| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nadezhda Dudova | -- | 4484 | 2022-09-15 16:22:15 | | | |

| 2 | Lindsay Dong | + 23 word(s) | 4507 | 2022-09-19 03:11:14 | | | | |

| 3 | Lindsay Dong | Meta information modification | 4507 | 2022-09-19 03:12:47 | | | | |

| 4 | Lindsay Dong | Meta information modification | 4507 | 2022-09-20 08:30:45 | | |

Video Upload Options

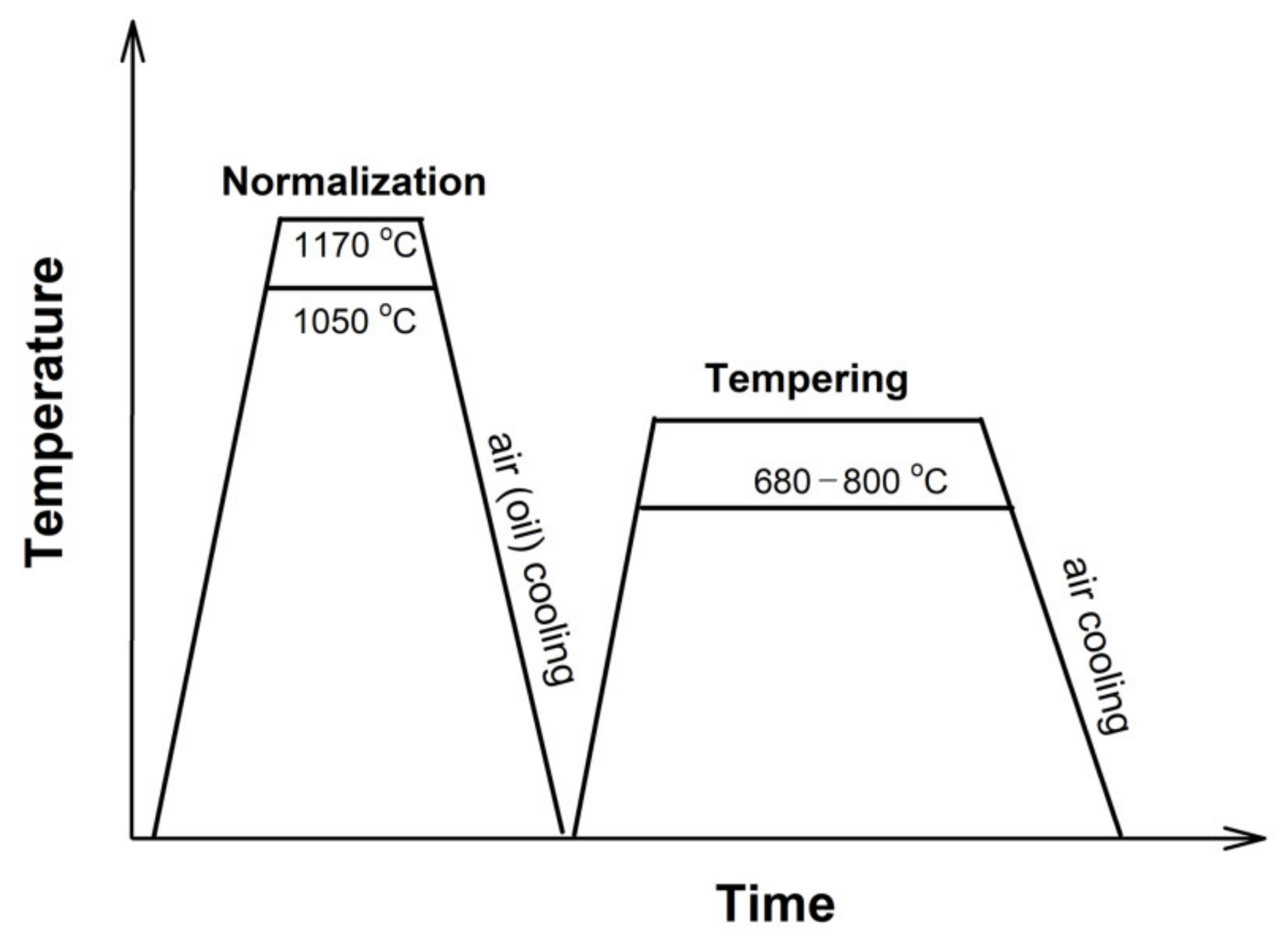

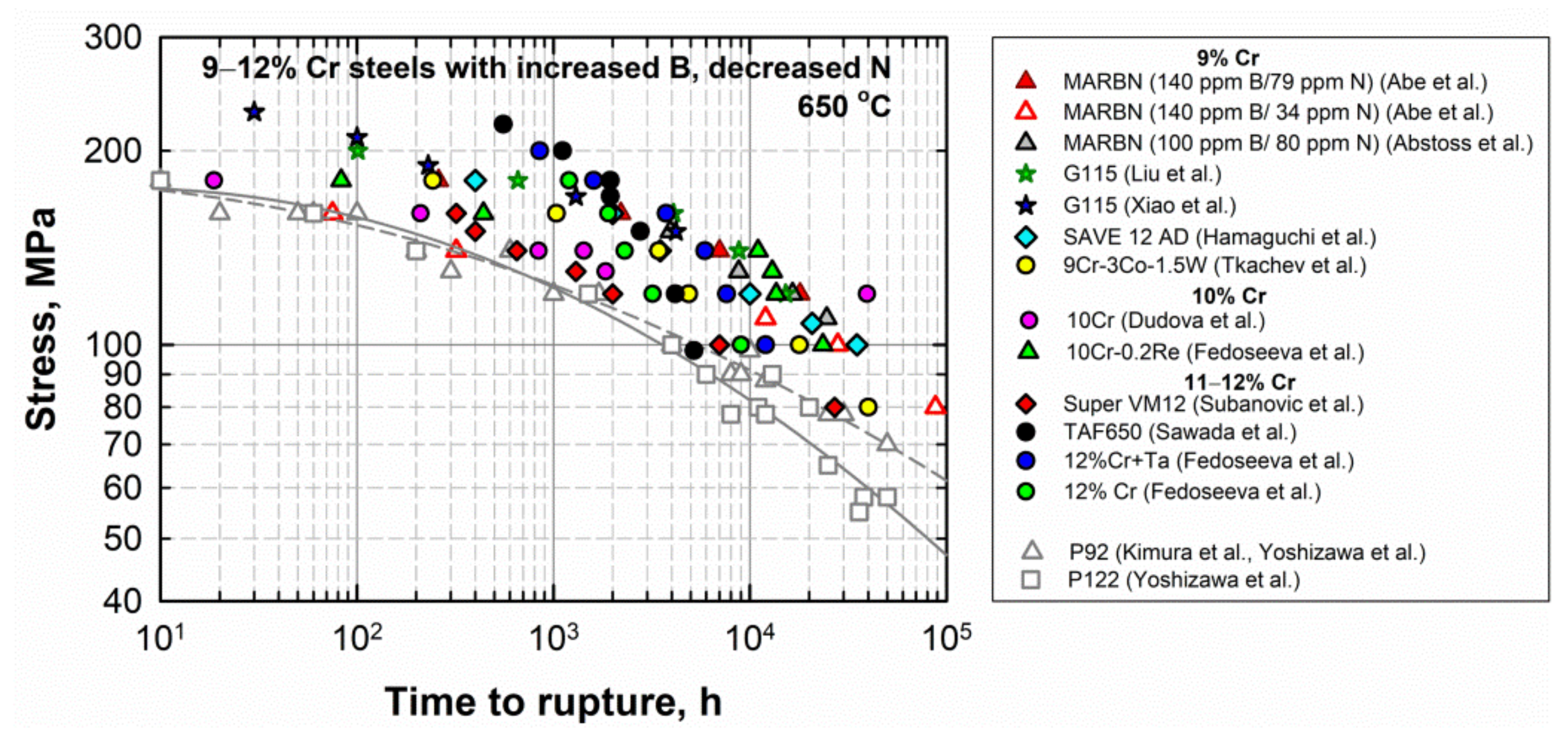

As a promising alloying approach, the modification of chemical composition by increasing the B content and decreasing the N content has been applied to improve the creep resistance of various 9–12% Cr heat-resistant martensitic steels. The 9–12% Cr steels have to exhibit high long-term creep strength, oxidation resistance in a high temperature steam, low cycle fatigue resistance, impact toughness, etc. The creep resistance is the main critical requirement: the minimum long-term creep rupture strength on the base of 100,000 h should be 100 MPa or higher at 650 °C.

1. Introduction

2. Obtaining and Heat Treatment of Steels

2.1. Chemical Composition of Steels

2.1.1. The 9% Cr Steels

2.1.2. The 10% Cr Steels

2.1.3. The 11–12% Cr Steels

2.2. Vacuum Induction Melting of Steels

2.3. Heat Treatment

3. The Boron/Nitrogen Ratio in the Steels

-

Preventing the formation of BN phase. On the one hand, an increased boron content enhances the coarsening resistance of M23C6-type carbides during creep. On the other hand, the presence and content of nitrogen strongly affects the efficiency of alloying with boron. Nitrogen affects the solubility of boron in the ferritic matrix. At excess nitrogen content, the undesirable BN phase is formed during normalization. The coarse BN precipitates can act as initiation sites for creep cavities that reduce the creep resistance and creep ductility. Formation of BN leads to a depletion of boron from the ferritic matrix.

-

Optimal fraction of MX phase. The nitrogen content determines the volume fraction of MX carbonitrides, namely N- and V-enriched precipitates, in steels. At optimal B content, the N content should not be too high or too low.

-

Preventing MX→Z-phase transformation. In the steels with 10–12% Cr, a low N concentration prevents the transformation of the MX phase into the undesirable coarse Z-phase particles (CrVN). Thus, in the experimental 12% Cr steels with 20 ppm N, the Z phase was not observed even after long-term creep for >20,000 h at 650 °C [15]. In the Super VM12 steel with 110 ppm N, the Z-phase was not revealed after long-term creep during 23,844 h at 650 °C [48].

4. Microstructure and Creep Properties of Advanced 9–12% Cr Steels

4.1. Creep Properties of the 9–12% Cr Steels

4.2. The 9% Cr Steels

4.3. The 10% Cr and 11–12% Cr Steels

- -

-

preferential recovery of martensitic microstructure near the PAG boundaries;

- -

-

Z-phase formation and disappearance of MX strengthening precipitates;

- -

-

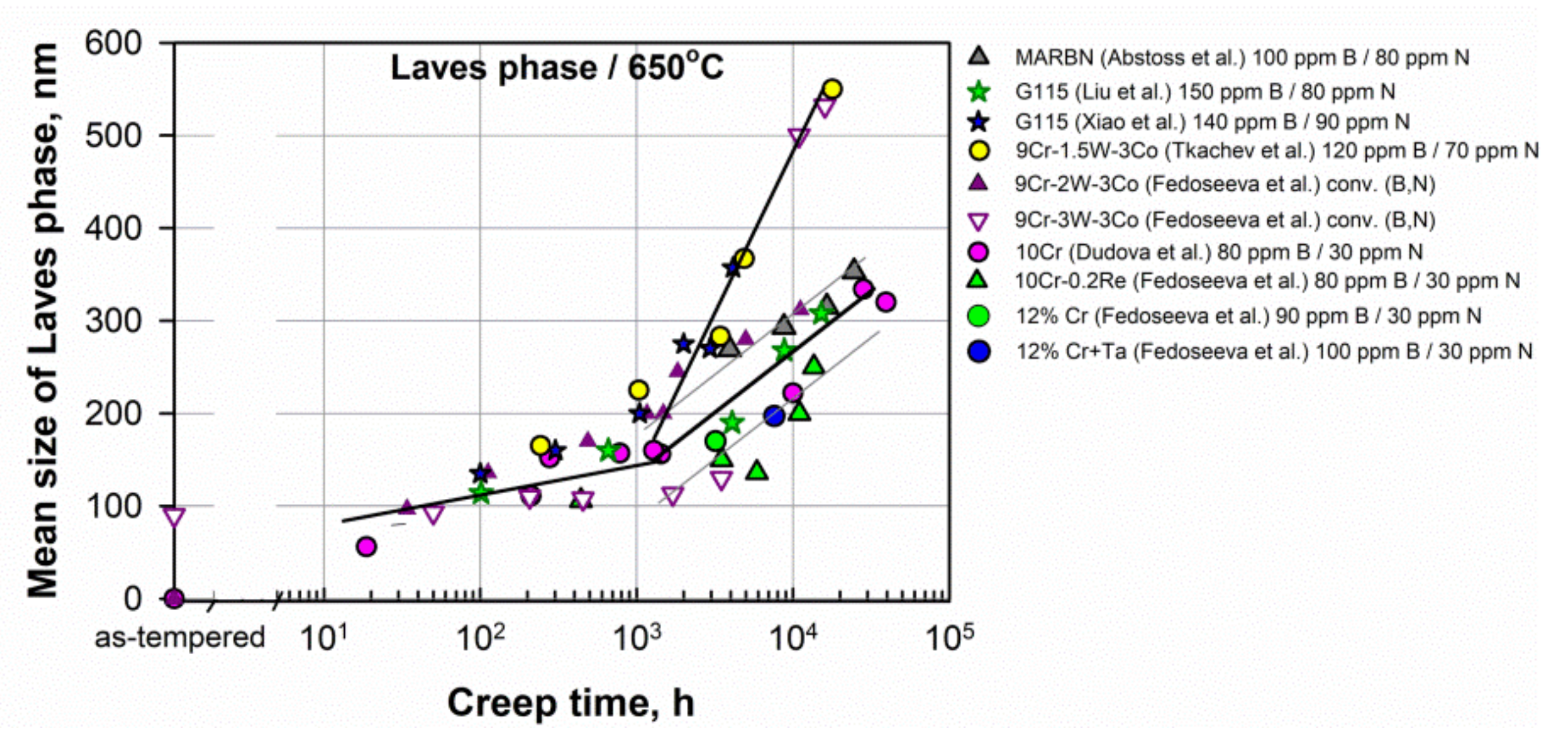

Laves phase formation, etc.

5. Strengthening Factors in the 9–12% Cr Steels

5.1. Solid Solution Strengthening

5.2. Boundary and Sub-Boundary Strengthening

5.3. Dislocation Strengthening

5.4. Precipitation Strengthening

Threshold stress. The M23C6 carbides and Laves phase particles are the main phases precipitated on the boundaries of lath, blocks, packets and PAGs.

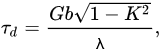

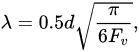

The stresses created by small precipitates cause the threshold stress for the onset of creep. Dudova et al. examined the creep behavior of the 10Cr steel in terms of threshold stress and found a high threshold stress of 111.5 MPa, which is about 30% larger than that in the P92-type steel [6]. The calculation of the stresses required for a dislocation to pass through particles at the minimum creep rate stage was carried out. The Orowan mechanism (to bow a dislocation between two particles), climb mechanism (to generate the additional length of dislocation to climb over an obstacle), and detachment mechanism (to detach the dislocation from an attractive particle after finishing the climb) were taken into account. It was revealed that the threshold stress is associated with the stress required for detachment of dislocations from M23C6 carbides, MX carbonitrides, and Laves phase particles after finishing the climb. Further, essentially stable M23C6 carbides exert the main part of threshold stress. The detachment stress can be calculated by equation [56]:

where G is the shear modulus, b is the Burgers vector, K—relaxation parameter, λ is the mean interparticle spacing, which is determined as [57]:

where d is the mean size of particles, Fv is the volume fraction of particles.

6. Summary

- -

-

The approach to alloying by the increased B (80–150 ppm) and decreased N (30–100 ppm) contents is successfully applied to advanced 9% Cr, as well as 10–12% Cr martensitic steels. The predicted long-term creep rupture strength at 650 °C for 100,000 h attained:

- ○

-

80–110 MPa for the 9% Cr steels, such as the MARBN (9Cr-3Co-3W-100–140 ppm B/30–80 ppm N), G115 (9Cr-3Co-3W-1Cu-150 ppm B/80 ppm N), and SAVE12AD (9Cr-3Co-3W-0.04Nd-100 ppm B/100 ppm N) steels, which sufficiently exceeds the creep strength for the 9% Cr Co-free P92 steel (~60 MPa) and 3% Co-modified P92 steels (~65–70 MPa) with conventional B (~50 ppm) and N (~500 ppm) contents;

- ○

-

110 MPa for the 10% Cr experimental steel (10Cr-3Co-2W-0.7Mo-80 ppm B/30 ppm N), which sufficiently exceeds the creep strength for the 11%Cr Co-free P122 steel (~45 MPa), 10% Cr Co-containing NF12 steel (10Cr-2Co-2.5W-50 ppm B/200 ppm N) (40 MPa), and advanced 10Cr-3Co-1.8W-100 ppm B/200 ppm N (TOS 110) steel (80 MPa);

- ○

-

Approximately 65 MPa for the 11–12% Cr steels, such as SuperVM12 steel (11Cr-1.8Co-2W-0.5Mo-140 ppm B/110 ppm N), which is sufficiently higher than that for the previous VM12-SHC steel (~50 MPa), 11%Cr Co-free P122 steel (~45 MPa), and slightly higher than that for 9% Cr P92 steel (~60 MPa) with conventional B (~50 ppm) and N (~500–600 ppm) contents;

- -

-

An increase in the B content and a decrease in the N content enhance the creep resistance in the long-term region at a low stress, while the creep strength in the short-term region at the higher stresses corresponds to that for the steels with conventional B and N contents;

- -

-

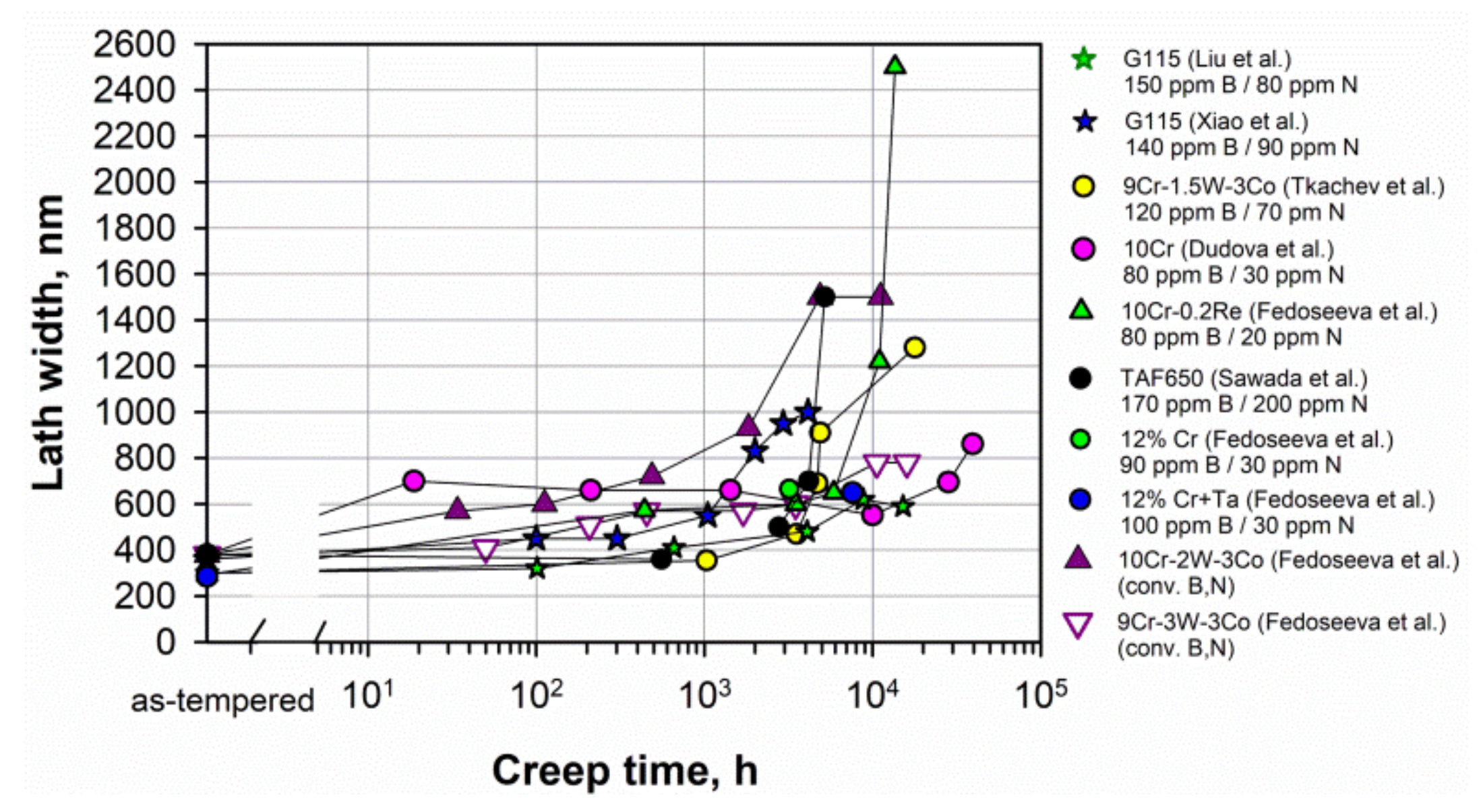

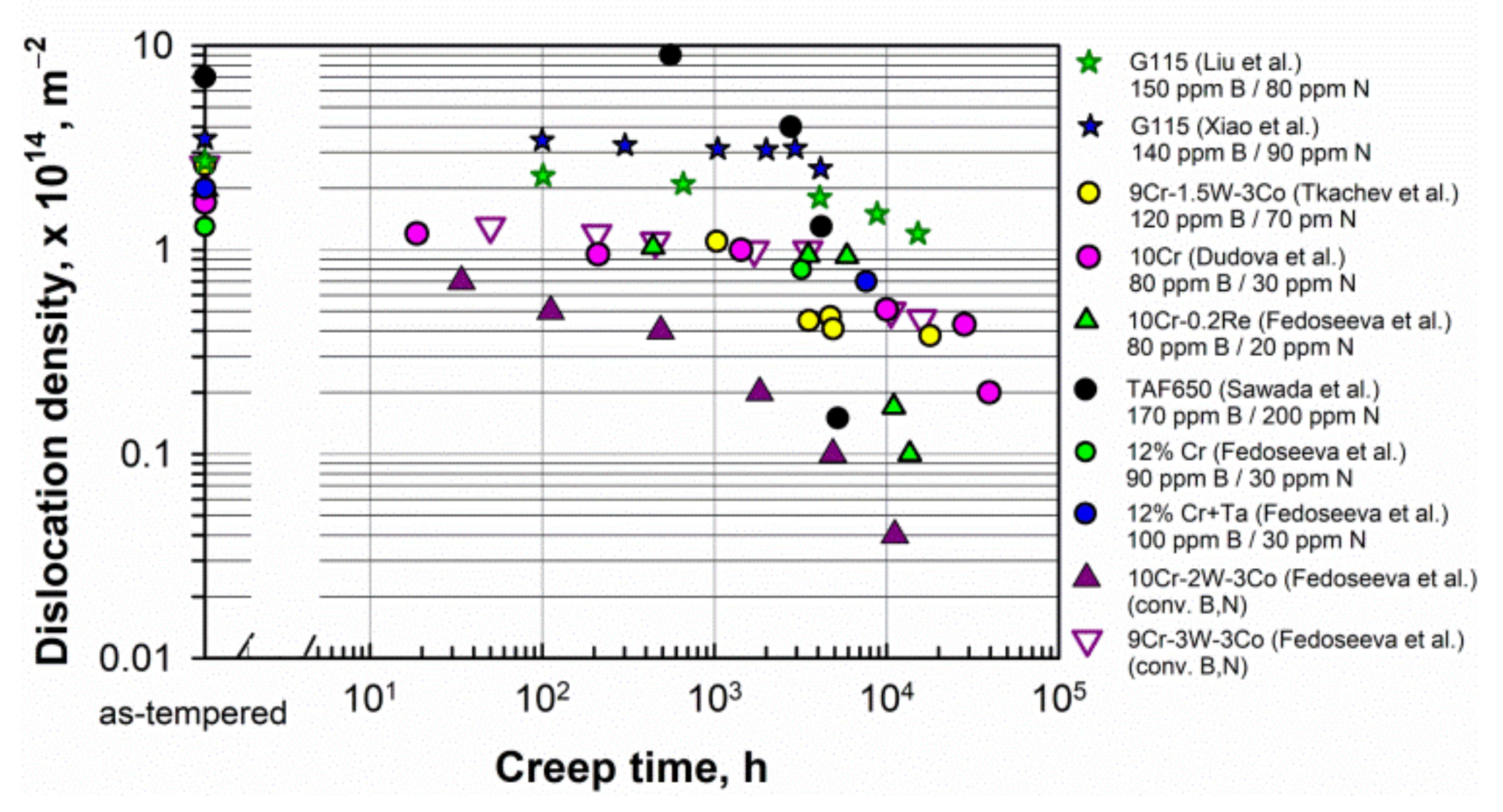

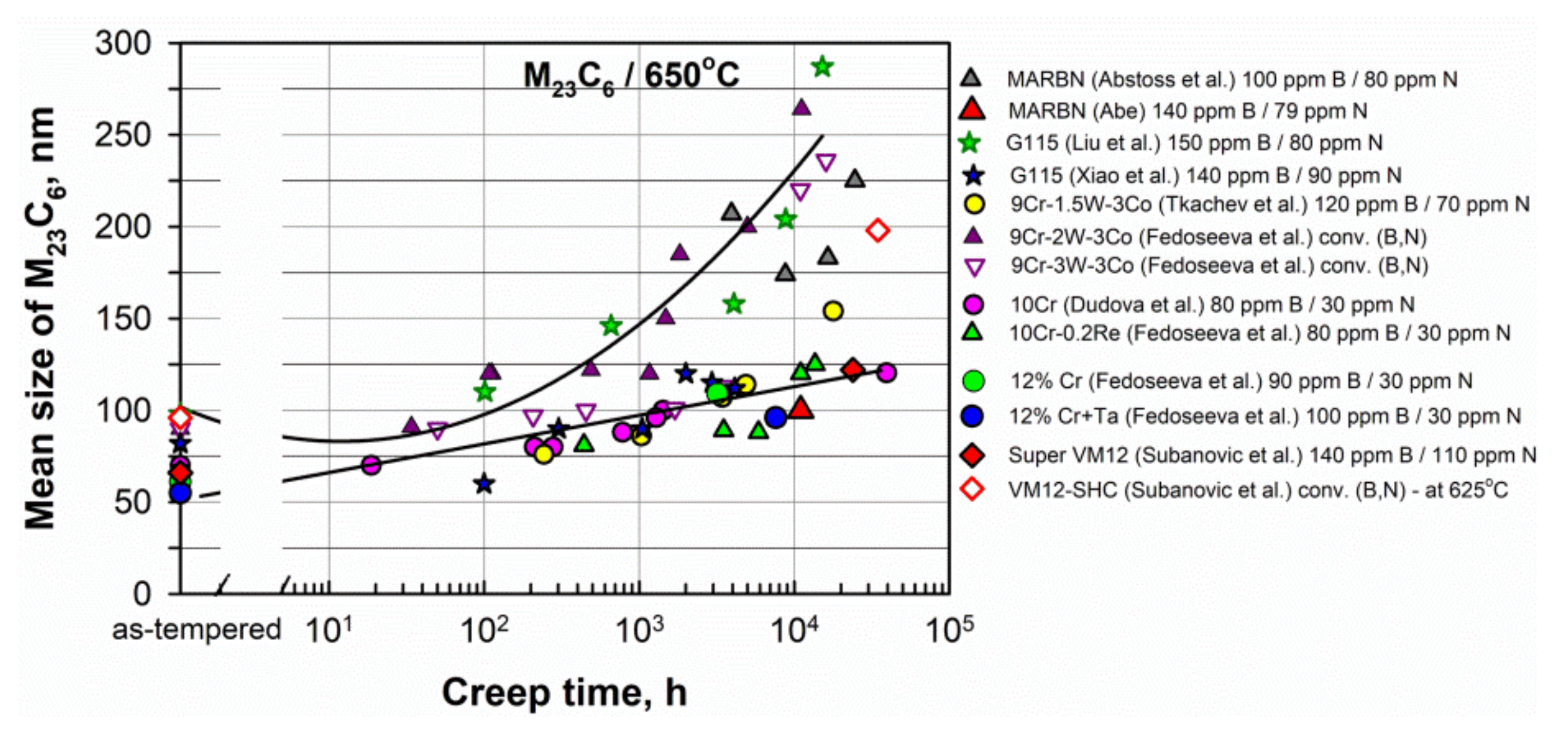

A high B content at a low N content effectively increases the coarsening resistance of M23C6 carbides during creep at 650 °C in all considered steels;

- -

-

A positive effect of B on the creep strength is associated with enrichment of M23C6 carbides located near the PAG boundaries, which increases their coarsening resistance during creep. Stable M23C6 carbides are able to impede the recovery of the lath structure in the vicinity of PAG boundaries and, hence, retard the local deformation in the PAG boundary regions;

- -

-

Even if the B content was already high in steel, then lowering the N content less than the solubility limit can increase the long-term creep rupture strength due to full utilization of soluble boron in the matrix and M23(B,C)6-type carbides;

- -

-

Precipitation of small MX particles during the transient stage of long-term creep effectively reduces the creep rate and increases the time to rupture, as was shown in the MARBN steel with 140 ppm B and 79 ppm N and the 10Cr experimental steel with 80 ppm B and 30 ppm N;

- -

-

An increase in the B content and a decrease in the N content is an effective way to enhance the dispersion strengthening by: fine and highly coarsening-resistant M23C6 carbides, which, in turn, can provide the slower coarsening of Laves phase particles; moreover, the MX phase, despite the low N content, can enhance the creep strength in the long-term region. This provides a stable tempered martensite lath structure over a long creep time and prevents the transformation of the lath structure into a subgrain structure.

References

- Abe, F. Research and development of heat-resistant materials for advanced USC power plants with steam temperatures of 700 °C and above. Engineering 2015, 1, 211–224.

- Abe, F.; Kern, T.-U.; Viswanathan, R. Creep-Resistant Steels; Woodhead Publishing: Cambridge, UK, 2008.

- Xie, X.; Wu, Y.; Chi, C.; Zhang, M. Superalloys for Advanced Ultra-Super-Critical Fossil Power Plant Application. In Superalloys; Aliofkhazraei, M., Ed.; IntechOpen: London, UK, 2015; pp. 51–76.

- Maruyama, K.; Sawada, K.; Koike, J. Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ Int. 2001, 41, 641–653.

- Abe, F. New martensitic steels. In Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants; Di Gianfrancesco, A., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 323–374.

- Dudova, N.; Mishnev, R.; Kaibyshev, R. Creep behavior of a 10%Cr heat-resistant martensitic steel with low nitrogen and high boron contents at 650 °C. Mater. Sci. Eng. A 2019, 766, 138353.

- Mitsuhara, M.; Yamasaki, S.; Miake, M.; Nakashima, H.; Nishida, M.; Kusumoto, J.; Kanaya, A. Creep strengthening by lath boundaries in 9Cr ferritic heat resistant steel. Philos. Mag. Lett. 2016, 96, 76–83.

- Dudko, V.; Belykov, A.; Kaibyshev, R. Evolution of lath substructure and internal stresses in a 9% Cr steel during creep. ISIJ Int. 2017, 57, 540–549.

- Semba, H.; Abe, F. Alloy design and creep strength of advanced 9%Cr USC boiler steels containing high concentration of boron. Energy Mater. 2007, 1, 238–244.

- Hald, J. Microstructure and long-term creep properties of 9–12% Cr steels. Int. J. Press. Vessels Pip. 2008, 85, 30–37.

- Abe, F. Effect of boron on microstructure and creep strength of advanced ferritic power plant steels. Procedia Eng. 2011, 10, 94–99.

- Horiuchi, T.; Igarashi, M.; Abe, F. Improved utilization of added B in 9Cr heat-resistant steels containing W. ISIJ Int. 2002, 42, S67–S71.

- Mishnev, R.; Dudova, N.; Kaibyshev, R. On the origin of the superior long-term creep resistance of a 10% Cr steel. Mater. Sci. Eng. A 2018, 713, 161–173.

- Liu, Z.; Liu, Z.; Chen, Z.; Wang, X.; Bao, H.; Dong, C. Microstructure and creep strength evolution in G115 steel during creep at 650 °C. Mater. Res. Express 2020, 7, 016528.

- Fedoseeva, A.; Nikitin, I.; Fedoseev, A.; Kaibyshev, R. Evolution of the tempered lath structure of the 12%Cr steels with low N and high B contents during creep. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1014, 012011.

- Tkachev, E.; Belyakov, A.; Kaibyshev, R. Creep behavior and microstructural evolution of a 9%Cr steel with high B and low N contents. Mater. Sci. Eng. A 2018, 725, 228–241.

- Helis, L.; Toda, Y.; Hara, T. Effect of cobalt on the microstructure of tempered martensitic 9Cr steel for ultra-supercritical power plants. Mater. Sci. Eng. A 2009, 510, 88–94.

- Dudova, N.; Plotnikova, A.; Molodov, D.; Belyakov, A.; Kaibyshev, R. Structural changes of tempered martensitic 9%Cr–2%W–3%Co steel during creep at 650 °C. Mater. Sci. Eng. A 2012, 534, 632–639.

- Fedoseeva, A.; Dudova, N.; Kaibyshev, R. Creep strength breakdown and microstructure evolution in a 3%Co modified P92 steel. Mater. Sci. Eng. A 2016, 654, 1–12.

- Fedoseeva, A.; Dudova, N.; Kaibyshev, R. Creep behavior and microstructure of a 9Cr–3Co–3W martensitic steel. J. Mater. Sci. 2016, 52, 2974–2988.

- Kipelova, A.; Odnobokova, M.; Belyakov, A.; Kaibyshev, R. Effect of Co on creep behavior of a P911 steel. Metall. Mater. Trans. A 2012, 44, 577–583.

- Abe, F.; Tabuchi, M.; Tsukamoto, S. Mechanisms for boron effect on microstructure and creep strength of ferritic power plant steels. Energy Mater. 2012, 4, 166–174.

- Abe, F.; Tabuchi, M.; Semba, H.; Igarashi, M.; Yoshizawa, M.; Komai, N.; Fujita, A. Feasibility of MARBN steel for application to thick section boiler components in USC power plant at 650 °C. In Proceedings of the 5th EPRI International Conference, Marco Island, FL, USA, 3–5 October 2007; pp. 92–106.

- Abstoss, K.G.; Schmigalla, S.; Schultze, S.; Mayr, P. Microstructural changes during creep and aging of a heat resistant MARBN steel and their effect on the electrochemical behaviour. Mater. Sci. Eng. A 2019, 743, 233–242.

- Yan, P.; Liu, Z.-D.; Liu, W.; Bao, H.-S.; Weng, Y.-Q.J. Hot Deformation Behavior of a New 9% Cr Heat Resistant Steel G115. J. Iron Steel Res. Int. 2013, 20, 73–79.

- Yan, P.; Liu, Z.; Bao, H.; Weng, Y.; Liu, W. Effect of normalizing temperature on the strength of 9Cr–3W–3Co martensitic heat resistant steel. Mater. Sci. Eng. A 2014, 597, 148–156.

- Liu, Z.; Bao, H.; Chen, Z.; Xu, S.; Zhao, H.; Wang, Q. Creep Strength and Oxidation Resistance of Industrially Made G115 Steel Pipe. In Energy Materials 2017; Liu, X., Liu, Z., Brinkman, K., Das, S., Dryepondt, S., Fergus, J.W., Guo, Z., Han, M., Hawk, J.A., Horita, T., et al., Eds.; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2017; pp. 153–159.

- Yoshizawa, M.; Igarashi, M.; Moriguchi, K.; Iseda, A.; Armaki, H.G.; Maruyama, K. Effect of precipitates on long-term creep deformation properties of P92 and P122 type advanced ferritic steels for USC power plants. Mater. Sci. Eng. A 2009, 510–511, 162–168.

- Igarashi, M. Alloy design philosophy of creep-resistant steels. In Creep-Resistant Steels; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing: Cambridge, UK, 2008; pp. 539–572.

- Fedoseeva, A.; Nikitin, I.; Dudova, N.; Kaibyshev, R. Coarsening of Laves phase and creep behaviour of a Re-containing 10% Cr-3% Co-3% W steel. Mater. Sci. Eng. A 2021, 812, 141137.

- Fedoseeva, A.; Nikitin, I.; Tkachev, E.; Mishnev, R.; Dudova, N.; Kaibyshev, R. Effect of alloying on the nucleation and growth of Laves phase in the 9–10%Cr-3%Co martensitic steels during creep. Metals 2021, 11, 60.

- Fedoseeva, A.; Nikitin, I.; Dudova, N.; Kaibyshev, R. Strain and temperature contributions to structural evolution in a Re-containing 10% Cr-3% Co-3% W steel during creep. Mater. High Temp. 2021, 38, 237–246.

- Tsuda, T.; Yamada, M.; Ishii, R.; Watanabe, O. Advances in Turbine Materials, Design and Manufacturing. In Proceedings of the Fourth International Charles Parsons Turbine Conference, Newcastle upon Tyne, UK, 4–6 November 1997; Strang, A., Ed.; CRC Press: Boca Raton, FL, USA, 1997; Volume 689.

- Viswanathan, R.; Bakker, W. Materials for Ultrasupercritical Coal Power Plants—Turbine Materials: Part II. J. Mater. Eng. Perform. 2001, 10, 96–101.

- Takasawa, K.; Miki, K. Development of high-and intermediate-pressure steam turbine rotors for efficient fossil power generation technology. JSW Tech. Rev. 2018, 20, 15–22. Available online: https://www.jsw.co.jp/en/product/technology/technical_review/technical_review1542456266489048621/main/0/link/File024476424.pdf (accessed on 1 January 2020).

- Hidaka, K.; Fukui, Y.; Nakamura, S.; Kaneko, R.; Tanaka, Y.; Fujita, T. Development of Heat Resistant 12CrWCoB Steel Rotor for USC Power Plant. In Advanced Heat Resistant Steels for Power Generation; Viswanathan, R., Nutting, J., Eds.; The Institute of Materials: London, UK, 1999; pp. 482–493.

- Fujita, T. Advances in 9–12%Cr heat resistant steels for power plant. In Proceedings of the 3rd Conference on Advances in Material Technology for Fossil Power Plants, London, UK, 5–6 April 2001; Viswanathan, R., Bakker, W.T., Parker, J.D., Eds.; ASM International: Materials Park, OH, USA; pp. 33–65.

- Fujita, T.; Takahashi, N. The Effects of V and Nb on the Long Period Creep Rupture Strength of 12 %Cr Heat-resisting Steel Containing Mo and B. Trans. Iron Steel Inst. Jpn. 1978, 18, 269–278.

- Sawada, K.; Takeda, M.; Maruyama, K.; Ishii, R.; Yamada, M.; Nagae, Y.; Komine, R. Effect of W on recovery of lath structure during creep of high chromium martensitic steels. Mater. Sci. Eng. A 1999, 267, 19–25.

- Sklenicka, V.; Kucharova, M.; Svoboda, M.; Kloc, L.; Bursık, J.; Kroupa, A. Long-term creep behavior of 9–12%Cr power plant steels. Mat. Char. 2003, 51, 35–48.

- Svoboda, M.; Dlouhý, A.; Podstranská, I.; Sklenička, V.; Mayer, K.H. Microstructural changes in creep of TAF 650 steel at 650 °C. In Proceedings of the 9th International Metallurgical Conference METAL 2000, Ostrava, Czech Republic, 16–18 May 2000; pp. 1–8.

- Svoboda, M.; Bursik, J.; Podstranska, I.; Krouppa, A.; Sklenicka, V.; Mayer, K.H. High temperature creep behaviour and microstructural changes of TAF 650 steel. In Materials for Advanced Power Engineering; Lecomte-Beckers, J., Carton, M., Schubert, F., Ennis, P.J., Eds.; Forschungszentrum Jülich GmbH: Liege, Belgium, 2002; pp. 1521–1530.

- Sieverts, A.; Zapf, G. Eisen und Stickstoff. Z. Phys. Chem. 1935, 172, 314–315.

- El-Kashif, E.; Asakura, K.; Shibata, K. Effects of Nitrogen in 9Cr–3W–3Co Ferritic Heat Resistant Steels Containing Boron. ISIJ Int. 2002, 42, 1468–1476.

- Sakuraya, K.; Okada, H.; Abe, F. BN type inclusions formed in high Cr ferritic heat resistant steel. Energy Mater. 2006, 1, 158–166.

- Abe, F.; Tabuchi, M.; Tsukamoto, S.; Liu, Y. Alloy design of tempered martensitic 9Cr-boron steel for A-USC boilers. In Proceedings of the 7th EPRI Conference on Advances in Materials Technology for Fossil Power Plants, Waikoloa, HI, USA, 22–25 October 2013; pp. 1127–1138.

- Abe, F.; Ohba, T.; Miyazaki, H.; Toda, Y.; Tabuchi, M. Effect of boron nitrides and aluminum nitrides on long-term creep life and rupture ductility of martensitic 9 to 12Cr steels. In Proceedings of the Joint EPRI–123HiMAT International Conference on Advances in High Temperature Materials, Nagasaki, Japan, 21–24 October 2019; Shingledecker, J., Takeyama, M., Eds.; ASM International: Materials Park, OH, USA, 2019; pp. 336–347.

- Subanović, M.; Abellán, J.P.; Gauss, A.; Jarrar, M.; Schneider, A. Super VM12—A new 12% Cr boiler steel. In Proceedings of the Joint EPRI–123HiMAT International Conference on Advances in High Temperature Materials, Nagasaki, Japan, 21–24 October 2019; Shingledecker, J., Takeyama, M., Eds.; ASM International: Materials Park, OH, USA, 2019; pp. 205–216.

- Masuyama, F.; Yamaguchi, T. New ferritic steel beyond Grade 92 and its creep degradation assessment by hardness method for Grade 91. In Proceedings of the ASME 2014 Symposium on Elevated Temperature Application of Materials for Fossil, Nuclear, and Petrochemical Industries, Seattle, WA, USA, 25–27 March 2014; No. ETAM2014-1007. pp. 54–61.

- Xiao, B.; Xu, L.; Zhao, L.; Jing, H.; Han, Y. Deformation-mechanism-based creep model and damage mechanism of G115 steel over a wide stress range. Mater. Sci. Eng. A 2019, 743, 280–293.

- Xiao, B.; Xu, L.; Tang, Z.; Zhao, L.; Jing, H.; Han, Y.; Li, H. A physical-based yield strength model for the microstructural degradation of G115 steel during long-term creep. Mater. Sci. Eng. A 2019, 747, 161–176.

- Hamaguchi, T.; Okada, H.; Hirata, H.; Kurihara, S.; Semba, H.; Yoshizawa, M. Creep Rupture Strength and Microstructures of SAVE12AD Welded Joints; Technical Report No. 119; Nippon Steel & Sumitomo Metal: Tokyo, Japan, 2018; pp. 32–38.

- Fukuda, M.; Tsuda, Y.; Yamashita, K.; Shinozaki, Y.; Takanashi, T. Materials and design for advanced high temperature steam turbines. In Proceedings of the Fourth International Conference on Advances in Materials Technology for Fossil Power Plants, Hilton Head Island, SC, USA, 25–28 October 2004; ASM International: Materials Park, OH, USA, 2005; pp. 491–505.

- Fedoseeva, A.; Nikitin, I.; Fedoseev, A.; Kaibyshev, R. Degradation of the creep resistance of a Re-containing 10%Cr steel upon creep testing at low applied stress. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1014, 012012.

- Tkachev, E.; Belyakov, A.; Kaibyshev, R. Creep strength breakdown and microstructure in a 9%Cr steel with high B and low N contents. Mater. Sci. Eng. A 2020, 772, 138821.

- Rosler, J.; Arzt, E. A new model-based creep equation for dispersion strengthened materials. Acta Metall. Mater. 1990, 38, 671–683.

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Ltd.: Kidlington, UK, 2004.