [17].

Figure 8. Ultrasonic pulse velocity (UPV): data source [17].

2.4. Sulfate Resistance

2.4.1. Visual Observation

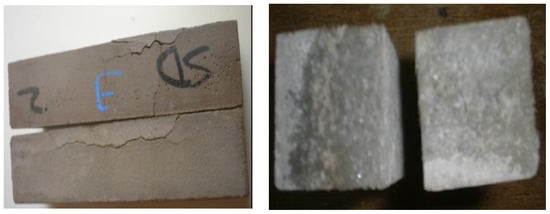

Every month, a comprehensive visual inspection was conducted on the mortar specimens subjected to sulfate assault to assess any evident symptoms of softening, cracking and spalling. Figure 9 depicts typical instances of the harm that sulfate assault on mortar specimens causes after 180 days of immersion in sodium sulfate. It was found that the mortar samples’ corners always showed the first signs of degradation, and the broad cracks caused by the expansion strain on the cement matrix were substantial, as shown in Figure 9. After 180 days of immersion, the dune sand mortar began to visually deteriorate as a result of the mortar structure losing its cohesion. Additionally, a layer of white material was discovered deposited on the mortar faces, which was verified by the XRD investigation to be gypsum and ettringite formation.

Figure 9. Beam of dune sand mortars immersed in sodium sulfate solution (5%) at 180 days [27].

2.4.2. X-ray Diffraction (XRD)

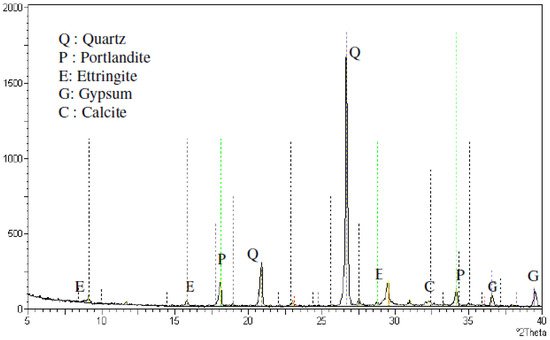

Figure 10 shows the X-ray Diffraction (XRD) examination of mortar that was exposed to a five percent sodium sulfate solution for 180 days, which shows diffractograms demonstrating the gypsum-specific peaks. On the degraded portions of cube mortar samples that were evaluated for compressive strength, the XRD analysis was performed. It can be seen that some ettringite peaks were found as a result of sulfate assault, together with calcite. Peaks made of quartz and portlandite (made from sand) were visible. The mortars for all showed gypsum and ettringite are two common sulfate attack byproducts that lead to mortar strength loss [28].

Figure 10. XRD of dune sand mortars immersed in sodium sulfate solution (5%) at 180 days [27].

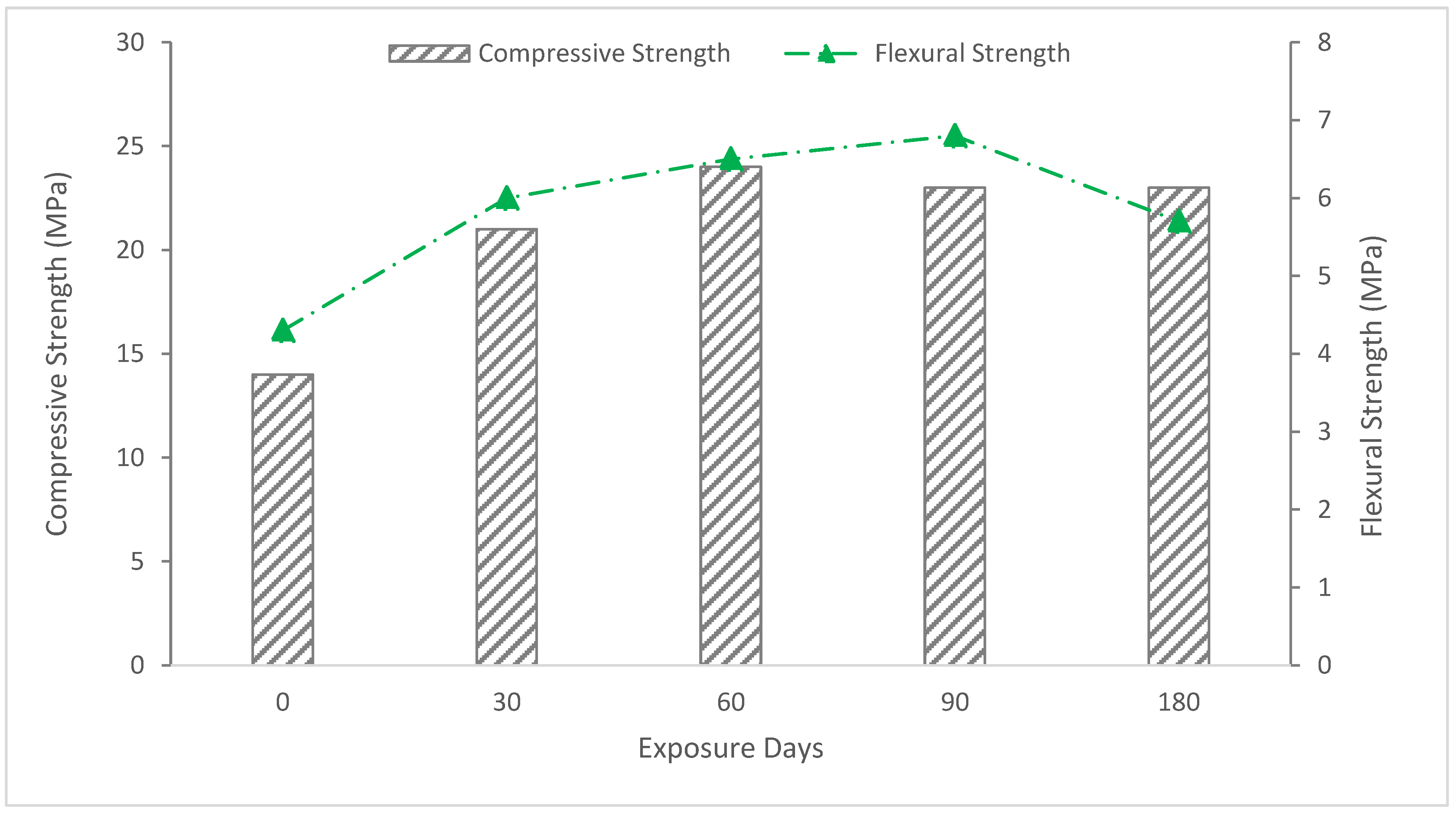

5.4.3. Strength (Compressive and Flexural)

Strength changes in mortar specimens subjected to sodium sulfate solution (5%) are shown in Figure 11. It can be seen that all mortars demonstrate a strength increase at the beginning of the exposure duration and a subsequent decline in strength development. Strength initially increased in sulfate solution as a result of additional hydration products filling the pores, but strength afterward reduced as a result of microcracking caused by expanding components of sulfate assault. After 180 days of exposure, mortar exhibited a quick loss of strength, and the loss of strength for dune sand mortar was considerable.

Figure 11. Strength of dune sand mortars immersed in sodium sulfate solution (5%) at 180 days [27].

References

- Al-Harthy, A.; Halim, M.A.; Taha, R.; Al-Jabri, K. The properties of concrete made with fine dune sand. Constr. Build. Mater. 2007, 21, 1803–1808.

- Seif, E.; Sedek, E.S. Performance of Cement Mortar Made with Fine Aggregates of Dune Sand, Kharga Oasis, Western Desert, Egypt: An Experimental Study. Jordan J. Civ. Eng. 2013, 7, 270–284.

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014; ISBN 0071797874.

- Rmili, A.; Ben Ouezdou, M.; Added, M.; Ghorbel, E. Incorporation of Crushed Sands and Tunisian Desert Sands in the Composition of Self Compacting Concretes Part II: SCC Fresh and Hardened States Characteristics. Int. J. Concr. Struct. Mater. 2009, 3, 11–14.

- Bouziani, T.; Bederina, M.; Hadjoudja, M. Effect of dune sand on the properties of flowing sand-concrete (FSC). Int. J. Concr. Struct. Mater. 2012, 6, 59–64.

- Guettala, S.; Mezghiche, B. Compressive strength and hydration with age of cement pastes containing dune sand powder. Constr. Build. Mater. 2011, 25, 1263–1269.

- Liu, Y.; Li, Y.; Jiang, G. Orthogonal experiment on performance of mortar made with dune sand. Constr. Build. Mater. 2020, 264, 120254.

- Rennani, F.Z.; Makani, A.; Agha, N.; Tafraoui, A.; Benmerioul, F.; Zaoiai, S. Mechanical Properties of High-Performance Concrete Made Incorporating Dune Sand as Fine Aggregate. Rev. Rom. Ing. Civ. 2020, 11, 37–46.

- Siala, A.; Khay, S.E.E.; Loulizi, A.; Neji, J. Improving the performance of porous asphalt with reclaimed asphalt, dune sand and lime. Proc. Inst. Civ. Eng.-Constr. Mater. 2021, 174, 214–226.

- Zeghichi, L.; Benghazi, Z.; Baali, L. Comparative Study of Self-Compacting Concrete with Manufactured and Dune Sand. J. Civ. Eng. Arch. 2012, 6, 1429–1434.

- Abadou, Y.; Mitiche-Kettab, R.; Ghrieb, A. Ceramic waste influence on dune sand mortar performance. Constr. Build. Mater. 2016, 125, 703–713.

- Althoey, F.; Farnam, Y. The effect of using supplementary cementitious materials on damage development due to the formation of a chemical phase change in cementitious materials exposed to sodium chloride. Constr. Build. Mater. 2019, 210, 685–695.

- Rao, G. Development of strength with age of mortars containing silica fume. Cem. Concr. Res. 2001, 31, 1141–1146.

- Kwan, A.K.H. Use of Condensed Silica Fume for Making High-Strength, Self-Consolidating Concrete. Can. J. Civ. Eng. 2000, 27, 620–627.

- Saidi, M.; Safi, B.; Samar, M.; Benmounah, A. Formulation and Physicochemical Characterization of Ultra-High Performance Fiber Concrete Based of Sand Dunes (UHPFC). In Proceedings of the 3rd International Conference on Material Modeling incorporating the 13th European Mechanics of Materials Conference, Warsaw, Poland, 8–11 September 2013.

- Benmerioul, F.; Tafraoui, A.; Makani, A.; Zaouai, S. A Study on Mechanical Properties of Self-Compacting Concrete Made Utilizing Ground Dune Sand. Rev. Rom. Mater. J. Mater. 2017, 47, 328–335.

- Dawood, A.O.; Jaber, A.M. Effect of Dune Sand as Sand Replacement on the Mechanical Properties of the Hybrid Fiber Reinforced Concrete. Civ. Environ. Eng. 2022, 18, 111–136.

- Mohammed, M.; Abdelouahed, K.; Allaoua, B. Compressive Strength of Dune Sand Reinforced Concrete. AIP Conf. Proc. 2017, 1814, 020023.

- Abadou, Y.; Ghrieb, A.; Bustamante, R. Crushed concrete waste influence on dune sand mortar performance. Contribution to the valorization. Mater. Today Proc. 2020, 33, 1758–1761.

- Lee, E.; Ko, J.; Yoo, J.; Park, S.; Nam, J. Effect of Dune Sand on Drying Shrinkage Cracking of Fly Ash Concrete. Appl. Sci. 2022, 12, 3128.

- Ahmad, J.; Manan, A.; Ali, A.; Khan, M.W.; Asim, M.; Zaid, O. A Study on Mechanical and Durability Aspects of Concrete Modified with Steel Fibers (SFs). Civ. Eng. Arch. 2020, 8, 814–823.

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; El Ouni, M.H.; Khedher, K.M. Performance of sustainable self-compacting fiber reinforced concrete with substitution of marble waste (MW) and coconut fibers (CFs). Sci. Rep. 2021, 11, 23184.

- Benabed, B.; Azzouz, L.; Kadri, E.-H.; Kenai, S.; Belaidi, A.S.E. Effect of fine aggregate replacement with desert dune sand on fresh properties and strength of self-compacting mortars. J. Adhes. Sci. Technol. 2014, 28, 2182–2195.

- Li, Z.; Yang, S.; Luo, Y. Experimental evaluation of the effort of dune sand replacement levels on flexural behaviour of reinforced beam. J. Asian Arch. Build. Eng. 2020, 19, 480–489.

- Ahmad, J.; Aslam, F.; Zaid, O.; Alyousef, R.; Alabduljabbar, H. Mechanical and durability characteristics of sustainable concrete modified with partial substitution of waste foundry sand. Struct. Concr. 2021, 22, 2775–2790.

- Ahmad, J.; Martínez-García, R.; De-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430.

- Azzouz, L.; Benabed, B.; Belaidi, A.S.E.; Menadi, B. Physical, Mechanical and Durability of Dunes Sand Mortar in The Region of Laghouat–Algeria. 2008. Available online: https://www.thbbakademi.org/wp-content/uploads/2020/12/B2008.012-1.pdf (accessed on 22 June 2022).

- Al-Dulaijan, S.; Maslehuddin, M.; Al-Zahrani, M.; Sharif, A.; Shameem, M.; Ibrahim, M. Sulfate resistance of plain and blended cements exposed to varying concentrations of sodium sulfate. Cem. Concr. Compos. 2003, 25, 429–437.

More

Information

Subjects:

Engineering, Civil

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

3 times

(View History)

Update Date:

26 Sep 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No