| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Helen Onyeaka | -- | 1818 | 2022-09-14 06:20:53 | | | |

| 2 | Jessie Wu | Meta information modification | 1818 | 2022-09-15 06:43:37 | | |

Video Upload Options

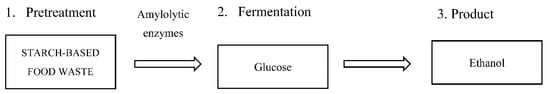

Food wastes are organic wastes or biodegradables. They are generated from various sources such as restaurants and cafeterias, industrial sectors, commercial and domestic kitchens, food processing plants, and other areas where a large number of people consume food. The global demand for fuel keeps increasing daily. The massive depletion of fossil fuels and their influence on the environment as pollution is a severe problem. Meanwhile, food waste disposal is also a complex problem in solid-waste management since one-third of every food consumed is discarded as waste. The standard waste management methods, including food waste incineration and landfilling, are considered hazardous to the environment. Food waste constituents are majorly starch-based and contain various biomolecules, including sugar, lipids, proteins, vitamins, cellulose, etc. These polysaccharides can be hydrolysed into monosaccharides such as glucose, which can then be fermented using microorganisms to produce ethanol through the fermenting of sugars derived from enzymatic hydrolysis treatment of food wastes. The human food system is rich in starch, which can be a potential resource for bioethanol production.

1. Bioethanol Production on Starch-Based Food Wastes

2. Pretreatment

3. Starch Hydrolysis

4. Fermentation

5. Methodologies for Enhanced Bioethanol Production

| Method | Microorganism | Enzyme Used | Process Parameters |

Ethanol (g/L) | Reference |

|---|---|---|---|---|---|

| Simultaneous saccharification and fermentation |

S. cerevisiae—Fusarium oxysporum | on-site produced enzymes glucoamylase | Ratio I:FW = 1/10 w/w Ci = 30% w/v pH = 6.0 T = 30 ± 1 °C t = 94 h Agitation = 80 rpm Mode = Batch |

30.8 | [27] |

| Open fermentative production | Zymomonas mobilis | Ratio I:FW = 10% v/v Ci = 200 g glucose/L Initial pH = 4 T = 30 °C t = 44–48 h Agitation = 100 rpm Mode = Batch |

99.78 | [28] | |

| Separate hydrolysis and fermentation | S. cerevisiae (dry baker’s yeast) |

on-site produced enzymes | Ratio I:FW = 15 mg/g solids Ci = 25 g hydrolyzed FW/100 mL pH = 4.5 T = 30 °C t = 48 h Agitation = 100 rpm Mode = N/A |

19.27 | [29] |

| Separate hydrolysis and fermentation | S. cerevisiae (dry baker’s yeast) |

on-site produced enzymes | Ratio I:FW = 10% v/v Ci = 116 g/L pH = 4.5 T = 30 °C t = 72 h Agitation = 100 rpm |

58.0 | [30] |

| Simultaneous saccharification and fermentation |

S. cerevisiae (dry baker’s yeast) |

Cellulase | Ratio I:FW = 10% v/v Ci = 64.8 ± 1.8 g/L pH = 4.5 T = 30 °C t = 48 h Agitation = 150 rpm |

23.3 | [31] |

| Separate hydrolysis and fermentation | S. cerevisiae | Glucoamylase, amylase | Ratio I:FW = 1 mL to 50 mL Ci = 5.4 mg/mL pH = 6 T = 30 °C t = 24 h Agitation = 150 rpm |

8.0 | [32] |

| Simultaneous saccharification and fermentation |

S. cerevisiae | Carbohydrase, glucoamylase, amylase | Ratio I:FW = N/A Ci = 30 g/L pH = 4.5 T = 35 °C t = 14 days Agitation = N/A |

44 | [33] |

| Simultaneous saccharification | S. cerevisiae | Glucoamylase | Mode = Continuous Ratio I:FW = N/A Ci = N/A pH = 4.18 T = 35 °C t = 67.6 h Agitation = N/A Mode = open batch fermentation |

33.05 | [34] |

References

- Robak, K.; Balcerek, M. Review of second generation bioethanol production from residual biomass. Food Technol. Biotechnol. 2018, 56, 174.

- Xia, J.; Yang, Y.; Liu, C.-G.; Yang, S.; Bai, F.-W. Engineering Zymomonas mobilis for robust cellulosic ethanol production. Trends Biotechnol. 2019, 37, 960–972.

- Ntaikou, I.; Menis, N.; Alexandropoulou, M.; Antonopoulou, G.; Lyberatos, G. Valorization of kitchen biowaste for ethanol production via simultaneous saccharification and fermentation using co-cultures of the yeasts Saccharomyces cerevisiae and Pichia stipitis. Bioresour. Technol. 2018, 263, 75–83.

- Cao, L.; Tang, X.; Zhang, X.; Zhang, J.; Tian, X.; Wang, J.; Xiong, M.; Xiao, W. Two-stage transcriptional reprogramming in Saccharomyces cerevisiae for optimizing ethanol production from xylose. Metab. Eng. 2014, 24, 150–159.

- Barbhuiya, R.I.; Singha, P.; Singh, S.K. A comprehensive review on impact of non-thermal processing on the structural changes of food components. Food Res. Int. 2021, 149, 110647.

- Abinaya, S.; Mounika, D.S.; Suganya, A. Bioconversion of food waste into ethanol using enzymatic Hydrolyzation—Mini review. J. Emerg. Technol. Innov. Res. 2020, 7, 819–823.

- Xie, M.; An, F.; Zhao, Y.; Wu, R.; Wu, J. Metagenomic analysis of bacterial community structure and functions during the fermentation of da-jiang, a Chinese traditional fermented food. Lwt 2020, 129, 109450.

- Lima, C.O.d.C.; Vaz, A.B.; De Castro, G.M.; Lobo, F.; Solar, R.; Rodrigues, C.; Pinto, L.R.M.; Vandenberghe, L.; Pereira, G.; da Costa, A.M. Integrating microbial metagenomics and physicochemical parameters and a new perspective on starter culture for fine cocoa fermentation. Food Microbiol. 2021, 93, 103608.

- Song, Q.; Zhao, F.; Wang, B.; Han, Y.; Zhou, Z. Metagenomic insights into Chinese northeast suancai: Predominance and diversity of genes associated with nitrogen metabolism in traditional household suancai fermentation. Food Res. Int. 2021, 139, 109924.

- Soyuçok, A.; Yurt, M.N.Z.; Altunbas, O.; Ozalp, V.C.; Sudagidan, M. Metagenomic and chemical analysis of Tarhana during traditional fermentation process. Food Biosci. 2021, 39, 100824.

- Mojović, L.; Pejin, D.; Grujić, O.; Markov, S.; Pejin, J.; Rakin, M.; Vukašinović, M.; Nikolić, S.; Savić, D. Progress in the production of bioethanol on starch-based feedstocks. Chem. Ind. Chem. Eng. Q./CICEQ 2009, 15, 211–226.

- Kolusheva, T.; Marinova, A. A study of the optimal conditions for starch hydrolysis through thermostable α-amylase. J. Univ. Chem. Technol. Metall. 2007, 42, 93–96.

- Sasmal, S.; Mohanty, K. Advance in Bioethanol Technology: Production and Characterization. In Liquid Biofuels: Fundamentals, Characterization, and Applications; Wiley: Hoboken, NJ, USA, 2021; pp. 215–230.

- Kumar, V.; Ahluwalia, V.; Saran, S.; Kumar, J.; Patel, A.K.; Singhania, R.R. Recent developments on solid-state fermentation for production of microbial secondary metabolites: Challenges and solutions. Bioresour. Technol. 2021, 323, 124566.

- Kawai, M.; Nagao, N.; Tajima, N.; Niwa, C.; Matsuyama, T.; Toda, T. The effect of the labile organic fraction in food waste and the substrate/inoculum ratio on anaerobic digestion for a reliable methane yield. Bioresour. Technol. 2014, 157, 174–180.

- Wu, C.; Wang, Q.; Yu, M.; Zhang, X.; Song, N.; Chang, Q.; Gao, M.; Sonomoto, K. Effect of ethanol pre-fermentation and inoculum-to-substrate ratio on methane yield from food waste and distillers’ grains. Appl. Energy 2015, 155, 846–853.

- Gomes, D.; Cruz, M.; de Resende, M.; Ribeiro, E.; Teixeira, J.; Domingues, L. Very high gravity bioethanol revisited: Main challenges and advances. Fermentation 2021, 7, 38.

- Anwar Saeed, M.; Ma, H.; Yue, S.; Wang, Q.; Tu, M. Concise review on ethanol production from food waste: Development and sustainability. Environ. Sci. Pollut. Res. 2018, 25, 28851–28863.

- Bai, F.; Anderson, W.; Moo-Young, M. Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol. Adv. 2008, 26, 89–105.

- Mohammadipanah, F.; Kazemi Shariat Panahi, H.; Imanparast, F.; Hamedi, J. Development of a reversed-phase liquid chromatographic assay for the quantification of total persipeptides in fermentation broth. Chromatographia 2016, 79, 1325–1332.

- Panahi, H.K.S.; Mohammadipanah, F.; Dehhaghi, M. Optimization of Extraction Conditions for Liquidliquid Extraction of Persipeptides from Streptomyces Zagrosensis Fermentation Broth. Eur. Chem. Bull. 2016, 5, 408–415.

- Sajedi, H.; Mohammadipanah, F.; Shariat Panahi, H.K. An image analysis-aided method for redundancy reduction in differentiation of identical Actinobacterial strains. Future Microbiol. 2018, 13, 313–329.

- Singh, V.; Haque, S.; Niwas, R.; Srivastava, A.; Pasupuleti, M.; Tripathi, C. Strategies for fermentation medium optimization: An in-depth review. Front. Microbiol. 2017, 7, 2087.

- Thenmozhi, R.; Victoria, J. Optimization and improvement of ethanol production by the incorporation of organic wastes. Pelagia Res. Libr. 2013, 4, 119–123.

- Panahi, H.K.S.; Dehhaghi, M.; Dehhaghi, S.; Guillemin, G.J.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Engineered bacteria for valorizing lignocellulosic biomass into bioethanol. Bioresour. Technol. 2022, 344, 126212.

- Joshi, J.; Dhungana, P.; Prajapati, B.; Maharjan, R.; Poudyal, P.; Yadav, M.; Mainali, M.; Yadav, A.P.; Bhattarai, T.; Sreerama, L. Enhancement of ethanol production in electrochemical cell by Saccharomyces cerevisiae (CDBT2) and Wickerhamomyces anomalus (CDBT7). Front. Energy Res. 2019, 7, 70.

- Prasoulas, G.; Gentikis, A.; Konti, A.; Kalantzi, S.; Kekos, D.; Mamma, D. Bioethanol production from food waste applying the multienzyme system produced on-site by Fusarium oxysporum F3 and mixed microbial cultures. Fermentation 2020, 6, 39.

- Ma, K.; Ruan, Z.; Shui, Z.; Wang, Y.; Hu, G.; He, M. Open fermentative production of fuel ethanol from food waste by an acid-tolerant mutant strain of Zymomonas mobilis. Bioresour. Technol. 2016, 203, 295–302.

- Matsakas, L.; Christakopoulos, P. Ethanol production from enzymatically treated dried food waste using enzymes produced on-site. Sustainability 2015, 7, 1446–1458.

- Kiran, E.U.; Liu, Y. Bioethanol production from mixed food waste by an effective enzymatic pretreatment. Fuel 2015, 159, 463–469.

- Cekmecelioglu, D.; Uncu, O.N. Kinetic modeling of enzymatic hydrolysis of pretreated kitchen wastes for enhancing bioethanol production. Waste Manag. 2013, 33, 735–739.

- Walker, K.; Vadlani, P.; Madl, R.; Ugorowski, P.; Hohn, K.L. Ethanol fermentation from food processing waste. Environ. Prog. Sustain. Energy 2013, 32, 1280–1283.

- Kim, J.H.; Lee, J.C.; Pak, D. Feasibility of producing ethanol from food waste. Waste Manag. 2011, 31, 2121–2125.

- Wang, Q.; Ma, H.; Xu, W.; Gong, L.; Zhang, W.; Zou, D. Ethanol production from kitchen garbage using response surface methodology. Biochem. Eng. J. 2008, 39, 604–610.